Global Reflective Fabric Market Size, Share, Growth Analysis By Product (Fabrics, Sheet, Paints and Inks, Tape and Films, Coatings, Specialty Products, Others), By Type (Occupational Apparel, Recreational Apparel, Textile Accessories, Others), By Application (Textiles, Construction and Roads, Automotive, Electronics and Semiconductors, Others), By Material (Glass Beads, Prismatic Retroreflective, Micro Prismatic, Metalized, Others), By Grade (Class 1, Class 2, Class 3, Class 4, Others), By Technology (Woven Reflective Fabric, Knitted Reflective Fabric, Non-Woven Reflective Fabric, Others), By End-Use Industry (Automotive, Construction, Energy, Healthcare, Logistics and Transportation, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: March 2025

- Report ID: 67990

- Number of Pages: 238

- Format:

-

keyboard_arrow_up

Quick Navigation

- Report Overview

- Key Takeaways

- Product Analysis

- Type Analysis

- Application Analysis

- Material Analysis

- Grade Analysis

- Technology Analysis

- End-Use Industry Analysis

- Key Market Segments

- Driving Factors

- Restraining Factors

- Growth Opportunities

- Emerging Trends

- Regional Analysis

- Competitive Landscape

- Recent Developments

- Report Scope

Report Overview

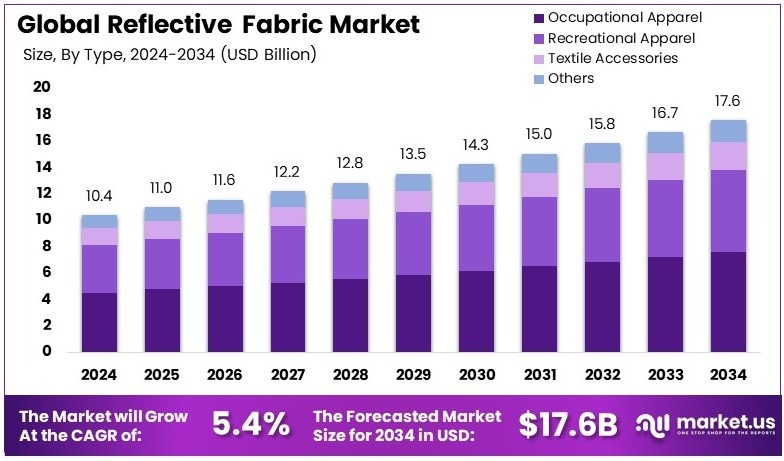

The Global Reflective Fabric Market size is expected to be worth around USD 17.6 Billion by 2034, from USD 10.4 Billion in 2024, growing at a CAGR of 5.4% during the forecast period from 2025 to 2034.

Reflective fabric is a type of material that reflects light, making it highly visible in low-light conditions. It is often used in safety clothing, like vests and jackets, to improve visibility. This fabric is essential in industries like construction and emergency services to protect workers and reduce accidents.

The reflective fabric market involves the production and sale of materials that enhance visibility, especially in safety gear and road signage. With the increase in road traffic and workplace accidents, the demand for reflective fabric has grown. It is used in clothing, signage, and other products that require high visibility for safety.

The demand for reflective fabric is rising due to growing concerns about road safety and worker protection. According to the World Health Organization, around 1.19 million people die annually in road traffic accidents. As a result, there is a global push for stricter safety measures, which in turn drives the demand for high-visibility clothing made from reflective fabric.

Additionally, workplace safety is also becoming more critical. According to the Health and Safety Executive (HSE), the UK has seen a 20% rise in fatal construction injuries over the past five years. This highlights the need for high-visibility clothing in industries like construction, which increases the demand for reflective fabric products.

Consequently, the reflective fabric market remains highly competitive, with both established players and new entrants offering a wide range of products. Companies are focusing on innovation to meet rising safety demands, such as improving the comfort and durability of reflective clothing. As such, competition in this market is expected to grow.

Government regulations also drive the growth of the reflective fabric market. As safety standards become stricter globally, there is increased demand for high-quality reflective fabric. For instance, new safety measures in construction and traffic zones make reflective clothing and signage necessary. This regulatory environment supports the market and encourages businesses to innovate and improve their products.

Key Takeaways

- The Reflective Fabric Market was valued at USD 10.4 billion in 2024 and is expected to reach USD 17.6 billion by 2034, with a CAGR of 5.4%.

- In 2024, Fabrics dominated the product segment with 34.4%, widely used in safety and visibility applications.

- In 2024, Occupational Apparel led the type segment with 43.3%, driven by workplace safety regulations.

- In 2024, Textiles accounted for 37.4%, supported by rising demand for high-visibility clothing.

- In 2024, Glass Beads held 43.4% in the material segment due to their superior reflective properties.

- In 2024, Class 1 reflective fabric led with 35.5%, preferred for general safety applications.

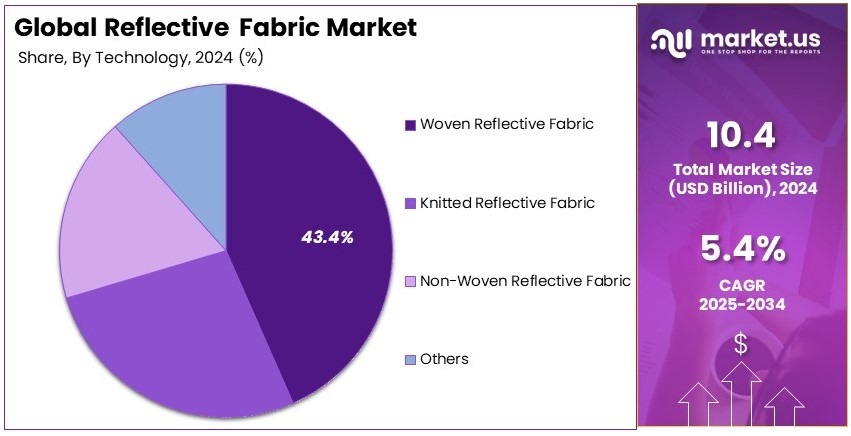

- In 2024, Woven Reflective Fabric accounted for 43.4%, widely used for its durability and flexibility.

- In 2024, Automotive held 35.5%, driven by its application in vehicle safety features.

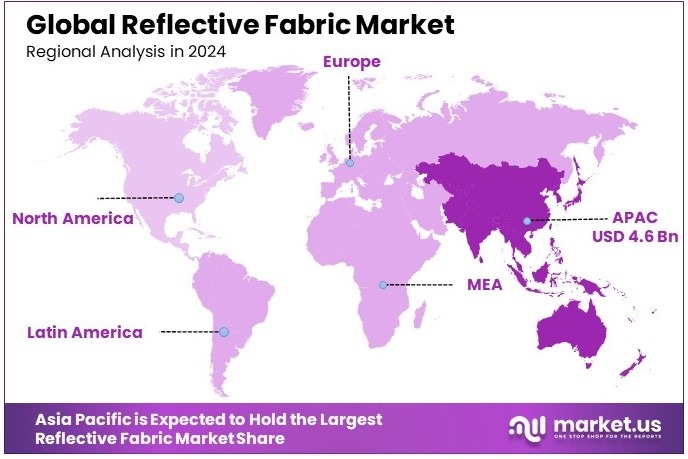

- In 2024, APAC dominated with 44.5% and valued at USD 4.6 billion, driven by growing infrastructure projects and road safety regulations.

Product Analysis

Fabrics dominate with 34.4% due to their versatile use across various applications.

In the Reflective Fabric Market, the Fabric sub-segment holds the largest market share, accounting for 34.4%. Reflective fabrics are extensively used in a range of industries due to their durability, flexibility, and superior reflective properties.

These fabrics are primarily used in protective clothing, safety apparel, and equipment, providing visibility in low-light environments, which is crucial in sectors like construction, automotive, and emergency services. The market growth for reflective fabrics can be attributed to their ability to blend well with different materials, their comfort, and their longevity.

Other products, such as Sheet, Paints and Inks, and Tape and Films, have a smaller but important role in the market. Reflective sheets are used in signage and road safety applications, while paints and inks are often employed for creating reflective coatings on various surfaces.

Tape and films are used for marking roads and vehicles for better visibility. Though these segments support the reflective fabric market, they do not match the widespread demand and versatility of fabrics.

Type Analysis

Occupational Apparel dominates with 43.3% due to high demand for safety in hazardous environments.

The Occupational Apparel sub-segment holds the largest share in the Reflective Fabric Market, with 43.3%. This segment benefits from the increasing need for protective clothing in various hazardous industries such as construction, transportation, and emergency services.

Reflective apparel is vital for workers in low-visibility conditions, ensuring their safety by making them easily visible at all times. The global push for better safety standards and regulations, especially in high-risk environments, has directly contributed to the growth of reflective fabrics in occupational apparel.

Recreational Apparel and Textile Accessories contribute to the market, but they hold smaller shares. Reflective fabrics in recreational apparel are mainly used in sports and outdoor gear, providing visibility for athletes and outdoor enthusiasts.

Similarly, textile accessories, such as bags or hats, use reflective materials for enhanced safety. Though these segments are important, they do not generate the same level of demand as occupational apparel.

Application Analysis

Textiles dominate with 37.4% due to the extensive use of reflective materials in everyday products.

The Textiles sub-segment leads the Reflective Fabric Market with a 37.4% share. Reflective fabrics are widely used in textiles due to their ability to provide safety features without sacrificing comfort. Common applications include safety uniforms, workwear, and other textile products where visibility in low-light conditions is critical.

The rise in urban infrastructure projects, combined with increasing awareness about worker safety, drives this demand. Reflective textiles are also commonly used in fashion and outdoor apparel, expanding the market further.

The construction and automotive industries also play important roles in the growth of reflective fabrics. In construction, workers use reflective clothing to ensure they are seen on job sites, reducing accidents. In automotive applications, reflective materials are used for vehicle decals and safety gear, further promoting visibility. However, these segments contribute less compared to textiles, which are the foundation of reflective fabric use in multiple industries.

Material Analysis

Glass Beads dominate with 43.4% due to their superior reflective properties.

Glass beads hold the dominant share in the Reflective Fabric Market, accounting for 43.4%. They are widely used in reflective fabrics due to their high efficiency in reflecting light, especially in low-light conditions.

Glass beads enhance the visibility of the fabric, making it a preferred material for safety apparel and road safety products. The durable and cost-effective nature of glass beads, along with their ability to work across various types of reflective applications, solidifies their leading market position.

Other materials such as prismatic retroreflective and micro prismatic materials offer different reflective qualities, which are more suitable for specialized applications. These materials provide better reflection at wider angles, making them useful in high-performance reflective products. However, glass beads remain the dominant choice due to their practicality, efficiency, and cost-effectiveness.

Grade Analysis

Class 1 dominates with 35.5% due to its use in low-risk applications.

Class 1 reflective fabrics hold the largest market share in the Reflective Fabric Market, accounting for 35.5%. These fabrics are commonly used in applications that involve lower levels of risk, such as for workers in retail or light-duty tasks.

Class 1 materials are sufficient for ensuring visibility in environments where the risk of accidents is lower, but visibility is still essential. They are cost-effective and widely used across various industries, making them a leading choice in the market.

Class 2 and Class 3 fabrics are used in higher-risk environments, such as for workers in construction or emergency services. These grades provide enhanced visibility and are used where there is a greater chance of exposure to hazardous conditions. While they are essential, they cater to more specific needs, contributing less to the overall market share than Class 1 fabrics.

Technology Analysis

Woven Reflective Fabric dominates with 43.4% due to its durability and versatility.

Woven reflective fabrics lead the market with a 43.4% share. These fabrics are known for their strength, durability, and flexibility, making them ideal for a wide range of applications. They are commonly used in safety apparel for workers, including in construction and transportation. The woven nature of these fabrics allows them to withstand wear and tear, which is crucial in environments where clothing experiences heavy use.

Knitted reflective fabrics, though valuable, serve more specific needs, offering flexibility and comfort in apparel such as sportswear or fashion items. Non-woven reflective fabrics are also used in certain applications, particularly where lightweight and cost-effective materials are required. However, woven fabrics remain the dominant technology due to their balance of durability and performance.

End-Use Industry Analysis

Automotive dominates with 35.5% due to the increasing use of reflective materials for vehicle safety.

The Automotive sub-segment leads the Reflective Fabric Market with a 35.5% share. Reflective fabrics are used extensively in vehicle safety products such as decals, reflective tapes, and emergency vehicle gear.

As road safety regulations become stricter and vehicles increasingly require enhanced visibility, the demand for reflective fabrics in the automotive industry continues to grow. This market is driven by the need for better visibility for vehicles and pedestrians, particularly in low-light conditions or during night-time operations.

The construction and energy industries also contribute to the market, using reflective materials in their safety equipment. Healthcare and logistics also use reflective materials in various applications, but their share of the market remains smaller compared to automotive applications.

Key Market Segments

By Product

- Fabrics

- Sheet

- Paints and Inks

- Tape and Films

- Coatings

- Specialty Products

- Others

By Type

- Occupational Apparel

- Recreational Apparel

- Textile Accessories

- Others

By Application

- Textiles

- Construction and Roads

- Automotive

- Electronics and Semiconductors

- Others

By Material

- Glass Beads

- Prismatic Retroreflective

- Micro Prismatic

- Metalized

- Others

By Grade

- Class 1

- Class 2

- Class 3

- Class 4

- Others

By Technology

- Woven Reflective Fabric

- Knitted Reflective Fabric

- Non-Woven Reflective Fabric

- Others

By End-Use Industry

- Automotive

- Construction

- Energy

- Healthcare

- Logistics and Transportation

- Others

Driving Factors

Safety Regulations and High-Visibility Clothing Drive Market Growth

Rising safety regulations in industries such as construction, road safety, and mining are significant factors driving the growth of the Reflective Fabric market. As safety standards become more stringent, reflective materials are increasingly being used in workwear to ensure visibility in low-light or hazardous conditions.

High-visibility clothing is now a requirement in many work environments to protect workers from accidents. Reflective fabrics are essential in helping workers stay visible, especially in industries like construction, mining, and transportation.

Additionally, growing adoption of reflective fabrics in high-visibility clothing continues to drive demand. These materials are used not only in safety jackets but also in pants, hats, and other gear, ensuring workers’ safety across different environments.

The increasing demand for reflective materials in outdoor and sportswear is another growth driver. Reflective fabrics are being used in sports and outdoor clothing to enhance visibility during night-time activities or in low-light conditions.

Whether for joggers, cyclists, or adventurers, reflective fabrics are now commonly incorporated into these garments to improve safety. Technological advancements in fabric weaving and coating also contribute to market growth by increasing the durability and effectiveness of reflective fabrics.

Restraining Factors

High Costs and Limited Awareness Restrain Market Growth

Despite the benefits, several factors restrain the growth of the Reflective Fabric market. One of the key challenges is the high cost of reflective fabrics compared to conventional materials. Reflective materials often require specialized manufacturing processes, which increases their production cost. This makes them more expensive than traditional fabrics, which can deter some buyers, particularly in cost-sensitive industries.

Limited awareness in emerging economies about the benefits of reflective materials is another barrier. While the use of reflective fabrics is well-established in developed markets, awareness in regions with growing industrial sectors, such as parts of Asia and Africa, is still limited. This lack of knowledge prevents these regions from fully embracing reflective materials in safety gear and other applications.

Additionally, challenges related to the durability and washability of reflective fabrics are concerns for both consumers and manufacturers. Over time, repeated washing can reduce the reflectivity of fabrics, which compromises their effectiveness.

This issue is particularly relevant in high-use industries, where clothing needs frequent cleaning. Lastly, competition from alternative high-visibility materials, such as fluorescent colors and LED-based solutions, may limit the growth of reflective fabrics in certain applications.

Growth Opportunities

Growing Demand in Safety Gear and Fashion Provides Market Opportunities

The Reflective Fabric market presents several growth opportunities. One of the most significant is the expanding demand for reflective fabrics in transportation and safety gear. As road safety regulations tighten globally, there is an increasing need for reflective fabrics in uniforms, vests, and other safety gear. These fabrics are critical in reducing accidents involving pedestrians and road workers, especially in poorly lit areas.

In addition, the growing popularity of reflective fabrics in fashion and sportswear applications offers new market potential. Reflective materials are being incorporated into streetwear, activewear, and fashion items, catering to consumers looking for stylish yet functional products. This trend aligns with the broader focus on safety and personal style.

Moreover, innovations in eco-friendly and recyclable reflective fabrics present opportunities for market growth. With increasing consumer demand for sustainable products, manufacturers are exploring materials that are both high-performing and environmentally friendly.

Another growth opportunity comes from the increase in government regulations and safety standards for public workers, which is likely to create further demand for reflective fabrics, particularly in uniforms and workwear.

Emerging Trends

Smart Textiles and Weather-resistant Materials Shape Market Trends

Several trends are shaping the future of the Reflective Fabric market. One of the most notable is the integration of smart textiles with reflective materials for enhanced functionality. Smart fabrics, which can monitor body temperature, heart rate, or other vital signs, are now being combined with reflective materials to create garments that offer both safety and health monitoring. This integration provides additional value in sectors such as healthcare, sports, and personal safety.

Advances in lightweight and flexible reflective fabrics are also a significant trend. As comfort becomes a priority, especially in activewear and workwear, the demand for flexible, lightweight fabrics is rising. These innovations improve the comfort of high-visibility garments without compromising on safety.

Rising demand for reflective fabrics in urban fashion and streetwear is another trend. As fashion trends shift toward utility and high-visibility designs, reflective materials are increasingly incorporated into everyday clothing. This growing interest in urban fashion represents an emerging market for reflective fabrics outside traditional safety applications.

Lastly, the development of high-performance, weather-resistant reflective materials is transforming the market. These materials offer enhanced durability and reflectivity in harsh weather conditions, making them ideal for outdoor work environments and extreme weather conditions. These innovations ensure that reflective fabrics remain an essential part of safety and fashion in the years to come.

Regional Analysis

Asia Pacific Dominates with 44.5% Market Share

Asia Pacific leads the Reflective Fabric Market with 44.5% market share, valued at USD 4.6 billion. The region’s dominance is driven by rapid industrialization, expanding infrastructure projects, and rising demand for personal safety in industries like construction and automotive. The growing adoption of reflective fabrics for safety gear, such as jackets and vests, is a key contributor to this market share.

The region benefits from a large manufacturing base and increasing urbanization, particularly in countries like China and India. The demand for reflective fabrics is growing in sectors that require high visibility for worker safety, such as road construction, mining, and emergency services. Moreover, the presence of cost-effective production and technological advancements in fabric manufacturing further strengthens APAC’s position in the global market.

Looking ahead, the market presence of APAC is expected to continue expanding. As industries in the region focus more on workplace safety and regulatory compliance, the demand for high-quality reflective fabrics will increase. Technological innovations and the growing trend of wearable safety products will also support market growth in the region, ensuring its leading position.

Regional Mentions:

- North America: North America accounts for a significant share of the reflective fabric market, driven by high safety standards in industries such as construction and transportation. The focus on workplace safety regulations, particularly in the U.S. and Canada, further strengthens demand for reflective materials.

- Europe: Europe is witnessing steady growth in the reflective fabric market, largely due to strict regulations in road safety and workplace standards. Countries like Germany and France emphasize reflective gear for transportation and public safety.

- Middle East & Africa: In the Middle East and Africa, the market for reflective fabrics is driven by the region’s infrastructure boom. Countries investing in large-scale construction and energy projects, like the UAE and Saudi Arabia, are contributing to growing demand for safety equipment.

- Latin America: Latin America is seeing increasing adoption of reflective fabrics, particularly in sectors like construction, mining, and public safety. Countries like Brazil and Mexico are investing in worker safety initiatives, pushing the demand for reflective materials.

Key Regions and Countries Covered in the Report

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Competitive Landscape

The Reflective Fabric market is dominated by several key players, with 3M Company, DM-Reflective Material, PS Enterprises, and Yangzhou Tonming Reflective Material Co., Ltd. standing out. These companies lead the market by offering advanced reflective materials used in safety apparel, road signs, and other applications that require high visibility.

3M Company is a global leader in the reflective fabric market, offering a wide range of innovative reflective materials. Known for its strong focus on safety, 3M provides products that meet stringent industry standards. Their fabrics are widely used in the manufacturing of high-visibility workwear, traffic safety products, and outdoor gear.

DM-Reflective Material specializes in high-quality reflective fabrics designed for various industrial and safety applications. The company’s products are known for their durability and superior reflectivity, making them ideal for use in safety vests, uniforms, and protective clothing.

PS Enterprises is recognized for its expertise in reflective fabrics and safety solutions. The company focuses on delivering high-performance materials that provide excellent visibility in low-light conditions, catering to industries such as construction, transportation, and emergency services.

Yangzhou Tonming Reflective Material Co., Ltd. produces a broad range of reflective materials, including fabrics used in safety apparel and signage. Known for its advanced manufacturing techniques, the company offers products that combine high reflectivity with comfort and flexibility, making them suitable for various protective clothing applications.

These companies play a significant role in the growth of the Reflective Fabric market. Their products support a wide range of industries that prioritize safety and visibility, ensuring worker protection and regulatory compliance. By continuing to innovate, they maintain strong positions in the global market for reflective fabrics.

Major Companies in the Market

- 3M Company

- DM-Reflective Material

- PS Enterprises

- Yangzhou Tonming Reflective Material Co. Ltd.

- Changzhou Hua R Sheng Reflective Material Co. Ltd.

- Yeshili Reflective Materials Co. Ltd (YSL)

- Zhejiang Caiyuan Reflecting Materials Co. Ltd.

- Innovative Insulation Inc.

- Reflomax Co. Ltd.

- Mauritzon Inc.

- Bally Ribbon Mills (BRM)

- Apex Mills

- Aurora Specialty Textiles Group Inc.

- Erez Thermoplastic Products

- Hangzhou Chinastars Reflective Material Co. Ltd.

- Roadstar Reflective Material Co. Ltd.

- Nirmal Sagar Enterprises

- Marketing Action Executives

- Shivam Narrow Fabric

Recent Developments

- Nike: On February 2025, Nike is scheduled to release the Air Max Sunder “Silver Reflective” in extended women’s sizing, priced at $200 USD. This iteration features a synthetic reflective upper that appears black and grey under normal lighting but reveals an iridescent glow when exposed to light. The design includes the silhouette’s signature neoprene-like material and zip-up shroud, complemented by a black and white sole unit.

- Development of Highly Reflective Black Paint: On May 2024, chemists reported the creation of a highly reflective black paint designed to improve the visibility of dark objects to autonomous vehicles equipped with lidar sensors.

Report Scope

Report Features Description Market Value (2024) USD 10.4 Billion Forecast Revenue (2034) USD 17.6 Billion CAGR (2025-2034) 5.4% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product (Fabrics, Sheet, Paints and Inks, Tape and Films, Coatings, Specialty Products, Others), By Type (Occupational Apparel, Recreational Apparel, Textile Accessories, Others), By Application (Textiles, Construction and Roads, Automotive, Electronics and Semiconductors, Others), By Material (Glass Beads, Prismatic Retroreflective, Micro Prismatic, Metalized, Others), By Grade (Class 1, Class 2, Class 3, Class 4, Others), By Technology (Woven Reflective Fabric, Knitted Reflective Fabric, Non-Woven Reflective Fabric, Others), By End-Use Industry (Automotive, Construction, Energy, Healthcare, Logistics and Transportation, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape 3M Company, DM-Reflective Material, PS Enterprises, Yangzhou Tonming Reflective Material Co. Ltd., Changzhou Hua R Sheng Reflective Material Co. Ltd., Yeshili Reflective Materials Co. Ltd (YSL), Zhejiang Caiyuan Reflecting Materials Co. Ltd, Innovative Insulation Inc., Reflomax Co. Ltd, Mauritzon Inc, Bally Ribbon Mills (BRM), Apex Mills, Aurora Speciality Textiles Group Inc, Erez Thermoplastic Products, Hangzhou Chinastars Reflective Material Co. Ltd, Roadstar Reflective Material Co. Ltd, Nirmal Sagar Enterprises, Marketing Action Executives, Shivam Narrow Fabric Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- 3M Company

- DM-Reflective Material

- PS Enterprises

- Yangzhou Tonming Reflective Material Co.Ltd.

- Changzhou Hua R Sheng Reflective Material Co. Ltd.

- Yeshili Reflective Materials Co. Ltd (YSL)

- Zhejiang Caiyuan Reflecting Materials Co.Ltd

- Innovative Insulation Inc.

- Reflomax Co.Ltd

- Mauritzon Inc

- Bally Ribbon Mills (BRM)

- Apex Mills

- Aurora Speciality Textiles Group Inc

- Erez Thermoplastic Products

- Hangzhou Chinastars Reflective Material Co. Ltd

- Roadstar Reflective Material Co.Ltd

- Nirmal Sagar Enterprises

- Marketing Action Executives

- Shivam Narrow Fabric