Global Functionally Graded Materials (FGM) Market Size, Share, And Business Benefits By Material Type (Ceramics-Based FGM, Metal-Based FGM, Polymer-Based FGM, Composite-Based FGM, Others), By End-Use Industry (Aerospace and Defense, Automotive, Healthcare, Energy, Electronics, Industrial Manufacturing, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: January 2025

- Report ID: 137958

- Number of Pages: 251

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

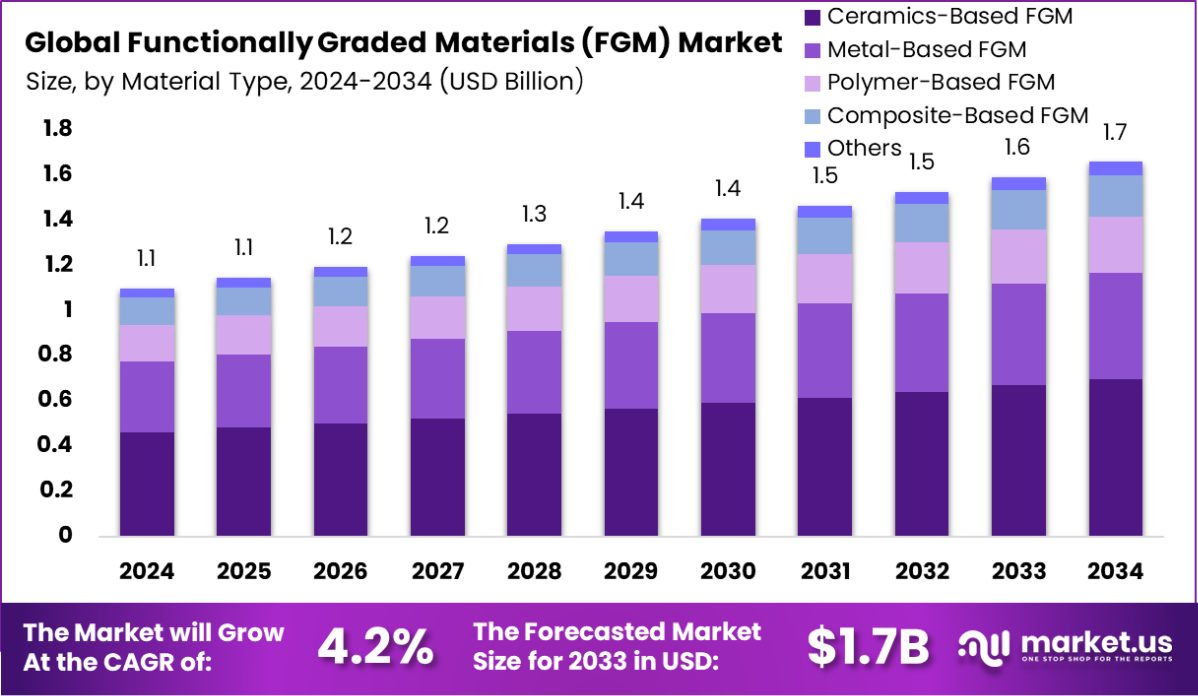

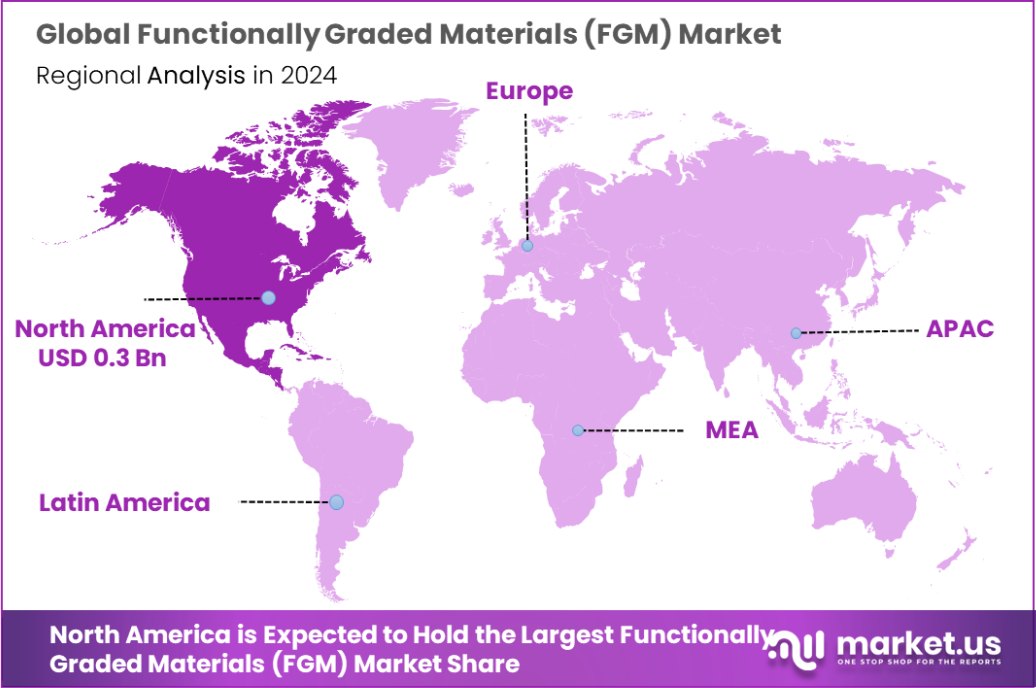

The Global Functionally Graded Materials (FGM) Market is expected to be worth around USD 1.7 Billion by 2034, up from USD 1.1 Billion in 2024, and grow at a CAGR of 4.2% from 2025 to 2034. North America Holds 32.4% Share, USD 0.3 Bn FGM Market.

The Functionally Graded Materials (FGM) Market is witnessing significant advancements, driven by rapid technological developments and increasing applications across aerospace, biomedical, and energy sectors. FGMs are advanced composite materials with gradual variations in composition and structure, enhancing their mechanical and thermal properties.

The industrial landscape for FGMs is evolving with the integration of Additive Manufacturing (AM) techniques such as Laser Metal Deposition (LMD) and Wire Arc Additive Manufacturing (WAAM). These methods have achieved remarkable breakthroughs, attaining relative densities of up to 99.44% for FGM layers, significantly enhancing their mechanical properties while minimizing defects.

Additionally, FGMs composed of Stainless Steel 316L/Inconel 718 or TiC/Ti have demonstrated exceptional crack resistance and thermal stability when fabricated using AM technologies. These advancements are crucial for industries requiring high durability and performance under extreme conditions, such as aerospace engine components and biomedical implants.

Market growth is further bolstered by increasing investments and government initiatives supporting advanced materials research. While FGMs share an acronym with Female Genital Mutilation (FGM), which has received over $5 million in grants from the U.S. Department of Justice’s Office for Victims of Crime between FY2020 and FY2021 to combat victimization, this unrelated acronymic overlap underscores the importance of industry-specific terminologies to avoid confusion in policy discussions.

Moreover, the U.S. Department of State’s annual $5 million contribution to UNICEF for the UNFPA-UNICEF Joint Programme on the elimination of female genital mutilation highlights the global focus on human rights efforts, distinct from the material science domain.

The future of the FGM market is promising, with continuous advancements in material engineering and AM technologies expected to drive broader adoption. As industries increasingly seek lightweight, high-performance materials with superior thermal and mechanical properties, FGMs are set to play a pivotal role in next-generation manufacturing.

Key Takeaways

- The Global Functionally Graded Materials (FGM) Market is expected to be worth around USD 1.7 Billion by 2034, up from USD 1.1 Billion in 2024, and grow at a CAGR of 4.2% from 2025 to 2034.

- Ceramics-based FGMs dominate the market, accounting for a 42.3% share globally.

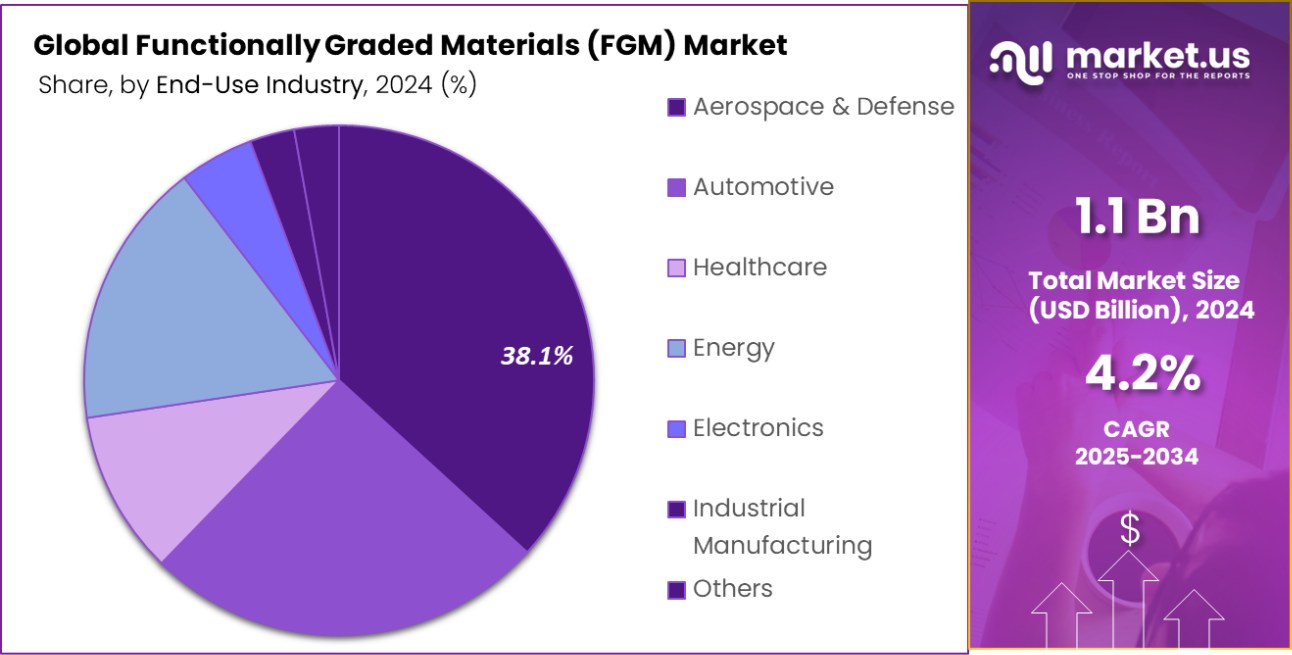

- The aerospace and defense sector leads with a 38.1% share in the FGMs market.

- North America Holds 32.4% Share of Functionally Graded Materials (FGM) Market, USD 0.3 Bn.

Business Benefits of Functionally Graded Materials (FGM) Market

Functionally Graded Materials (FGMs) offer significant business benefits in various industries, especially in the healthcare sector. In orthopedic implants, FGMs have shown notable advancements in performance and patient outcomes.

For instance, FGM-based orthopedic implants have demonstrated up to a 47% increase in osteoblast cell proliferation rate after 7 days compared to non-graded implants. This higher cell proliferation enhances the healing process, potentially reducing recovery time and improving long-term implant success.

Moreover, FGMs can substantially reduce the stress-shielding effect, a common issue where the implant absorbs too much stress, leading to a reduction in bone density and eventual implant failure. In some cases, FGMs can decrease this effect by up to 78%, ensuring better integration between the implant and bone, thus extending the lifespan of the implant and reducing the likelihood of costly replacements.

These advancements provide compelling business advantages, including reduced healthcare costs, improved patient outcomes, and a competitive edge in the orthopedic implant market. The increased adoption of FGMs can also open opportunities for innovation in other sectors, such as aerospace and automotive, where customized material properties are critical for performance and durability.

By Material Type Analysis

The ceramics-based functionally graded materials (FGM) segment dominates the market, accounting for 42.3% globally.

In 2024, Ceramics-Based FGM held a dominant market position in the By Material Type segment of the Functionally Graded Materials (FGM) market, with a 42.3% share. This segment’s growth is driven by ceramics’ ability to withstand high temperatures and harsh environments, making them ideal for applications in aerospace, automotive, and biomedical sectors.

Ceramics-based FGM continues to lead the market, owing to its excellent thermal and electrical properties. These materials are widely used in high-performance sectors such as aerospace, energy, and healthcare, where durability and thermal resistance are crucial. The segment’s growth is fueled by advancements in manufacturing techniques, allowing for more precise material gradation.

Metal-based FGMs account for a significant portion of the market, representing 28.5%. These materials are favored for their mechanical strength and high-temperature resistance. Commonly used in aerospace, automotive, and energy applications, metal-based FGMs are known for their durability and ease of integration into existing manufacturing processes. Demand for these materials is expected to grow as industries push for lighter and stronger components.

Polymer-based FGMs hold 17.1% of the market share, driven by their versatility and cost-effectiveness. These materials are widely used in industries such as electronics, packaging, and medical devices. Their flexibility and ease of processing, combined with the ability to customize material properties, make them attractive for applications requiring both strength and lightweight characteristics.

Composite-based FGMs, holding a 12.1% market share, combine the advantages of different materials to offer improved mechanical properties and performance. These FGMs are particularly sought after in industries requiring high strength-to-weight ratios, such as automotive and aerospace. The growth of this segment is supported by innovations in composite manufacturing and the increasing demand for multifunctional materials.

By End-Use Industry Analysis

The aerospace and defense sector leads the functionally graded materials (FGM) market, capturing a 38.1% share worldwide.

In 2024, Aerospace and Defense held a dominant market position in the By End-Use Industry segment of the Functionally Graded Materials (FGM) market, with a 38.1% share. This sector’s demand for advanced materials with superior thermal resistance, durability, and lightweight properties has driven the growth of FGMs, particularly in critical applications like propulsion systems and structural components.

Aerospace and Defense leads the FGM market, accounting for 38.1% of the share. The industry demands materials that can withstand extreme conditions, such as high temperatures and pressures. FGMs are crucial for manufacturing turbine blades, heat shields, and other critical components, where performance and reliability are paramount. Increased defense spending and space exploration initiatives continue to drive this segment’s growth.

The Automotive sector represents 22.6% of the FGM market. The push for lightweight materials with high strength-to-weight ratios in vehicle manufacturing is boosting demand for FGMs. These materials are used in components like engine parts, exhaust systems, and battery casings, contributing to fuel efficiency, safety, and sustainability. Ongoing advancements in electric vehicles (EVs) further fuel the segment’s growth.

Healthcare is another rapidly growing segment, accounting for 16.3% of the market. FGMs are finding increasing applications in prosthetics, implants, and medical devices where biocompatibility, durability, and customizability are essential. The ability to design tailored materials that gradually transition in properties makes FGMs ideal for improving patient outcomes, particularly in orthopedic and dental applications.

The Energy sector, accounting for 11.5%, relies on FGMs for applications requiring high thermal resistance and durability. These materials are crucial in power generation, particularly in turbine components, reactors, and energy storage systems. The growing need for efficient, sustainable energy solutions, particularly in renewable energy, is expected to drive further adoption of FGMs in this industry.

Electronics make up 6.2% of the FGM market, where FGMs are used in components like sensors, heat exchangers, and circuit boards. The demand for miniaturization, improved performance, and thermal management in electronic devices is accelerating the adoption of FGMs. As consumer electronics evolve, there is growing potential for these materials in the development of more advanced and efficient devices.

The Industrial Manufacturing segment represents 5.4% of the FGM market. FGMs are increasingly used in applications such as tooling, machine parts, and wear-resistant coatings. Their unique material gradation properties allow manufacturers to enhance the performance and longevity of tools and machinery in sectors like manufacturing, construction, and mining, where wear resistance is critical for productivity.

Key Market Segments

By Material Type

- Ceramics-Based FGM

- Metal-Based FGM

- Polymer-Based FGM

- Composite-Based FGM

- Others

By End-Use Industry

- Aerospace and Defense

- Automotive

- Healthcare

- Energy

- Electronics

- Industrial Manufacturing

- Others

Driving Factors

Increasing Demand for High-Performance Materials in Aerospace

Functionally Graded Materials (FGMs) are gaining significant traction in the aerospace industry due to their ability to withstand extreme conditions like temperature fluctuations, high pressure, and mechanical stress. The aviation sector’s need for lighter, stronger, and more durable components has driven the adoption of FGMs, which combine different material properties across their structure.

These materials help improve fuel efficiency, reduce maintenance costs, and enhance the overall performance of aircraft, making them a key factor in the growing market demand for FGMs in aerospace applications.

Rising Focus on Sustainable and Efficient Manufacturing Practices

The growing emphasis on sustainability and energy efficiency is boosting the use of Functionally Graded Materials (FGMs) in various industries. FGMs enable better material optimization, reducing waste and energy consumption during manufacturing processes. Their ability to combine materials with varying properties allows manufacturers to create products that are stronger, more durable, and cost-effective.

This helps companies meet environmental regulations and sustainability goals while improving the performance of their products. As a result, FGMs are increasingly viewed as a solution for creating environmentally friendly and resource-efficient materials.

Advancements in Medical Implants and Bio-compatible Materials

In the medical sector, FGMs are being increasingly used for bio-compatible implants due to their ability to mimic the mechanical properties of human bone. These materials allow for smoother integration into the human body, minimizing rejection rates and improving patient outcomes.

Their graded structure also enables better load distribution, reducing the risk of implant failure. As demand for advanced medical devices rises, especially in orthopedic and dental applications, FGMs are seen as a key innovation in improving the functionality and longevity of medical implants, driving market growth in the sector.

Restraining Factors

High Production Costs Hindering Market Widespread Adoption

One of the major challenges limiting the adoption of Functionally Graded Materials (FGMs) is the high production cost. The complex process of creating these materials—often requiring advanced technology and specialized equipment—can be expensive.

As a result, manufacturers may face challenges in scaling up production to make FGMs more cost-effective. This limits their use to high-end applications such as aerospace, medical devices, and advanced engineering, slowing down their widespread integration into other industries, particularly in price-sensitive sectors.

Limited Availability of Suitable Raw Materials

The limited availability of suitable raw materials is another factor restraining the growth of the FGM market. For FGMs to function optimally, manufacturers need high-quality raw materials with specific properties that can be precisely graded throughout the material.

These materials are often not readily available or require complex sourcing and processing. This limits production flexibility and adds to the overall cost, particularly in industries where budget constraints exist. As demand for FGMs increases, securing a consistent and reliable supply of these specialized materials remains a significant challenge.

Lack of Standardization and Regulatory Frameworks

The lack of standardized processes and regulatory frameworks for Functionally Graded Materials (FGMs) is another major restraint. Since FGMs are still a relatively new technology, there is no universal standard for their design, testing, and certification across industries.

This uncertainty can deter potential adopters, particularly in fields like medical implants and aerospace, where safety and performance are critical. Without established guidelines, manufacturers may face difficulties in ensuring the quality, reliability, and consistency of FGMs, thus hindering their broader adoption and integration into mainstream markets.

Growth Opportunity

Expanding Applications in Renewable Energy Technologies

Functionally Graded Materials (FGMs) offer significant growth opportunities in the renewable energy sector. Their ability to withstand extreme environments, such as high temperatures and fluctuating pressures, makes them ideal for use in solar, wind, and geothermal energy systems.

FGMs can improve the efficiency and durability of energy storage systems, turbines, and heat exchangers. As global demand for clean energy solutions grows, the application of FGMs in energy-efficient technologies is expected to accelerate, providing manufacturers with a substantial market opportunity for innovation and expansion.

Advancements in 3D Printing and Additive Manufacturing

The rise of 3D printing and additive manufacturing is creating new opportunities for Functionally Graded Materials (FGMs). These technologies allow for the precise fabrication of materials with graded properties, which is a key characteristic of FGMs.

As 3D printing evolves, it will become easier to produce customized FGMs tailored to specific applications, reducing production costs and lead times. This opens up new possibilities for industries like aerospace, automotive, and healthcare to produce lightweight, high-performance components that can meet their exact design specifications, driving market growth.

Growing Demand for Customizable Medical Devices and Implants

Functionally Graded Materials (FGMs) present a strong growth opportunity in the medical sector, particularly for the development of customizable implants and prosthetics. FGMs can be tailored to match the mechanical properties of bone, allowing for more effective and longer-lasting implants.

As the global aging population increases, the demand for personalized medical devices will rise, driving the adoption of FGMs in orthopedic, dental, and other implantable technologies. This trend is expected to accelerate as healthcare providers and manufacturers seek innovative solutions to improve patient outcomes and reduce surgical complications.

Latest Trends

Integration of AI and Machine Learning in FGM Design

A key trend in the Functionally Graded Materials (FGM) market is the integration of artificial intelligence (AI) and machine learning (ML) in the design and optimization of FGMs. These technologies enable faster, more efficient design processes by predicting material behavior, optimizing performance, and reducing trial-and-error in FGM development.

By leveraging AI and ML, manufacturers can create custom FGMs that meet specific application requirements, improving material performance while reducing costs. This trend is helping accelerate innovation, especially in industries like aerospace, healthcare, and automotive.

Development of Biodegradable Functionally Graded Materials

A growing trend in the FGM market is the development of biodegradable Functionally Graded Materials, particularly for medical and environmental applications. Researchers are focusing on creating FGMs that can degrade over time without harming the environment or the human body.

These materials offer significant potential in fields like tissue engineering, where they could be used to develop implants that gradually dissolve once they have served their purpose. This trend aligns with the increasing focus on sustainability and the demand for eco-friendly, bio-compatible solutions in various industries.

Expansion of FGM Use in Additive Manufacturing Technologies

Additive manufacturing, or 3D printing, is increasingly being used to produce Functionally Graded Materials (FGMs), particularly for industries requiring complex, customized parts. The ability to precisely control the composition and structure of materials layer by layer allows manufacturers to create FGMs with tailored properties for specific applications.

This trend is revolutionizing sectors like aerospace, automotive, and healthcare, where lightweight, high-performance components are in high demand. As 3D printing technology advances, the use of FGMs in additive manufacturing is expected to continue growing, opening new possibilities for innovation and customization.

Regional Analysis

North America Holds 32.4% Share of Functionally Graded Materials (FGM) Market, Valued at USD 0.3 Billion.

The Functionally Graded Materials (FGM) market is experiencing regional variations in growth, driven by the distinct demands and technological advancements in each area. North America holds a dominant market share of 32.4%, valued at approximately USD 0.3 billion.

This region benefits from strong aerospace, automotive, and healthcare sectors, where FGMs are widely used for high-performance applications. The U.S. leads in innovation and adoption due to advanced manufacturing capabilities and significant investment in research and development.

In Europe, the FGM market is growing steadily, with key applications in aerospace, automotive, and medical devices. The region’s focus on sustainable manufacturing practices and eco-friendly technologies is also contributing to market expansion.

Asia Pacific is anticipated to witness the highest growth rate, fueled by rapid industrialization, particularly in countries like China, Japan, and India. The growing demand for FGMs in sectors like electronics, renewable energy, and automotive is accelerating market growth in this region.

Latin America and the Middle East & Africa represent emerging markets, where adoption is slower but shows potential due to increasing investments in infrastructure, energy, and healthcare. As these regions continue to focus on industrialization and technological advancement, demand for FGMs is expected to rise.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

The global Functionally Graded Materials (FGM) market in 2024 is characterized by a diverse and innovative landscape, with major players spanning various industries such as aerospace, defense, electronics, and manufacturing.

Key companies like 3M, Alcoa Corporation, Boeing, and GE play pivotal roles in driving technological advancements and product development within FGMs, which are crucial for applications requiring superior material properties, including thermal resistance, durability, and mechanical strength.

3M, a leader in materials science, contributes significantly to the market with its diverse portfolio of FGMs for industrial and electronic applications. Alcoa and Arconic, prominent players in the metals sector, focus on the development of advanced metallic FGMs, primarily for the aerospace and automotive industries, where material performance is critical under extreme conditions.

Boeing, with its extensive experience in aerospace, leverages FGMs to create lighter, more efficient components, particularly for high-stress applications. Similarly, NASA’s R&D efforts are focused on FGMs to optimize materials used in spacecraft and satellite structures, pushing the boundaries of material performance in extreme environments.

GE and Siemens AG bring innovation in manufacturing and energy, utilizing FGMs in gas turbines and energy-efficient systems. In the electronics sector, companies like Corning and Kyocera are pioneering FGM technologies, catering to applications in semiconductors and sensors, where material grading enhances the performance of electronic devices.

Other key players like Raytheon Technologies, Honeywell, and Sumitomo Electric Industries focus on integrating FGMs into defense, electronics, and automotive industries, ensuring that these materials meet high-performance requirements in mission-critical applications. The continued collaboration among these players, coupled with their ongoing R&D, is expected to drive significant growth and innovation in the FGM market.

Top Key Players in the Market

- 3M

- Alcoa Corporation

- Arconic

- Boeing

- CeramTec

- Corning Incorporated

- General Electric (GE)

- Hitachi Metals, Ltd.

- Honeywell International Inc.

- Kyocera Corporation

- NASA,

- Raytheon Technologies

- Siemens AG

- Sumitomo Electric Industries, Ltd.

- Toshiba

Recent Developments

- In 2024, 3M advanced Functionally Graded Materials (FGM) technology by enhancing material strength and thermal resistance for aerospace and medical applications. Their focus is on developing materials with gradual property transitions, improving performance in specialized industries.

- In 2023, Alcoa Corporation advanced its work in Functionally Graded Materials (FGM), focusing on improving the strength and thermal resistance of metals for aerospace and automotive applications. Their research aims to produce more durable, high-performance components for demanding industries.

Report Scope

Report Features Description Market Value (2024) USD 1.1 Billion Forecast Revenue (2034) USD 1.7 Billion CAGR (2025-2034) 4.2% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Material Type (Ceramics-Based FGM, Metal-Based FGM, Polymer-Based FGM, Composite-Based FGM, Others), By End-Use Industry (Aerospace and Defense, Automotive, Healthcare, Energy, Electronics, Industrial Manufacturing, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape 3M, Alcoa Corporation, Arconic, Boeing, CeramTec, Corning Incorporated, General Electric (GE), Hitachi Metals, Ltd., Honeywell International Inc., Kyocera Corporation, NASA,, Raytheon Technologies, Siemens AG, Sumitomo Electric Industries, Ltd., Toshiba Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Functionally Graded Materials (FGM) MarketPublished date: January 2025add_shopping_cartBuy Now get_appDownload Sample

Functionally Graded Materials (FGM) MarketPublished date: January 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- 3M

- Alcoa Corporation

- Arconic

- Boeing

- CeramTec

- Corning Incorporated

- General Electric (GE)

- Hitachi Metals, Ltd.

- Honeywell International Inc.

- Kyocera Corporation

- NASA,

- Raytheon Technologies

- Siemens AG

- Sumitomo Electric Industries, Ltd.

- Toshiba