Global Triethylenediamine Market Size, Share, And Business Benefits By Product Type (Rigid Foam, Flexible Foam, Coatings, Adhesives, and Sealants), By Application (Electronics, Communication, Textile Industries, Others), By Region, and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: November 2025

- Report ID: 166174

- Number of Pages: 343

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

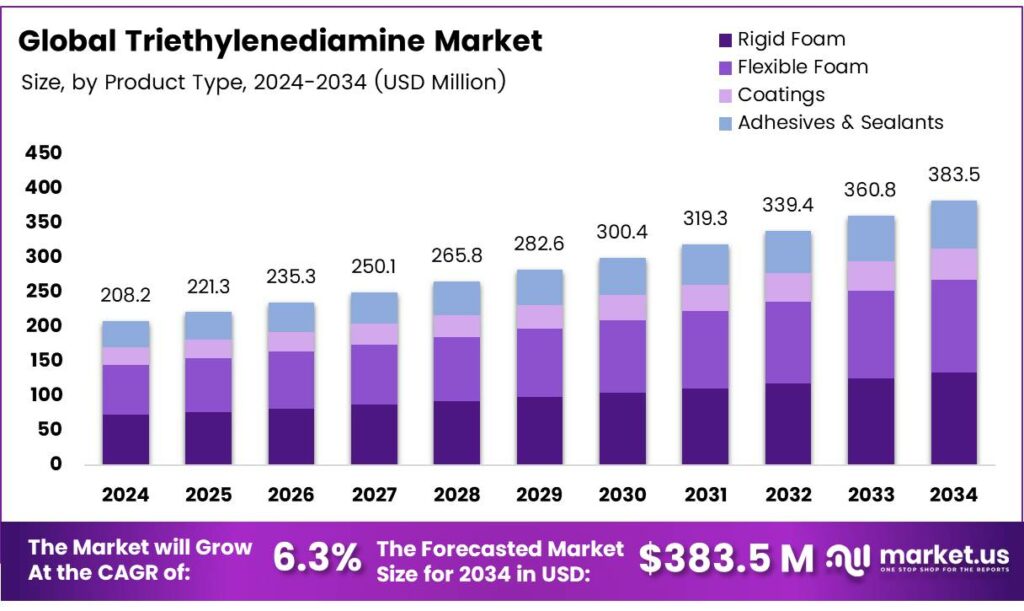

The Global Triethylenediamine Market size is expected to be worth around USD 383.5 million by 2034, from USD 208.2 million in 2024, growing at a CAGR of 6.3% during the forecast period from 2025 to 2034.

Triethylenediamine (TEDA), also known as 1,4-diazabicyclooctane or DABCO, is a crystalline solid amine at room temperature. It is flammable, highly hygroscopic, and readily absorbs moisture from the air, causing it to deliquesce. With a melting point of 158°C and a boiling point of only 174°C, TEDA sublimes easily even at room temperature. It is highly soluble in water, ethanol, aromatic hydrocarbons, and ketones. When exposed to air, it rapidly absorbs carbon dioxide and turns pale yellow, which is why commercial samples typically appear light yellow rather than colorless.

- TEDA significantly accelerates the early hydration reaction of the cementitious system in dry ice grouting materials. As TEDA content increases from 2% to 8% by mass, the gel/space ratio markedly improves. For specimens cured for 3 days, the ratio rises from 1.7% to 1.9%, while for 7-day cured specimens, it increases from 1.9% to 2.0%. This enhancement is attributed to the promoted formation of key hydration products, including ettringite (AFt), calcium silicate hydrate (C-S-H), and calcium carbonate (CaCO₃).

Proper storage of triethylenediamine is critical due to its sensitivity to moisture and carbon dioxide. It must be kept in tightly sealed containers under inert conditions to maintain purity. Triethylenediamine is a versatile and widely used catalyst in the chemical industry, particularly valued for its role in polyurethane production. It efficiently catalyzes the reaction between polyols and isocyanates, enabling the synthesis of polyurethane foams, elastomers, coatings, and adhesives.

Beyond polyurethanes, TEDA catalyzes the curing of epoxy resins, the polymerization of ethylene and ethylene oxide, and various other organic synthesis processes. In addition to its catalytic applications, triethylenediamine and its derivatives have several specialized uses. It acts as a stabilizer to prevent UV-induced fading in fuels and dyes, functions as an initiator in pesticide manufacturing, and serves as an environmentally friendly cyanide-free additive in electroplating processes, helping reduce toxic waste.

Derivatives of TEDA are also employed as corrosion inhibitors, emulsifiers, and intermediates in the production of light-stabilizing materials. Triethylenediamine plays an essential role in the synthesis of organic polymers and numerous industrial applications, particularly in plastics and fine chemicals. Its broad utility and effectiveness as a catalyst ensure strong market demand and continued importance in modern chemical manufacturing.

Key Takeaways

- The Global Triethylenediamine Market is valued at USD 208.2 million in 2024 and projected to reach USD 383.5 million by 2034, growing at a 6.3% CAGR during 2025–2034.

- Rigid Foam dominates with a 34.8% share due to strong usage in insulation and construction-grade foam applications.

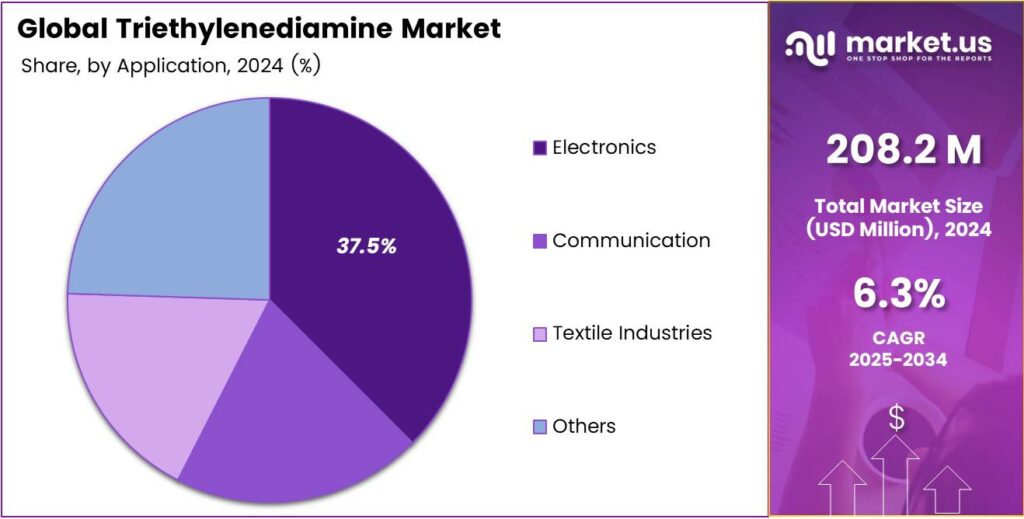

- Electronics leads with a market share of 37.5% driven by rising demand for high-performance insulation and encapsulation materials.

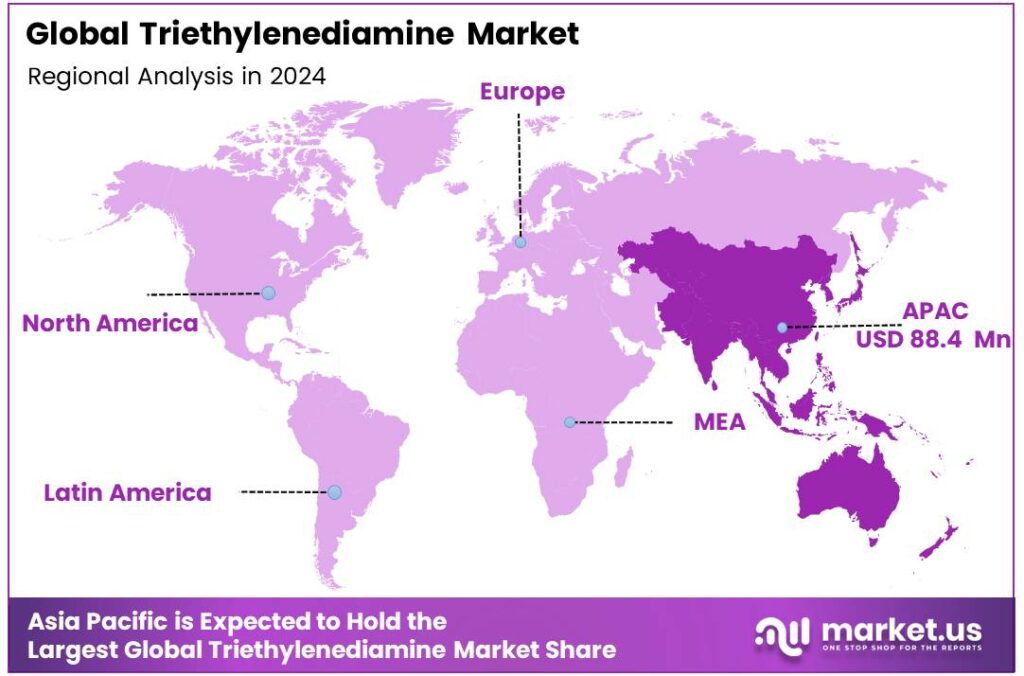

- Asia Pacific holds the largest regional market share at 42.5%, valued at USD 88.4 million, due to expanding manufacturing and construction sectors.

By Product Type Analysis

Rigid Foam dominates with 34.8% due to its high compatibility in insulation and structural foam production.

In 2024, Rigid Foam held a dominant market position in the ‘By Product Type’ Analysis segment of the Triethylenediamine Market, with a 34.8% share. This sub-segment benefits from rising insulation demand, especially in industrial and construction-grade polyurethane foam. Its strong catalytic response accelerates foam curing, improves dimensional stability, and aligns with sustainable building requirements.

Flexible Foam forms another key sub-segment in this structure due to its relevance in bedding, furniture, and automotive cushioning. Although it follows behind Rigid Foam, it remains vital due to its soft formulation support. Triethylenediamine enhances foam resilience, uniform pore structure, and longevity, ensuring better comfort and flexible material adaptability in consumer goods.

Coatings also represent a notable utilization area where Triethylenediamine improves curing speed and cross-linking performance, especially in polyurethane-based coating systems. Its chemical stability enhances adhesion, moisture resistance, and durability levels. Additionally, its reactive nature supports protective coatings for flooring, marine parts, and industrial machinery where lasting surface protection is crucial.

Adhesives and Sealants complete this category and leverage Triethylenediamine for consistent bond strength and quick setting times. It enhances formulation stability across construction panels, packaging, automotive interiors, and electronics fixtures. The catalytic efficiency presents improved sealing, gap-filling, and adhesive layer uniformity while maintaining higher thermal resistance and lifespan efficiency.

By Application Analysis

Electronics dominates with 37.5% due to the rising demand for lightweight insulation materials.

In 2024, Electronics held a dominant market position in the ‘By Application’ Analysis segment of the Triethylenediamine Market, with a 37.5% share. Electronic components require precision foam sealing, shock absorption, and heat-resistant encapsulation, making Triethylenediamine highly preferred. The segment grows with EV electronics, circuit insulation, and compact hardware manufacturing.

Communication uses Triethylenediamine to enhance durable and lightweight infrastructure components for cables, server units, antennas, and networking housings. The chemical ensures smooth polymer foaming and better penetration resistance for equipment exposed to temperature fluctuations. It supports long-lasting bandwidth systems for both indoor and outdoor communication hardware.

Textile Industries use Triethylenediamine for foam-based padding, lamination, and comfort performance layers. It supports fabric cushioning, breathable substrate development, and apparel enhancement technologies. The compound improves uniformity, lightweight feel, and textile processing efficiency through polyurethane-based applications in footwear, sportswear, furniture fabrics, and fashion accessories.

Key Market Segments

By Product Type

- Rigid Foam

- Flexible Foam

- Coatings

- Adhesives and Sealants

By Application

- Electronics

- Communication

- Textile Industries

- Others

Emerging Trends

Shift towards energy-efficient foam systems in polyurethane catalysis

One major emerging trend for Triethylenediamine (TEDA) is its increasing use as a catalyst in high-performance, energy-efficient polyurethane foam systems, especially for insulation in buildings and appliances. Demand for such foams is being driven by stringent energy-efficiency regulations, sustainability goals, and a move away from heavier/high-emission materials.

- ISOPA reports that polyurethanes (of which TEDA plays a key catalytic role) are one of the most resource-efficient materials – they use less than 0.1% of the oil consumed worldwide and save up to 100 times more in terms of energy performance. As building-materials manufacturers look for catalysts that support low-VOC, energy-efficient foam systems, TEDA is becoming more attractive.

Also, sustainability pushes (less energy consumed during the lifecycle, lighter transport weight, longer product lives) give catalysts like TEDA added value in the chain. The push for energy-efficient buildings and lightweight high-performance materials is a tailwind for TEDA usage in polyurethane foams. The opportunity lies in aligning catalyst-technology (purity grades, reaction kinetics) with green-building regulations and low-carbon material systems.

Drivers

Surge in Energy-Efficient Construction & Insulation Demand

- The increasing global push for energy-efficient buildings is a major driver for the demand for Triethylenediamine (TEDA) as a catalyst in rigid polyurethane (PU) foams and insulation materials. In Europe, buildings account for about 40% of energy consumption and around 50% of gas use in the EU.

The revised Energy Performance of Buildings Directive (EPBD) entered into force in May 2024, aiming for a fully decarbonised building stock and mandating national building-renovation plans that will require the worst-performing buildings to upgrade. As more governments tighten regulations and set higher performance standards for building insulation, the demand for high-performance insulation solutions rises.

Rigid PU foams, where TEDA acts as an efficient catalyst, are widely used because they deliver excellent thermal resistance, structural stability, and durability in thinner panel forms (helping space efficiency). Industry commentary notes that such PU insulation plays a crucial role in reaching nearly zero energy demand levels in new and retrofit construction.

Restraints

Stringent environmental and safety regulations

One of the major restraints for the Triethylenediamine (TEDA) market stems from increasing regulatory burdens aimed at hazardous or high-performance specialty chemicals. While TEDA is valued as a catalyst in polyurethane foams, coatings, and other specialty applications, its handling, emissions, and end-of-life disposal are under sharper regulatory scrutiny.

Global frameworks such as the European Chemicals Agency’s (ECHA) REACH Regulation set strict requirements for chemical registration, evaluation, authorisation and restriction, including submission of full risk assessments for substances produced or imported above defined tonnage thresholds.

In dedicated industry commentary, regulatory pressure is explicitly cited as a key challenge for TEDA manufacturers: Regulatory factors impacting the triethylenediamine (TEDA) market include stringent environmental and safety regulations enforced by authorities such as the U.S. Environmental Protection Agency (EPA) and the ECHA.

Opportunity

Rising Demand from Energy-Efficient Construction and Lightweight Mobility

One of the key growth drivers for Triethylenediamine (TEDA) is its role as a catalyst in the expanding world of energy-efficient building materials and lightweight automotive components. As buildings and vehicles increasingly aim for sustainability, lightweight polyurethane foams and insulation systems that rely on TEDA are gaining traction.

- The U.S. Department of Energy, properly insulating and air-sealing a home using materials such as polyurethane foam, can save homes up to 50% on heating and cooling costs. These savings incentivize builders and manufacturers to adopt higher-performance insulating systems, driving demand for catalysts like TEDA.

The Bureau of Energy Efficiency (BEE) in India has implemented building-efficiency measures through its voluntary Star Rating Programme and the adoption of the Energy Conservation Building Code (ECBC), which promotes energy-efficient construction materials. This regulatory push implicitly favours advanced insulation and foam products—thus feeding the downstream catalyst demand.

Regional Analysis

Asia Pacific Dominates the Triethylenediamine Market with a Market Share of 42.5%, Valued at USD 88.4 Million

The Asia Pacific region leads the global Triethylenediamine (TEDA) market, holding a commanding 42.5% share worth USD 88.4 million, supported by strong polyurethane applications in construction, automotive, footwear, and insulation industries. Expanding manufacturing hubs, rising residential infrastructure, and growing energy-efficient building materials drive continuous product consumption.

North America shows consistent TEDA usage driven by advancements in rigid and flexible polyurethane foams for insulation, refrigeration, and automotive seating materials. Strong sustainability policies and enhanced thermal-insulation guidelines further support market consumption across industrial and residential projects. The region benefits from mature chemical processing standards, technology integration, and continuous improvement in catalyst substitution efficiency.

Europe maintains a steady demand due to high compliance with energy-saving building codes and automotive lightweight material adoption. The market is influenced by stringent regulatory frameworks on emissions, VOC content, and eco-friendly polyurethane applications, which support stable consumption. Growth in thermal retrofit projects, cold-chain systems, and furniture manufacturing sustains long-term market potential.

The Middle East and Africa region observes gradual market expansion supported by construction activities, industrial output, and growth in energy-efficient insulation systems for extreme climatic conditions. Rising interest in modern building materials and international investment inflows enhance polyurethane demand. Adoption remains moderate but shows positive progression.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

Air Products and Chemicals Inc. plays a strong role in the Triethylenediamine market by leveraging its experience in industrial gases and chemical intermediates. The company focuses on continuous process optimization, safe handling technologies, and efficient supply chain capabilities, helping improve cost reliability for polyurethane producers. Its long-term strategy appears centered on selective capital deployment, high-purity product assurance, and collaborative development with foam and insulation manufacturers across key regional clusters.

Eastman Chemical Company contributes to product consistency and formulation flexibility through its expertise in amine-based catalysts and integrated chemical operations. The company benefits from a diversified raw-material sourcing network and a strong research pipeline, ensuring steady demand from automotive, electronics, and rigid insulation customers. Eastman’s value positioning seems aligned with low-emission production methods, long-term partnerships, and tailored supply agreements for evolving polyurethane chemistry demands.

BASF SE remains a crucial innovation-driven stakeholder with extensive polyurethane catalyst capabilities supported by global manufacturing footprints. The company’s focus on advanced mobility materials, efficient insulation platforms, and sustainability-linked catalyst systems strengthens its strategic fit in TEDA usage. BASF invests in material science research, digital formulation platforms, and climate-aligned product development, making it competitive in sectors seeking lighter, durable, and more energy-efficient solutions.

Top Key Players in the Market

- Air Products and Chemicals Inc.

- Eastman Chemical Company

- BASF SE

- Huntsman Corporation

- Evonik Industries AG

- Dow Inc.

- Clariant AG

- Solvay S.A.

Recent Developments

- In 2025, Huntsman is positioned as a key TEDA supplier, with its portfolio including amine catalysts for epoxy and PU formulations. Technical document highlights TEDA derivatives in epoxy curing, emphasizing balanced catalysis for gelling and blowing reactions. Huntsman’s involvement in PU additives drives market growth in flexible foams for furniture and automotive seating.

- In 2024, Evonik showcased its expanded DABCO portfolio at UTECH Europe, introducing low-emission variants (DABCO NE) and trimerization catalysts for rigid and flexible foams. These enhance structural stability, reduce defects, and support LCF options based on renewable raw materials, targeting automotive interiors, CASE (coatings, adhesives, sealants, elastomers), and electronics.

Report Scope

Report Features Description Market Value (2024) USD 208.2 Million Forecast Revenue (2034) USD 383.5 Million CAGR (2025-2034) 6.3% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product Type (Rigid Foam, Flexible Foam, Coatings, Adhesives, and Sealants), By Application (Electronics, Communication, Textile Industries, Others) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape Air Products and Chemicals Inc., Eastman Chemical Company, BASF SE, Huntsman Corporation, Evonik Industries AG, Dow Inc., Clariant AG, Solvay S.A. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited Users and Printable PDF)  Triethylenediamine MarketPublished date: November 2025add_shopping_cartBuy Now get_appDownload Sample

Triethylenediamine MarketPublished date: November 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Air Products and Chemicals Inc.

- Eastman Chemical Company

- BASF SE

- Huntsman Corporation

- Evonik Industries AG

- Dow Inc.

- Clariant AG

- Solvay S.A.