Electrostatic Precipitator Market Report By Type (Dry, Wet), By Application (Particulate Matter Control, Gaseous Pollutant Control), By End-User Industry (Power Generation, Chemicals and Petrochemicals, and Others, By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: March 2024

- Report ID: 28357

- Number of Pages: 261

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

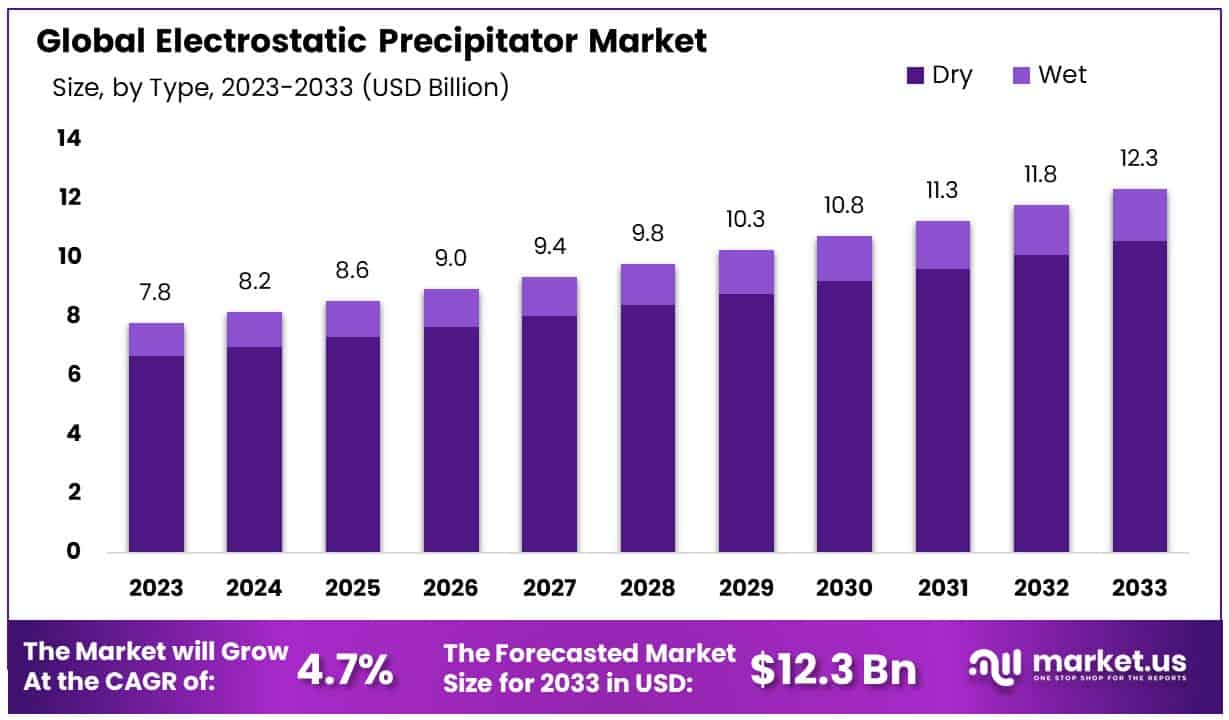

The Global Electrostatic Precipitator Market size is expected to be worth around USD 12.3 Billion by 2033, from USD 7.8 Billion in 2023, growing at a CAGR of 4.70% during the forecast period from 2024 to 2033.

The Electrostatic Precipitator Market involves technology essential for removing particles from exhaust gases. It uses electrical forces to capture dust, smoke, and other impurities, making it crucial for industries focused on air quality control. This market caters to sectors like power generation, cement manufacturing, steel, and others where clean air standards are strict.

Its growth is driven by regulatory pressures and the global demand for cleaner industrial processes. The market’s technologies offer solutions for achieving emissions targets and enhancing air quality, aligning with sustainability goals.

The Electrostatic Precipitator Market is increasingly relevant in today’s industrial landscape, where air quality standards are becoming stringent due to rising awareness about environmental health.

The “State of the Air” 2023 report underscores this urgency, revealing that nearly 36% of Americans, approximately 119.6 million people, reside in locales with harmful levels of air pollution, including fine particles and ozone. This scenario underscores the necessity for industries to adopt effective pollution control technologies.

Electrostatic precipitators, leveraging electrical forces to remove particulates from exhaust gases, emerge as a critical solution to this challenge. They align with the Clean Air Act (CAA) mandates, where the Environmental Protection Agency (EPA) is tasked with establishing National Ambient Air Quality Standards (NAAQS) for major pollutants such as particulate matter and sulfur dioxide.

The technology’s importance is further highlighted by innovations like the Korea Institute of Machinery and Materials (KIMM)’s development of a pioneering filter-free indoor ultrafine particle reduction technology utilizing an electrostatic approach.

This backdrop of regulatory requirements and technological advancements positions the Electrostatic Precipitator Market for significant growth. As businesses navigate the complexities of environmental regulations, the electrostatic precipitator market represents a beacon of innovation and compliance, essential for sustainable industrial operations.

Key Takeaways

- Market Value: The Global Electrostatic Precipitator Market is projected to reach USD 12.3 Billion by 2033, growing at a CAGR of 4.70% from USD 7.8 Billion in 2023.

- Major Segments:

- Type Analysis: The Dry type dominates the Electrostatic Precipitator Market with an 85.6% market share, owing to its versatility and efficiency in handling various industrial applications.

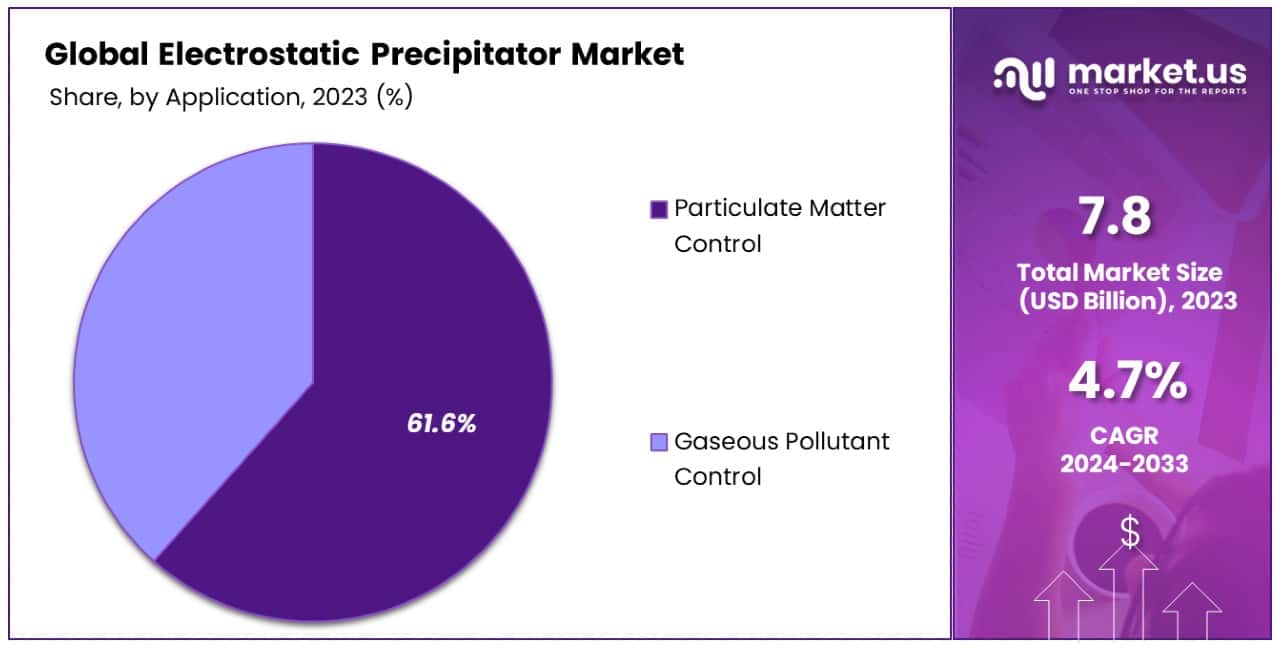

- Application Analysis: Particulate Matter Control segment leads with a 61.6% market share, indicating the industry’s focus on reducing solid and liquid particulate emissions. Gaseous Pollutant Control segment, though smaller, is essential for reducing hazardous gas emissions, reflecting tightening regulations worldwide.

- End-User Industry Analysis: Power Generation emerges as the largest end-user, constituting 38.5% of the market, driven by the need for robust emission control solutions in coal-fired and oil-fired power plants.

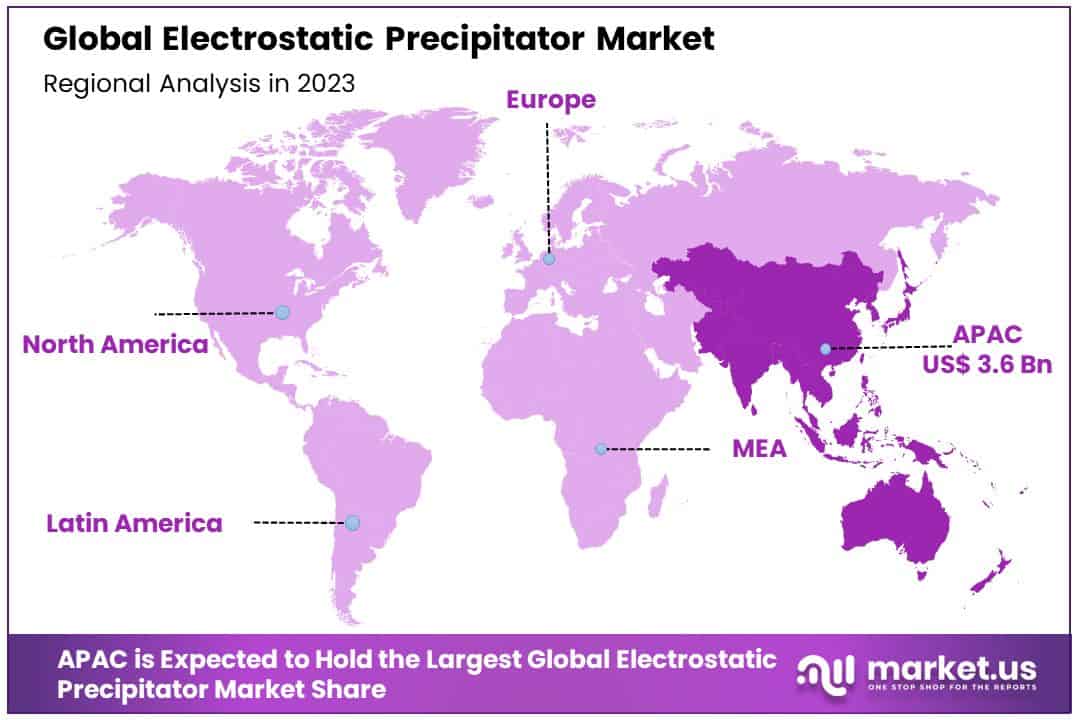

- Regional Analysis: APAC dominates the market with a 47.2% market share, driven by industrial expansion and environmental concerns. North America exhibits steady growth, fueled by infrastructure renewal and stringent environmental regulations.

- Analyst Viewpoint: Analysts anticipate continued growth in the electrostatic precipitator market, fueled by increasing environmental regulations and industrialization. The emphasis on clean air standards and emission reduction policies globally is expected to drive demand for electrostatic precipitators across various industries.

- Growth Opportunities: Emerging opportunities lie in sectors such as marine and transportation, indicating potential growth areas for electrostatic precipitator technology. Technological advancements aimed at enhancing efficiency and addressing specific industrial challenges present avenues for market expansion and innovation.

Driving Factors

Stringent Environmental Regulations Drive Market Growth

Stringent environmental regulations across the globe act as a pivotal driver for the Electrostatic Precipitator Market. Governments worldwide are adopting stricter emission controls and air quality standards to combat pollution. This regulatory pressure forces industries to implement advanced pollution control technologies, among which electrostatic precipitators are a primary choice.

India’s National Clean Air Programme, aiming to cut particulate matter pollution by 20-30% by 2024, exemplifies these efforts. Such initiatives not only underscore the critical need for effective emission reduction solutions but also create a direct pathway for the expansion of the electrostatic precipitator market. The synergy between regulatory mandates and market response underlines a growing trend towards environmental stewardship, pushing industries towards cleaner and more sustainable operations.

Expansion of Cement and Metal Production Catalyzes Market Growth

The rapid urbanization in emerging economies is fueling an unprecedented demand for infrastructure and development, leading to a surge in cement and metal production. This expansion is a significant catalyst for the Electrostatic Precipitator Market. As these industries are among the largest contributors to air pollution, the need for effective pollution control technologies is paramount.

Electrostatic precipitators, with their ability to efficiently collect dust particulate from emissions, are increasingly becoming an essential component of environmental compliance strategies in the cement and metal sectors. This growing demand is a testament to the market’s responsiveness to industrial growth, reflecting a broader move towards sustainable industrial practices.

Rising Power Generation Fuels Market Demand

The global increase in power generation, driven by coal and other fuels, necessitates the adoption of pollution control mechanisms at thermal power plants. The International Energy Agency (IEA) projects a yearly growth in electricity demand of 2.1% until 2040, signaling a continuous rise in power generation.

This growth trajectory directly influences the Electrostatic Precipitator Market, as thermal power plants seek efficient ways to meet emission standards while coping with increased production demands. The installation of electrostatic precipitators is becoming an industry standard, reflecting the critical role of these systems in aligning power generation practices with environmental sustainability goals. The interplay between rising energy needs and emission control requirements highlights the precipitators’ indispensable role in modern power generation.

Restraining Factors

High Capital and Operating Costs Restrain Market Growth

Electrostatic precipitators come with significant initial investment and operational expenses, primarily due to their high electricity consumption and the complexity of their design and maintenance. This financial burden poses a considerable challenge for small-scale industries, which may find alternatives like fabric filters more cost-effective.

The high costs associated with electrostatic precipitators can deter potential new entrants in the market, especially in regions where cost-efficiency is a primary concern. This factor limits the market expansion, as affordability becomes a crucial decision-making aspect for industries prioritizing budget constraints over technological advancements.

Limitations in Collection of Fine Particles Restrain Market Growth

The conventional electrostatic precipitator’s efficiency diminishes when capturing particles less than 1 μm in diameter. This technological limitation hinders its adoption in sectors requiring stringent control of ultra-fine particulates.

Industries focused on reducing health hazards associated with fine and ultra-fine particles may seek alternative solutions offering higher efficiency for these smaller particulates. This restraint impacts the electrostatic precipitator market’s growth potential, especially in applications where the capture of such fine particles is critical for compliance with environmental regulations and protection of public health.

Type Analysis

In the Electrostatic Precipitator Market, the ‘Dry’ type dominates, holding an 85.6% market share. This overwhelming dominance is attributed to the dry electrostatic precipitators’ versatility and efficiency in handling a wide range of temperatures and particulate conditions, making them suitable for various industrial applications.

They are particularly favored in industries where particulate emissions are dry and can be easily collected without the need for moisture. This includes applications in power generation, cement manufacturing, and metal processing, where dry particulates are the norm.

The ‘Wet’ segment, while smaller, plays a critical role in industries where gas streams contain moist, sticky, or highly corrosive particulates. Wet electrostatic precipitators are essential in controlling emissions in such conditions, offering efficient collection of fine particles and ensuring compliance with environmental regulations. Despite its smaller share, the wet segment is crucial for industries like chemicals and petrochemicals, where gas streams can be highly corrosive or where particulate matter is difficult to collect in a dry state.

Application Analysis

The ‘Particulate Matter Control’ segment leads the Electrostatic Precipitator Market with a 61.6% share, highlighting the industry’s focus on controlling solid and liquid particulates in emissions. This dominance reflects the global emphasis on reducing particulate matter due to its significant health and environmental impacts. Industries such as power generation, cement, and metal processing rely heavily on electrostatic precipitators to meet stringent particulate matter emission standards, driving growth in this segment.

‘Gaseous Pollutant Control’, although smaller, is an essential application of electrostatic precipitators, particularly in sectors focused on reducing hazardous gas emissions, like sulfur dioxide and nitrogen oxides. This segment’s role is increasingly critical as regulations around the world tighten controls on gaseous pollutants to protect public health and mitigate environmental damage. The development of technologies within this segment is vital for industries aiming to achieve compliance and improve air quality.

End-User Industry Analysis

The ‘Power Generation’ sector emerges as the largest end-user, constituting 38.5% of the Electrostatic Precipitator Market. This segment’s lead is driven by the high volume of particulate and gaseous pollutants generated by coal-fired and oil-fired power plants, necessitating robust emission control solutions. Electrostatic precipitators are integral in helping power generation facilities meet air quality standards, thereby securing their position as the dominant market segment.

Other significant end-user industries include Chemicals and Petrochemicals, Cement, Metal Processing & Mining, and Manufacturing, each contributing to the market in varying degrees. These industries are essential for the broader adoption and technological advancement of electrostatic precipitators, addressing specific challenges related to particulate and gaseous pollutant control. The ‘Marine’ and ‘Others’ segments, though smaller, represent emerging opportunities for the application of electrostatic precipitator technology, especially in reducing emissions from shipping and other transportation modes.

Key Market Segments

By Type

- Dry

- Wet

By Application

- Particulate Matter Control

- Gaseous Pollutant Control

By End-User Industry

- Power Generation

- Chemicals and Petrochemicals

- Cement

- Metal Processing & Mining

- Manufacturing

- Marine

- Others

Growth Opportunities

Increasing Adoption in Cement Industry Offers Growth Opportunity

The global surge in construction activity predicates an upswing in cement production, which is set to expand precipitator market opportunities significantly. This growth is driven by the need to control emissions from cement kilns, which are notorious for high volumes of particulate matter.

As cement production is projected to increase to meet the construction sector’s demands, companies specializing in electrostatic precipitators are presented with a lucrative opportunity to enhance their technologies. By focusing on precipitators that can handle high inlet gas volumes and temperatures typical of cement manufacturing processes, suppliers can tap into the expanding market, providing solutions that are both efficient and necessary for environmental compliance.

Developing Wet Precipitator Solutions Offers Growth Opportunity

Wet electrostatic precipitators present a significant market opportunity due to their superior efficiency in collecting fine particulate matter. With industries increasingly focusing on reducing the emission of fine and ultra-fine particles due to their health and environmental impacts, the demand for wet precipitator solutions is on the rise.

This creates a ripe environment for precipitator suppliers to innovate and make wet precipitator technologies more affordable and accessible. The development of cost-effective, efficient wet precipitators could unlock new market segments, catering to industries where gas streams are moist or contain highly corrosive particulates, thus broadening the electrostatic precipitator market’s scope.

Trending Factors

Smart and Connected Precipitators Are Trending Factors

The integration of Internet of Things (IoT) and data analytics into electrostatic precipitators marks a significant trend in the market. This shift towards smart and connected precipitators allows for real-time monitoring of performance parameters, significantly reducing maintenance costs and minimizing unplanned downtime for end-users.

The ability to constantly monitor and adjust the operation of precipitators ensures they are running at optimal efficiency, leading to enhanced environmental compliance and cost savings. This trend not only represents a technological advancement within the sector but also offers a competitive edge to companies that adopt these innovations, driving the market towards more sustainable and efficient emission control solutions.

Adoption of Predictive Maintenance Are Trending Factors

Predictive maintenance, facilitated by advanced data analytics and condition monitoring solutions, is rapidly becoming a trend within the Electrostatic Precipitator Market. End-users are increasingly leveraging these technologies to predict potential failures before they occur, allowing for timely maintenance and thus significantly reducing overall maintenance costs.

This proactive approach to maintenance aligns with the broader industry trend towards minimizing operational disruptions and enhancing the lifespan of precipitators. The adoption of predictive maintenance strategies represents a shift towards more intelligent and cost-effective management of pollution control equipment, further driving the market’s growth by appealing to industries keen on reducing operational risks and expenses.

Regional Analysis

APAC Dominates with 47.2% Market Share

The Asia Pacific (APAC) region holds a commanding 47.2% share of the Electrostatic Precipitator Market, underpinned by rapid industrial growth and stringent environmental regulations. The region’s dominance is attributed to the massive expansion of power generation, cement, and metal processing industries, especially in countries like China and India. These nations are aggressively addressing air pollution, compelling industries to adopt electrostatic precipitators for emission control. Furthermore, APAC’s focus on sustainable development and renewable energy projects necessitates efficient pollution control technologies, further boosting the market.

The market dynamics in APAC are shaped by the region’s industrialization pace and environmental policy framework. The burgeoning power sector, alongside the cement and steel industries, has a high demand for electrostatic precipitators, driven by the need to meet air quality standards. APAC’s commitment to reducing carbon footprints and controlling industrial pollution also plays a crucial role. The region’s diverse economic landscape presents unique challenges and opportunities for market players, with demand for advanced and cost-effective precipitator technologies rising.

- North America: With a focus on renewing infrastructure and stringent environmental policies, North America shows steady growth in the electrostatic precipitator market. However, its market share is considerably smaller compared to APAC.

- Europe: Europe, with its robust environmental regulations and advanced industrial sectors, holds a significant market share. The region’s commitment to sustainability and pollution control supports a demand for electrostatic precipitators.

- Middle East & Africa (MEA): While smaller, MEA’s market share is increasing, fueled by industrial development and environmental initiatives.

- Latin America: Experiencing growth due to industrial expansion and emerging focus on environmental regulations, though its overall market share remains modest compared to APAC.

Key Regions and Countries

- North America

- The US

- Canada

- Mexico

- Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

In the Electrostatic Precipitator Market, the presence of key players such as General Electric Company, Mitsubishi Hitachi Power Systems, Ltd., Babcock & Wilcox Enterprises, Inc., and others signifies a competitive and technologically advanced landscape. These companies play pivotal roles in shaping market dynamics through their innovative solutions and global reach.

General Electric and Siemens AG, with their extensive research and development resources, lead in introducing cutting-edge technologies that enhance efficiency and environmental compliance. Mitsubishi Hitachi and Sumitomo Heavy Industries, known for their robust engineering capabilities, offer customized solutions that cater to diverse industry needs, from power generation to manufacturing.

Companies like Thermax Limited and FLSmidth & Co. A/S are strategically positioned to address the specific requirements of the cement and power sectors, leveraging their expertise to meet stringent emission control standards. Babcock & Wilcox and Amec Foster Wheeler underscore the importance of reliability and performance in their offerings, ensuring clients achieve regulatory compliance and operational efficiency. Emerging players like Fujian Longking Co., Ltd., and Ducon Technologies Inc. contribute to market diversity with their localized strategies and innovative approaches, enhancing the overall competitive landscape.

Together, these key players drive the Electrostatic Precipitator Market’s growth by focusing on technological advancements, strategic global positioning, and a deep understanding of regulatory environments. Their collective impact and market influence are pivotal in meeting the evolving demands of industries seeking to mitigate environmental impacts while maintaining operational excellence.

Market Key Players

- General Electric Company

- Mitsubishi Hitachi Power Systems, Ltd.

- Babcock & Wilcox Enterprises, Inc.

- Amec Foster Wheeler

- FLSmidth & Co. A/S

- Thermax Limited

- Ducon Technologies Inc.

- Siemens AG

- Sumitomo Heavy Industries, Ltd.

- Fujian Longking Co., Ltd.

- Hamon Group

- KC Cottrell Co., Ltd.

Recent Developments

- September 2023: Valmet is set to deliver an electrostatic precipitator (ESP) to Shandong Huatai Paper in China for their 700,000 tonnes chemical pulp project. The delivery is scheduled for January 2025 as part of Valmet’s orders received in the third quarter of 2023.

- April 2023: The Korea Institute of Machinery and Materials (KIMM) has developed a groundbreaking filter-free indoor ultrafine particle reduction technology using an electrostatic method. This innovative technology has been transferred to companies specializing in air cleaning technology for commercialization.

- August: Potato processors in the food industry are adopting Dürr Megtec’s advanced wet electrostatic precipitator (WESP) as an efficient emissions control solution. This technology offers improved design features compared to the original WESP, including faster installation, a smaller footprint.

Report Scope

Report Features Description Market Value (2023) USD 7.8 Billion Forecast Revenue (2033) USD 12.3 Billion CAGR (2024-2033) 4.70% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Dry, Wet), By Application (Particulate Matter Control, Gaseous Pollutant Control), By End-User Industry (Power Generation, Chemicals and Petrochemicals, Cement, Metal Processing & Mining, Manufacturing, Marine, Others) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape General Electric Company, Mitsubishi Hitachi Power Systems, Ltd. , Babcock & Wilcox Enterprises, Inc., Amec Foster Wheeler, FLSmidth & Co. A/S, Thermax Limited, Ducon Technologies Inc., Siemens AG, Sumitomo Heavy Industries, Ltd., Fujian Longking Co., Ltd., Hamon Group, KC Cottrell Co., Ltd. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is the expected market size of the Electrostatic Precipitator Market by 2033?The Global Electrostatic Precipitator Market is projected to be worth around USD 12.3 Billion by 2033, growing at a CAGR of 4.70%.

What is driving the growth of the Electrostatic Precipitator Market in the Power Generation sector?The Power Generation sector constitutes 38.5% of the market, driven by the high volume of particulate and gaseous pollutants generated by coal-fired and oil-fired power plants, necessitating robust emission control solutions.

Which region dominates the Electrostatic Precipitator Market, and what factors contribute to this dominance?The Asia Pacific (APAC) region dominates the market with a 47.2% market share, driven by rapid industrial growth, stringent environmental regulations, and the expansion of power generation, cement, and metal processing industries.

Who are the key players in the Electrostatic Precipitator Market?Key players include General Electric Company, Mitsubishi Hitachi Power Systems, Ltd., Babcock & Wilcox Enterprises, Inc., and others, driving technological innovation and market expansion.

How are smart and connected precipitators impacting the market?The integration of IoT and data analytics into electrostatic precipitators allows for real-time monitoring, reducing maintenance costs, minimizing downtime, and enhancing environmental compliance.

What are the key factors restraining the growth of the Electrostatic Precipitator Market?High capital and operating costs, as well as limitations in the collection of fine particles, restrain market growth, especially for small-scale industries and applications requiring efficient capture of ultra-fine particulates.

Electrostatic Precipitator MarketPublished date: March 2024add_shopping_cartBuy Now get_appDownload Sample

Electrostatic Precipitator MarketPublished date: March 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- Siemens AG

- General Electric

- Mitsubishi Hitachi Power

- Babcock & Wilcox

- AMEC Foster Wheeler

- Thermax Global

- Ducon Technologies

- Fujian Long king

- Hamon Group

- Other Key Players