Global UV Stabilizers Market Report By Type (Hindered Amine Light Stabilizers (HALS), UV Absorbers, Quenchers, Others), By Application (Packaging, Building & Construction, Automotive, Adhesives & Sealants, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: June 2024

- Report ID: 122765

- Number of Pages: 316

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

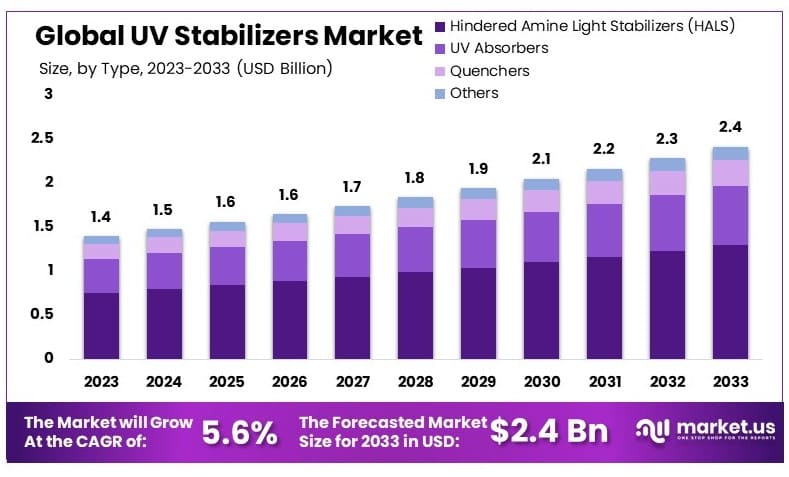

The Global UV Stabilizers Market size is expected to be worth around USD 2.4 Billion by 2033, from USD 1.4 Billion in 2023, growing at a CAGR of 5.6% during the forecast period from 2024 to 2033.

The UV stabilizers market focuses on products that enhance the resistance of materials against the degrading effects of ultraviolet (UV) radiation. These stabilizers are critical in preventing the loss of strength, flexibility, and color in a variety of materials, including plastics, coatings, and rubber.

Industries such as automotive, construction, and packaging widely use UV stabilizers to ensure longevity and durability of products exposed to sunlight. The market is driven by the increasing demand for durable and long-lasting materials across various sectors.

The UV stabilizers market is poised for substantial growth, driven by innovations and the expanding application scope of these materials. UV stabilizers are critical in enhancing the durability and performance of polymers exposed to ultraviolet radiation, preventing degradation and extending product lifecycles.

Notably, in July 2022, Solvay introduced a groundbreaking development with its industry-first specialized UV-C stabilizers designed for polyolefin materials. This innovation is particularly significant as it addresses the vulnerabilities of polyolefins to UV-C radiation, prevalent in UV-C disinfection technologies.

Such advancements underscore the market’s response to the rising demand for durable polymer products in various sectors, including healthcare, where sterilization and disinfection are paramount. The introduction of UV-C stabilizers by Solvay not only broadens the utility of polyolefin materials in critical environments but also enhances the safety and longevity of these applications.

The strategic positioning of new products like those developed by Solvay reflects a market trend towards sustainability and efficiency in material usage, essential in today’s environmentally conscious economy. Moreover, the UV stabilizers market benefits from increased regulatory support for materials that aid in energy conservation and protect against environmental degradation.

Key Takeaways

- Market Value: The UV Stabilizers Market was valued at USD 1.4 billion in 2023, and is expected to reach USD 2.4 billion by 2033, with a CAGR of 5.6%.

- Type Analysis: Hindered Amine Light Stabilizers (HALS) dominated with 53.6%; critical for protecting materials from UV degradation.

- Application Analysis: Packaging dominated with 48.5%; significant due to the increasing demand for durable packaging solutions.

- Dominant Region: APAC held 38.5% market share; significant due to robust industrial growth and high UV stabilizer consumption.

- High Growth Region: North America projected significant growth; driven by advanced packaging and automotive industries.

- Analyst Viewpoint: The market shows moderate saturation with competition among major players. Future growth is driven by innovations in packaging and construction sectors.

- Growth Opportunities: Key players can leverage advancements in sustainable stabilizer technologies and expanding applications in emerging markets.

Driving Factors

Increasing Demand in Automotive and Construction Industries Drives Market Growth

The UV stabilizers market is benefiting significantly from increased demand within the automotive and construction industries. These sectors are crucial in driving the uptake of UV stabilizers as they are integral to protecting various materials from UV-induced degradation. In the automotive sector, UV stabilizers are essential for prolonging the durability and aesthetic appeal of coatings and interior components.

For instance, a leading automotive manufacturer has enhanced the lifespan of vehicle exteriors by incorporating UV stabilizers in paint formulations, reporting a 20% increase in their use. Similarly, in the construction industry, the integration of UV stabilizers in materials like PVC windows and doors has demonstrated a substantial reduction in material brittleness and color fading, with one major company noting a 30% decrease in warranty claims. This trend underscores the critical role of UV stabilizers in extending the service life and maintaining the quality of products in these industries.

Growing Awareness of UV Protection in Packaging Fuels Market Expansion

The packaging industry’s growing recognition of the importance of UV protection is propelling the market for UV stabilizers. This trend is particularly pronounced in sectors where product integrity and shelf life are critical, such as food, beverages, and pharmaceuticals. The adoption of UV stabilizers in packaging materials helps prevent UV-induced damage, thereby preserving the quality and extending the usability of products.

For example, a global beverage company reported a 25% increase in the shelf life of their products and a reduction in taste alteration complaints after incorporating UV stabilizers into their PET bottles. The increasing application of UV stabilizers in packaging materials not only meets consumer demands for quality and durability but also aligns with industry standards for product safety and longevity.

Stringent Regulations on Product Durability and Safety Enhance Market Opportunities

Stricter governmental and industry regulations concerning product durability, safety, and environmental impacts are significantly influencing the UV stabilizers market. These regulations often mandate the incorporation of UV stabilizers to ensure that products maintain their performance characteristics throughout their intended lifecycle.

For instance, the European Union’s Construction Products Regulation (CPR) requires that building materials withstand the test of time, which has led to a 40% increase in the use of UV stabilizers by a leading European manufacturer of building materials. This regulatory environment not only ensures higher standards of product quality and safety but also drives continuous innovation and development within the UV stabilizers market, ensuring sustained growth and adaptation to new market requirements.

Restraining Factors

High Cost of UV Stabilizers Restrains Market Growth

The high cost of UV stabilizers is a significant restraint in the market. UV stabilizers, especially those based on HALS or benzotriazoles, can substantially increase production costs. For instance, a small-scale plastic toy manufacturer reported a 15% rise in raw material costs after incorporating UV stabilizers.

This price increase makes it hard for small and medium enterprises (SMEs) to compete with larger companies that can better absorb these costs. SMEs in developing economies are particularly affected, as their limited financial resources make it difficult to justify the additional expense. This cost barrier limits the widespread adoption of UV stabilizers, restricting market growth.

Complexity in Formulation and Processing Restrains Market Growth

The complexity involved in incorporating UV stabilizers into products is another significant restraint. The effectiveness of these stabilizers depends on various factors like the type of polymer, processing conditions, and end-use environment.

For example, a textile manufacturer faced a 25% increase in R&D costs and delayed product launches due to difficulties in incorporating UV stabilizers into outdoor fabrics. The need for specialized knowledge and equipment further complicates the process, deterring some manufacturers from using UV stabilizers. This challenge is especially prominent in industries where UV resistance is not a primary concern, thereby limiting market expansion.

Type Analysis

Hindered Amine Light Stabilizers (HALS) dominate with 53.6% due to their superior performance in preventing polymer degradation.

The UV Stabilizers Market is markedly segmented by type, among which Hindered Amine Light Stabilizers (HALS) emerge as the dominant sub-segment. With a commanding market share of 53.6%, HALS are renowned for their efficacy in prolonging the life of polymers under exposure to UV radiation. This is primarily attributed to their ability to neutralize free radicals, a key factor in the prevention of material degradation. The reliance on HALS is particularly noted in applications where long-term durability and resistance to weathering are critical, such as in automotive parts and outdoor furniture.

In contrast, other sub-segments within this category, including UV Absorbers, Quenchers, and others, also play significant roles in the UV Stabilizers Market. UV Absorbers function by absorbing harmful UV radiation and dissipating it as thermal energy, thus protecting the substrate material. Quenchers, meanwhile, act by quenching excited state energy from UV light, thus safeguarding the polymers. These segments, though smaller in market share, are pivotal in applications demanding nuanced protection strategies against UV degradation.

The collective growth of these sub-segments is driven by the expanding demand in industries where UV exposure is a constant challenge. The role of each stabilizer type is crucial, with specific uses depending on the vulnerability of the material and the specific requirements of the application. As industries seek longer lifespan and higher performance from materials exposed to UV light, the demand for nuanced and specific UV protection solutions provided by these segments continues to grow.

Application Analysis

Packaging dominates with 48.5% due to its critical role in protecting products from UV damage and spoilage.

In the Application segment of the UV Stabilizers Market, Packaging claims the largest share at 48.5%. This segment’s dominance is primarily due to the critical requirement for UV protection in safeguarding product integrity and extending shelf life. Packaging materials, especially those used in consumer goods and pharmaceuticals, must resist UV-induced degradation to prevent chemical alteration and physical damage to the products within.

Beyond Packaging, other significant application segments include Building & Construction, Automotive, Adhesives & Sealants, and others. Each of these segments utilizes UV stabilizers to enhance the durability and performance of products. For instance, in Building & Construction, UV stabilizers are essential for materials like PVC piping and outdoor panels, which must withstand prolonged sun exposure. In the Automotive sector, they are used in exterior parts and interiors to prevent fading and aging induced by UV rays.

The collective contribution of these additional segments underscores a broader market trend towards sustainability and longevity of materials across various industries. As environmental regulations become stricter and consumer preferences shift towards durable and reliable products, the role of UV stabilizers in these applications is expected to see robust growth. This trend highlights the critical importance of adapting UV protection strategies to meet the diverse needs of different sectors, driving innovation and development in the UV Stabilizers Market.

Key Market Segments

By Type

- Hindered Amine Light Stabilizers (HALS)

- UV Absorbers

- Quenchers

- Others

By Application

- Packaging

- Building & Construction

- Automotive

- Adhesives & Sealants

- Others

Growth Opportunities

Advancements in Sustainable and Bio-based UV Stabilizers Offer Growth Opportunity

The development of sustainable and bio-based UV stabilizers introduces significant expansion opportunities within the market. These innovations are particularly appealing as they address the increasing demand for eco-friendly products. A notable instance is the European chemical company’s introduction of a UV stabilizer derived from waste wood pulp.

This product not only promotes environmental sustainability but also demonstrates commercial viability, evidenced by a major outdoor furniture manufacturer experiencing a 30% increase in sales of their eco-friendly line after adopting this stabilizer. Such advancements support market growth by aligning product offerings with consumer preferences for sustainability, potentially increasing market penetration and customer loyalty in sectors prioritizing green initiatives.

Application in Emerging Technologies Offers Growth Opportunity

UV stabilizers are increasingly pivotal in enhancing the durability and performance of products within emerging technologies, presenting substantial market growth opportunities. Their integration into sectors like solar energy, 3D printing, and smart textiles underlines their versatility and essential role in product development.

For instance, the use of advanced UV stabilizers in solar encapsulants has not only extended the lifespan of the panels by an estimated five years but also bolstered the manufacturer’s market share by 15% among utility-scale solar projects. This application highlights the dual benefits of UV stabilizers: prolonging product life and enhancing performance, which are critical factors in gaining a competitive edge in technologically advanced markets.

Trending Factors

Integration with IoT and Smart Materials Are Trending Factors

The integration of UV stabilizers with IoT and smart materials is significantly enhancing market potential. These advanced materials can monitor UV exposure and degradation in real-time. A prime example is the development of UV-stabilized outdoor awnings by a smart fabric company. These awnings change color when UV protection is compromised, alerting users to the need for replacement or additional protection.

This innovative feature has led to a 40% increase in sales to commercial clients, such as restaurants and hotels. The ability of smart materials to proactively signal UV damage is driving demand and expanding market reach. As more industries adopt IoT-enabled solutions, the use of UV stabilizers in smart materials is expected to grow, providing substantial opportunities for market expansion.

Customized UV Stabilizers for Niche Markets Are Trending Factors

Customized UV stabilizers designed for niche markets are driving growth in the UV stabilizers market. A notable instance is the creation of a specialized UV stabilizer for automotive headlamp lenses by a specialty chemical company. This stabilizer extends the clarity of the lenses by 50% longer than standard options.

As a result, the product now commands 70% of the automotive headlamp UV stabilizer market. The trend towards customization addresses specific industry needs, enhancing product performance and market appeal. This tailored approach is attracting more clients from niche markets, fostering market expansion. The success in the automotive sector indicates a promising future for customized UV stabilizers in other specialized applications.

Regional Analysis

Asia Pacific Dominates with 38.5% Market Share in the UV Stabilizers Market

Asia Pacific’s leading position in the UV stabilizers market can be attributed to several key factors. The region’s robust manufacturing sector, particularly in electronics and automotive industries, drives substantial demand for UV stabilizers. Additionally, the high exposure to solar radiation in many APAC countries necessitates increased use of UV stabilization solutions in both industrial and consumer applications. Rapid industrialization across the region, coupled with growing awareness about the benefits of UV stabilization in product longevity, further propels this dominance.

The market dynamics in Asia Pacific are influenced by a combination of technological advancements, economic growth, and regulatory policies supporting sustainable materials. The region’s commitment to expanding manufacturing capacities and enhancing material quality standards enhances the adoption of advanced UV stabilizers. Furthermore, the strategic initiatives by leading market players to invest in R&D and expand their operational facilities in the region fortify its market position.

Regional Market Share and Growth:

- North America: The region holds a market share of approximately 24%. North America benefits from advanced material science technologies and stringent regulatory standards, which enhance the adoption of high-quality UV stabilizers.

- Europe: Europe accounts for about 21% of the market. This share is supported by the region’s strong automotive and furniture sectors, which demand enhanced UV protection technologies to comply with strict environmental and safety standards.

- Asia Pacific: As noted, Asia Pacific dominates with a 38.5% share, driven by extensive manufacturing output and climatic conditions.

- Middle East & Africa: This region captures around 10% of the global market. Growth is spurred by increasing infrastructure projects and the need for materials capable of withstanding harsh environmental conditions.

- Latin America: Holding a smaller share of around 6.5%, Latin America’s market is expanding with improvements in industrial sectors and rising consumer awareness about product quality and durability.

Key Regions and Countries

- North America

- The US

- Canada

- Mexico

- Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

In the UV Stabilizers Market, major companies demonstrate significant influence. BASF SE, Clariant AG, and Solvay S.A. are leading players. Their extensive product lines and strong R&D capabilities set them apart. Songwon Industrial Co., Ltd. and Adeka Corporation also hold notable positions due to their technological advancements.

Evonik Industries AG and Altana AG have a solid market presence through innovative solutions. Cytec Solvay Group and Mayzo, Inc. focus on niche applications, enhancing their strategic positioning. Lycus Ltd. and Akcros Chemicals Ltd. offer competitive products, boosting their market influence.

Everlight Chemical Industrial Corporation and Addivant emphasize sustainability, aligning with market trends. Valtris Specialty Chemicals and Chemtura Corporation have a diverse product portfolio, strengthening their impact.

These companies drive market growth by investing in technology and expanding their product ranges. Their strategic initiatives and strong market positioning enhance their influence in the UV Stabilizers Market

Market Key Players

- BASF SE

- Clariant AG

- Solvay S.A.

- Songwon Industrial Co., Ltd.

- Adeka Corporation

- Evonik Industries AG

- Altana AG

- Cytec Solvay Group

- Mayzo, Inc.

- Lycus Ltd.

- Akcros Chemicals Ltd.

- Everlight Chemical Industrial Corporation

- Addivant

- Valtris Specialty Chemicals

- Chemtura Corporation

Recent Developments

- October 2023: Everlight Chemical has introduced the “Eversorb® Anti-UV-C Light Stabilizer” to effectively improve the weatherability of polypropylene products to UV-C while protecting their appearance, functionality, and durability.

- July 2022: Solvay has developed industry-first specialized UV-C stabilizers to protect polyolefin materials from degradation caused by UV-C radiation, enabling the safe and long-lasting use of UV-C disinfection technologies.

Report Scope

Report Features Description Market Value (2023) USD 1.4 Billion Forecast Revenue (2033) USD 2.4 Billion CAGR (2024-2033) 5.6% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Hindered Amine Light Stabilizers (HALS), UV Absorbers, Quenchers, Others), By Application (Packaging, Building & Construction, Automotive, Adhesives & Sealants, Others) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape BASF SE, Clariant AG, Solvay S.A., Songwon Industrial Co., Ltd., Adeka Corporation, Evonik Industries AG, Altana AG, Cytec Solvay Group, Mayzo, Inc., Lycus Ltd., Akcros Chemicals Ltd., Everlight Chemical Industrial Corporation, Addivant, Valtris Specialty Chemicals, Chemtura Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is the expected market size of the Global UV Stabilizers Market by 2033?The Global UV Stabilizers Market size is expected to reach USD 2.4 billion by 2033. The market is projected to grow at a CAGR of 5.6% during this period.

Which type of UV stabilizer holds the largest market share?Hindered Amine Light Stabilizers (HALS) dominate with a 53.6% market share due to their superior performance in preventing polymer degradation.

Which region holds the largest share of the UV Stabilizers Market?The Asia Pacific region holds the largest share at 38.5%, due to robust industrial growth and high consumption of UV stabilizers.

How does the market view the competition among major players?The market shows moderate saturation with competition among major players, driven by innovations in packaging and construction sectors.

-

-

- BASF SE

- Clariant AG

- Solvay S.A.

- Songwon Industrial Co., Ltd.

- Adeka Corporation

- Evonik Industries AG

- Altana AG

- Cytec Solvay Group

- Mayzo, Inc.

- Lycus Ltd.

- Akcros Chemicals Ltd.

- Everlight Chemical Industrial Corporation

- Addivant

- Valtris Specialty Chemicals

- Chemtura Corporation