Global Polyether Ether Ketone Market Size, Share, and Business Benefits By Product (Unfilled, Carbon-filled, Glass-filled), By Application (Automotive, Medical, Aerospace, Industrial and General Engineering, Electric and Electronic, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: November 2025

- Report ID: 165135

- Number of Pages: 253

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

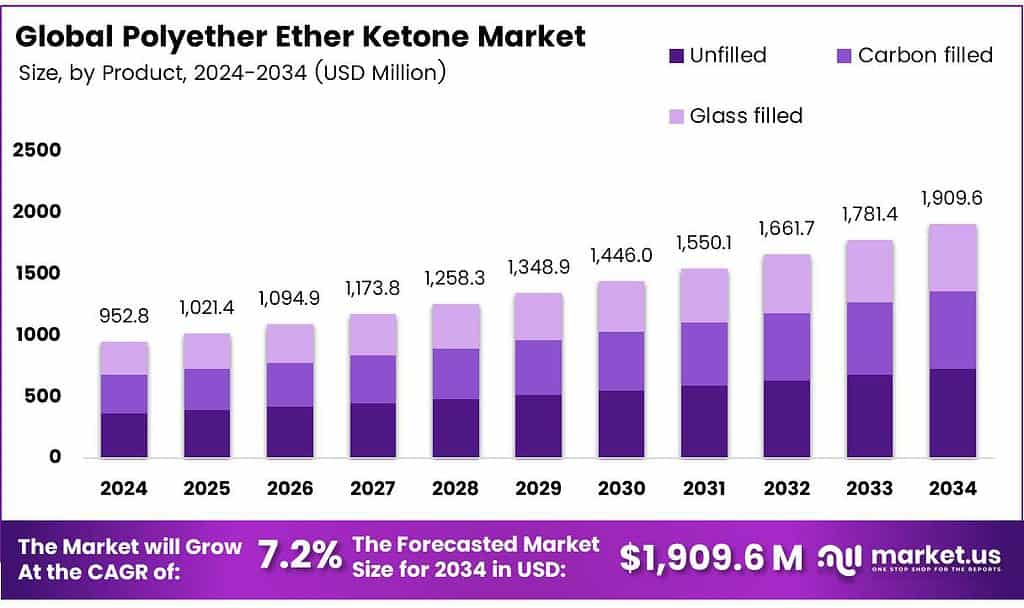

The Global Polyether Ether Ketone Market size is expected to be worth around USD 1909.6 Million by 2034, from USD 952.8 Million in 2024, growing at a CAGR of 7.2% during the forecast period from 2025 to 2034.

Polyether ether ketone (PEEK) is a high-performance thermoplastic polymer known for its exceptional thermal resistance, superior mechanical properties, and outstanding chemical stability. It is produced through the polycondensation reaction of 4,4-fluorobenzophenone and hydroquinone. Commonly used in medical, electronics, telecommunications, and aircraft applications, PEEK stands out for its reliability in demanding environments.

PEEK is a semicrystalline, linear, and aliphatic polymer synthesized via step-growth polymerization through the dialkylation of bisphenolate salts. Its structure features a stiff aromatic backbone, as illustrated, which contributes to high thermal transitions and a continuous use temperature of around 240°C. This rigid structure also enables up to 48% maximum crystallinity, enhancing its mechanical strength and chemical resistance comparable to fluoropolymers.

- The physical properties of PEEK include a density of 1.32 g/cm³ and water absorption of 0.5% over 24 hours. Mechanically, it exhibits tensile strength of 14,000 psi, tensile modulus of 490,000 psi, and elongation at break of 60%. Its flexural strength reaches 24,600 psi, with a flexural modulus of 590,000 psi and notched IZOD impact strength of 1.6 ft-lb/in. Thermally, PEEK offers a coefficient of linear thermal expansion of 2.6 × 10⁻⁵ in./in./°F, heat deflection temperature of 306°F at 264 psi, melting point of 649°F, and maximum operating temperature of 338°F.

In biomedical engineering, PEEK is widely utilized due to its high melting point of 334°C and excellent wear resistance. Its mechanical properties closely match natural bone, with tensile strength up to 100 MPa, elongation of 50%–150%, and Young’s modulus of about 3.7 GPa. PEEK’s biocompatibility, confirmed by in-vitro and in-vivo studies showing minimal inflammatory response, along with MRI compatibility and radiolucency, makes it ideal for load-bearing orthopedic devices such as spinal fusion cages, knee joints, and craniofacial implants.

PEEK is typically synthesized through nucleophilic substitution of 4,4′-difluorobenzophenone with hydroquinone in the presence of anhydrous carbonate salt in a polar aprotic solvent like diphenyl sulfone. While many companies employ proprietary methods to tailor material properties, the core aromatic backbone consistently delivers superior temperature and wear resistance, making PEEK a preferred choice across high-performance applications.

Key Takeaways

- The Global Polyether Ether Ketone Market is projected to grow from USD 952.8 million in 2024 to USD 1909.6 million by 2034 at a 7.2% CAGR (2025-2034).

- Unfilled PEEK dominated product segment in 2024 with 38.3% share, favored for purity, chemical resistance, thermal stability, and suitability for injection molding/extrusion.

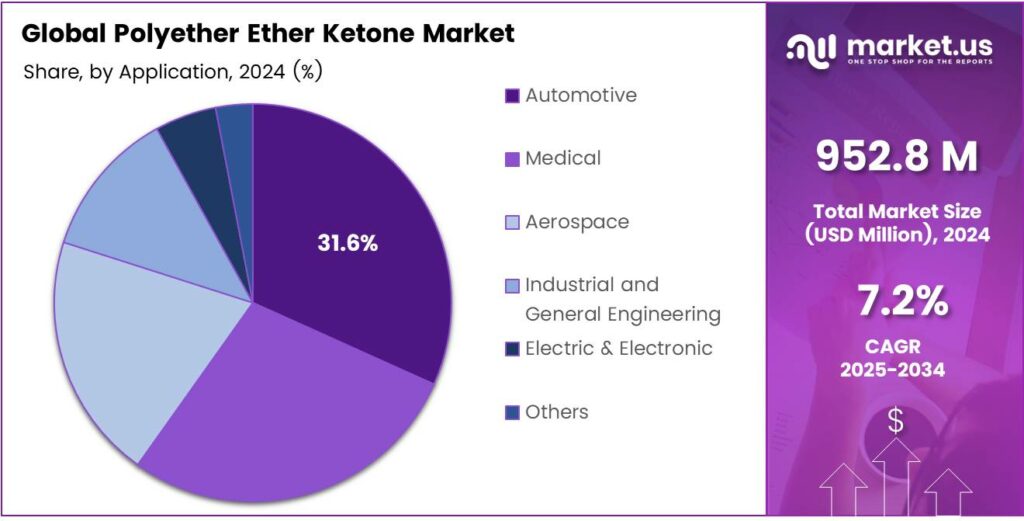

- Automotive led application segment in 2024 with 31.6% share, utilizing PEEK’s high strength-to-weight ratio for engine parts/seals to cut vehicle mass and improve fuel efficiency/emissions compliance.

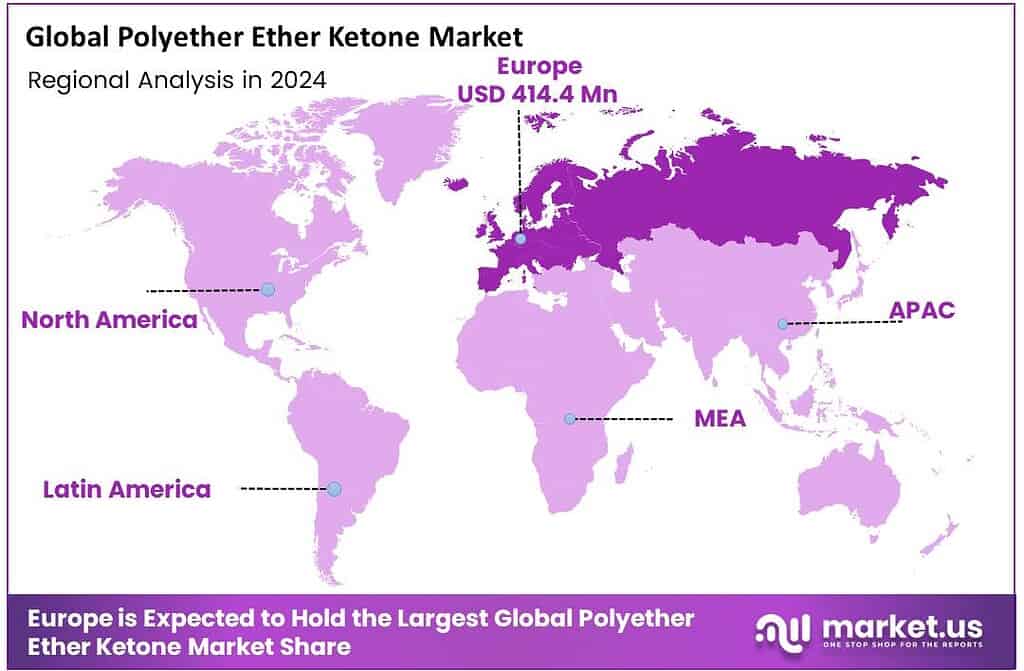

- Europe commanded 43.5% of global PEEK revenues in 2024, USD 414.4 million, driven by advanced manufacturing, robust aerospace/automotive supply chains, and demand for high-performance thermoplastics.

By Product Analysis

Unfilled dominates with 38.3% due to its versatility and broad applicability.

In 2024, Unfilled held a dominant market position in the By Product Analysis segment of the Polyether Ether Ketone Market, with a 38.3% share. This variant excels in purity, offering excellent chemical resistance and thermal stability. Manufacturers prefer it for injection molding and extrusion processes. Consequently, it supports diverse components in electronics and industrial settings.

Its ease of processing drives widespread adoption, ensuring consistent performance under demanding conditions. Transitioning smoothly, Carbon-filled captures significant attention next. It enhances strength and stiffness, making it ideal for high-load applications. Engineers select this grade to replace metals in aerospace parts.

Similarly, glass-filled contributes valuably through improved rigidity. This sub-segment reinforces mechanical properties for structural uses. It resists wear effectively in automotive gears and valves. Therefore, it extends the component lifespan under friction. Glass-filled also maintains dimensional stability at elevated temperatures.

By Application Analysis

Automotive dominates with 31.6% due to rising demand for lightweight components.

In 2024, Automotive held a dominant market position in the By Application Analysis segment of the Polyether Ether Ketone Market, with a 31.6% share. This sector leverages PEEK’s high strength-to-weight ratio for engine parts and seals. It reduces vehicle mass, enhancing fuel efficiency. Automakers integrate it to meet emission standards.

Thus, Automotive accelerates the shift toward sustainable mobility solutions. Moreover, Medical emerges as a vital growth area. PEEK’s biocompatibility suits implants and surgical tools. It withstands sterilization without degrading. Surgeons rely on its radiolucency for precise imaging.

Consequently, Medical advances patient outcomes through durable, safe devices. Additionally, Aerospace utilizes PEEK for lightweight brackets and insulators. This application demands extreme heat resistance and low flammability. It cuts aircraft weight, improving fuel economy. Therefore, Aerospace fosters cutting-edge designs for safer flights.

Key Market Segments

By Product

- Unfilled

- Carbon filled

- Glass filled

By Application

- Automotive

- Medical

- Aerospace

- Industrial and General Engineering

- Electric and Electronic

- Others

Emerging Trends

3D Printing, Composites, and Green Mobility Shape Market Trends

Additive manufacturing is revolutionizing PEEK usage. 3D-printed PEEK implants are gaining momentum in medical fields, offering lightweight and customizable solutions. These innovations are enabling surgeons to produce on-demand, biocompatible parts tailored to individual patient anatomy.

- Composite integration is another key trend. The International Council on Clean Transportation found that a 10% vehicle weight reduction reduces fuel use by 6–7%. PEEK-carbon fiber composites support automakers in meeting decarbonization targets while maintaining performance.

Finally, green mobility and electrification trends strengthen its role in EV battery modules and hydrogen fuel cell systems. This transition toward sustainable transportation and precision engineering cements PEEK as a strategic material for future industries.

Drivers

Lightweighting and Medical Innovation Drive PEEK Demand

The shift toward lightweight materials in transportation fuels demands PEEK. According to the U.S. Department of Energy, a 10% reduction in vehicle weight can improve fuel economy by 6–8%. Its high strength-to-weight ratio makes it ideal for replacing metals in automotive and aerospace parts. In the medical sector, PEEK’s biocompatibility supports implant applications.

- The OECD reports hip replacement rates averaging 172 per 100,000 people globally. This rising demand for orthopedic implants fuels greater adoption of PEEK-based medical components. Overall, regulatory pushes for cleaner vehicles, expanding aerospace manufacturing, and advanced healthcare needs continue to position PEEK as a preferred high-performance polymer for the next generation of durable, efficient materials.

Restraints

High Processing Costs and Supply Constraints Limit Wider Use

PEEK production remains cost-intensive, often 10–20 times higher than commodity plastics due to high polymerization temperatures above 340°C. These processing challenges raise end-product costs, discouraging small-scale manufacturers from adopting. Energy-intensive operations also limit its sustainability in large-volume manufacturing.

Limited availability of key monomers like hydroquinone and difluorobenzophenone restricts global supply. Such feedstock constraints have led to production volatility and longer lead times in Asia and Europe, where sourcing depends heavily on a few chemical producers.

- Although lightweighting offers energy savings, transitioning manufacturing lines to high-temperature thermoplastics requires specialized tooling. The International Energy Agency notes that global hydrogen electrolyser capacity reached 1.4 GW in 2023, potentially 5 GW by 2024. However, adapting to such advanced materials in clean-energy equipment remains expensive.

Opportunity

Expanding Aerospace and Hydrogen Sectors Unlock New Opportunities

- The aerospace industry’s drive for energy-efficient materials continues to expand PEEK applications. Airbus delivered 766 aircraft in 2024, reflecting a strong post-pandemic rebound. PEEK composites reduce aircraft weight and maintenance, helping meet EU targets of zero CO₂ emissions for new cars and vans.

In the energy sector, hydrogen systems and fuel cells require thermally stable seals and manifolds. The IEA projects global installed electrolyser capacity could reach 5 GW by 2024, with China leading deployments. This creates opportunities for PEEK components resistant to high pressure and hydrogen embrittlement. Medical manufacturing is another expanding frontier.

PEEK polymers in surgical implants support custom 3D-printed devices. This enables patient-specific implants that improve recovery and durability, particularly in orthopedics. PEEK’s adoption in semiconductor fabrication, aerospace composites, and hydrogen applications highlights a multi-sector growth path powered by technological innovation and sustainability imperatives.

Regional Analysis

Europe leads with a 43.5% share and a USD 414.4 Million market value.

In Europe, the PEEK market is firmly established and continues to lead as the dominating region, accounting for 43.5 % of global revenues, equivalent to approximately USD 414.4 million. The region’s dominance is underpinned by its advanced manufacturing infrastructure, strong aerospace and automotive supply chains, and a high level of end-use engineering applications requiring high-performance thermoplastics.

Major economies such as Germany, the UK, and Belgium are key hubs, benefitting from demand for lightweight, high-temperature, and chemically resistant components in sectors ranging from mobility and industrial equipment to medical implants. Europe’s mature aerospace and automotive industries drive the use of PEEK for structural components, bearings, gears, and high-end electrical insulators.

The region’s strong focus on sustainable materials and lightweighting aligns with PEEK’s value proposition—this provides favourable tailwinds. Although growth rates may not match emerging regions, the stable base volume, high-value application mix, and concentration of high-spec industrial users make Europe a profitable and strategic market for PEEK producers.

Going forward, opportunities remain in electrified mobility, additive manufacturing of PEEK parts, and medical device growth across the region. However, suppliers must navigate cost pressures, regulatory compliance, and competition from alternative materials. Nonetheless, Europe’s role as a major PEEK market is clear: commanding nearly half of global value today and setting the stage for future high-end application growth.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

VICTREX PEEK product portfolio and a strong focus on research and development. Its strategy emphasizes deep technical collaboration with clients across aerospace, automotive, and medical sectors to develop application-specific solutions. This vertical integration, from polymer manufacturing to finished part support, solidifies its market position and allows it to command a premium, leveraging its unparalleled expertise and intellectual property.

Caledonian Industries is a key European distributor and compounder of engineering plastics, including PEEK. The company’s strength lies in its robust distribution network and value-added services, such as custom compounding and technical support. By tailoring PEEK grades with specific additives—like carbon fibers or PTFE—for enhanced properties, they serve diverse industrial needs. Their role is crucial in the supply chain.

Celanese is a major force in the PEEK market through its engineered materials division and the well-known Zeniva PEEK product line. The company leverages its vast global manufacturing footprint and broad customer base to drive growth. Its strategy focuses on innovation for demanding applications in healthcare, electronics, and transportation. By offering a wide range of high-performance materials.

Top Key Players in the Market

- Victrex plc

- Caledonian Industries Ltd.

- Celanese Corporation

- Saudi Basic Industries Corporation (SABIC)

- LyondellBasell Industries Holdings B.V.

- J.K. Overseas

- Cytec Solvay Group

- Evonik Industries AG

- Ensinger GmbH

- Others

Recent Developments

- In 2025, Victrex achieved higher volumes but lower profits due to medical and FX headwinds. Key highlights include a new ERP system launch for digital enhancements and progress in the ‘Magma’ mega programme, a PEEK-based composite pipe for energy with a Technique FMC contract award from Petrobras.

- In 2025, Continued production of Caltrex PEEK tubes and seals using DCMS, emphasizing reduced stresses, no annealing needs, and applications in oil/gas downhole tools. CNC machining supports custom seals in PEEK/PTFE for high-temperature, low-friction uses.

Report Scope

Report Features Description Market Value (2024) USD 952.8 Million Forecast Revenue (2034) USD 1909.6 Million CAGR (2025-2034) 7.2% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product (Unfilled, Carbon-filled, Glass-filled), By Application (Automotive, Medical, Aerospace, Industrial and General Engineering, Electric and Electronic, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – GCC, South Africa, Rest of MEA Competitive Landscape Victrex plc, Caledonian Industries Ltd., Celanese Corporation, Saudi Basic Industries Corporation (SABIC), LyondellBasell Industries Holdings B.V., J.K. Overseas, Cytec Solvay Group, Evonik Industries AG, Ensinger GmbH, Others Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited Users and Printable PDF)  Polyether Ether Ketone MarketPublished date: November 2025add_shopping_cartBuy Now get_appDownload Sample

Polyether Ether Ketone MarketPublished date: November 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Victrex plc

- Caledonian Industries Ltd.

- Celanese Corporation

- Saudi Basic Industries Corporation (SABIC)

- LyondellBasell Industries Holdings B.V.

- J.K. Overseas

- Cytec Solvay Group

- Evonik Industries AG

- Ensinger GmbH

- Others