Global Linear Bearings Market By Type (Standard Linear Bearing, Superball Bearing, Flanged Linear Bearing, Stainless Linear Bearing, Ceramic Linear Bearing, Others), By Application (Automotive, Agriculture, Machinery and Equipment, Medical, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: Nov 2024

- Report ID: 27573

- Number of Pages: 363

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

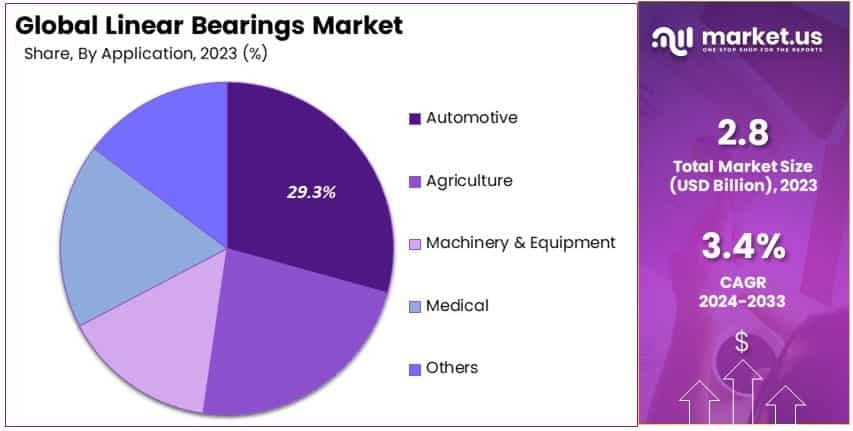

The Global Linear Bearings Market size is expected to be worth around USD 3.9 Billion by 2033, from USD 2.8 Billion in 2023, growing at a CAGR of 3.4% during the forecast period from 2024 to 2033.

Linear bearings are mechanical components that support and guide motion along a straight path. They reduce friction between moving parts, ensuring smooth, precise movement. Commonly used in industries like manufacturing, automation, and robotics, linear bearings improve accuracy and efficiency in systems requiring linear motion.

The linear bearings market involves the production and supply of bearings for industries needing precise motion control. This market supports sectors like robotics, automotive, and packaging by offering reliable, low-friction components. As industries advance in automation, demand for linear bearings rises due to their role in enhancing performance and reducing operational costs.

Global demand for automation drives linear bearings market growth, as noted by the International Federation of Robotics (IFR). By 2023, about 4 million industrial robots were operational worldwide, a 10% increase from the previous year. China, with 1.8 million robots, leads in demand, accounting for 51% of installations. This trend signals robust demand for linear bearings, which support precise industrial robotic functions across industries.

In the United States, the presence of 381,964 industrial robots marks a 12% rise, with 37,587 new installations in 2023. This aligns with increased use of collaborative robots, or cobots, which work alongside humans for enhanced productivity. Linear bearings are essential to these robots, allowing smooth, precise operations that drive efficiency on manufacturing floors.

To support this, global investment in energy-efficient and advanced automation technologies is also expanding. According to the International Energy Agency (IEA), over USD 400 billion was allocated to energy-efficient technologies in 2024. This investment strengthens the linear bearings market, as automation technologies increasingly require reliable, friction-reducing components to enhance operational efficiency.

Key Takeaways

- The Linear Bearings Market was valued at USD 2.8 billion in 2023 and is expected to reach USD 3.9 billion by 2033, with a CAGR of 3.4%.

- In 2023, Standard Linear Bearings led the type segment with 31.4%, used widely for their simplicity and cost-effectiveness.

- In 2023, Automotive was the dominant application with 29.3%, driven by the growing demand for precision components in vehicles.

- In 2023, North America held 36.7% of the market, driven by technological advancements in automotive and machinery sectors.

Type Analysis

Standard Linear Bearing dominates with 31.4% due to its widespread adoption across various industries for its cost-effectiveness and high efficiency.

Standard Linear Bearings hold the largest market share, accounting for 31.4% of the segment. The dominance of this sub-segment can be attributed to its versatility and cost-effectiveness, making it a preferred choice across multiple industries including automotive, manufacturing, and industrial machinery.

These bearings provide low friction, which helps in achieving higher precision and efficiency in various mechanical applications. The growth of this sub-segment is further supported by advancements in material science and manufacturing processes, which improve the performance and durability of these bearings.

Superball Bearings are designed for applications requiring smooth and precise motion at high speeds. They typically find use in sectors like aerospace, where performance and reliability are critical. Although they command a smaller share of the market, the demand for Superball Bearings is expected to grow as industries seek higher performance solutions.

Flanged Linear Bearings incorporate flanges at one or both ends, facilitating axial positioning and mounting. This design is particularly useful in automated machinery and robotics. Their role in the growth of the linear bearings market is linked to the increasing automation in manufacturing processes.

Stainless Linear Bearings are favored for their corrosion resistance and are predominantly used in medical and food processing industries where hygiene and cleanliness are paramount. These bearings are crucial for applications that are exposed to corrosive environments, supporting market growth through their specialized applications.

Ceramic Linear Bearings are preferred for high-speed applications that require low inertia. The ceramics provide excellent wear resistance and operate at higher speeds without significant heating. Their adoption is increasing in the semiconductor and medical sectors, driving their market share.

Application Analysis

Automotive dominates with 29.3% due to the critical role of linear bearings in vehicle performance and manufacturing automation.

The Automotive sector is the largest application area for linear bearings, holding 29.3% of the market. This dominance is driven by the extensive use of these bearings in vehicle assembly lines and in the components of the vehicles themselves, such as steering systems and suspension units. The automotive industry’s push towards automation and increased manufacturing precision has significantly contributed to the growth of this segment.

In Agriculture, linear bearings are used in various machinery and equipment, including tractors and combined harvesters. The durability and efficiency of linear bearings under harsh conditions make them ideal for agricultural applications, supporting productivity in farming operations.

This segment covers a broad range of industrial applications. Linear bearings are crucial in the smooth operation of various types of machinery, enhancing precision and reducing mechanical wear, which is essential for maintaining the longevity and efficiency of industrial equipment.

The Medical segment uses linear bearings in numerous applications, from medical scanning equipment to advanced robotic surgical devices. The demand for high precision and reliability in medical equipment drives the adoption of high-quality linear bearings.

Key Market Segments

By Type

- Standard Linear Bearing

- Superball Bearing

- Flanged Linear Bearing

- Stainless Linear Bearing

- Ceramic Linear Bearing

- Others

By Application

- Automotive

- Agriculture

- Machinery & Equipment

- Medical

- Others

Drivers

Automation and Robotics Demand Drive Market Growth

The Linear Bearings Market is primarily driven by the increasing demand for automation in manufacturing industries. As factories and industrial facilities adopt automated processes to improve productivity and efficiency, the need for reliable linear motion systems, including linear bearings, is growing. These bearings are critical in ensuring smooth, precise motion in automated machinery.

Furthermore, growth in the automotive industry is contributing to the market’s expansion. Automotive manufacturers rely heavily on linear bearings in various applications, from assembly lines to robotics used in vehicle manufacturing. The rising demand for electric vehicles is also boosting this trend as electric vehicle manufacturers require high-precision components to enhance production processes.

Rising investments in industrial machinery are another key driver. Industries across the globe are upgrading their equipment to meet the demands of modern production environments, which is increasing the need for high-quality linear bearings. Additionally, advancements in robotics and material handling systems are pushing the market forward.

Restraints

High Costs and Cheaper Alternatives Restraint Market Growth

The Linear Bearings Market faces several restraining factors, with high initial costs being a major challenge. Advanced bearings, particularly those designed for specialized applications, come with significant costs that can deter smaller manufacturers from investing. This creates a barrier to adoption, especially in cost-sensitive industries.

The availability of cheaper alternatives is another restraint. In some cases, industries opt for less expensive options, such as bushings or conventional ball bearings, which offer lower performance but are more affordable. This price-sensitive approach can limit the market’s growth, particularly in regions where cost-cutting is a priority.

Additionally, fluctuations in raw material prices add uncertainty to the market. The costs of materials such as steel and other alloys used in the production of linear bearings can vary, affecting the overall pricing structure and profitability of manufacturers. Finally, technical challenges in extreme environments, such as high temperatures or corrosive conditions, can limit the application of certain types of linear bearings, hindering broader market adoption.

Opportunity

Emerging Markets and Electric Vehicles Provide Opportunities

The Linear Bearings Market presents numerous growth opportunities, especially in emerging markets. Rapid industrialization in regions such as Asia-Pacific and Latin America is driving demand for high-performance industrial components, including linear bearings. As manufacturing facilities expand in these regions, the need for efficient, durable bearings is expected to grow.

Additionally, the increasing demand for precision engineering and high-performance applications opens opportunities for market expansion. Industries such as aerospace, medical devices, and electronics require precise linear motion systems, creating demand for advanced linear bearings that can meet stringent performance requirements.

The development of lightweight and corrosion-resistant bearings is another promising opportunity. With the increasing emphasis on material science, manufacturers are developing new bearing designs that offer both durability and lightweight characteristics, making them suitable for high-performance applications. Lastly, the rising adoption of electric vehicles is creating a demand for linear bearings in battery assembly lines, drive systems, and other critical components.

Challenges

Technical Complexity and Maintenance Challenges Market Growth

Several challenges could hinder the growth of the Linear Bearings Market. One of the primary challenges is the technological complexity in high-load applications. As industries demand more robust systems that can handle greater loads, designing bearings that meet these requirements becomes more complex and expensive.

Maintenance requirements for continuous operations also present a challenge. Linear bearings, particularly those used in demanding industrial environments, require regular maintenance to ensure optimal performance. This can lead to increased operational costs and downtime, which some industries are keen to avoid.

Limited awareness of the benefits of linear bearings in small-scale industries further challenges market growth. In many smaller operations, traditional bearing solutions are still preferred due to their lower cost and ease of use, despite the advantages that linear bearings can provide in terms of precision and efficiency.

Supply chain disruptions, particularly in the wake of global events such as the COVID-19 pandemic, have impacted the availability of components, including linear bearings. Manufacturers facing delays in the supply chain struggle to meet production schedules, posing additional hurdles for market expansion.

Growth Factors

Industrial Automation and Precision Applications Are Growth Factors

The Linear Bearings Market is experiencing significant growth due to the rapid rise in industrial automation across various sectors. As companies automate their manufacturing processes, the demand for precise, reliable motion control systems, such as linear bearings, is expanding.

Growing applications in precision tools and equipment are another factor driving market growth. Industries such as medical devices, aerospace, and electronics require highly accurate components, and linear bearings offer the precision needed for these advanced applications.

The increasing demand for enhanced efficiency in manufacturing processes is also fueling the market. As manufacturers seek ways to improve productivity and reduce costs, they are turning to linear bearings to optimize machine performance and reduce friction in moving parts.

Lastly, the growing focus on reducing downtime and improving productivity is propelling the market forward. Linear bearings are designed to offer long-lasting performance, which helps industries maintain continuous operations without frequent maintenance interruptions, making them a preferred choice in many industrial applications.

Emerging Trends

Smart Bearings and Additive Manufacturing Are Latest Trending Factor

The integration of smart bearings with IoT sensors is a key trend driving the Linear Bearings Market. These smart bearings can monitor performance in real-time, enabling predictive maintenance and reducing the risk of machinery breakdowns. This innovation is gaining traction in industries focused on minimizing downtime.

Another major trend is the increased focus on energy-efficient solutions. As industries aim to reduce energy consumption, linear bearings that offer low friction and smoother movement are becoming more popular. This trend aligns with the broader push for sustainability in manufacturing.

The growth of additive manufacturing, or 3D printing, is also impacting the linear bearings market. Custom bearing designs made possible by additive manufacturing enable industries to create specialized bearings tailored to unique operational requirements, increasing the demand for these products.

Lastly, there is a rising adoption of eco-friendly and sustainable materials in bearing production. Manufacturers are looking for ways to reduce the environmental impact of their products by using recyclable or less harmful materials, aligning with the global push toward greener manufacturing practices.

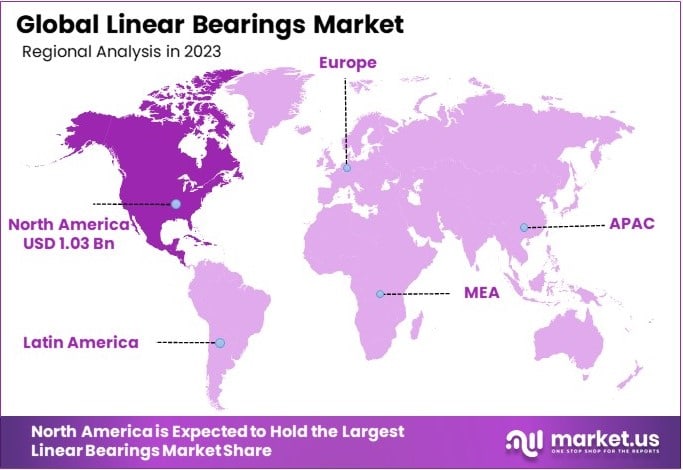

Regional Analysis

North America Dominates with 36.7% Market Share

North America leads the Linear Bearings Market with a 36.7% share, valued at USD 1.03 billion. This dominance is driven by the region’s strong manufacturing base, technological advancements, and increasing demand for automation in industries like automotive, aerospace, and healthcare. North America’s robust infrastructure and focus on industrial efficiency further enhance its leadership in this market.

The region benefits from a high level of innovation, with a strong presence of key market players investing in advanced technologies. The growing trend toward automation in manufacturing and industrial sectors accelerates the adoption of linear bearings. Additionally, North America’s focus on precision engineering, particularly in high-tech industries, further supports the demand for reliable, efficient bearing solutions.

Regional Mentions:

- Europe: Europe maintains a strong presence in the Linear Bearings Market, driven by demand in automotive, machinery, and renewable energy sectors. The region emphasizes energy efficiency and precision engineering, which supports the use of linear bearings.

- Asia Pacific: Asia Pacific is rapidly expanding in the linear bearings market, fueled by strong industrial growth in China, Japan, and South Korea. The region’s focus on manufacturing and technological advancement drives market demand.

- Middle East & Africa: The Middle East & Africa region is showing growing interest in linear bearings, particularly in oil and gas, and infrastructure development sectors. Investments in industrial expansion support the market.

- Latin America: Latin America is steadily growing in the linear bearings market, with demand driven by the automotive and manufacturing sectors. Increased industrialization and infrastructure development are contributing to market growth.

Key Regions and Countries covered іn thе rероrt

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

The Linear Bearings Market is highly competitive, with major companies like Schaeffler Technologies, SKF, and THK Co. Ltd. leading the industry. These key players provide high-precision bearings for industries such as automotive, manufacturing, and electronics, where smooth and accurate motion control is essential.

Their product offerings include various types of linear bearings, such as ball bushings, roller bearings, and linear guides. Companies like Nippon Bearing and NTN Bearing focus on high-performance bearings that cater to specific industrial applications, ensuring optimal load-carrying capacity and durability.

In terms of market strategies, these players invest heavily in R&D to develop innovative bearing technologies and expand their product range. They also strengthen partnerships with manufacturers to deliver customized solutions. Pricing strategies are competitive, offering both premium and cost-efficient products to meet diverse industrial needs.

Geographically, these companies have a strong presence in North America, Europe, and Asia-Pacific, with increasing demand in emerging markets. Global distribution networks enable them to meet the needs of industrial clients worldwide.

Innovation is a key focus, with companies continuously working on improving the precision, durability, and efficiency of their bearings through advanced materials and technology integration.

The competitive edge of these companies lies in their ability to deliver reliable, high-performance bearings and offer tailored solutions, ensuring a leading position in the global Linear Bearings Market.

Top Key Players in the Market

- Schaeffler Technologies

- SKF

- Nippon Bearing

- Norgren Inc

- JTEKT Corporation

- NTN Bearing

- NBB-Bearing

- The Timken Company

- NBI Bearings Europe

- MPS Microsystem

- Ningbo Yinzhou Weixing Bearing

- Samick

- THK Co. Ltd.

Recent Developments

- PI Americas: In October 2024, PI Americas released new precision motion stages manufactured in Hopkinton, Massachusetts, USA. These stages are equipped with non-contact, direct-drive linear motors and integrated encoders, designed for precise positioning in sectors such as semiconductor, photonics, and life sciences, optimizing automation in imaging, alignment, and metrology.

- Güdel: In October 2024, at the FabTech expo, Güdel showcased its new linear motion technology for robots. This includes advanced cam follower systems that offer improved resilience in harsh environments and a simplified maintenance process, along with a no-weld anchoring solution for installations in thin concrete, promoting flexibility and cost-efficiency in robot deployment.

Report Scope

Report Features Description Market Value (2023) USD 2.8 Billion Forecast Revenue (2033) USD 3.9 Billion CAGR (2024-2033) 3.4% Base Year for Estimation 2023 Historic Period 2019-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Standard Linear Bearing, Superball Bearing, Flanged Linear Bearing, Stainless Linear Bearing, Ceramic Linear Bearing, Others), By Application (Automotive, Agriculture, Machinery and Equipment, Medical, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Schaeffler Technologies, SKF, Nippon Bearing, Norgren Inc., JTEKT Corporation, NTN Bearing, NBB-Bearing, The Timken Company, NBI Bearings Europe, MPS Microsystem, Ningbo Yinzhou Weixing Bearing, Samick, THK Co. Ltd. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- Schaeffler Technologies

- SKF

- Nippon Bearing

- Norgren Inc

- JTEKT Corporation

- NTN Bearing

- NBB-Bearing

- The Timken Company

- NBI Bearings Europe

- MPS Microsystem

- Ningbo Yinzhou Weixing Bearing

- Samick

- THK Co. Ltd.