Global Industry 4.0 Market By Technology (Industrial IoT, 3D Printing, Block Chain, Industrial Robotics, and Other Technologies), By Industrial Verticals (Manufacturing, Automotive, Energy & Utilities, Oil & Gas, Aerospace and Defense, and Other Industrial Verticals), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2023-2032

- Published date: Dec 2024

- Report ID: 100153

- Number of Pages: 332

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

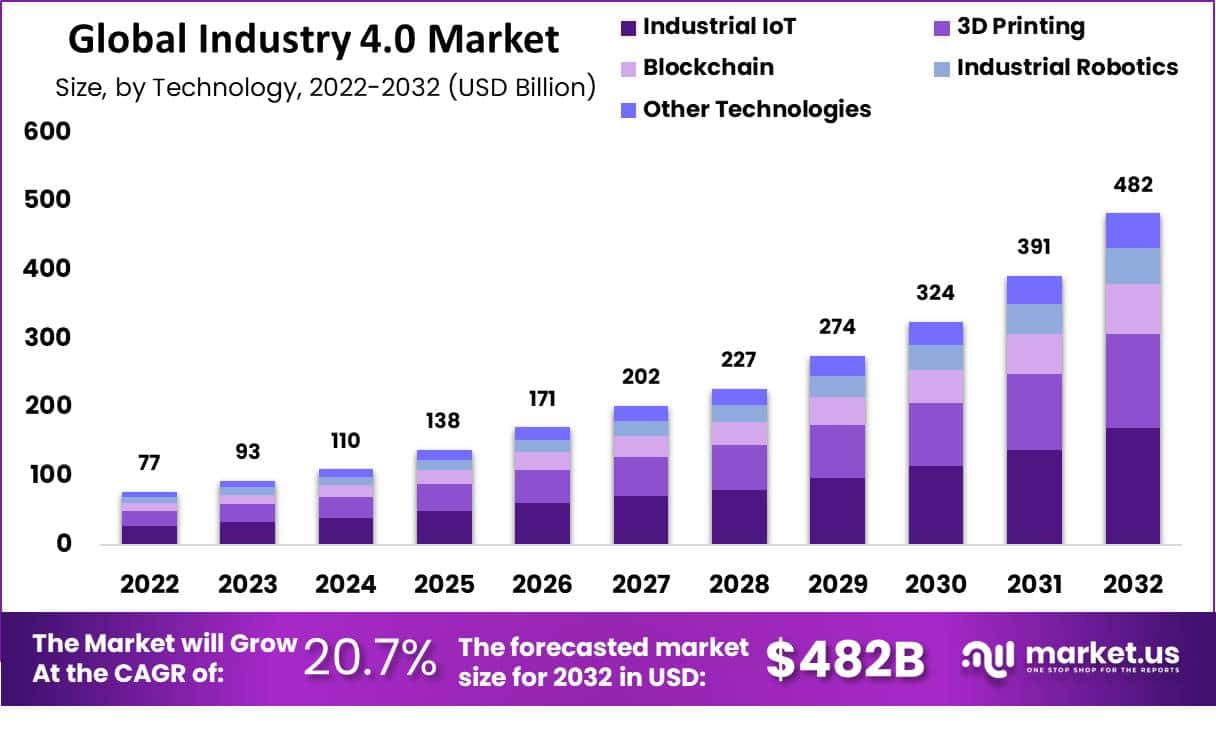

The Global Industry 4.0 market size is expected to be worth around USD 482 billion by 2032 from USD 93 billion in 2023, growing at a CAGR of 20.7% during the forecast period from 2023 to 2032

Industry 4.0 is also known as the fourth industrial revolution. It refers to the constant digital transformation and automation of the manufacturing industry. It includes adopting advanced technologies such as cloud computing, machine learning, the Internet of Things, and artificial intelligence into the production process to create a more efficient, flexible, and connected manufacturing environment.

The major driving factors of the global Industry 4.0 market was the rising adoption of automated tools and equipment on factory floors, warehouse, & manufacturing, the emergence of digital technologies such as cloud services, ML, AI, IoT, & others, and the increasing investment towards additive manufacturing.

Note: Actual Numbers Might Vary In The Final Report

All the factors mentioned above were estimated to increase the market’s demand. Furthermore, the increasing use of the industrial internet was estimated to be the key factor that will likely propel the market growth during the forecast period. Additionally, during the forecast period, it was also expected that the market’s growth would increase because of the rise in the use of automation for high-quality production. Also, the growing acceptance of automation for quality manufacturing, increasing use of digital technology around the industry, cutting the cost of production, and the rising focus on efficiency are the other factors that enhance the market’s growth.

Key Takeaways

Driving Factors

Increasing Adoption of Industrial Robots

Over the few years, robots have been developed from being excessively costly machines with minimal capabilities to low-cost machines capable of performing a wide range of tasks. At the same time, industrial robots are extensively used by people worldwide. As per the newest robotics trends in the industry, industrial robots are progressively being used in manufacturing hubs, resulting in rapid evolution, development, and advancements.

The manufacturing sector has experienced an increasing acceptance of robotics engineering and technology in production processes due to the rapid technological advancement in robotics. Industrial robots are automatically programmable and controllable. A few famous industrial robot applications are testing, product inspection, palletizing, picking & position, assembling, ironing, heavy-lifting, and welding.

Restraining Factors

Data Risks Linked with the Implementation of Advanced Technologies

The implementation and integration of the industry solutions have various benefits, but they also have many risks that may hinder business developments during the forecast period. For example, the data and security challenges linked to integrating advanced technologies were estimated to hinder the market growth during the forecast period.

Furthermore, industry 4.0 could not prevent hackers from collecting all sensitive details and accessing manufacturers’ data because of their susceptibility to attacks. Thus, it is necessary to increase the consciousness about such threats and understand the need for cybersecurity solutions at all levels of organizational networks.

By Technology Analysis

The Industrial IoT Segment held the Largest Market Share

The technology segment is divided into industrial IoT, 3D printing, blockchain, industrial robotics, and other technologies. The industrial IoT segment had the majority share of 39% of the market. The numerous benefits of IoT technology have inspired various industrial equipment manufacturers to adopt IoT. For example, manufacturers can know the current state of machines and increase their performance while understanding the potential failure during the maintenance program planning by connecting industrial equipment using wireless connectivity and collecting sensor data. Furthermore, industrial automation offers a wide range of technologies that will help reduce human intervention. Also, it helps in the quality and flexibility of manufacturing processes.

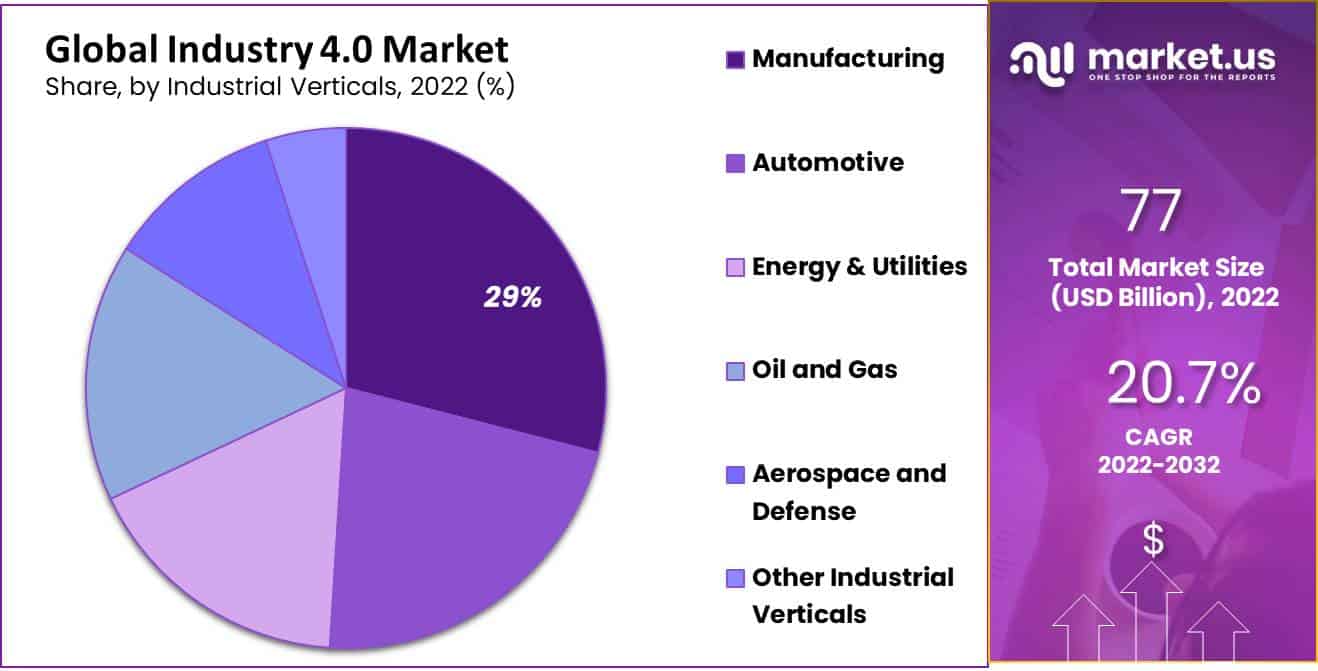

By Industrial Verticals Analysis

Industrial Verticals Segment Estimated to Collect the Highest Share

The industrial verticals segment is divided into manufacturing, automotive, energy & utilities, oil & gas, aerospace and defense, and other industrial verticals. The manufacturing segment is expected to hold the largest market share. On the other hand, the chemical, transportation, and automotive segment was estimated to grow as most of the verticals are adopting Industry 4.0. The implementation of smart robots as well as machines in the manufacturing sector results in an increasing trend during the forecast period. Also, R&D investments are undergoing to design an integrated system in which humans and robots can work on complex tasks using sensor-connected human-machine interfaces.

Key Market Segments

By Technology

- Industrial IoT

- 3D Printing

- Blockchain

- Industrial Robotics

- Other Technologies

By Industrial Verticals

- Manufacturing

- Automotive

- Energy & Utilities

- Oil and Gas

- Aerospace and Defense

- Other Industrial Verticals

Growth Opportunity

Increasing Popularity of 5G in Cloud Robotics Sector

The demand for cloud robotics was increasing steadily because of the rising deployment of robots in the manufacturing units worldwide. The cloud robotics have the aim to place the system intelligence in the clod and after that integrate it with the robots deployed in the factory. The huge use of cloud robotics around the manufacturing sector was resulted in the requirement for a high-performance network like 5G and this provide lower latency and high bandwidth than Wi-Fi.

The 5G supports tasks that can trust on massive datasets and video in real time. Also, it provides smooth incorporation of robots with the cloud network that was installed in the factory and hence this was progressively preferred in robotics.

Latest Trends

Predictive Maintenance with the help of Digital Twin Solution

In the recent years, the digital twins have attracted a lot of attention as the Internet of Things has gain popularity. The digital twin is a virtual model and it follow a physical entity lifecycle. This technology has permitted the automakers and OEM manufacturers to remotely track and manage the services & equipment by providing near real-time insights among the digital and physical worlds. The digital twin technology delivers an unparalleled insight into production and assets.

Numerous companies are integrating digital win technology which detect the irregularities and anomalies in operations to gain an insight into the equipment’s performance. The spare component maintenance can be scheduled ahead of time to decrease time-to-service and avoid costly asset failure. Furthermore, the companies are introducing advanced twin solutions which will offer greater operational efficiency and provide better visibility into equipment.

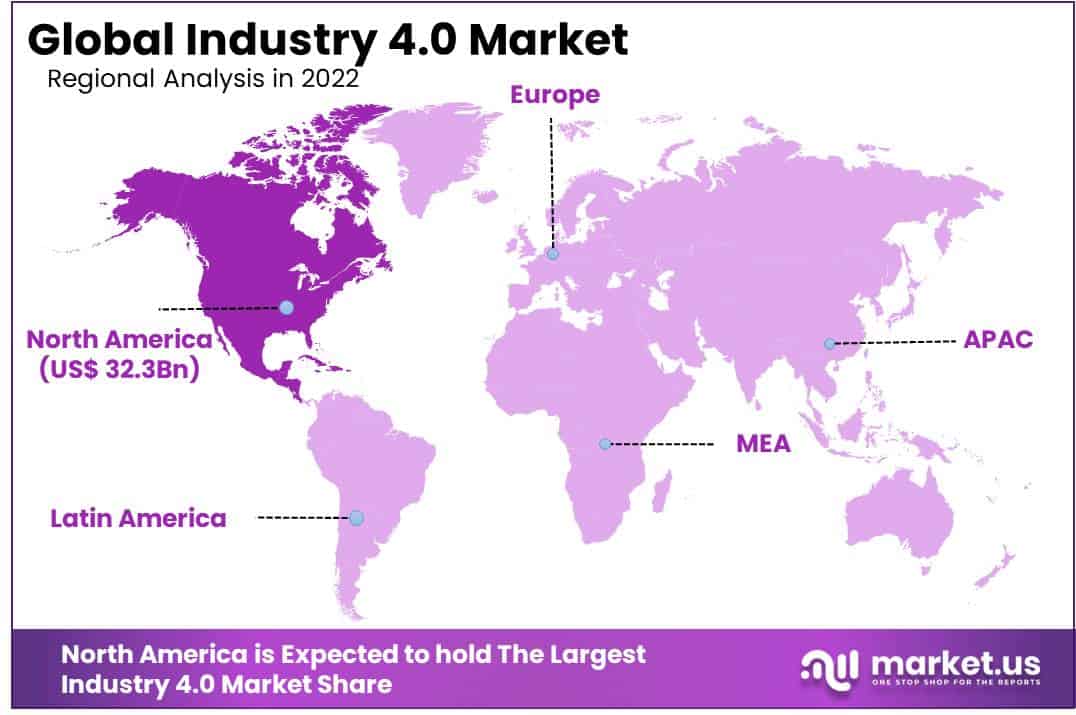

Regional Analysis

North America Dominated the Global Industry 4.0 Market

North America accounted for the largest revenue share of 42% of the overall market and the dominance of the region was likely to be continue during the forecast period. The most of the factories which was operating in the market was equipped with smart factory technologies and new machinery. This will result in the transition of other businesses from conventional manufacturing methods to smart manufacturing. Increasing funding in R&D activities, government initiatives, and prominent players in the market are a few factors which was responsible for the enhancement in growth of market during the forecast period.

Europe was estimated to have a fastest CAGR during the forecast period. For maintaining its position in the global market, the European industry was making considerable investment in skills and technologies. The automation techniques and deployment of connected objects has transformed the German manufacturing process. This have given rise to the industry 4.0 revolution. The real-time data processing, networked objects, and the establishment of connectivity, are few of the shifting ideals in the market. The Asia-Pacific region was expected to have a significant growth during the forecast period.

Note: Actual Numbers Might Vary In The Final Report

Key Regions and Countries Covered in this Report:

- North America

- The US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherland

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

Key Players Are Implementing Numerous Strategies

Cisco Systems Inc., Oracle Corporations, and others are few of the prominent players in the market that enhance the market growth. Also, they are presently deploying advanced solutions which was integrated with the 3D printing and digital twins, among others. Moreover, the high competition in the market players forcing them to have their focus on the strategy of acquisition for strengthening their positions in the market.

Top Key Players in Industry 4.0 Market:

- Robert Bosch GmbH

- ABB Ltd

- Honeywell International Inc.

- Schneider Electric SE

- General Electric Company

- Cisco Systems Inc.

- Emerson Electric Co

- Siemens AG

- Rockwell Automation, Inc

- Cognex Corporation

- Other Key Players

Key Industry Developments

- In June 2022– HCL Technologies launched Industry NeXT. It is a transformative architecture which will supports the clients in digitally reinventing their enterprises. The NeXt platform is assembled on the framework of industry 4.0 which assists organizations across the globe to organize, plan, and readily transition into a cooperative environment and this was possible by allowing resilient processes, linked interactions, and the delivery of igital and physical commodities & services enhanced by the advanced digital solutions.

- In February 2021– ABB Ltd. introduced GoFa to support the workers. Additionally, this launch will further support the increasing demand for the robots because they are capable of handling heavier payloads to increase the productivity and flexibility.

Report Scope

Report Features Description Market Value (2023) US$ 93 Bn Forecast Revenue (2032) US$ 482 Bn CAGR (2023-2032) 20.7% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Technology- Industrial IoT, 3D Printing, Blockchain, Industrial Robotics, and Other Technologies; and By Industrial Verticals-Manufacturing, Automotive, Energy & Utilities, Oil & Gas, Aerospace and Defense, and Other Industrial Verticals. Regional Analysis North America – The U.S. & Canada; Europe – Germany, France, The UK, Spain, Italy, Russia, Netherlands & Rest of Europe; APAC- China, Japan, South Korea, India, Australia, New Zealand, Singapore, Thailand, Vietnam & Rest of APAC; Latin America- Brazil, Mexico & Rest of Latin America; Middle East & Africa- South Africa, Saudi Arabia, UAE & Rest of MEA Competitive Landscape Robert Bosch GmbH, ABB Ltd, Honeywell International Inc., Schneider Electric SE, General Electric Company, Cisco Systems Inc., Emerson Electric Co, Siemens AG, Rockwell Automation, Inc,Cognex Corporation, and Other Key Players. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

How big industry 4.0 market?The Industry 4.0 market size is expected to be worth around USD 482 billion by 2032 from USD 77 billion in 2022, growing at a CAGR of 20.7 % during the forecast period from 2023 to 2032

What challenges will Industry 4.0 will face?Integration of new technology can present organizations with several challenges, while real-time threats such as Cybercrime must also be considered when handling customer data.

How Industry 4.0 will change everything?Industry 4.0 has revolutionized how businesses create, improve, and distribute their products. Manufacturers are adopting cutting-edge technologies into their production and operations such as Internet of Things devices, cloud computing services, analytics programs, AI algorithms and machine learning to streamline production and operations.

How Industry 4.0 will impact the economy?Industry 4.0 provides new opportunities for international trade growth by connecting multiple companies - industrial, commercial and service firms alike - into one system. China boasts the highest rate of industrial robot installations.

Is Industry 4.0 a threat or opportunity?Industry 4.0 presents manufacturers with incredible opportunities. They can gain valuable insight, streamline processes and create more flexible and efficient operations - but the smart, connected nature of advanced manufacturing may expose them to risks.

-

-

- Robert Bosch GmbH

- ABB Ltd

- Honeywell International Inc.

- Schneider Electric SE

- General Electric Company

- Cisco Systems Inc.

- Emerson Electric Co

- Siemens AG

- Rockwell Automation, Inc

- Cognex Corporation

- Other Key Players