Global Epoxy Adhesives Market Report By Technology (One Component, Two Component, Others), By Application (Automotive & Transportation, Building & Construction, Power & Energy, Electrical & Electronics, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: June 2024

- Report ID: 28378

- Number of Pages: 203

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

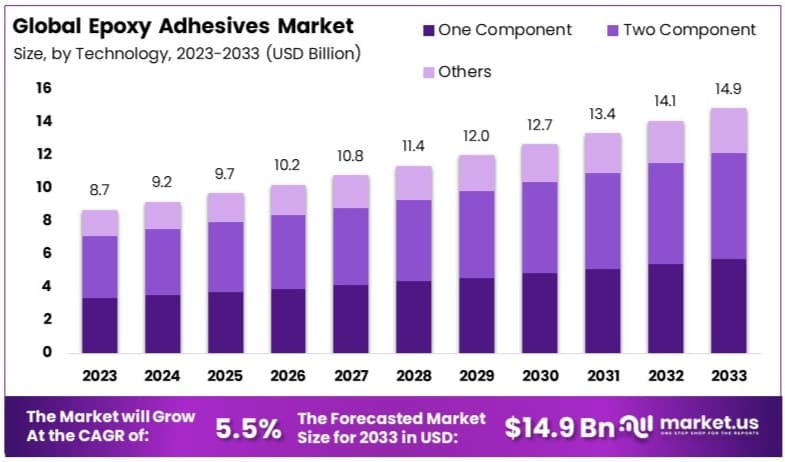

The Global Epoxy Adhesives Market size is expected to be worth around USD 14.9 Billion by 2033, from USD 8.7 Billion in 2023, growing at a CAGR of 5.5% during the forecast period from 2024 to 2033.

The Epoxy Adhesives market involves the production and sale of epoxy-based adhesives, which are known for their strong bonding capabilities and durability. These adhesives are widely used in industries like construction, automotive, electronics, and aerospace due to their excellent mechanical and thermal properties.

The market is driven by the growing demand for lightweight and high-performance materials in various applications. Key players focus on innovation and development of eco-friendly products. Trends indicate steady growth due to the increasing adoption of advanced materials in manufacturing and construction.

The global epoxy adhesives market is poised for significant growth, driven by substantial urbanization and increased investment in infrastructure. Over the past three decades, the level of urbanization has risen from 39% to 52%, catalyzing the demand for durable and versatile bonding solutions offered by epoxy adhesives. These adhesives are crucial in various applications, ranging from construction to automotive manufacturing, reflecting their versatility and strength.

Investments in infrastructure are crucial for sustaining this growth trajectory. According to the Asian Development Bank, an annual investment of USD 1.7 trillion is required across Asia through 2030 to support continuous growth and address the impacts of climate change. This substantial financial commitment underscores the expanding opportunities for the epoxy adhesives market within the construction sector.

Moreover, the global construction industry is expected to expand from USD 9.7 trillion in 2022 to USD 13.9 trillion by 2037, marking a near 30% increase. This growth signifies a robust demand environment for epoxy adhesives, as they are essential for high-strength, durable construction applications. The reduction in vehicle emissions, with a 27.6% decrease overall between 2002 and 2022 models, aligns with increasing regulatory pressures and a shift toward sustainability, which also influences the automotive sector’s adhesive requirements.

The projection that low-emission vehicles will constitute nearly 60% of new vehicle sales by 2030 further emphasizes the need for innovations in epoxy adhesives that support environmental standards and performance criteria. Consequently, the epoxy adhesives market is not only expanding due to traditional drivers such as construction and automotive production but is also being reshaped by global trends toward sustainability and new regulatory environments. This dynamic market landscape offers extensive opportunities for growth, innovation, and the development of new products that meet evolving technical and environmental standards.

Key Takeaways

- Market Value: The Epoxy Adhesives Market was valued at USD 8.7 billion in 2023, and is expected to reach USD 14.9 billion by 2033, with a CAGR of 5.5%.

- Technology Analysis: Two Component systems dominated with 43.6%; essential for their superior bonding strength and versatility.

- Application Analysis: Automotive & Transportation led with 42.6%; crucial for high-performance bonding in vehicle manufacturing.

- Dominant Region: APAC held 41.3%; significant due to extensive manufacturing activities and demand in automotive and construction sectors.

- Analyst Viewpoint: The epoxy adhesives market is moderately saturated with strong competition. Future predictions indicate steady growth driven by automotive, construction, and electronics applications.

- Growth Opportunities: Companies can explore advancements in adhesive technologies and expand applications in high-growth industries to enhance market presence.

Driving Factors

Rapid Industrialization and Urbanization in Emerging Economies Drives Market Growth

Rapid industrialization and urbanization in emerging economies such as China, India, and Brazil are significantly boosting the epoxy adhesives market. These countries are experiencing substantial growth in sectors like construction, automotive, and electronics, which heavily rely on the high bonding strength and versatility of epoxy adhesives. For instance, China’s Belt and Road Initiative, which aims to enhance regional connectivity and infrastructure across Asia, Africa, and Europe, is a major driver. This initiative alone is expected to fuel numerous infrastructure projects, increasing the need for durable adhesives in the construction of bridges, roads, and buildings.

Epoxy adhesives are indispensable in these large-scale infrastructure projects due to their excellent bonding properties, which ensure long-lasting and resilient connections. Additionally, the ongoing urbanization in these regions necessitates the development of residential and commercial buildings, further driving the demand for epoxy adhesives. In India, the government’s Smart Cities Mission, which aims to develop 100 smart cities, is another example where the application of epoxy adhesives is critical. These projects require materials that can withstand various environmental stresses, making epoxy adhesives a preferred choice.

Growing Automotive Industry and Lightweight Vehicle Trend Drives Market Growth

The growing automotive industry and the trend toward lightweight vehicles are key factors driving the epoxy adhesives market. The global push for fuel efficiency and reduced emissions is prompting automakers to use lightweight materials such as composites and aluminum instead of traditional steel. Epoxy adhesives are essential in bonding these materials, offering advantages over traditional welding and mechanical fasteners. For example, BMW’s i3 electric car employs a carbon-fiber-reinforced polymer (CFRP) passenger cell bonded with epoxy adhesives, resulting in a weight reduction of 250-350 kg compared to conventional steel structures.

This trend is further accelerated by the rise of electric vehicles (EVs), which require lightweight materials to enhance battery efficiency and range. The increasing adoption of EVs globally is expected to boost the demand for epoxy adhesives significantly. In addition, the automotive industry’s focus on enhancing vehicle safety and performance through the use of advanced materials also contributes to the growing market for epoxy adhesives. The integration of these adhesives in automotive manufacturing processes ensures strong, durable bonds that improve overall vehicle integrity and safety.

Increasing Adoption in Electronics and Consumer Goods Drives Market Growth

The increasing adoption of epoxy adhesives in electronics and consumer goods is another major growth driver for the market. The miniaturization of electronic devices and the surge in wearable technology demand adhesives that provide excellent electrical insulation, thermal conductivity, and resistance to harsh environments. For instance, Apple uses epoxy adhesives in its AirPods to bond components within a compact, waterproof design, highlighting the importance of these adhesives in advanced consumer electronics.

As the Internet of Things (IoT) devices proliferate in smart homes and cities, the need for reliable, durable epoxy adhesives will continue to grow. These adhesives are critical in ensuring the functionality and longevity of IoT devices, which are often exposed to varying environmental conditions. Moreover, the consumer electronics industry’s continuous innovation and the introduction of new, sophisticated devices necessitate the use of high-performance adhesives that can meet stringent technical requirements. This trend is expected to sustain the growth of the epoxy adhesives market, driven by the ever-evolving demands of the electronics and consumer goods sectors.

Restraining Factors

Environmental and Health Concerns Restrain Market Growth

Environmental and health concerns significantly hinder the growth of the epoxy adhesives market. Many epoxy adhesives contain Bisphenol A (BPA) and volatile organic compounds (VOCs), which pose health risks. Prolonged exposure to these chemicals can cause respiratory issues, skin irritation, and potential hormonal disruptions.

For example, in 2015, the European Chemicals Agency added certain epoxy hardeners to the REACH Candidate List of Substances of Very High Concern, leading to stricter regulations. This regulatory scrutiny forces manufacturers to shift towards eco-friendly alternatives, which are often more expensive and sometimes less effective. These challenges deter market expansion as companies face increased costs and technical limitations in developing safer adhesives.

High Raw Material Costs and Supply Chain Disruptions Restrain Market Growth

High raw material costs and supply chain disruptions are major factors restraining the epoxy adhesives market. Epoxy adhesives are primarily made from petroleum derivatives like epichlorohydrin and bisphenol A. Fluctuations in oil prices directly impact production costs. For instance, in 2021, the Texas winter storm disrupted petrochemical plants, causing a significant spike in epoxy resin prices.

The COVID-19 pandemic further exposed vulnerabilities in global supply chains, leading to price volatility and supply shortages. These factors make epoxy adhesives less competitive compared to alternatives like polyurethanes or acrylics. As a result, companies may seek cheaper and more stable options, limiting the growth of the epoxy adhesives market.

Technology Analysis

Two Component technology dominates with 43.6% due to superior bonding strength and versatility.

The Epoxy Adhesives Market is segmented by technology into One Component, Two Component, and Others. Among these, the Two Component technology segment dominates the market, holding a significant share of 43.6%. This dominance is attributed to its superior bonding strength and durability, making it highly suitable for demanding applications. Two Component epoxy adhesives consist of a resin and a hardener that are mixed before application. This type of adhesive provides excellent chemical resistance, high strength, and long-term stability, making it ideal for industrial applications where performance is critical.

Two Component epoxy adhesives are extensively used in automotive and transportation, construction, and electronics industries. Their ability to bond dissimilar materials, such as metals, plastics, and composites, makes them indispensable in these sectors. For instance, in the automotive industry, they are used for structural bonding, which enhances vehicle durability and safety. Similarly, in the construction sector, these adhesives are used in high-stress applications like bridge and building construction.

The One Component epoxy adhesives segment also plays a vital role in the market. These adhesives are pre-mixed and ready to use, which simplifies the application process and reduces labor costs. They are widely used in applications requiring quick bonding and curing, such as electronics assembly and minor repairs. However, they generally offer lower performance compared to Two Component systems, limiting their use in high-stress applications.

The Others segment includes specialized epoxy adhesives designed for niche applications. These may include adhesives with unique properties such as extreme temperature resistance, underwater curing, or specific chemical resistance. While this segment holds a smaller market share, it is crucial for specific industries requiring specialized bonding solutions.

Application Analysis

Automotive & Transportation application dominates with 42.6% due to the demand for lightweight and fuel-efficient vehicles.

The Epoxy Adhesives Market is also segmented by application into Automotive & Transportation, Building & Construction, Power & Energy, Electrical & Electronics, and Others. The Automotive & Transportation segment is the dominant sub-segment, accounting for 42.6% of the market share. This segment’s growth is driven by the increasing demand for lightweight and fuel-efficient vehicles, which necessitates the use of advanced materials and bonding technologies.

In the automotive industry, epoxy adhesives are used for structural bonding, component assembly, and panel bonding. Their high strength and durability make them suitable for bonding metals, plastics, and composites, contributing to vehicle weight reduction and improved fuel efficiency. The trend towards electric vehicles further boosts the demand for epoxy adhesives, as these vehicles require lightweight materials to enhance battery efficiency and range.

The Building & Construction segment is another significant contributor to the epoxy adhesives market. These adhesives are used in various construction applications, including structural bonding, concrete repair, and sealing. Their ability to withstand harsh environmental conditions and provide long-lasting bonds makes them ideal for critical infrastructure projects. The growing urbanization and infrastructure development in emerging economies further drive the demand for epoxy adhesives in this segment.

The Power & Energy segment includes applications in renewable energy systems, such as wind turbines and solar panels. Epoxy adhesives are used for bonding and sealing components, ensuring structural integrity and durability. The increasing focus on renewable energy sources and the expansion of wind and solar power installations boost the demand for epoxy adhesives in this segment.

The Electrical & Electronics segment encompasses applications in consumer electronics, industrial electronics, and electrical equipment. Epoxy adhesives are used for bonding, encapsulating, and potting electronic components, providing protection against moisture, chemicals, and mechanical stress. The miniaturization of electronic devices and the rise of wearable technology further drive the demand for epoxy adhesives in this segment.

Key Market Segments

Technology

- One Component

- Two Component

- Others

Application

- Automotive & Transportation

- Building & Construction

- Power & Energy

- Electrical & Electronics

- Others

Growth Opportunities

Renewable Energy Sector Offers Growth Opportunity

The renewable energy sector presents significant growth opportunities for the epoxy adhesives market. Wind turbine blades, solar panel installations, and tidal energy systems require adhesives that can endure extreme conditions. For example, Hexion’s EPIKOTE resin, used in wind turbine blade manufacturing, offers high fatigue resistance and low exotherm, making it suitable for large-scale applications.

With global renewable capacity projected to expand by over 60% from 2020 to 2026, according to the International Energy Agency (IEA), this sector’s expansion offers substantial growth potential for epoxy adhesives. The increasing focus on renewable energy sources and the need for durable, high-performance materials drive the demand for epoxy adhesives in this market.

Medical and Dental Applications Offer Growth Opportunity

Medical and dental applications provide robust growth opportunities for epoxy adhesives. Certain epoxy formulations’ biocompatibility and strong bonding properties make them ideal for medical devices and dental applications.

For instance, ADHESIVETEC’s EPO-TEK 301-2 is a biocompatible epoxy used in catheters, pacemakers, and dental composites. With an aging global population and rising healthcare spending, there is an increasing demand for advanced medical and dental products. This trend supports the growth of specialized, high-value epoxy adhesives in the medical and dental sectors, where reliable performance and safety are critical.

Trending Factors

Bio-based and Recyclable Epoxies Are Trending Factors

Bio-based and recyclable epoxies are emerging as significant trends in the epoxy adhesives market. In response to environmental concerns, companies like Sicomin are developing epoxy systems using bio-based carbon, which reduces the carbon footprint.

Additionally, researchers at the US Department of Energy’s Lawrence Berkeley National Laboratory have created a recyclable epoxy that can be dissolved and reused. These innovations address sustainability concerns and align with the growing demand for eco-friendly products. As environmental regulations become stricter and consumer awareness increases, the market for bio-based and recyclable epoxy adhesives is expected to grow.

Smart and Self-healing Adhesives Are Trending Factors

Smart and self-healing adhesives are increasingly trending in the epoxy adhesives market. These advanced adhesives can change properties in response to stimuli or self-heal when damaged. For example, researchers at the University of Illinois have developed a microcapsule-based self-healing epoxy that can repair small cracks, enhancing longevity in aerospace and automotive applications.

As the Internet of Things (IoT) and sensor technologies advance, the demand for smart adhesives in critical applications is likely to rise. These adhesives offer improved durability and maintenance efficiency, driving their adoption in industries requiring high-performance bonding solutions.

Regional Analysis

APAC Dominates with 41.3% Market Share

The Asia-Pacific (APAC) region holds a dominant 41.3% market share in the epoxy adhesives market, valued at USD 3.6 billion. This dominance is driven by rapid industrialization and urbanization in countries like China, India, and South Korea. The robust growth in construction, automotive, and electronics sectors boosts the demand for epoxy adhesives. Large-scale infrastructure projects, such as China’s Belt and Road Initiative, further fuel the market. Additionally, the presence of major manufacturers and low production costs contribute to the region’s leadership.

APAC’s regional characteristics significantly impact the epoxy adhesives market. The region’s strong manufacturing base, coupled with high investments in infrastructure and automotive industries, supports market growth. The burgeoning middle class and increasing disposable incomes drive demand for consumer electronics and vehicles, further boosting epoxy adhesives consumption. Moreover, favorable government policies and incentives for industrial growth attract investments, enhancing market performance.

APAC’s market presence is expected to strengthen in the future, with continued investments in infrastructure, automotive, and electronics sectors. The region’s focus on renewable energy projects and sustainable practices will also drive demand for high-performance epoxy adhesives. With increasing urbanization and industrial activities, APAC is poised to maintain its dominant position and potentially increase its market share.

North America – 25% Market Share

North America holds a 25% market share in the epoxy adhesives market. The region benefits from advanced technology adoption and significant investments in aerospace, automotive, and construction industries. The focus on sustainable and eco-friendly adhesives is also driving market growth. The United States and Canada lead in technological innovations, contributing to the high demand for epoxy adhesives.

Europe – 20% Market Share

Europe accounts for 20% of the epoxy adhesives market. The region’s stringent environmental regulations and strong focus on renewable energy sources propel the demand for high-performance adhesives. Germany, France, and the UK are major contributors, driven by advancements in automotive and aerospace industries. The growing trend towards lightweight and fuel-efficient vehicles also supports market growth.

Middle East & Africa – 8% Market Share

The Middle East & Africa region holds an 8% market share. The market growth is driven by significant infrastructure projects and the expansion of the construction sector. Countries like the UAE and Saudi Arabia invest heavily in construction and industrial development. The oil and gas industry’s demand for durable adhesives further boosts the market.

Latin America – 5.7% Market Share

Latin America represents a 5.7% market share in the epoxy adhesives market. The region’s growth is fueled by the construction and automotive sectors. Brazil and Mexico are the major contributors, with increasing investments in infrastructure and industrial activities. The region’s economic recovery and industrialization efforts support market expansion.

Key Regions and Countries

- North America

- The US

- Canada

- Mexico

- Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

The Epoxy Adhesives Market is highly competitive, with several key players making significant contributions to its growth and development. Companies like Henkel AG & Co. KGaA, Sika Group, and 3M are at the forefront, leveraging their extensive R&D capabilities and broad product portfolios to maintain strong market positions. These firms emphasize innovation, sustainability, and strategic acquisitions to enhance their market influence and expand their global footprint.

Henkel AG & Co. KGaA is renowned for its diverse adhesive technologies and strong brand reputation. Sika Group focuses on construction and industrial applications, with a strong presence in emerging markets. 3M’s expertise in various adhesive technologies allows it to cater to multiple industries, from automotive to electronics.

H.B. Fuller Company and DuPont are also prominent, with robust distribution networks and a focus on high-performance adhesives. Ashland Inc. and Bostik SA emphasize eco-friendly solutions, addressing increasing environmental regulations and consumer demand for sustainable products.

Mapei SPA and Sika AG are leaders in the construction sector, providing specialized adhesives for infrastructure projects. Permabond LLC and Lord Corporation focus on niche markets with innovative bonding solutions, enhancing their strategic positioning.

Illinois Tool Works Incorporation and DELO Industrie Klebstoffe GmbH & Co. KGaA excel in high-tech applications, while RPM International and Huntsman Corporation leverage their diversified business models to maintain market stability and growth. Collectively, these companies drive innovation, market expansion, and competitive dynamics within the epoxy adhesives market.

Market Key Players

- Henkel AG & Co. KGaA

- Sika Group

- 3M

- H.B. Fuller Company

- DuPont

- Ashland Inc.

- Bostik SA

- Mapei SPA

- Sika AG

- Permabond LLC

- Lord Corporation

- Illinois Tool Works Inc.

- DELO Industrie Klebstoffe GmbH & Co. KGaA

- RPM International

- Huntsman Corporation

Recent Developments

- June 2024: Master Bond introduces Master Bond UV15DC80-1Med, a one-component, dual cure epoxy adhesive for medical applications. It offers a unique dual cure mechanism utilizing UV light for initial fixation followed by heat for complete polymerization, addressing limitations of traditional UV adhesives.

- May 2024: The development of a new smart adhesive with unmatched strength and versatility. The adhesive is designed to provide high bonding strength and flexibility, making it suitable for various applications, including medical devices and electronics.

Report Scope

Report Features Description Market Value (2023) USD 8.7 Billion Forecast Revenue (2033) USD 14.9 Billion CAGR (2024-2033) 5.5% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Technology (One Component, Two Component, Others), By Application (Automotive & Transportation, Building & Construction, Power & Energy, Electrical & Electronics, Others) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Henkel AG & Co. KGaA , Sika Group , 3M , H.B. Fuller Company , DuPont , Ashland Inc., Bostik SA, Mapei SPA, Sika AG, Permabond LLC, Lord Corporation, Illinois Tool Works Incorporation, DELO Industrie Klebstoffe GmbH & Co. KGaA, RPM International, Huntsman Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is epoxy adhesive?Epoxy adhesives are strong, versatile, and high-performance bonding agents used in various industries. They consist of epoxy resin and a hardening agent that, when mixed together, create a durable and strong bond.

In which industries are epoxy adhesives commonly used?Epoxy adhesives find applications in industries like construction, automotive, aerospace, electronics, marine, healthcare, and manufacturing for bonding, sealing, and encapsulation purposes.

What is the future outlook for the epoxy adhesive market?The market is expected to grow due to increasing demand in construction, automotive lightweighting, electronics miniaturization, and ongoing research and development for enhanced formulations meeting specific industry requirements.

How does epoxy adhesive compare to other bonding methods?Compared to traditional mechanical fastening or other adhesives, epoxy adhesives offer superior bonding strength, resistance to environmental factors, and the ability to bond dissimilar materials effectively.

What is the expected market size of the Global Epoxy Adhesives Market by 2033?The Global Epoxy Adhesives Market is projected to be worth around USD 14.9 Billion by 2033, growing at a CAGR of 5.5% from USD 8.7 Billion in 2023.

-

-

- 3M

- Ashland

- Bostik

- Dow

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Mapei S.P.A

- Parker Hannifin Corp

- Permabond LLC

- Sika AG