Global Dark Factories Market Size, Share, Growth Analysis By Type (Industrial Robotics, Additive Manufacturing, Industrial Internet of Things, Automated Guided Vehicles), By Deployment (Greenfield Projects, Brownfield Projects), By End-user (Automotive, Pharmaceuticals, Aerospace, Electronics, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: March 2025

- Report ID: 143495

- Number of Pages: 203

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

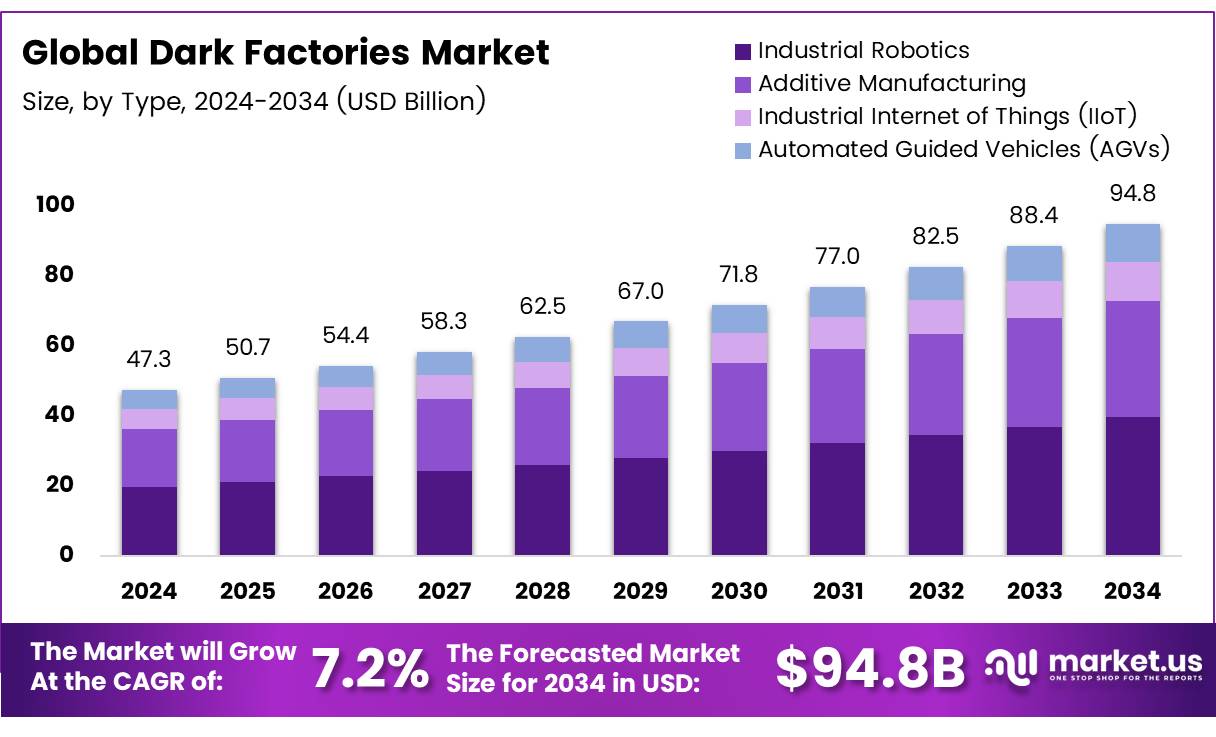

The Global Dark Factories Market size is expected to be worth around USD 94.8 Billion by 2034, from USD 47.3 Billion in 2024, growing at a CAGR of 7.2% during the forecast period from 2025 to 2034.

Dark factories, also known as lights-out factories, represent a cutting-edge segment of the manufacturing industry where operations are fully automated and human presence is either reduced or absent. This market is primarily driven by advancements in robotics, artificial intelligence, and machine learning, enabling factories to operate around the clock with minimal human intervention.

The dark factories market has seen considerable growth due to the increasing need for efficiency and cost reduction in manufacturing processes. Moreover, the trend towards sustainability and reduced workplace hazards supports the expansion of this sector.

dark factories not only enhance production efficiency but also significantly decrease operational costs. These facilities are pivotal in industries where precision and repeatability are paramount. The integration of IoT and smart technologies in dark factories facilitates real-time monitoring and remote management, further enhancing operational efficiencies.

However, the transition to fully automated factories requires substantial capital investment and poses challenges in terms of workforce displacement and the need for highly specialized staff.

The dark factories market is poised for substantial growth, driven by technological advancements and increasing automation in manufacturing. According to TexSpaceToday, China installed 290,367 industrial robots in recent years, representing 52% of global installations, which underscores the country’s commitment to integrating automation across its manufacturing sectors.

This surge in robot installations indicates robust market opportunities for companies involved in the production and maintenance of robotic systems and related technologies. Furthermore, the growing robot density in China, which reached 392 robots per 10,000 manufacturing workers in 2023, surpassing the global average of 141, highlights the expanding scope for dark factory environments globally.

Government initiatives and regulatory frameworks play a crucial role in the development of dark factories. Increased government investment in automation technology research and infrastructure, coupled with incentives for adopting industrial automation, are vital for market growth.

Regulations concerning safety, data security, and ethical considerations of automation also shape the market dynamics. These regulatory measures ensure that the deployment of dark factories aligns with labor laws and safety standards, facilitating a smoother integration of these technologies into the mainstream manufacturing landscape.

Key Takeaways

- The global Dark Factories Market is projected to double from USD 47.3 Billion in 2024 to USD 94.8 Billion by 2034, with a CAGR of 7.2%.

- Industrial Robotics leads the Type Analysis segment with a 45.2% market share in 2024, driven by increasing automation demands.

- Greenfield Projects dominate the Deployment Analysis segment, holding a 54.1% share in 2024, favored by the adoption of new, fully automated facilities.

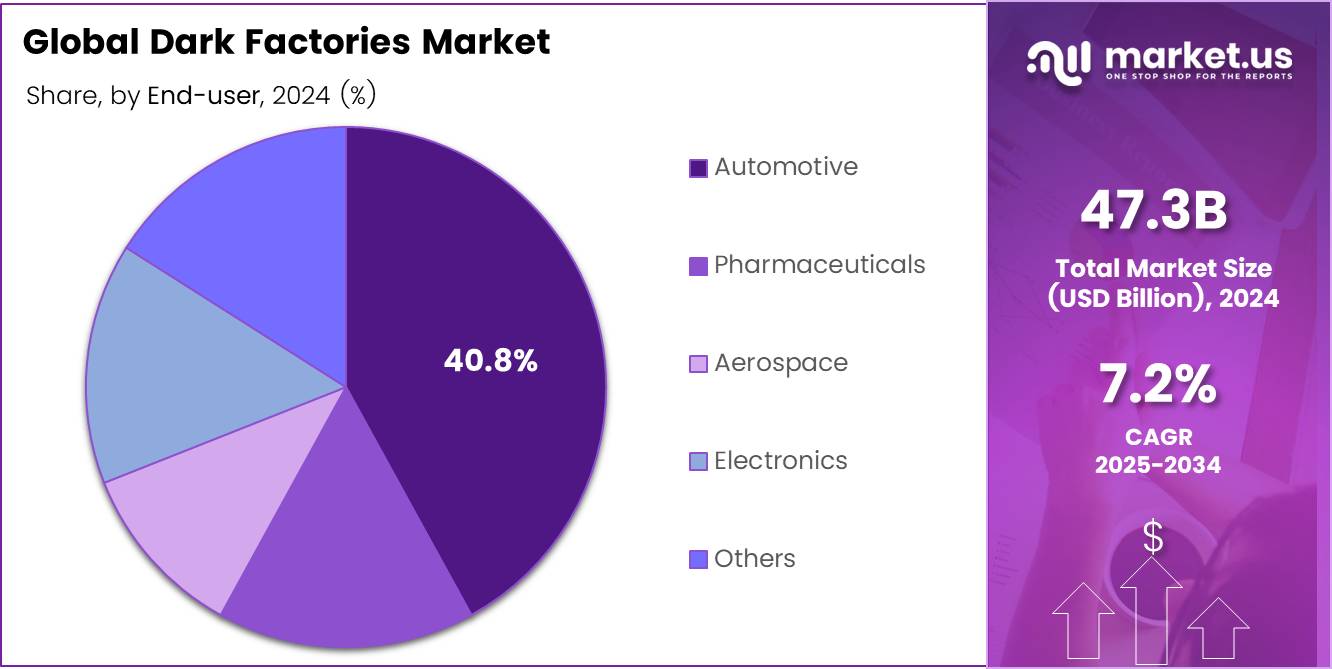

- The automotive sector is the largest end-user in the Dark Factories Market, capturing 40.8% of the market in 2024, due to advanced robotics adoption.

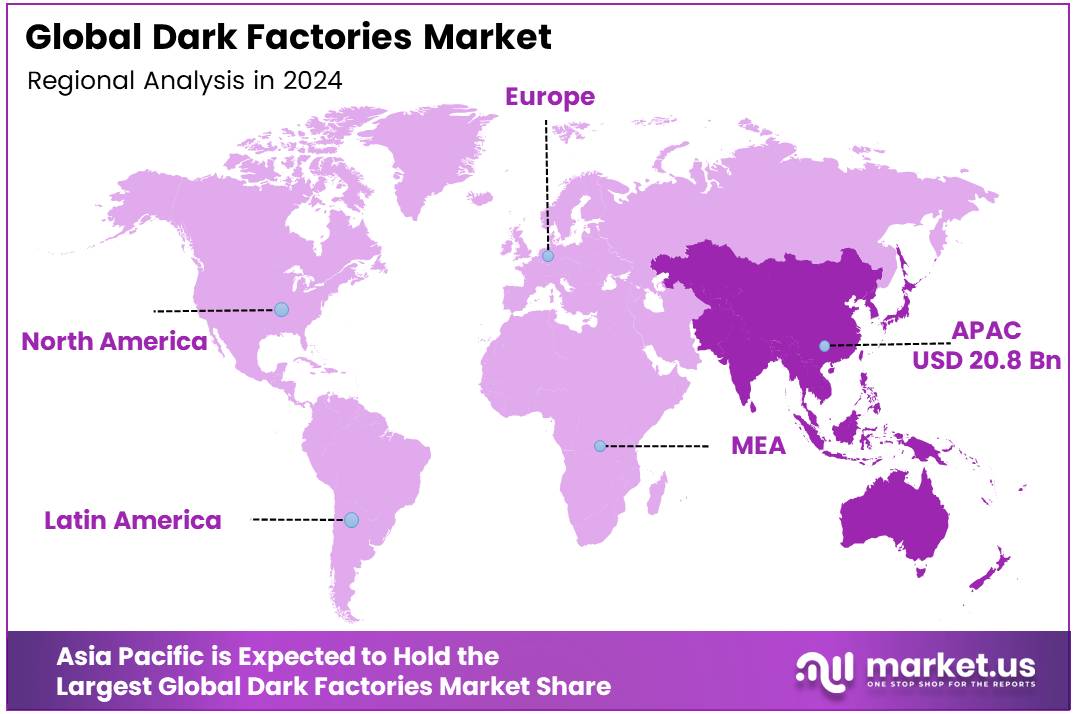

- Asia Pacific is the leading region, representing 44.8% of the market in 2024, driven by rapid industrialization and significant investments in automation.

Type Analysis

Industrial Robotics Leads with 45.2% in Dark Factories Type Analysis for 2024

In 2024, Industrial Robotics maintained a dominant market position in the By Type Analysis segment of the Dark Factories Market, capturing a 45.2% share. This segments growth can be attributed to the increasing automation and efficiency demands in manufacturing processes. Industrial Robotics enhances production capabilities while minimizing human error and operational costs, thus being a pivotal factor in the expansion of dark factories.

Following Industrial Robotics, Additive Manufacturing has emerged as a significant contributor to the market, driven by its ability to expedite production processes and reduce waste through precision and customization. The adoption of Additive Manufacturing is accelerating as industries seek more agile and innovative manufacturing solutions.

The Industrial Internet of Things (IIoT) also plays a crucial role in this market, enhancing connectivity and data exchange between devices. IIoT technologies enable real-time monitoring and adjustments in manufacturing operations, leading to improved efficiency and productivity.

Automated Guided Vehicles (AGVs) are increasingly integrated into dark factories to automate material handling and intra-logistics. AGVs contribute to safer and more streamlined operations by reducing the need for manual labor in potentially hazardous environments.

Collectively, these technologies are transforming the landscape of manufacturing, driving the Dark Factories Market toward more autonomous and efficient production systems.

Deployment Analysis

Greenfield Projects Lead with 54.1% Market Share in Dark Factories Deployment

In 2024, Greenfield Projects held a dominant market position in the By Deployment Analysis segment of the Dark Factories Market, securing a 54.1% share. This significant market share can be attributed to the increasing adoption of fully automated manufacturing facilities from scratch, which allows for the seamless integration of advanced technologies without the constraints of existing infrastructures.

Greenfield projects are particularly favored for their ability to incorporate cutting-edge automation systems and robotics from the ground up, optimizing operational efficiency and reducing long-term costs.

Conversely, Brownfield Projects, involving the upgrade or integration of new technologies into existing factory setups, accounted for the remainder of the market. While these projects are crucial for modernizing and extending the life of current facilities, they often encounter challenges such as spatial constraints and compatibility issues with old systems, which can hinder the full integration of new automation technologies.

The preference for Greenfield over Brownfield projects in the Dark Factories Market highlights a strategic shift towards building future-ready production environments that prioritize efficiency and technological advancement.

End-user Analysis

Automotive Leads End-User Segments with 40.8% Market Share

In 2024, the automotive sector held a dominant position in the By End-user Analysis segment of the Dark Factories Market, accounting for a substantial 40.8% share. This substantial market presence can be attributed to the increased automation and integration of advanced robotics in automotive manufacturing, aimed at enhancing efficiency and reducing human intervention.

Following closely, the pharmaceuticals sector emerged as another significant contributor, leveraging dark factory environments to ensure precision and compliance with stringent regulatory standards. This sectors adoption of fully automated production lines underscores a shift towards more controlled and error-free production processes.

The aerospace industry also capitalized on dark factory capabilities, particularly for the manufacturing of complex components that require high precision. Automation in this sector has been crucial in maintaining consistent quality and meeting the rigorous safety standards essential in aerospace manufacturing.

In the electronics segment, dark factories have been instrumental in the assembly of intricate electronic components, where precision and repeatability are paramount. The trend towards miniaturization of electronic devices continues to drive the adoption of robotics in manufacturing processes within this sector.

Other industries, including consumer goods and industrial manufacturing, are progressively exploring dark factory solutions to enhance their production lines, indicating a broadening acceptance and application of these technologies across various market sectors.

Key Market Segments

By Type

- Industrial Robotics

- Additive Manufacturing

- Industrial Internet of Things (IIoT)

- Automated Guided Vehicles (AGVs)

By Deployment

- Greenfield Projects

- Brownfield Projects

By End-user

- Automotive

- Pharmaceuticals

- Aerospace

- Electronics

- Others

Drivers

Advancements in Robotics and AI Drive Dark Factories Market Expansion

The dark factories market is experiencing significant growth, primarily driven by continuous advancements in robotics and artificial intelligence. These technological improvements are crucial as they enhance the automation of manufacturing processes, which not only boosts productivity but also reduces the incidence of human error.

Additionally, there is a rising demand for customized products, which dark factories are uniquely equipped to handle due to their highly adaptable and automated systems. This demand is being met with increased operational efficiency, as these factories operate continuously, unrestricted by human work schedules, thus maximizing throughput and operational output.

Furthermore, the integration of dark factories with cutting-edge supply chain management technologies leads to superior inventory control and shorter production lead times, optimizing the entire supply chain. These factors collectively contribute to the robust expansion of the dark factories market, highlighting their increasing importance in modern manufacturing landscapes.

Restraints

Skilled Workforce Shortage Limits Dark Factories’ Expansion

The development of dark factories, facilities operating with minimal or no human presence due to extensive automation and robotics, faces significant restraints. One primary limitation is the lack of a skilled workforce.

The successful operation and maintenance of these highly automated factories require professionals adept in robotics, artificial intelligence, and advanced automation systems. This specialized skill set is scarce, leading to a talent shortage that hampers the growth and efficient running of dark factories.

Additionally, integrating such sophisticated technologies with existing industrial setups poses substantial challenges. The process is not only complex and labor-intensive but also fraught with potential operational disruptions, further complicating the transition towards fully automated manufacturing environments. These factors collectively create barriers that can slow the adoption rate of dark factories, impacting their potential market expansion.

Growth Factors

Expansion in Emerging Markets Drives Dark Factories Adoption

The dark factories market is poised for significant growth, particularly as emerging economies enhance their manufacturing sectors. The adoption of dark factories within these markets presents a unique opportunity to streamline production processes and markedly reduce labor costs. This shift is driven by the need for efficiency and cost-effectiveness in manufacturing, making dark factories a favorable option.

Furthermore, the flexibility of dark factories allows for on-demand manufacturing and customization, meeting the increasing consumer demand for bespoke products. Additionally, these automated factories support sustainability initiatives by optimizing production schedules and reducing waste and energy consumption.

The integration of Internet of Things (IoT) technology enhances this growth potential, enabling real-time monitoring and predictive maintenance, thus increasing the efficiency and reliability of operations. Collectively, these factors position dark factories as a transformative force in the global manufacturing landscape, offering substantial opportunities for market expansion and technological integration.

Emerging Trends

Industry 4.0 Technologies Fueling Dark Factory Adoption

The dark factories market is experiencing a significant transformation, largely driven by the rapid adoption of Industry 4.0 technologies. This integration of the Internet of Things (IoT), artificial intelligence (AI), and automation is revolutionizing manufacturing by enhancing operational intelligence and efficiency.

Another pivotal factor is Robotics as a Service (RaaS), which is democratizing access to automation technologies, especially for smaller manufacturers who may find the initial investment prohibitive. Furthermore, the surge in smart manufacturing technologies that utilize AI, machine learning, and predictive analytics is expanding the capabilities within dark factories.

These technologies are not only optimizing production processes but also paving the way for fully autonomous manufacturing systems that aim to eliminate human intervention entirely. This shift towards autonomous operations underscores the growing industry trend towards more innovative and efficient manufacturing environments.

Regional Analysis

Asia Pacific Leads Dark Factories Market with 44.8% Share, Valued at USD 20.8 Billion

The global market for dark factories is distinctly segmented by regions including North America, Europe, Asia Pacific, the Middle East & Africa, and Latin America, each showcasing unique growth patterns and market dynamics.

Asia Pacific emerges as the dominating region, accounting for 44.8% of the global market with a valuation of USD 20.8 billion. This substantial market share can be attributed to rapid industrialization, significant investments in automation technologies, and the strong presence of manufacturing industries in countries like China, Japan, and South Korea. Additionally, the region’s push towards reducing human involvement in manufacturing to increase productivity and reduce costs fuels the expansion of dark factories.

Regional Mentions:

In North America, the market is driven by advancements in artificial intelligence and machine learning, with the United States leading in the adoption of fully automated manufacturing facilities. This region’s focus on innovation and the presence of numerous tech giants further support the growth of dark factories.

Europe also shows a robust growth trajectory, supported by stringent regulations regarding worker safety and energy efficiency. The region’s emphasis on sustainable manufacturing processes and the integration of smart technologies are pivotal to the development of dark factories.

The Middle East & Africa, although still nascent in the dark factories market, are gradually adopting these technologies. The growth here is spurred by the diversification of economies and the gradual shift away from oil dependency to more sustainable and technologically advanced industries.

Latin America is witnessing gradual adoption influenced by the modernization of manufacturing capabilities and the increasing need for efficient production methods. Countries such as Brazil and Mexico are at the forefront, leveraging their existing industrial bases to integrate dark factory technologies.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

In the global Dark Factories Market for 2024, several key players are expected to influence the trajectory of industry growth and innovation. Among them, companies such as Deephawk, Amazon, and FANUC Corporation stand out due to their substantial investments in automation technologies and artificial intelligence.

Deephawk is anticipated to play a pivotal role, leveraging its advanced robotics and machine learning capabilities to enhance production efficiency and reduce human intervention in manufacturing processes. The company’s commitment to integrating sophisticated algorithms for predictive maintenance and real-time decision-making positions it as a frontrunner in driving the future of dark factories.

Amazon, with its vast resources and expertise in logistical operations, is also set to significantly impact the market. The company’s use of autonomous robots and AI-driven systems in warehousing and distribution centers exemplifies its potential to further adapt these technologies for fully automated manufacturing environments. Amazon’s ongoing innovation in AI and robotics is likely to propel its standing in the market, enhancing its capability to manage complex, lights-out operations.

FANUC Corporation, a veteran in industrial robotics, continues to be instrumental in shaping the dark factories landscape. Known for its robust robotic systems and automation solutions, FANUC’s contribution to the dark factories market is marked by its ability to customize technologies for a diverse range of manufacturing settings. The company’s expertise in CNC, robotic arms, and factory automation systems makes it a critical player in enabling seamless, unmanned production lines.

Collectively, these companies are not only enhancing their competitive edges but are also setting the standards for innovation and efficiency in the dark factories market. Their developments are likely to catalyze significant shifts in how manufacturing processes are structured and executed, heralding a new era of industrial automation.

Top Key Players in the Market

- Deephawk

- Amazon

- Basetwo AI

- Clevertech

- STILRIDE

- FANUC Corporation

- Blynksolve

- Geofabrica

- Xaba

- Wootzano

- StartProto

- Changying Precision Technology Company

- MOLG

- Simplifyber

- Athena 3D Manufacturing

Recent Developments

- In March 2025, Foxconn implemented a significant shift at its Kunshan factory, replacing 60,000 workers with robots, demonstrating a commitment to automating 30% of its operations by the year 2025.

- In October 2024, CSi palletising announced its acquisition by Mpac Group plc, a global leader in high-speed packaging and automation solutions, marking a significant expansion in its market capabilities.

- In September 2024, HomeLane successfully expanded its portfolio by acquiring DesignCafe through a share swap arrangement, enhancing its offerings in the home design and renovation sector.

Report Scope

Report Features Description Market Value (2024) USD 47.3 Billion Forecast Revenue (2034) USD 94.8 Billion CAGR (2025-2034) 7.2% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Industrial Robotics, Additive Manufacturing, Industrial Internet of Things, Automated Guided Vehicles), By Deployment (Greenfield Projects, Brownfield Projects), By End-user (Automotive, Pharmaceuticals, Aerospace, Electronics, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Deephawk, Amazon, Basetwo AI, Clevertech, STILRIDE, FANUC Corporation, Blynksolve, Geofabrica, Xaba, Wootzano, StartProto, Changying Precision Technology Company, MOLG, Simplifyber, Athena 3D Manufacturing Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- Deephawk

- Amazon

- Basetwo AI

- Clevertech

- STILRIDE

- FANUC Corporation

- Blynksolve

- Geofabrica

- Xaba

- Wootzano

- StartProto

- Changying Precision Technology Company

- MOLG

- Simplifyber

- Athena 3D Manufacturing