Global Precision Link Conveyor Market Size, Share, Growth Analysis By Type (PLC Pallet Type, PBC Belt Type, Others), By Application (Automotive, Electronic, Medical & Pharmaceutical, Telecommunications, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: March 2025

- Report ID: 35968

- Number of Pages: 394

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

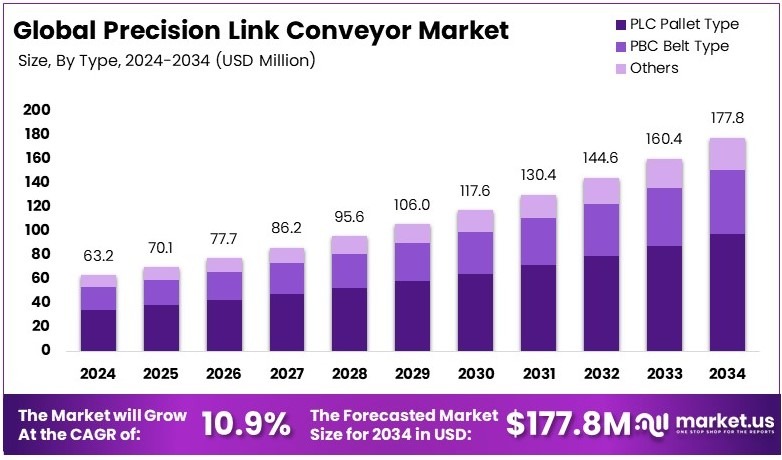

The Global Precision Link Conveyor Market size is expected to be worth around USD 177.8 Million by 2034, from USD 63.2 Million in 2024, growing at a CAGR of 10.9% during the forecast period from 2025 to 2034.

A precision link conveyor is an industrial conveyor system that uses linked metal plates or segments to move materials. This system is designed to transport heavy loads with high accuracy, often in sectors like automotive and manufacturing. It is known for its reliability and ability to handle precise and challenging transport tasks.

The precision link conveyor market refers to the sector focused on manufacturing, selling, and maintaining these conveyors. The market serves industries such as automotive, electronics, and packaging. As automation becomes more widespread, the demand for precision link conveyors is growing, presenting new opportunities for businesses within this space.

According to the International Federation of Robotics (IFR), the global base of operational industrial robots reached 4.1 million by 2023, with key markets in China, the U.S., Japan, South Korea, and Germany.

In recent years, automation has become essential in many industries. According to Kissflow, 94% of companies perform repetitive tasks, and automation has led to productivity improvements for 66% of knowledge workers.

This trend directly impacts the precision link conveyor market, as businesses look for efficient ways to transport materials accurately in automated production lines. As a result, the demand for precision link conveyors continues to grow, especially in industries that rely heavily on automation to increase productivity and reduce human error.

However, despite the growing demand, the market is experiencing moderate saturation. Numerous established companies are already serving the industry, though new entrants are also emerging. Companies that innovate and offer conveyors with advanced features, such as better energy efficiency and adaptability, gain a competitive advantage.

Additionally, the precision link conveyor market is highly competitive, with several firms striving to differentiate themselves based on the quality and functionality of their products. Consequently, businesses must focus on technological advancements to stay relevant.

On a broader scale, precision link conveyors are crucial for enhancing industrial efficiency worldwide. These systems play a key role in reducing manual labor and increasing productivity. Locally, they significantly impact industries by streamlining manufacturing processes and making operations more cost-effective.

For instance, industries in Germany and Japan, known for their advanced automation practices, have successfully integrated precision link conveyors to optimize production lines. This helps to improve both the speed and accuracy of their operations.

Key Takeaways

- The Precision Link Conveyor Market was valued at USD 63.2 million in 2024 and is expected to reach USD 177.8 million by 2034, with a CAGR of 10.9%.

- In 2024, PLC Pallet Type dominated the type segment with 54.8% due to its high precision and reliability in automated manufacturing.

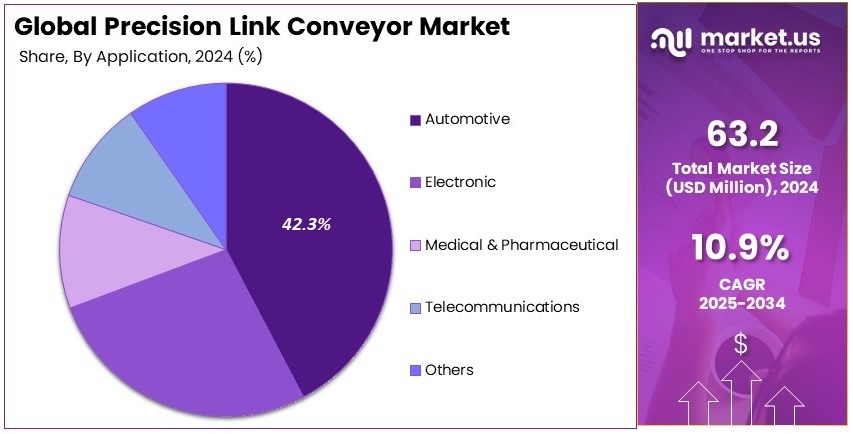

- In 2024, Automotive led the application segment with 42.3%, driven by the increasing automation in vehicle production.

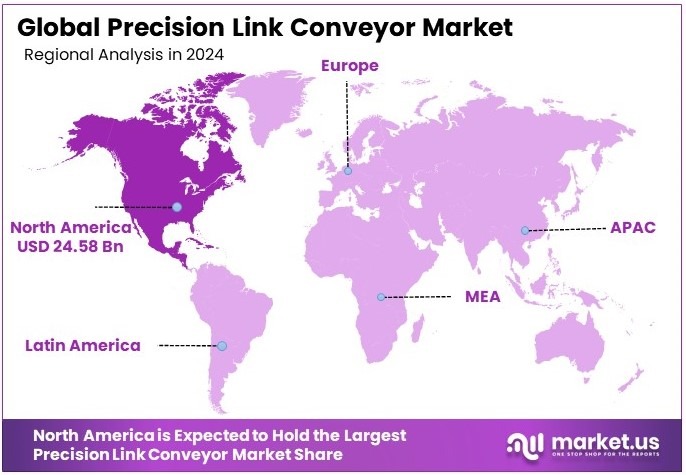

- In 2024, North America dominated the market with 38.9% and valued at USD 24.58 billion, attributed to strong demand from industrial automation.

Type Analysis

PLC Pallet Type dominates with 54.8% due to its versatility and efficiency in automation.

The Precision Link Conveyor market is significantly shaped by the Type segment, where the PLC Pallet Type has emerged as the leader with a market share of 54.8%. This dominance can be attributed to its widespread use across industries requiring precise material handling and high-throughput automation. The PLC Pallet Type is preferred for its ability to carry heavy loads and move components with high precision, making it ideal for industries like automotive and electronics manufacturing.

The increased demand for automation solutions that improve operational efficiency and reduce human intervention has also contributed to the growth of this sub-segment. In addition, the rise in industrial robots and automated assembly lines further solidifies the PLC Pallet Type’s role in market leadership.

On the other hand, the PBC Belt Type, while important, holds a smaller share due to its suitability for less intricate applications compared to the PLC Pallet Type. The PBC Belt Type is typically used for simpler material transport tasks that don’t require the level of precision or heavy load capabilities offered by PLC Pallet systems.

However, it remains relevant for applications in industries where cost efficiency is crucial and the complexity of automation needs is low. The “Others” sub-segment, encompassing less common conveyor types, holds a small but notable market share. This sub-segment includes specialized systems that are customized for unique requirements, though their growth is comparatively slower due to niche demand.

Application Analysis

Automotive application dominates with 42.3% due to high demand for automated production lines.

The Automotive sector holds a dominant position in the Precision Link Conveyor market with a share of 42.3%. The growth in this sector is mainly driven by the increasing need for automation in vehicle production, where high precision and efficiency are critical. The automotive industry’s focus on improving production speed and product quality while reducing operational costs has led to an increase in demand for advanced conveyor systems.

Additionally, the trend of electric vehicle production, which often requires more precise material handling, further fuels the need for precision link conveyors. These conveyors ensure smooth handling of parts like engine components and vehicle bodies through highly automated manufacturing processes.

The Electronic industry, while holding a smaller share, benefits from the increasing demand for precision and speed in component assembly. The Medical & Pharmaceutical sector also shows promise, though its share is limited due to the more specialized needs of medical device production, which may not always align with standard conveyor types.

Lastly, Telecommunications, while not as dominant, has seen growth as the demand for quick assembly and testing of electronic components rises. “Others” in this segment, covering niche markets such as food production and packaging, still play a crucial role in the growth of the overall market.

Key Market Segments

By Type

- PLC Pallet Type

- PBC Belt Type

- Others

By Application

- Automotive

- Electronic

- Medical & Pharmaceutical

- Telecommunications

- Others

Driving Factors

Increasing Automation Drives Growth in the Market

The increasing demand for automation in manufacturing processes is a major factor driving the growth of the Precision Link Conveyor market. As companies seek to improve efficiency, reduce costs, and maintain competitiveness, automation technologies have become essential. These systems reduce the need for manual labor while increasing the speed and accuracy of material handling.

In industries such as automotive, electronics, and pharmaceuticals, the need for automated systems is rising. Precision link conveyors, with their high-speed capabilities and reliability, are ideal for transporting products in automated environments. Moreover, as automation technologies become more accessible, even small and medium-sized businesses are adopting these systems, further expanding the market.

The combination of automation and precision link conveyors leads to more streamlined production processes and a reduction in human error, which increases overall productivity. These advancements help businesses keep up with increasing production demands while maintaining high-quality standards.

With automation being integrated into more aspects of manufacturing, the demand for precision link conveyors is expected to grow. Companies are realizing the benefits of automation systems in enhancing efficiency and maintaining a competitive edge in the market.

Restraining Factors

High Costs and Complex Maintenance Restrain Market Growth

While automation offers many benefits, several factors restrain the market’s growth. High initial capital investment is one of the key barriers, as advanced precision link conveyor systems can be expensive to install and set up. For smaller businesses with limited budgets, this can be a significant hurdle.

In addition, fluctuating raw material prices affect the overall manufacturing costs, making it difficult for companies to maintain profitability. These price fluctuations create uncertainty for manufacturers and may delay or limit investment in new equipment.

Another challenge is the lack of a skilled workforce to handle these advanced systems. Many companies struggle to find employees with the necessary technical expertise to maintain and operate these complex systems. This shortage of skilled labor can lead to operational inefficiencies and increased training costs.

Finally, specialized equipment often comes with high maintenance costs and potential downtime. These factors combined can slow the adoption of precision link conveyors, limiting their market potential. Businesses may hesitate to invest in new systems due to concerns about long-term costs and disruptions.

Growth Opportunities

Industry 4.0 and Eco-Friendly Solutions Provide Opportunities

The Precision Link Conveyor market has several growth opportunities. The adoption of Industry 4.0 and IoT integration offers significant potential for improving monitoring and control of material handling systems. By using sensors and data analytics, companies can optimize performance and reduce energy consumption.

Additionally, there is growing interest in eco-friendly and energy-efficient technologies. Manufacturers are focusing on creating conveyors that use less energy and reduce environmental impact. As sustainability becomes a priority for many industries, this shift towards greener technologies presents a valuable opportunity for the market.

Customization and modular systems are also gaining traction, as businesses look for solutions tailored to their specific needs. These systems allow for more flexibility in production lines, leading to cost savings and greater efficiency. The ability to modify systems based on changing demands is a key advantage.

As emerging markets continue to develop, new opportunities for expansion are expected to open, especially in sectors such as logistics and manufacturing. Companies that adopt these innovations are well-positioned to capture the growing demand for more efficient and sustainable solutions in material handling.

Emerging Trends

AI and Sustainability Are Shaping Market Trends

The Precision Link Conveyor market is also being influenced by several trending factors. The integration of AI and machine learning into conveyor systems is improving predictive maintenance capabilities. By using AI, companies can identify potential issues before they cause downtime, reducing maintenance costs and increasing system reliability.

Similarly, the rise of wearable safety technologies in high-risk environments is enhancing worker protection, aligning with growing concerns about workplace safety. These technologies help monitor workers’ health and ensure they are safe while operating heavy machinery, improving overall safety standards.

There is also an increasing demand for lightweight and durable materials that can withstand the rigors of heavy-duty operations. Businesses are looking for solutions that provide durability without adding unnecessary weight to the systems.

Additionally, sustainability practices are becoming more important in manufacturing and supply chains. Companies are adopting green technologies to meet regulatory standards and reduce environmental footprints, which is driving the demand for energy-efficient and eco-friendly precision link conveyors. These trends highlight a shift towards smarter, safer, and more sustainable systems in the industry.

Regional Analysis

North America Dominates with 38.9% Market Share

North America leads the Precision Link Conveyor Market with a 38.9% share, amounting to USD 24.58 billion. This dominance is driven by the region’s advanced manufacturing capabilities, high adoption of automation, and significant investments in infrastructure. The U.S. and Canada have a well-established industrial base with a focus on optimizing logistics and production lines, making precision link conveyors highly essential.

The demand for efficient and precise conveyor systems in industries like automotive, food processing, and pharmaceuticals contributes to North America’s market share. Additionally, the region benefits from technological advancements, particularly in the automation sector, which enhances the performance and efficiency of these conveyor systems. A growing trend towards Industry 4.0 and the integration of smart technologies further boosts the market for precision link conveyors in North America.

Looking ahead, the North American market for precision link conveyors is expected to maintain its strong position. The continued shift toward automated production lines, coupled with increasing demand for customization and flexibility in conveyor systems, is likely to fuel market growth. The region’s innovation-driven environment ensures that North America will remain a key player in the market, with further expansion anticipated in the next few years.

Regional Mentions:

- Europe: Europe accounts for a notable share in the precision link conveyor market, driven by its advanced manufacturing sector and a strong emphasis on sustainability. The region’s automotive and food processing industries heavily rely on precision link conveyors to improve operational efficiency and product quality.

- Asia Pacific: Asia Pacific is witnessing rapid growth, led by manufacturing hubs like China and Japan. The rise in automation and the increasing demand for efficient logistics in industries like electronics and automotive are fueling market expansion in the region.

- Middle East & Africa: The Middle East & Africa market is growing steadily due to investments in infrastructure and logistics. Precision link conveyors are gaining traction in sectors such as mining, food, and beverage, where the need for efficient material handling is rising.

- Latin America: Latin America’s market for precision link conveyors is in its early stages, but it’s expanding due to the industrial growth in Brazil and Mexico. Increased investment in manufacturing and logistics is expected to drive future market growth in the region.

Key Regions and Countries Covered in the Report

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Competitive Landscape

The Precision Link Conveyor market is led by several key players, including Motion Index Drivers, DESTACO, QC Industries, and Cyclo-Index. These companies are recognized for their advanced technologies and contributions to automated material handling systems.

Motion Index Drivers specializes in precision-driven products and custom solutions, providing automated systems that enhance efficiency in industries requiring high accuracy. Their conveyors are particularly valued for their ability to meet the demanding needs of complex manufacturing processes.

DESTACO is another prominent player, offering a broad range of automation and material handling solutions. Its precision link conveyors are well-regarded for their adaptability in complex assembly lines and high-speed production processes, making them a go-to choice for companies seeking flexibility and reliability.

QC Industries focuses on providing flexible, high-performance conveyor systems that are easy to integrate into automated environments. Their products cater to industries that demand smooth and efficient product movement, delivering high functionality with ease of integration.

Cyclo-Index offers durable and precise conveyors, known for their ability to operate reliably even in harsh environments and under high stress. Their systems are ideal for industries where long-term performance and robustness are critical.

These companies lead the market by delivering innovative solutions that cater to the growing demand for efficiency, precision, and reliability in various industrial applications. Their continued advancements in automation technologies ensure their strong position in the Precision Link Conveyor market.

Major Companies in the Market

- Motion Index Drivers

- DESTACO

- QC Industries

- Cyclo-Index

- Cam Driven Systems (CDS)

- SANKYO

- Arthur G. Russell

- Interfaced Technologies

- Camfield Engineers

- Stelron Components

- Bettinelli

Recent Developments

- Sovda: In December 2024, Sovda introduced the Precision Silo, a green coffee storage, loading, and blending system. The system boasts a total capacity of 4,800 kilograms, distributed across eight 600-kilogram chambers. Equipped with a pneumatic loader that transfers 40 kilograms per minute, it enables the loading of a full pallet of green coffee into the silo in approximately 20 minutes.

Report Scope

Report Features Description Market Value (2024) USD 63.2 Million Forecast Revenue (2034) USD 177.8 Million CAGR (2025-2034) 10.9% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (PLC Pallet Type, PBC Belt Type, Others), By Application (Automotive, Electronic, Medical & Pharmaceutical, Telecommunications, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Motion Index Drivers, DESTACO, QC Industries, Cyclo-Index, Cam Driven Systems (CDS), SANKYO, Arthur G. Russell, Interfaced Technologies, Camfield Engineers, Stelron Components, Bettinelli Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Precision Link Conveyor MarketPublished date: March 2025add_shopping_cartBuy Now get_appDownload Sample

Precision Link Conveyor MarketPublished date: March 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Motion Index Drivers

- DESTACO

- QC Industries

- Cyclo-Index

- Cam Driven Systems (CDS)

- SANKYO

- Arthur G. Russell

- Interfaced Technologies

- Camfield Engineers

- Stelron Components

- Bettinelli