Global Hydraulic Bolt Tensioner Market Based on Type (Topside Bolt Tensionersm Sub Sea Bolt Tensioners, Wind Bolt Tensioners), Based on Application (Oil and Gas, Wind & Power Generation, Industrial, Other Applications), Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: October 2024

- Report ID: 15612

- Number of Pages: 300

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

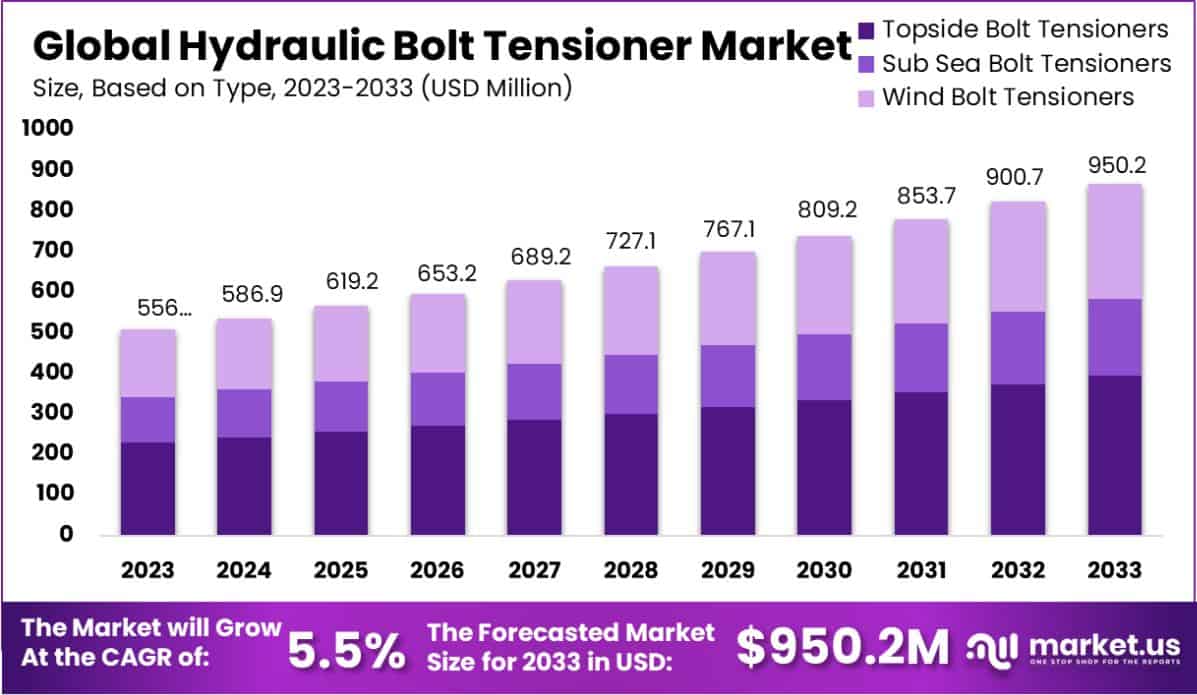

The Global Hydraulic Bolt Tensioner Market size is expected to be worth around USD 950.2 Million by 2033, From USD 556.3 Million by 2023, growing at a CAGR of 5.5% during the forecast period from 2024 to 2033.

A hydraulic bolt tensioner is a mechanical device used to apply a specific, controlled amount of tension to bolts. It utilizes hydraulic pressure to stretch the bolt and subsequently load a nut, ensuring that the bolt is tightened with precise force, minimizing the risk of damage or uneven loading on critical joints, especially in large-scale industrial applications such as wind turbines, oil rigs, and large machinery.

The Hydraulic Bolt Tensioner Market refers to the commercial landscape surrounding the production, distribution, and sale of hydraulic bolt tensioners. This market is driven by the growing need for precise bolt tensioning in various industrial sectors, including energy, automotive, and manufacturing, to ensure safety and operational efficiency.

The expansion of energy infrastructure and increasing investments in renewable energy projects significantly drive the demand for hydraulic bolt tensioners, as these devices are crucial for assembling heavy machinery with high precision.

The rising focus on safety and maintenance standards in heavy industries creates a continuous demand for hydraulic bolt tensioners. These tools are essential for ensuring the integrity and reliability of bolted joints in critical equipment and structures.

Technological advancements in hydraulic tensioning systems present significant opportunities for market growth. Innovations that offer improved efficiency, automation, and adaptability to various bolt sizes and types can expand the market’s reach and applicability across different sectors.

The Hydraulic Bolt Tensioner market is witnessing significant technological advancements that are set to transform operational efficiencies, particularly in the renewable energy sector. One notable development is the strategic fusion of technologies by industry leaders such as GE Renewable Energy, which is anticipated to drastically reduce maintenance and repair expenses.

For instance, this integration is projected to slash bolt maintenance costs by 75% in the UK’s wind sector by 2030, translating into an annual saving of approximately £150 million across both onshore and offshore operations. This reflects a broader trend towards cost-efficiency and sustainability in energy infrastructure maintenance.

Furthermore, Torque Tension Systems Ltd., a key player based in Northumberland, U.K., reported revenues of around £5.1 million in 2009. The company’s product lineup, including Dura-Lite hydraulic torque wrenches and subsea bolt tensioners, exemplifies the industry’s shift towards high-performance and durable solutions engineered with advanced computer-aided technology.

Such innovations underscore the market’s direction towards enhancing product reliability and performance, catering to the demanding environments of today’s industrial applications. These developments not only highlight the growing financial stakes but also indicate a robust trajectory for market growth and technological integration in the coming years.

Key Takeaways

- The Global Hydraulic Bolt Tensioner Market size is expected to be worth around USD 950.2 Million by 2033, From USD 556.3 Million by 2023, growing at a CAGR of 5.5% during the forecast period from 2024 to 2033.

- In 2023, Topside Bolt Tensioners held a dominant market position Based on the Type segment of the Hydraulic Bolt Tensioner Market.

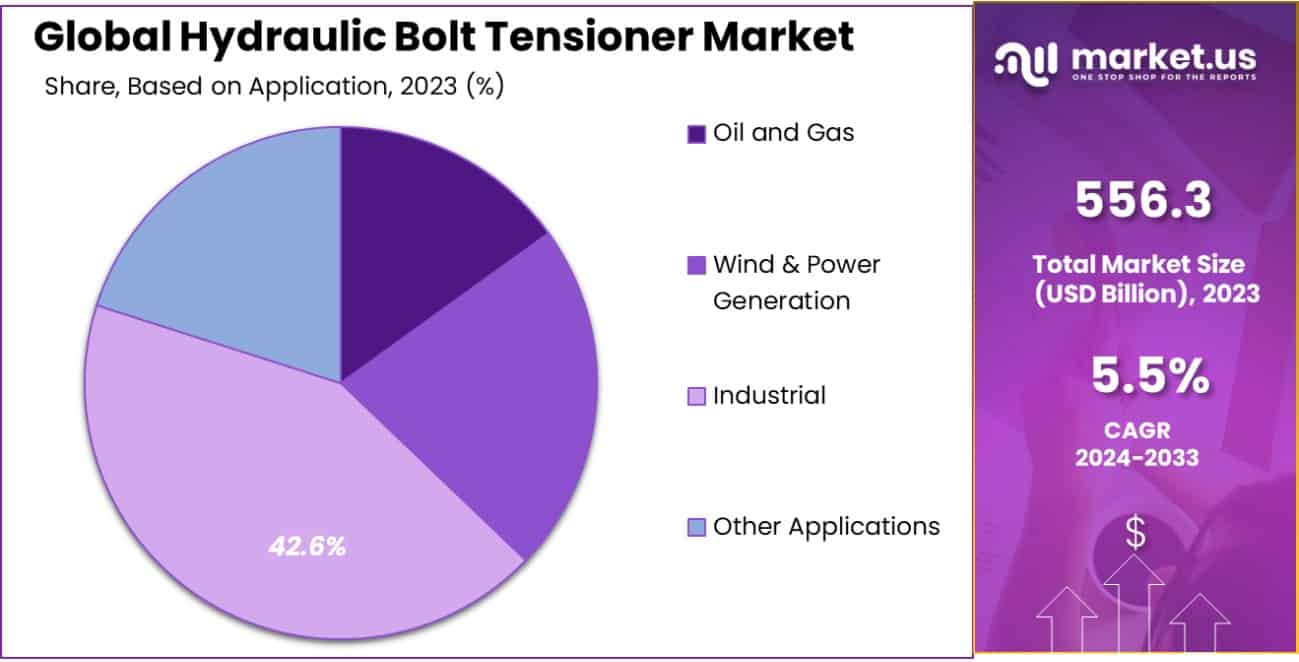

- In 2023, Industrial held a dominant market position in the Based on Application segment of the Hydraulic Bolt Tensioner Market, with a 42.6% share.

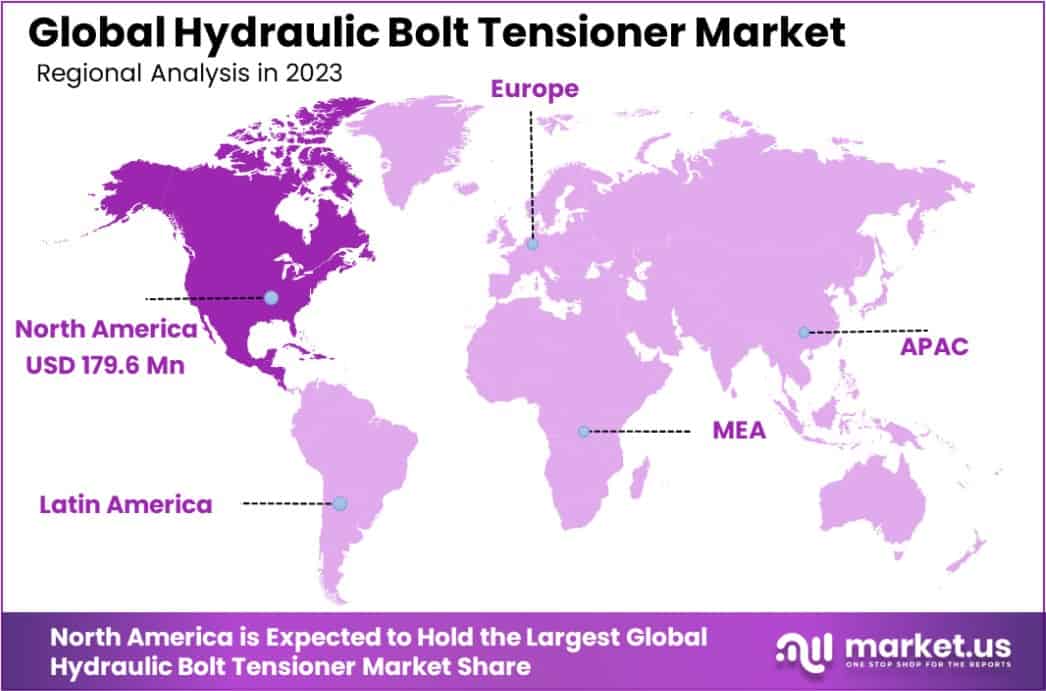

- North America dominated a 32.3% market share in 2023 and held USD 179.6 Million in revenue from the Hydraulic Bolt Tensioner Market.

Based on Type Analysis

In 2023, Topside Bolt Tensioners held a dominant market position in the “Based on Type” segment of the Hydraulic Bolt Tensioner Market. This category, which includes Topside Bolt Tensioners, Sub Sea Bolt Tensioners, and Wind Bolt Tensioners, has seen a marked preference for topside applications due to their critical role in maintaining structural integrity in offshore oil and gas operations.

The prominence of Topside Bolt Tensioners can be attributed to their enhanced efficiency and reliability in extreme environmental conditions, which are paramount in topside settings.

The market dominance of these tensioners is further supported by their technological advancements, which offer superior tensioning capabilities and safety features compared to their counterparts.

These innovations cater to the stringent safety and performance standards required in offshore platforms, thereby fostering their adoption. Moreover, the ongoing expansion of offshore exploration and production activities has stimulated demand for these tools, underpinning the segment’s growth.

Furthermore, the competitive landscape of this market segment is characterized by a focus on product innovation and strategic alliances among key players, aiming to enhance product portfolios and expand global footprints.

This strategy not only strengthens market presence but also drives the development of more robust and efficient tensioning solutions, ensuring sustained growth and market leadership of Topside Bolt Tensioners.

Based on Application Analysis

In 2023, the Industrial sector held a dominant market position in the “Based on Application” segment of the Hydraulic Bolt Tensioner Market, with a 42.6% share. This sector outpaced others including Oil and Gas, Wind & Power Generation, and Other Applications.

The substantial share held by the Industrial segment is indicative of the extensive deployment of hydraulic bolt tensioners across various smart manufacturing processes and maintenance operations where precision and safety are paramount.

The increasing adoption of these tensioners in the Industrial sector is driven by the critical need for operational reliability and efficiency in areas such as automotive assembly, heavy machinery maintenance, and infrastructure projects.

The effectiveness of hydraulic bolt tensioners in applying precise tensioning forces ensures the integrity and longevity of bolted joints, which is essential in high-load applications.

Furthermore, advancements in tensioner technology, characterized by enhancements in durability and ease of use, have facilitated their integration into diverse industrial applications, thereby broadening the market base.

The continued industrialization in emerging economies and the subsequent investment in infrastructure and manufacturing capabilities are expected to sustain the growth trajectory of the Hydraulic Bolt Tensioner Market within the Industrial segment.

Key Market Segments

Based on Type

- Topside Bolt Tensioners

- Sub Sea Bolt Tensioners

- Wind Bolt Tensioners

Based on Application

- Oil and Gas

- Wind & Power Generation

- Industrial

- Other Applications

Drivers

Key Drivers of the Hydraulic Bolt Tensioner Market

The expansion of the hydraulic bolt tensioner market is primarily propelled by increasing demands in sectors such as oil and gas, power generation, and construction. These devices are essential for achieving accurate bolt tensioning and ensuring joint integrity in critical applications, thus enhancing safety and operational reliability.

The market’s growth is further supported by technological advancements that improve the efficiency and accuracy of tensioners, catering to the evolving requirements of these heavy industries.

Additionally, the shift towards automated solutions and the integration of digital technologies like IoT for real-time monitoring and control are key trends that not only optimize the bolt tensioning process but also contribute to the market’s upward trajectory.

This progression is reflective of an industry moving towards more innovative and reliable solutions in infrastructure development and maintenance.

Restraint

Challenges Limiting Hydraulic Bolt Tensioner Growth

The hydraulic bolt tensioner market faces significant constraints, notably the high cost of advanced tensioning tools and the need for skilled personnel to operate them. These factors can deter smaller companies or those in developing regions from adopting such sophisticated equipment, thereby limiting market penetration.

Additionally, the presence of alternative bolt tensioning methods, such as torque wrenches, which are often perceived as more cost-effective, poses a competitive challenge. Economic downturns and budget constraints in key industries like oil and gas and construction further exacerbate the issue, as companies may delay or reduce investments in new, expensive technologies.

This economic sensitivity reflects a broader vulnerability in the market, where financial barriers can notably slow down adoption rates and technological advancements in the sector.

Opportunities

Expanding Opportunities in Bolt Tensioning

The hydraulic bolt tensioner market is poised for growth, driven by the escalating construction of large-scale infrastructure and renewable energy projects globally. As these projects demand precise and reliable bolt tightening to ensure structural integrity and safety, the need for hydraulic bolt tensioners is expected to rise.

This market is also likely to benefit from the increasing adoption of wind energy, where bolt tensioners play a critical role in assembling turbines. Moreover, the ongoing advancements in hydraulic technology, which improve the efficiency and adaptability of these tools, present significant opportunities for market expansion.

These technological improvements facilitate the development of more compact, lighter, and user-friendly tensioners, broadening their applicability across various industries, and thereby potentially increasing their market demand and user base.

Challenges

Navigating Market Barriers in Tensioning

Challenges in the hydraulic bolt tensioner market stem largely from operational complexities and the maintenance demands of these high-precision tools. The need for regular servicing, combined with the potential for operational errors by inadequately trained personnel, can hinder optimal usage and lifecycle performance.

Furthermore, the market is sensitive to fluctuations in industries such as oil and gas and construction, where project delays or cancellations directly affect demand for new equipment. This situation is compounded by stringent safety regulations and standards, which while necessary, impose additional costs and complexity on manufacturers and users alike.

These factors collectively create barriers to entry and can restrict market growth, especially in regions with less developed industrial bases or where there is a reluctance to invest in advanced, costlier technologies.

Growth Factors

Growth Drivers in Bolt Tensioning

The hydraulic bolt tensioner market is set to expand due to several growth-inducing factors. Key among these is the increasing emphasis on safety and efficiency in construction and manufacturing processes, which bolsters the demand for reliable and precise tensioning tools.

The ongoing advancements in hydraulic technology that enhance tool performance and durability also play a critical role. Additionally, the expansion of industries such as wind energy, which requires extensive use of bolt tensioners for turbine assembly, provides a significant boost to the market.

As regions around the world increase their investments in renewable energy and infrastructural projects, the demand for hydraulic bolt tensioners is expected to rise correspondingly.

This growth is further supported by the trend towards automation and precision engineering, which emphasizes the importance of effective bolt tensioning solutions in achieving desired outcomes and maintaining structural integrity.

Emerging Trends

Emerging Trends in Bolt Tensioning

Emerging trends in the hydraulic bolt tensioner market are significantly shaped by technological innovations and a shift toward sustainability. The integration of digital technologies such as IoT and real-time monitoring systems in hydraulic bolt tensioners is becoming increasingly prevalent, enhancing operational accuracy and predictive maintenance capabilities.

This digital transformation allows for more precise control and data analytics, leading to improved performance and reduced downtime. Furthermore, the market is witnessing a growing demand for environmentally friendly and energy-efficient solutions.

Manufacturers are responding by developing greener, more sustainable tensioning tools that align with global environmental standards and help reduce the carbon footprint of industrial operations. These trends are not only reshaping the market landscape but are also creating new opportunities for growth and differentiation in a competitive industry.

Regional Analysis

The hydraulic bolt tensioner market exhibits varied growth dynamics across different regions, reflecting distinct industrial, economic, and technological landscapes. In North America, which dominates the market with a 32.3% share valued at USD 179.6 million, growth is fueled by robust investments in oil and gas and renewable energy sectors.

This region benefits from advanced technological infrastructure and a strong focus on safety standards, driving demand for high-quality tensioning solutions.

Europe follows closely, leveraging its strong automotive and manufacturing base, and stringent safety regulations which necessitate the adoption of efficient bolt tensioning technologies. The shift towards renewable energy, particularly wind power, is a significant driver in this region.

The Asia Pacific region is experiencing the fastest growth due to rapid industrialization and expansion of infrastructure projects, especially in China and India. Increased investments in the construction and energy sectors are projected to boost the demand for hydraulic bolt tensioners significantly.

Conversely, the Middle East & Africa, and Latin America are emerging markets with potential growth opportunities, driven by developments in construction and natural resources extraction industries. However, these regions currently hold smaller market shares, often hindered by economic volatility and less developed industrial infrastructure.

Overall, while North America currently leads the global market, the Asia Pacific region is expected to exhibit the highest growth rates, driven by ongoing industrial advancements and infrastructural expansions.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

In 2023, the global hydraulic bolt tensioner market is significantly influenced by the activities and innovations of key players such as Atlas Copco AB, SKF AB, and SPX FLOW (SPX Corporation). Each of these companies plays a pivotal role in shaping the competitive landscape and driving technological advancements within the industry.

Atlas Copco AB has consistently emphasized innovation in its hydraulic bolt tensioner solutions, focusing on enhancing operational efficiency and reliability. Known for its robust R&D capabilities, Atlas Copco has introduced products that are not only energy-efficient but also equipped with advanced features like real-time monitoring systems, which cater to the increasing demand for smart and automated solutions across various industries

This strategic focus on technology and sustainability helps Atlas Copco maintain its leadership and expand its customer base globally.

SKF AB, another dominant force, leverages its expertise in precision engineering to offer hydraulic bolt tensioners that are highly accurate and durable. SKF’s commitment to quality and extensive service network ensures high customer satisfaction and repeat business, particularly in the heavy industries and renewable energy sectors.

By continuously improving product performance and integrating environmental considerations, SKF aligns itself with global sustainability trends, appealing to a market that increasingly values eco-friendly practices.

SPX FLOW (SPX Corporation), with its diverse portfolio and strong global presence, focuses on customized solutions to meet specific industry needs. SPX FLOW excels in providing tailor-made products that enhance the safety and efficiency of operations, particularly in the oil and gas and power generation sectors.

Their strategy to cater to niche market requirements through innovation and customization positions them well within the competitive market dynamics.

As of 2023, these companies not only dominate the market through technological innovation but also through strategic market penetration and comprehensive after-sales services, setting the standard for excellence in the hydraulic bolt tensioner industry.

Top Key Players in the Market

- Atlas Copco AB

- SKF AB

- SPX FLOW (SPX Corporation)

- HYTORC

- Siempelkamp Tensioning Systems

- WREN HYDRAULICS

- Pilgrim International

- Nord-Lock

- Hi-Force

- SCHAAF GmbH

- Beck Industries

- FPT – Fluid Power Technology.

- Hydraulics Technology Inc. (HTI)

- TorcUp Inc.

- ITH bolting technology

- Powermaster Engineers Pvt Ltd.

- Technofast Industries Pty Ltd

- Other Key Players

Recent Developments

- In August 2024, Pilgrim, a prominent direct-to-consumer beauty and personal care firm, successfully raised approximately $9 million in an extended Series B funding round. This funding was significantly backed by Fireside Ventures and Vertex Ventures, contributing to a notable rise in the company’s valuation and strategic growth initiatives.

- In August 2024, Schaeffler Group’s first-half 2024 revenue increased by 2.0% to €8,276 million, driven by growth in E-Mobility and Vehicle Lifetime Solutions, despite a decline in Bearings & Industrial Solutions.

Report Scope

Report Features Description Market Value (2023) USD 556.3 Million Forecast Revenue (2033) USD 950.2 Million CAGR (2024-2033) 5.5% Base Year for Estimation 2023 Historic Period 2019-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered Based on Type (Topside Bolt Tensionersm Sub Sea Bolt Tensioners, Wind Bolt Tensioners), Based on Application (Oil and Gas, Wind & Power Generation, Industrial, Other Applications) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Atlas Copco AB, SKF AB, SPX FLOW (SPX Corporation), HYTORC, Siempelkamp Tensioning Systems, WREN HYDRAULICS, Pilgrim International, Nord-Lock, Hi-Force, SCHAAF GmbH, Beck Industries, FPT – Fluid Power Technology., Hydraulics Technology Inc. (HTI), TorcUp Inc., ITH bolting technology, Powermaster Engineers Pvt Ltd., Technofast Industries Pty Ltd, Other Key Players Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Hydraulic Bolt Tensioner MarketPublished date: October 2024add_shopping_cartBuy Now get_appDownload Sample

Hydraulic Bolt Tensioner MarketPublished date: October 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- Atlas Copco AB

- SKF AB

- SPX FLOW (SPX Corporation)

- HYTORC

- Siempelkamp Tensioning Systems

- WREN HYDRAULICS

- Pilgrim International

- Nord-Lock

- Hi-Force

- SCHAAF GmbH

- Beck Industries

- FPT – Fluid Power Technology.

- Hydraulics Technology Inc. (HTI)

- TorcUp Inc.

- ITH bolting technology

- Powermaster Engineers Pvt Ltd.

- Technofast Industries Pty Ltd

- Other Key Players