Global Acrylic Solid Surface Market By Structure Type (Pure Acrylic, and Modified Acrylic), By End-Use (Commercial Spaces, Hotels & Restaurants, Healthcare & Medical Facilities, Residential, Public Buildings, and Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: Dec 2024

- Report ID: 31219

- Number of Pages: 271

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

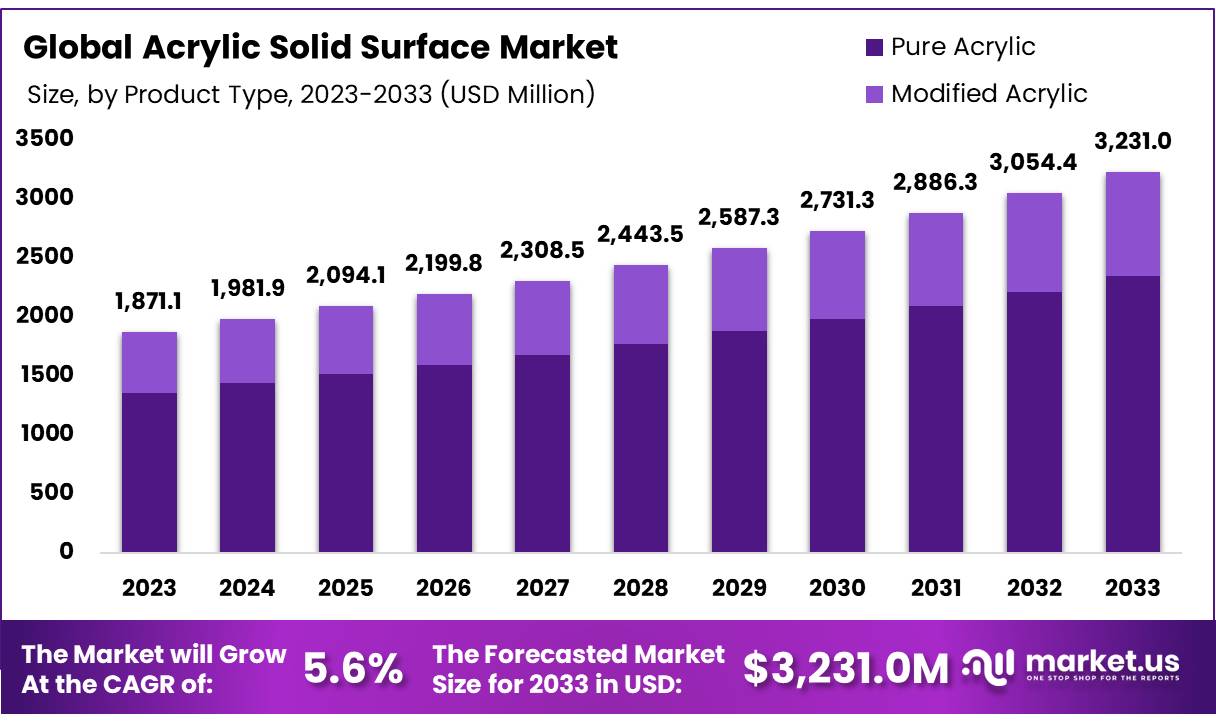

The Global Acrylic Solid Surface Market size is expected to be worth around USD 3231.0 Million by 2033, from USD 1,871.1 Million in 2023, growing at a CAGR of 5.6% during the forecast period from 2024 to 2033.

Acrylic solid surface is a man-made material typically used for countertop and surface applications in both residential and commercial settings. It is composed primarily of a mixture of acrylic polymer and alumina trihydrate (ATH), a material derived from bauxite ore. This composition provides the surfaces with their durable and non-porous characteristics.

The global acrylic solid surface market is experiencing substantial growth, driven by its widespread adoption in residential and commercial sectors for applications such as countertops, bathroom vanities, and wall paneling. This market’s expansion is fueled by the material’s desirable properties, including durability, ease of maintenance, and aesthetic versatility, which make it a preferred choice over traditional materials such as natural stone.

Acrylic solid surfaces are highly valued for their ability to be molded into various shapes and their seamless appearance, which is especially important in modern, minimalist designs. The material’s non-porous nature not only resists stains and microbes, making it ideal for kitchens and bathrooms, but also simplifies cleaning and maintenance, enhancing its appeal in healthcare and food service industries, where hygiene is paramount.

The global acrylic solid surface market is poised for continued growth, with advancements in material science and rising consumer demand for durable, stylish, and hygienic surfaces driving its expansion.

Key Takeaways

- The global acrylic solid surface market was valued at US$ 1,871.1 million in 2023.

- The global acrylic solid surface market is projected to reach US$ 3,231.0 million by 2033.

- Among product types, the pure acrylic product type held the majority of the revenue share at 72.6%.

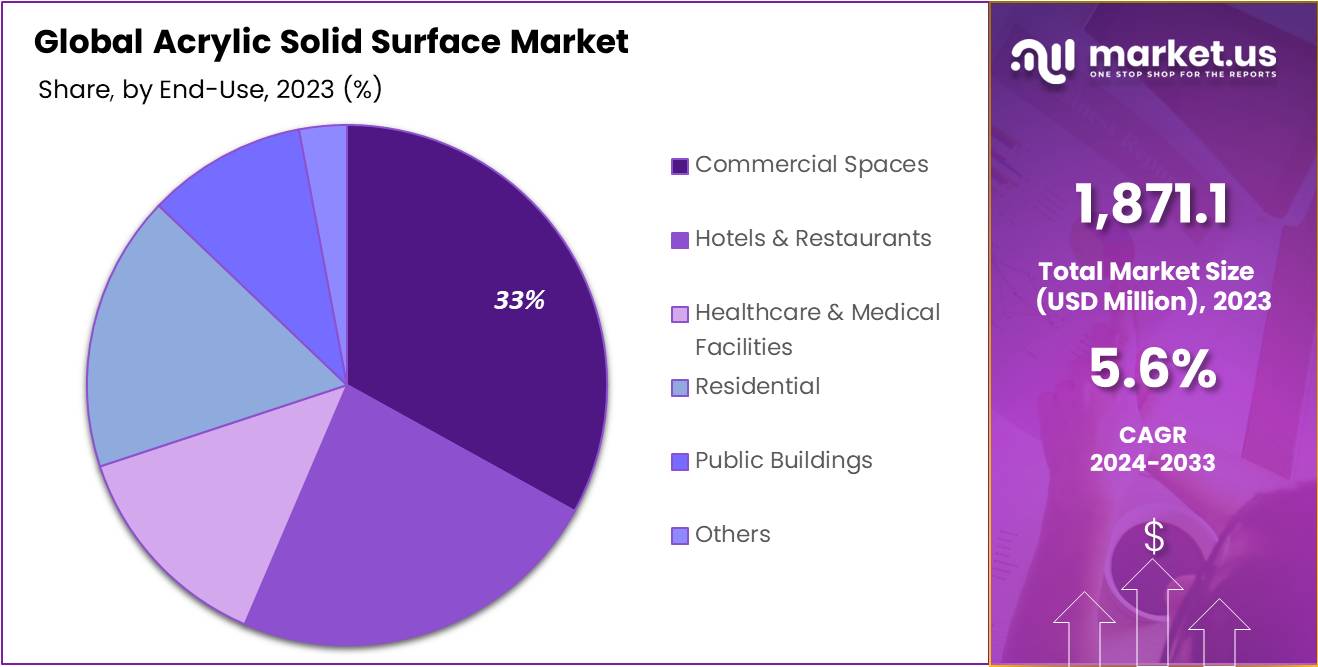

- Among these end-uses, commercial spaces accounted for the majority of the market share with 33.1%.

Product Type Analysis

Pure Acrylic is Widely Used Due To Its Enhanced Durability

The acrylic solid surface market is segmented based on product type into pure acrylic and modified acrylic. Among these, the pure acrylic type solid surface held the majority of revenue share in 2023, with a market share of 68.8%. This predominance is attributable to factor such as superior material properties and ease of maintenance as well as repair of these materials.

Pure acrylic solid surfaces are composed entirely of acrylic resin, resulting in enhanced durability, non-porosity, and resistance to stains and chemicals. These attributes make them particularly suitable for high-traffic areas and applications requiring stringent hygiene standards, such as healthcare facilities and kitchens.

The non-porous nature of pure acrylic surfaces ensures they are easy to clean and maintain. Additionally, minor damages such as scratches can often be repaired through sanding or buffing, extending the material’s lifespan and appeal to cost-conscious consumers.

End-Use Analysis

Commercial Spaces are the Major End-Users of Acrylic Solid Surfaces

Based on end-uses, the market is segmented into commercial spaces, hotels & restaurants, healthcare & medical facilities, residential, public buildings, others. Among these end-uses, commercial spaces accounted for the majority of the market share with 33.1%. Acrylic solid surfaces are renowned for their robustness and low maintenance requirements. These characteristics make them ideal for high-traffic commercial environments, such as retail stores and office buildings, where surfaces are subject to frequent use and require longevity.

The material offers a wide range of colors and patterns, allowing businesses to customize interiors that align with their brand identity. This adaptability is particularly beneficial in creating appealing customer-facing areas, enhancing the overall aesthetic appeal of commercial establishments. The non-porous nature of acrylic solid surfaces prevents the absorption of liquids and inhibits bacterial growth. This feature is crucial in commercial settings such as restaurants and healthcare facilities, where maintaining high hygiene standards is imperative.

Key Market Segments

By Product Type

- Pure Acrylic

- Modified Acrylic

By End-Use

- Commercial Spaces

- Hotels & Restaurants

- Healthcare & Medical Facilities

- Residential

- Public Buildings

- Others

Drivers

Growing Infrastructure and Construction Projects Are Anticipated Factor Which Is Boosting the Market’s Growth

The global acrylic solid surface market is experiencing substantial growth, largely driven by the increasing number of infrastructure and construction projects worldwide. The demand for high-performance, durable, and aesthetically versatile materials has surged as urbanization accelerates, particularly in emerging economies.

Acrylic solid surfaces, known for their seamless appearance, durability, and ease of maintenance, are becoming a preferred material in various construction sectors, including residential, commercial, healthcare, and public buildings.

The rapid pace of urbanization in emerging regions has triggered a need for new residential buildings, commercial spaces, and public infrastructure, thereby boosting the demand for versatile building materials such as acrylic solid surfaces.

In Asia-Pacific, particularly in China and India, large-scale urbanization projects and smart city initiatives are driving the need for modern and durable materials. The construction sector in China alone contributes to over 30% of the country’s GDP, and ongoing mega projects such as Beijing’s Daxing International Airport and numerous high-rise buildings have significantly increased the adoption of acrylic solid surfaces for countertops, cladding, and interior applications.

Restraints

Competition from Alternative Materials Impact the Adoption of Acrylic Solid Surface

Competition from alternative materials significantly impacts the adoption and growth of the acrylic solid surface market globally. Materials such as quartz, granite, and laminates pose substantial challenges due to their unique advantages.

For instance, quartz is highly regarded for its robustness and variety of designs, which often mimic natural stone with greater durability and less maintenance. Granite, while requiring more upkeep, appeals to consumers seeking natural aesthetics and longevity. Laminates offer a cost-effective alternative with a wide range of patterns and colors, though they lack the durability and repairability of acrylic solid surfaces.

These alternatives directly compete with acrylic solid surfaces in key areas like cost, aesthetic appeal, and perceived quality. Each material’s unique properties can sway consumer and commercial preferences, especially in markets sensitive to price and specific design requirements. For example, in high-end residential and commercial projects, the preference might lean towards natural stone for its premium look and status, despite the higher maintenance involved.

Moreover, technological advancements in the production of these competing materials have improved their stain and scratch resistance, challenging one of the key selling points of acrylic solid surfaces. As these materials continue to evolve, they can potentially erode the market share of acrylic solid surfaces unless manufacturers innovate in terms of product quality, environmental impact, and application versatility.

Thus, while acrylic solid surfaces remain popular due to their seamless finish and design flexibility, the competitive pressure from these alternative materials necessitates continuous innovation and strategic marketing to sustain growth in the global market.

Opportunity

Technological Integration in Manufacturing Process May Create Lucrative Opportunities For Emerging Manufacturers

Technological integration in the manufacturing process of acrylic solid surfaces presents lucrative opportunities for emerging manufacturers to carve a niche in the global market. By adopting advanced technologies such as automated production lines, CNC machinery, and 3D printing, new entrants can enhance efficiency, reduce production costs, and improve product quality.

These technologies enable precision in the manufacturing process, allowing for the creation of complex and customized designs that meet specific customer demands.

Moreover, the integration of digital tools can streamline operations, from design through production to quality control, ensuring consistency and reducing waste. Emerging manufacturers can also leverage technology to develop eco-friendly production processes, which are increasingly important in the market.

Innovations such as the use of recycled materials or the development of lower-emission manufacturing techniques can differentiate these new players from established competitors. Additionally, technology facilitates scalability, enabling small-scale manufacturers to adjust production volumes easily based on market demands without significant capital investment.

Trends

Technological Advancements and Product Innovation Such as Antibacterial Acrylic Solid Surface

Continued innovation in the development of acrylic solid surfaces presents significant opportunities for market expansion. Technological advancements, such as improved UV resistance, enhanced color stability, and the introduction of antimicrobial surfaces, can attract new customers in various sectors.

Additionally, offering surfaces that mimic the appearance of more expensive materials like marble or granite can help the acrylic solid surface market compete with natural stone, appealing to cost-conscious consumers looking for luxury at an affordable price.

With growing demand for hygienic, durable, and high-performance materials, manufacturers are focusing on developing surfaces that offer enhanced functionality. Antibacterial acrylic surfaces, for example, incorporate antimicrobial agents during production, providing continuous protection against bacteria, mold, and mildew. These surfaces are particularly favored in healthcare, food service, and hospitality sectors where hygiene is paramount.

Geopolitical Impact Analysis

Geopolitical Tensions Significantly Impacted the Growth of the Acrylic Solid Surface Market

The production of acrylic solid surfaces heavily relies on petrochemical derivatives, such as polymethyl methacrylate (PMMA), which is produced from crude oil. The Russia-Ukraine conflict significantly affected global oil prices due to disruptions in oil and natural gas supply chains, particularly in Europe. Russia is a major global supplier of energy, and sanctions imposed on the country led to a spike in oil prices, which in turn increased the cost of petrochemical raw materials.

This rise in raw material costs directly impacted the acrylic solid surface industry, as manufacturers faced higher production expenses. In 2022, crude oil prices experienced significant volatility, and this translated into fluctuating prices for PMMA, resins, and other key materials used in acrylic solid surfaces. Smaller manufacturers with less purchasing power were especially vulnerable, as they found it difficult to absorb these additional costs, potentially leading to reduced profit margins or the need to pass on cost increases to consumers.

The geopolitical conflicts of 2022-2023, particularly the Russia-Ukraine war, had wide-ranging effects on the global acrylic solid surface industry. Rising raw material and energy costs, supply chain disruptions, trade sanctions, and inflationary pressures all contributed to a challenging environment for manufacturers.

Europe was particularly affected, with high energy costs and reduced demand for construction materials, while other regions also experienced slower market growth due to these macroeconomic disruptions. Moving forward, manufacturers in the acrylic solid surface market will need to adapt by diversifying supply chains, exploring new markets, and embracing sustainability trends to mitigate the impact of geopolitical risks.

Regional Analysis

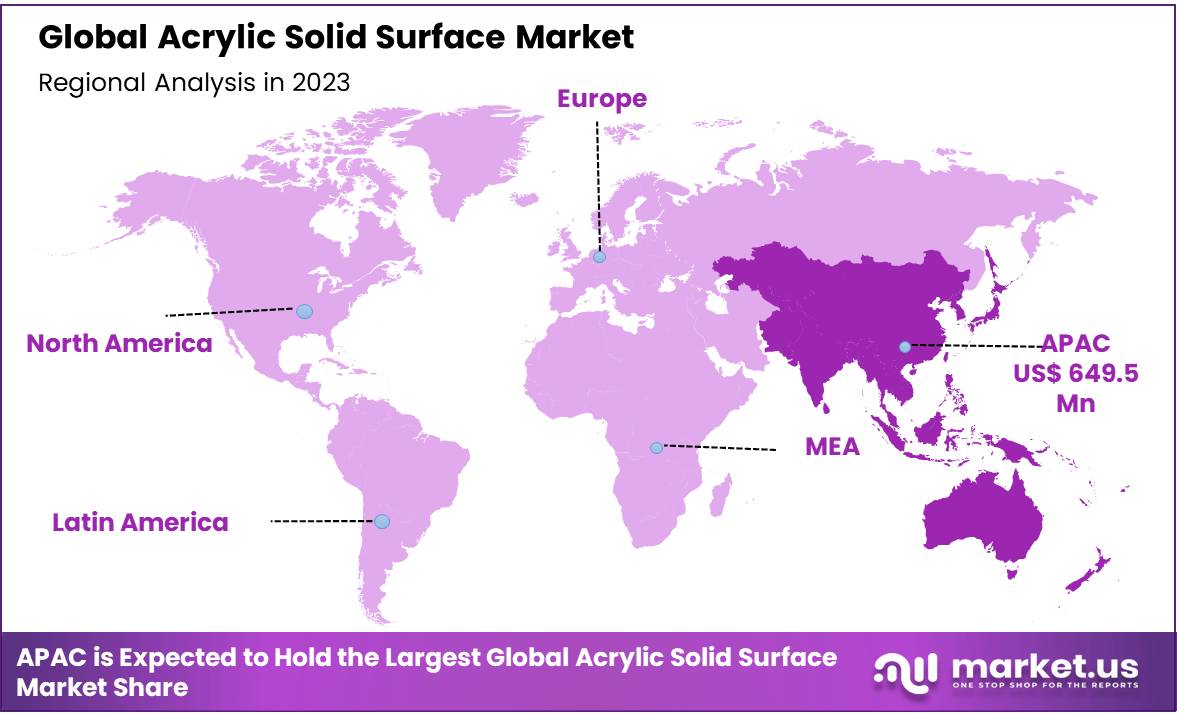

Asia-Pacific Dominated The Market Among Other Regions Owing to Their Strong Focus on Strategic Energy Policies

In 2023, Asia-Pacific held the largest market share of Acrylic Solid Surface with 34.7%. This dominance can be attributed to rapid urbanization and infrastructure development as well as growing construction industry. Countries within the Asia-Pacific region, notably China and India, have experienced significant urbanization and infrastructure expansion.

This growth has led to increased construction activities, thereby elevating the demand for durable and aesthetically pleasing building materials such as acrylic solid surfaces.

The surge in residential and commercial construction projects has bolstered the need for versatile materials. Acrylic solid surfaces are favored for their adaptability in design and ease of maintenance, making them suitable for various applications, including countertops, wall claddings, and furniture. The economic advancement in the region has led to higher disposable incomes, enabling consumers to invest in premium interior materials.

This economic prosperity has contributed to the increased adoption of acrylic solid surfaces in both residential and commercial settings. The region’s abundant raw materials and affordable labor costs have facilitated the production and supply of acrylic solid surfaces, making them more accessible and competitively priced in the market.

Key Regions and Countries

- North America

- The US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia & CIS

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- ASEAN

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

Market Players In The Acrylic Solid Surface Industry Are Evolving Through Various Strategies To Maintain Their Dominance.

Companies are investing in research and development to introduce new products with enhanced features, such as improved durability, a broader range of colors, and advanced designs. This approach caters to evolving consumer preferences and differentiates their offerings in a competitive market.

To tap into emerging markets, particularly in the Asia-Pacific region, firms are establishing new manufacturing facilities and expanding their distribution networks. This strategy aims to meet the growing demand in these areas and capitalize on regional growth opportunities.

Market Key Players

The adoption of advanced manufacturing technologies, such as automation and precision engineering, is enhancing production efficiency and product quality. These technological improvements enable companies to offer superior products at competitive prices, thereby maintaining their market competitiveness.

- DuPont de Nemours, Inc.

- Lotte Chemical Corporation

- Trinseo SA

- LX Hausys

- Wilsonart LLC

- Porcelanosa Group

- Hyundai L&C Corporation

- Plastiglas de Mexico S.A. C.V.

- Stylam Industries Ltd.

- Meganite

- Durlax Top Surface Limited

- Akrilika Kholing

- Renewed Materials, Inc.

- Other Key Players

Recent Development

- In April, 2024, Corian Design is excited to unveil the new 2024 Corian Quartz aesthetics, inspired by the classic and enduring beauty of stone and quartzite. These designs bring the grandeur of nature indoors, enhancing both residential and commercial spaces with their majestic appeal.

- In June, 2023, Trinseo, a provider of specialty material solutions, has introduced the Riverine Collection a nature-inspired palette to its AVONITE Acrylic Solid Surface lineup.

Report Scope

Report Features Description Market Value (2023) US$ 1,871.1 Mn Market Volume (KT) XX Forecast Revenue (2033) US$ 3,231.0 Mn CAGR (2024-2032) 5.6% Base Year for Estimation 2023 Historic Period 2020-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Structure Type (Pure Acrylic, and Modified Acrylic), By End-Use (Commercial Spaces, Hotels & Restaurants, Healthcare & Medical Facilities, Residential, Public Buildings, and Others Regional Analysis North America – The US & Canada; Europe – Germany, France, The UK, Spain, Italy, Russia & CIS, Rest of Europe; APAC– China, Japan, South Korea, India, ASEAN & Rest of APAC; Latin America– Brazil, Mexico & Rest of Latin America; Middle East & Africa– GCC, South Africa, & Rest of MEA Competitive Landscape DuPont de Nemours, Inc., Lotte Chemical Corporation, Trinseo SA, LX Hausys, Wilsonart LLC, Porcelanosa Group, Hyundai L&C Corporation, Plastiglas de Mexico S.A. C.V, Stylam Industries Ltd, Meganite, Durlax Top Surface Limited, Renewed Materials, Inc. and Akrilika Kholing Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate User License (Unlimited User and Printable PDF)  Acrylic Solid Surface MarketPublished date: Dec 2024add_shopping_cartBuy Now get_appDownload Sample

Acrylic Solid Surface MarketPublished date: Dec 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- DuPont de Nemours, Inc.

- Lotte Chemical Corporation

- Trinseo SA

- LX Hausys

- Wilsonart LLC

- Porcelanosa Group

- Hyundai L&C Corporation

- Plastiglas de Mexico S.A. C.V.

- Stylam Industries Ltd.

- Meganite

- Durlax Top Surface Limited

- Akrilika Kholing

- Renewed Materials, Inc.

- Other Key Players