Global 4D Printing Market By Material (Programmable Carbon Fiber, Programmable Textiles, Programmable Bio material, Others), By End User (Healthcare, Aerospace and Defense, Automotive, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2024-2033

- Published date: July 2024

- Report ID: 124654

- Number of Pages: 219

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

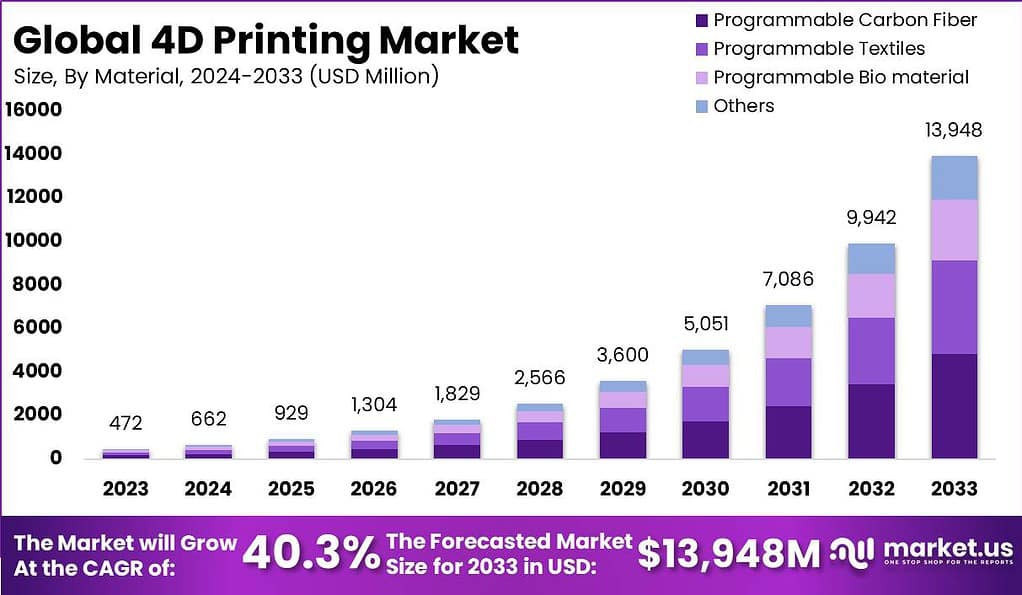

The Global 4D Printing Market size is expected to be worth around USD 13,948 Million By 2033, from USD 472 Billion in 2023, growing at a CAGR of 40.3% during the forecast period from 2024 to 2033.

4D printing, an evolution of 3D printing technology, introduces the dimension of time into the objects it creates. This innovative process allows printed objects to change shape or self-assemble over time in response to external stimuli such as temperature, light, or moisture. It leverages smart materials, which can be programmed to exhibit specific behaviors in response to environmental conditions.

The 4D Printing Market is set to redefine many industries by introducing the next evolution in additive manufacturing. This innovative technology is not only about creating objects but also about enabling them to change shape and functionality over time in response to external stimuli such as temperature, light, or moisture.

The growth of this market can be attributed to its potential applications across various sectors including healthcare, construction, and automotive industries, where it offers solutions for complex problems through smart materials and self-assembling structures. One of the key growth factors for 4D printing is its wide range of potential applications. From healthcare to architecture and beyond, the ability to create objects that can adapt and respond to external stimuli opens up a world of possibilities.

For instance, in the medical field, 4D printing could lead to the development of implants or prosthetics that can adjust and grow with the patient, improving treatment outcomes. Similarly, in architecture, 4D printing could enable the construction of structures that can self-assemble or change shape based on environmental conditions, enhancing energy efficiency and functionality.

According to Market.us, the size of the Global 3D Printing Market is projected to reach approximately USD 135.4 Billion by 2033, up from USD 19.8 Billion in 2023. This represents a Compound Annual Growth Rate (CAGR) of 21.2% during the forecast period from 2024 to 2033.There are significant opportunities for growth and innovation in the 4D printing market. Researchers, companies, and institutions are actively exploring and advancing the technology, pushing the boundaries of what is possible. As the technology matures and becomes more accessible, we can expect to see a wider adoption of 4D printing in various industries, leading to new and exciting applications.

However, there are several challenges that need to be addressed for 4D printing to reach its full potential. One of the main challenges is the development of suitable materials with the desired properties for self-transformation. Creating materials that can reliably and predictably change their shape or properties in response to specific triggers is a complex task. Additionally, refining the printing processes and ensuring cost-effectiveness are ongoing challenges that need to be overcome.

Key Takeaways

- The 4D Printing Market is projected to reach a valuation of approximately USD 13,948 Million by 2033, up from USD 472 Million in 2023, reflecting a compound annual growth rate (CAGR) of 40.3% during the forecast period from 2024 to 2033.

- In the year 2023, the Programmable Carbon Fiber segment achieved a significant share in the 4D printing market, representing 34.6% of the total market.

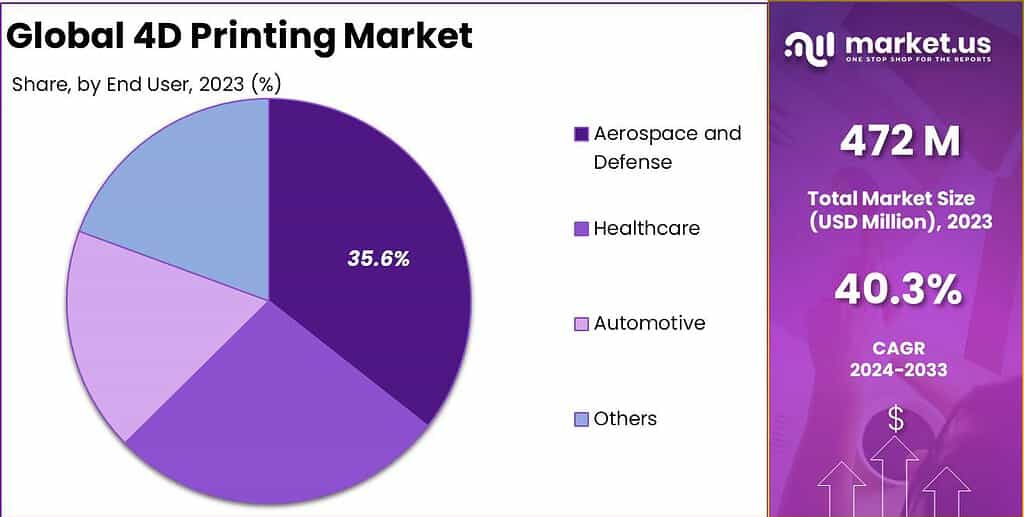

- Similarly, the Aerospace and Defense segment was predominant in the 4D printing market in 2023, securing 35.6% of the market share.

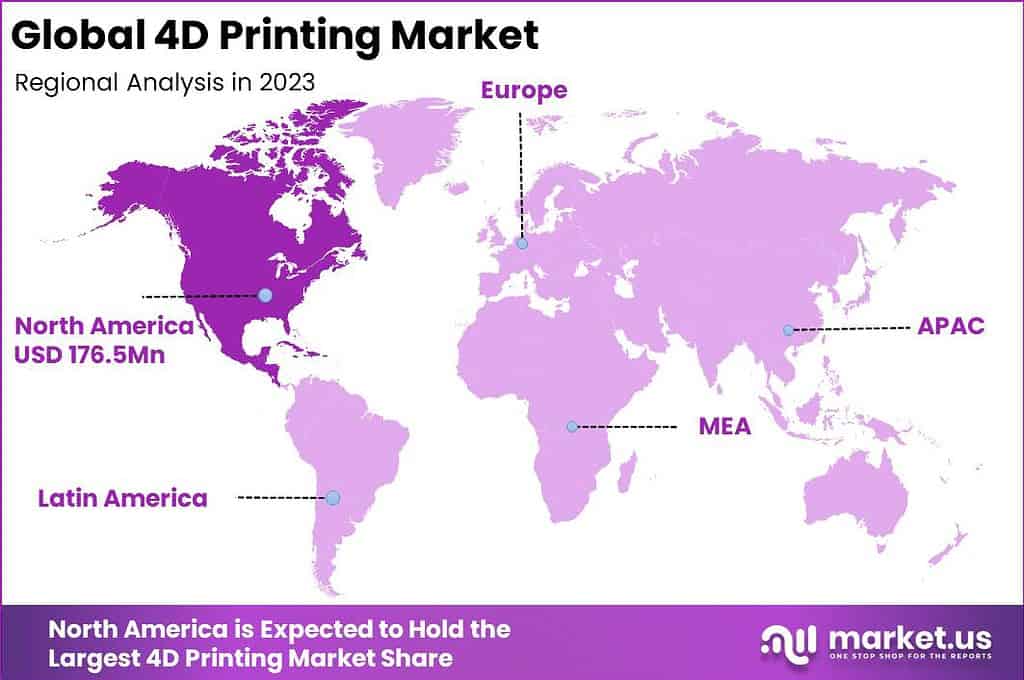

- In the regional analysis, North America emerged as the leading market for 4D printing in 2023, holding 37.4% of the global market with revenues totaling USD 176.5 Million.

Material Analysis

In 2023, the Programmable Carbon Fiber segment held a dominant market position in the 4D printing market, capturing more than a 34.6% share. This leading stance is primarily due to the superior properties of programmable carbon fiber, which include high strength-to-weight ratio, durability, and flexibility in design. These characteristics make it highly sought after in sectors that demand robust material performance such as aerospace, automotive, and sports equipment.

Programmable carbon fiber’s edge in the market is further sharpened by its adaptability in complex manufacturing scenarios. Unlike traditional materials, programmable carbon fiber can be engineered to change its properties in response to environmental stimuli. This adaptability opens up new applications in creating more efficient and responsive products, which can dynamically alter their structure for optimal performance. For example, in aerospace, components made of this material can adjust to temperature changes, reducing the need for additional mechanical parts and thus, lowering the overall weight of the aircraft.

The future growth of this segment is underpinned by continuous advancements in material science and digital manufacturing technologies. As research deepens our understanding and improves the cost-effectiveness of producing programmable carbon fibers, their applications are expected to expand. This will likely include innovations in energy efficiency, where materials can automatically adjust to optimize energy consumption, and in medical devices, where implants and supports can better adapt to the body’s needs over time.

Thus, the Programmable Carbon Fiber segment’s prominence in the 4D printing market is not only a reflection of its current applications but also an indicator of its potential to revolutionize multiple industries with smarter, more adaptive solutions. This segment is poised for further expansion as both technological advances and sectoral demands drive its growth.

End User Analysis

In 2023, the Aerospace and Defense segment held a dominant market position in the 4D printing market, capturing more than a 35.6% share. This leadership is largely attributed to the critical need for innovative materials that can adapt and perform under extreme conditions, which are commonly experienced in aerospace and defense environments.

Programmable materials in 4D printing offer the ability to change shape, repair themselves, or adjust their functionalities in response to environmental triggers, such as pressure and temperature changes, making them invaluable for these sectors.

The importance of 4D printing in aerospace and defense is further emphasized by its contribution to reducing the weight of components and enhancing the performance of military and aerospace machinery. For instance, parts that can adapt their aerodynamic properties in real-time can significantly improve fuel efficiency and the overall performance of aircraft. Additionally, the use of 4D printing in manufacturing parts that can self-adjust or repair on the battlefield provides strategic advantages in defense operations.

Moreover, the push for more sustainable practices within the aerospace and defense industry aligns well with the capabilities of 4D printing technologies. By enabling the creation of more efficient designs and reducing material waste, 4D printing supports the industry’s shift towards sustainability. The potential for 4D printed materials to be reused or recycled also presents future opportunities for cost savings and environmental benefits.

Overall, the Aerospace and Defense segment’s prominence in the 4D printing market is well-supported by the sector’s demand for advanced, reliable, and efficient technologies. As the capabilities of 4D printing continue to evolve, it is expected that its integration into aerospace and defense will deepen, driving further innovations and market growth.

Key Market Segments

By Material

- Programmable Carbon Fiber

- Programmable Textiles

- Programmable Bio material

- Others

By End User

- Aerospace and Defense

- Healthcare

- Automotive

- Others

Driver

Integration of 4D Printing with IoT and AI Technologies

The 4D printing market is significantly driven by its integration with IoT and AI technologies, which enhances its applications across various industries. This convergence allows for the creation of smarter and more adaptive structures that can interact with their environment and respond to changes in real-time.

For instance, in sectors like healthcare and automotive, this integration facilitates the development of parts that can change their properties or behaviors in response to specific stimuli or requirements, leading to more efficient and effective solutions. Such technological advancements not only improve the functionality of 4D printed materials but also broaden their potential applications, contributing to the market’s growth.

Restraint

High Cost and Complexity of Development

Despite its potential, the 4D printing market faces significant restraints due to the high costs associated with developing and implementing these technologies. The complexity of designing materials that can change properties over time requires substantial investment in research and development.

Moreover, the technology’s nascent stage means that there are fewer off-the-shelf solutions available, which increases the barrier to entry for many firms. These factors can limit the adoption of 4D printing technologies, particularly in industries where cost-efficiency is a crucial factor.

Opportunity

Advancements in Material Science

The ongoing advancements in material science present major opportunities for the 4D printing market. Researchers are continuously developing new materials that can respond to environmental stimuli with greater efficiency and reliability.

Such materials are crucial for expanding the practical applications of 4D printing in industries like aerospace, where materials that can alter their shape or properties in response to environmental changes can significantly enhance performance and safety. The ability to create more sophisticated and versatile materials also opens up new market segments for 4D printing, promising continued growth and innovation.

Challenge

Skill Gap in the Workforce

One of the major challenges facing the 4D printing industry is the skill gap in the workforce. The advanced nature of 4D printing technologies requires specialized knowledge and skills that are currently scarce in the job market. This lack of skilled professionals can hinder the development and widespread adoption of 4D printing applications.

Addressing this challenge is crucial for the growth of the industry, necessitating targeted educational programs and training initiatives to equip workers with the necessary skills to operate and innovate within this high-tech field.

Growth Factors

The 4D Printing Market is experiencing significant growth due to a convergence of technological advancements, sustainability efforts, and increasing demands for customization. Key growth factors include continuous innovations in additive manufacturing, which have expanded the capabilities and applications of 4D printing. The integration of IoT and AI technologies enhances the functionality of 4D-printed materials, making them adaptable in real-time, which is crucial for complex operations in industries such as aerospace and defense.

Additionally, the push for sustainability has made 4D printing a more attractive option due to its efficiency and reduced waste in manufacturing processes. Support from research and development activities, along with government backing, further stimulates the market by fostering a favorable environment for technological advancements.

Emerging Trends

Emerging trends in the 4D Printing Market are shaping its future across various sectors. There is a significant focus on the development of new programmable materials that can dynamically respond to environmental changes. In healthcare, 4D printing is being explored for creating more dynamic implants and drug delivery systems that adapt to the body’s needs over time.

The consumer sector is also seeing innovations with personalized products and apparel that adjust to environmental conditions or user preferences. In the realm of architecture and construction, 4D printing holds the potential for creating structures that adapt to weather changes, offering economic and environmental benefits.

Furthermore, collaborations between academic institutions and industry leaders are crucial in transitioning 4D printing from research labs to market applications, bridging the gap between theory and practical use. These factors and trends collectively highlight the transformative potential of the 4D printing market across diverse industries.

Regional Analysis

In 2023, North America held a dominant market position in the 4D Printing Market, capturing more than a 37.4% share with revenues amounting to USD 176.5 million. This leadership is largely attributed to the region’s robust technological infrastructure and strong governmental support for research and innovation in advanced manufacturing technologies.

North America is home to some of the world’s leading tech firms and research institutions that are at the forefront of developing and applying 4D printing technologies across various industries, including aerospace, automotive, and healthcare. The region’s focus on fostering innovation ecosystems has enabled significant advancements in material science and additive manufacturing, contributing to the growth of the 4D printing market.

Moreover, North America’s stringent regulatory standards in industries such as healthcare and automotive have propelled the demand for more advanced and reliable manufacturing solutions, including 4D printing, to meet these rigorous requirements.

Furthermore, the strategic partnerships between academic institutions and industry giants in North America have played a crucial role in transitioning 4D printing from experimental technology to commercial applications. These collaborations have facilitated the development of new programmable materials and the refinement of 4D printing processes, ensuring that North America remains at the cutting edge of this transformative technology.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

The 4D Printing Market, characterized by its advanced manufacturing processes involving programmable materials, is driven by several key players that have significantly shaped the landscape through strategic actions like acquisitions, new product launches, and mergers.

Stratasys Ltd., a leader in this arena, continues to innovate with new products that advance 4D printing capabilities. They have recently expanded their portfolio through strategic partnerships and development of new printing technologies that respond to environmental and mechanical changes.

Materialise NV, another major player, has strengthened its market position through both the launch of innovative software solutions that facilitate the design and simulation of 4D printed objects, and strategic acquisitions aimed at enhancing its technology stack and market reach.

Autodesk Inc. remains a pivotal force in the market with its continuous software advancements that support 4D printing applications. Their recent software upgrades facilitate more complex and precise designs, pushing the boundaries of what can be achieved in 4D printing.

Top Key Players in the Market

- Stratasys Ltd.

- Materialise NV

- Autodesk Inc.

- Hewlett Packard Enterprise Company

- CT Core Technology Group

- EnvisionTEC Inc.

- ExOne Corporation

- Norsk Titanium US Inc

- Materialise NV

Recent Developments

- Merger with Desktop Metal: In August 2023, Stratasys announced its plan to merge with Desktop Metal. This merger aims to combine the strengths of both companies in the 3D printing industry, enhancing their capabilities in 4D printing technology. The merger agreement includes an exchange ratio where each share of Desktop Metal’s Class A common stock will convert into 0.123 ordinary shares of Stratasys. The merger is expected to drive innovation and offer improved solutions in additive manufacturing.

- Acquisition of Innovate3D: In March 2024, Autodesk acquired Innovate3D, a company specializing in 4D printing technology. This acquisition is intended to integrate Innovate3D’s advanced materials and technologies into Autodesk’s existing suite of design and manufacturing software, expanding its capabilities in 4D printing

- New Product Launch: In May 2023, Materialise introduced a new suite of software tools aimed at optimizing 4D printing processes. These tools enhance the precision and efficiency of creating self-assembling structures, a key application of 4D printing technology.

- Partnership with SmartTech: In July 2023, HPE announced a strategic partnership with SmartTech to co-develop 4D printing solutions. This collaboration focuses on enhancing the adaptive and self-healing properties of printed materials, aiming to revolutionize sectors such as aerospace and healthcare.

Report Scope

Report Features Description Market Value (2023) USD 472 Mn Forecast Revenue (2033) USD 13,948 Mn CAGR (2024-2033) 40.3% Base Year for Estimation 2023 Historic Period 2019-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Material (Programmable Carbon Fiber, Programmable Textiles, Programmable Bio material, Others), By End User (Healthcare, Aerospace and Defense, Automotive, Others) Regional Analysis North America – The U.S. & Canada; Europe – Germany, France, The UK, Spain, Italy, Russia, Netherlands & Rest of Europe; APAC- China, Japan, South Korea, India, Australia, New Zealand, Singapore, Thailand, Vietnam & Rest of APAC; Latin America- Brazil, Mexico & Rest of Latin America; Middle East & Africa- South Africa, Saudi Arabia, UAE & Rest of MEA Competitive Landscape Stratasys Ltd., Materialise NV, Autodesk Inc., Hewlett Packard Enterprise Company, CT Core Technology Group, EnvisionTEC Inc., ExOne Corporation, Norsk Titanium US Inc, Materialise NV Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is 4D printing?4D printing is an extension of 3D printing technology that adds the dimension of transformation over time. Objects printed in 4D can change shape or properties when exposed to certain environmental conditions.

How big is 4D Printing Market?The Global 4D Printing Market size is expected to be worth around USD 13,948 Million By 2033, from USD 472 Billion in 2023, growing at a CAGR of 40.3% during the forecast period from 2024 to 2033.

What are the key factors driving the growth of the 4D Printing Market?Key factors include advancements in materials science, increasing demand for smart and adaptive materials, innovations in 3D printing technology, applications in various industries (such as healthcare, aerospace, and automotive), and the potential for reducing manufacturing and maintenance costs.

What are the current trends and advancements in the 4D Printing Market?Current trends include the development of new programmable materials, increased research in self-assembling and self-repairing materials, advancements in multi-material printing, and the integration of 4D printing with IoT for smart applications.

What are the major challenges and opportunities in the 4D Printing Market?Major challenges include high research and development costs, technical complexities, and scalability issues. Opportunities lie in creating innovative applications in medical devices, adaptive building materials, responsive textiles, and expanding the capabilities of existing 3D printing technologies.

Who are the leading players in the 4D Printing Market?Leading players include Stratasys Ltd., Materialise NV, Autodesk Inc., Hewlett Packard Enterprise Company, CT Core Technology Group, EnvisionTEC Inc., ExOne Corporation, Norsk Titanium US Inc, Materialise NV

-

-

- Stratasys Ltd.

- Materialise NV

- Autodesk Inc.

- Hewlett Packard Enterprise Company

- CT Core Technology Group

- EnvisionTEC Inc.

- ExOne Corporation

- Norsk Titanium US Inc

- Materialise NV