Global Waste Heat to Power Market Size, Share, And Industry Analysis Report By Technology (ORC, SRC, Kalina), By End Use (Petroleum Refining, Cement, Heavy Metal, Chemical, Paper, Food and Beverage, Glass), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: December 2025

- Report ID: 170197

- Number of Pages: 300

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

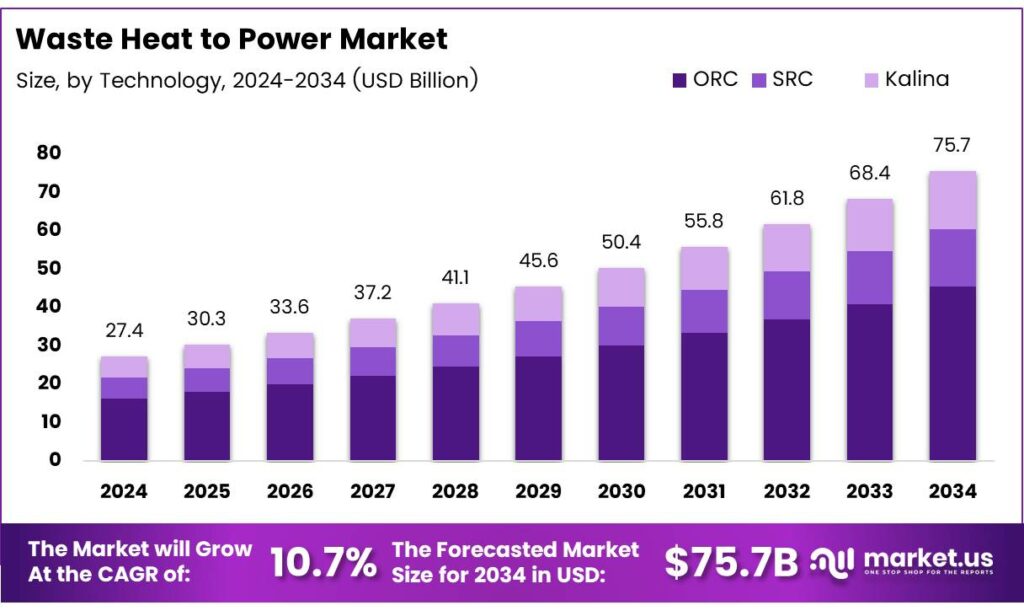

The Global Waste Heat to Power Market size is expected to be worth around USD 75.7 billion by 2034, from USD 27.4 billion in 2024, growing at a CAGR of 10.7% during the forecast period from 2025 to 2034.

The Waste Heat to Power Market focuses on converting unused industrial heat into usable electricity. It captures thermal energy released from furnaces, kilns, engines, and exhaust systems. Businesses reduce fuel costs, improve energy efficiency, and lower emissions while strengthening onsite power reliability across heavy industries. This market is moving from niche efficiency upgrades toward strategic energy infrastructure.

Growth momentum is supported by rising industrial energy intensity and tightening efficiency mandates. As manufacturers modernize plants, waste heat recovery integrates naturally with retrofits and digital energy management systems. Consequently, Waste Heat to Power solutions align well with long-term decarbonization strategies without disrupting core production processes or requiring fuel switching.

The U.S. Department of Energy explains that most waste heat is low-quality, often below 300 °F, making recovery historically uneconomical. Power generation efficiency depends strongly on the heat temperature. Therefore, economically viable projects have traditionally focused on sources above 500 °F, where conversion efficiency supports acceptable returns.

- However, technological progress is changing feasibility thresholds. Emerging organic Rankine cycle systems now recover heat below 450 °F, expanding addressable opportunities. According to U.S. DOE estimates, high-temperature waste heat above 450 °F could support nearly 7,600 MW of electric capacity, highlighting significant untapped market potential.

Therefore, cement, chemicals, food processing, and metals increasingly evaluate Waste Heat to Power projects as bankable investments rather than experimental efficiency tools. Industrial energy use represents the largest Waste Heat to Power potential. The industrial sector consumes over 33% of total domestic energy. Importantly, roughly one-third of this energy is lost as thermal discharge due to process inefficiencies and limited recovery capabilities.

Key Takeaways

- The Global Waste Heat to Power Market is projected to grow from USD 27.4 billion in 2024 to USD 75.7 billion by 2034, at a CAGR of 10.7% during 2025–2034.

- Organic Rankine Cycle (ORC) leads the market with a dominant share of 67.2% in 2024, driven by flexibility across low- to medium-temperature heat sources.

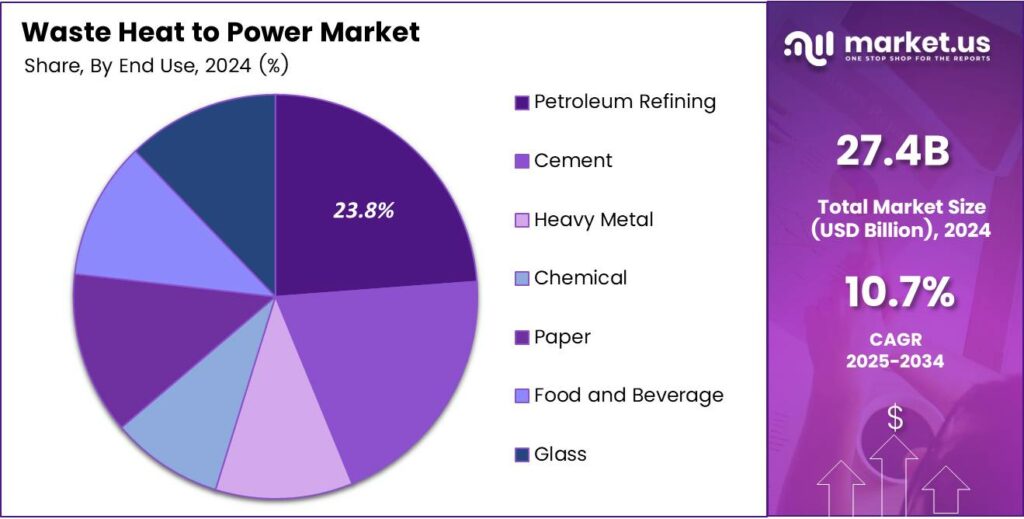

- Petroleum Refining holds the largest share at 23.8% in 2024, supported by continuous operations and high-temperature exhaust availability.

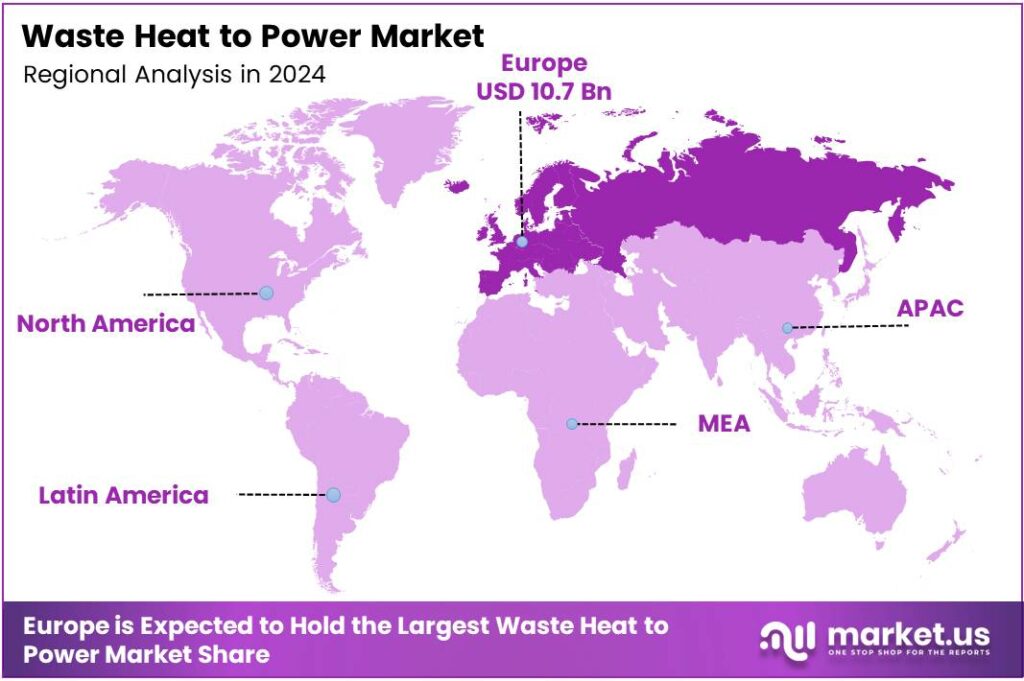

- Europe dominates the regional landscape with a market share of 39.4%, representing a valuation of USD 10.7 billion in 2024.

By Technology Analysis

ORC dominates with 67.2% due to its flexibility, modular design, and suitability for low- to medium-temperature heat sources.

In 2024, ORC held a dominant market position in the By Technology Analysis segment of the Waste Heat to Power Market, with a 67.2% share. It is widely adopted because it works efficiently with variable heat streams. As a result, industries prefer ORC for reliable, long-term waste heat recovery projects.

The SRC sub-segment continues to play a supportive role in specific industrial environments. It is mainly applied where water-based steam cycles integrate easily with existing systems. However, its dependence on higher operating pressures and maintenance needs limits broader adoption compared with ORC-based solutions across diverse industrial sites.

Kalina technology serves niche applications requiring better performance under fluctuating temperatures. It uses ammonia-water mixtures to improve thermodynamic efficiency. Still, system complexity and higher upfront engineering requirements slow widespread uptake. Therefore, Kalina remains selective despite its technical advantages in certain waste heat conditions.

By End Use Analysis

Petroleum Refining dominates with 23.8% driven by continuous operations and high-temperature exhaust streams.

In 2024, Petroleum Refining held a dominant market position in the By End Use Analysis segment of the Waste Heat to Power Market, with a 23.8% share. Refineries generate consistent high-grade waste heat. Therefore, Waste Heat to Power systems fit well into refinery efficiency and emission-reduction strategies.

The Cement sub-segment follows closely due to energy-intensive kiln operations. Large volumes of exhaust heat enable steady power generation. Meanwhile, rising fuel costs push cement producers to recover heat internally. As a result, Waste Heat to Power improves operating margins without affecting clinker production stability.

Heavy Metal and Chemical industries adopt Waste Heat to Power to manage thermal losses from furnaces and reactors. These sectors benefit from improved energy efficiency and reduced grid dependence. Although integration can be complex, gradual plant modernization encourages steady adoption across both industries.

Paper, Food and Beverage, and Glass sub-segments use Waste Heat to Power for process heating and power balance optimization. While temperatures are generally lower, continuous operations support recovery economics. Therefore, these industries increasingly evaluate modular systems to enhance sustainability and energy cost control.

Key Market Segments

By Technology

- ORC

- SRC

- Kalina

By End Use

- Petroleum Refining

- Cement

- Heavy Metal

- Chemical

- Paper

- Food and Beverage

- Glass

Emerging Trends

Shift Toward Advanced Organic Rankine Cycle Systems

A key trend in the Waste Heat to Power market is the growing use of Organic Rankine Cycle (ORC) technology. ORC systems can efficiently recover power from low- and medium-temperature heat, expanding WHP adoption beyond traditional heavy industries.

- Modular and skid-mounted WHP units are also gaining popularity. These systems reduce installation time and make projects easier to scale, especially for mid-sized plants. The U.S. Department of Energy, between 20% and 50% of industrial energy input is lost as waste heat through exhaust gases, cooling water, and heat escaping from equipment.

Digital monitoring and automation are improving system reliability and performance. Smart controls help optimize power output based on real-time heat availability, lowering operational risks. The integration of WHP with broader energy-management systems. Industries are combining WHP with solar, batteries, and smart grids to build hybrid energy solutions.

Drivers

Rising Industrial Energy Efficiency Needs Drive Waste Heat Recovery

Industries across cement, steel, chemicals, oil refining, and glass are under constant pressure to reduce energy costs. A large share of energy used in these sectors is lost as heat during production processes. Waste Heat to Power (WHP) systems help convert this unused heat into electricity, improving overall energy efficiency.

- High electricity prices in many regions are pushing factories to look for self-generated power options. WHP allows plants to reduce dependence on grid electricity and stabilize operating costs. According to the International Energy Agency (IEA), data centers currently use about 1.5% of global electricity demand, and this figure is expected to double by 2030 as computational needs grow.

Stricter environmental regulations are another strong driver. Governments are encouraging industries to cut emissions and improve energy utilization. WHP systems reduce fuel consumption and lower carbon emissions without changing core production processes.

Restraints

High Initial Capital Cost Limits Wider Adoption

One of the main restraints in the Waste Heat to Power market is the high upfront investment. Installing WHP systems requires advanced equipment such as heat recovery boilers, turbines, and control systems. These costs can be difficult for small and medium-sized industries to manage.

- The International Energy Agency highlights an eye-opening fact: nearly 4,000 wastewater treatment plants in Europe are located within 2 km of district heating networks, and collectively they could deliver about 175 terawatt-hours (TWh) of heat per year if integrated with heat pumps and reuse technologies.

Project complexity is another challenge. Each WHP system must be customized based on the type of industry, temperature level, and heat availability. This increases engineering time and project risk, slowing decision-making. Limited technical awareness also restricts adoption in developing regions. Many industries are still unfamiliar with WHP benefits or lack skilled personnel to operate and maintain these systems.

Growth Factors

Government Support for Decarbonization Creates New Growth Paths

Global focus on decarbonization is opening strong growth opportunities for the Waste Heat to Power market. Governments are promoting cleaner industrial practices through incentives, tax benefits, and energy-efficiency programs. These policies improve project economics and encourage investment.

Emerging economies are expanding cement, steel, and chemical production to support infrastructure growth. New plants offer ideal opportunities to integrate WHP systems during the design stage, reducing installation challenges. Rising demand for captive power generation also supports growth.

Industries want reliable, on-site electricity to avoid grid disruptions. WHP fits well into this strategy by using existing heat sources. Technological improvements are expanding WHP use to lower-temperature heat sources. This increases application potential across the food processing, paper, and textile industries.

Regional Analysis

Europe Dominates the Waste Heat to Power Market with a Market Share of 39.4%, Valued at USD 10.7 Billion

Europe leads the Waste Heat to Power Market due to strong industrial decarbonization targets and strict energy efficiency regulations. In this region, large-scale industries such as cement, steel, refining, and chemicals actively recover waste heat to reduce fuel use and emissions. Europe accounted for a dominant 39.4% share of the global market, with a valuation of USD 10.7 billion, driven by policy-backed energy recovery mandates and financial incentives supporting low-carbon power generation from industrial heat losses.

North America shows steady growth supported by rising electricity costs and a strong focus on industrial energy optimization. Manufacturing plants, oil & gas facilities, and heavy industries increasingly adopt waste heat recovery systems to lower operating expenses. Supportive federal and state-level energy efficiency programs further encourage adoption, especially in retrofitting existing industrial infrastructure.

Asia Pacific is emerging as a high-growth region due to rapid industrialization and expanding manufacturing capacity. Countries in this region are facing increasing energy demand and grid constraints, making waste heat recovery an attractive on-site power solution. Growth is also supported by government-led efficiency initiatives aimed at reducing coal dependency and improving industrial sustainability.

The Middle East and Africa region is gradually adopting waste heat to power systems, mainly in energy-intensive sectors such as oil refining, petrochemicals, and cement production. High process heat availability and rising interest in energy diversification are driving demand. Industrial operators in this region increasingly view waste heat recovery as a way to improve power reliability and operational efficiency.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

In 2024, the Waste Heat to Power (WHP) landscape is being shaped by players that can deliver reliable heat-recovery systems, shorten payback periods, and de-risk industrial retrofits. Buyers are prioritizing proven uptime, flexibility across heat grades, and strong project execution—especially where space, integration, and variable operating loads make WHP complex.

AC Boiler SpA is viewed as a practical execution-led participant, benefitting from deep know-how in boiler and heat-recovery integration. Its strength typically shows up where industrial sites need engineered solutions that fit existing layouts, tie into steam networks, and run steadily with minimal disruption to core operations.

Aura GmbH and CO. KG stand out for site-specific engineering and a focus on making challenging waste-heat streams usable. In 2024, its positioning is attractive for plants that require customization—where heat variability, fouling risks, or tight utility interfaces demand careful system design and commissioning discipline.

Climeon is often associated with compact, modular WHP approaches aimed at accelerating deployment and simplifying maintenance. The company’s value proposition resonates where customers want standardized units, faster installation cycles, and scalable rollouts across multiple sites without reinventing project engineering each time.

Cochran Ltd. is commonly perceived as a dependable industrial partner where steam, thermal equipment, and compliance-heavy environments matter. In WHP projects, its credibility tends to support conservative buyers looking for robust equipment, long service life, and strong support for operations teams post-handover.

Top Key Players in the Market

- AC Boiler SpA

- Aura GmbH and CO. KG

- Climeon

- Cochran Ltd.

- Dürr Group

- Exergy International Srl

- Forbes Marshall

- IHI Corporation

- Mitsubishi Heavy Industries, Ltd.

- Ormat Technologies

Recent Developments

- In 2025, AC Boiler SpA, part of the Sofinter Group, specializes in heat recovery steam generators and waste heat boilers for industrial applications. Recent developments focus on sustainability and process heat recovery enhancements, though specific project announcements are limited in public sources.

- In 2025, Aura GmbH & Co. KG will provide custom waste heat recovery solutions, including steam generators, thermal oil systems, and turbine exhaust recovery units. Publicly available recent developments are sparse, with emphasis on ongoing product offerings rather than new announcements. The company continues to cater to European industrial sectors with tailored waste heat packages.

Report Scope

Report Features Description Market Value (2024) USD 27.4 billion Forecast Revenue (2034) USD 75.7 billion CAGR (2025-2034) 10.7% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Technology (ORC, SRC, Kalina), By End Use (Petroleum Refining, Cement, Heavy Metal, Chemical, Paper, Food and Beverage, Glass) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape AC Boiler SpA, Aura GmbH and CO. KG, Climeon, Cochran Ltd., Dürr Group, Exergy International Srl, Forbes Marshall, IHI Corporation, Mitsubishi Heavy Industries, Ltd., Ormat Technologies Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited Users and Printable PDF)  Waste Heat to Power MarketPublished date: December 2025add_shopping_cartBuy Now get_appDownload Sample

Waste Heat to Power MarketPublished date: December 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- AC Boiler SpA

- Aura GmbH and CO. KG

- Climeon

- Cochran Ltd.

- Dürr Group

- Exergy International Srl

- Forbes Marshall

- IHI Corporation

- Mitsubishi Heavy Industries, Ltd.

- Ormat Technologies