Wafer Handling System Market Report By Product Type (Vacuum Wafer Handling System, Atmospheric Wafer Handling System), By Robot Type (Articulated Robots, Linear Robots, SCARA Robots, Cylindrical Robots, Others), By Wafer Size (Less than 150 mm, 150-200 mm, More than 200 mm), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: May 2024

- Report ID: 73670

- Number of Pages: 236

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

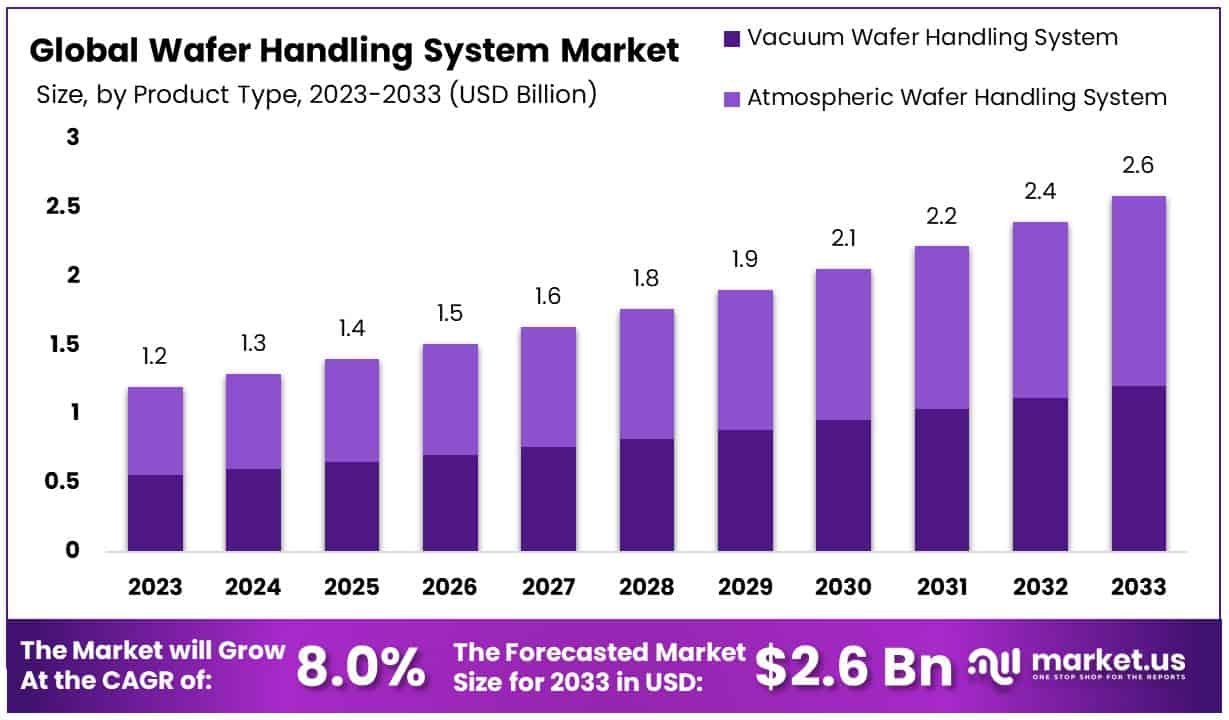

The Global Wafer Handling System Market size is expected to be worth around USD 2.6 Billion by 2033, from USD 1.2 Billion in 2023, growing at a CAGR of 8.0% during the forecast period from 2024 to 2033.

The Wafer Handling System Market comprises technologies and equipment designed to transport semiconductor wafers within manufacturing environments. These systems ensure efficient and safe handling of wafers, crucial for maintaining the integrity and cleanliness necessary in semiconductor production.

Key components include robotic arms, end effectors, and transport systems. This market is vital for industries relying on precise semiconductor applications, such as electronics and telecommunications. With the expanding demand for advanced electronics, the Wafer Handling System Market is positioned for significant growth, offering substantial opportunities for technological innovation and market expansion.

The Wafer Handling System Market is intricately linked to the broader semiconductor industry, which is experiencing robust growth. According to McKinsey, the semiconductor sector is projected to grow at an annual rate of 6 to 8 percent through 2030, with potential revenues poised to hit the $1 trillion mark. This expansion is driven by increasing demand for advanced electronics and technologies, including AI, IoT, and 5G.

Within this context, the Wafer Handling System Market plays a critical role. These systems are essential for the precise and contamination-free transfer of semiconductor wafers during the manufacturing process, a fundamental requirement for producing high-quality semiconductors. As the semiconductor industry expands, the demand for sophisticated wafer handling technologies is expected to surge, supporting the growth of this market.

Furthermore, significant investments underscore the industry’s growth trajectory. In the United States alone, the value of semiconductor projects currently underway, announced, or under consideration totals between $223 billion and $260 billion through 2030. This substantial financial commitment indicates a strong future demand for semiconductor manufacturing infrastructure, including wafer handling systems.

The market for wafer handling systems is thus poised for significant growth, fueled by technological advancements and capital investments. Companies operating in this space need to focus on innovation and efficiency to capitalize on the expanding opportunities. Overall, the Wafer Handling System Market is set to play a pivotal role in supporting the semiconductor industry’s growth, making it a key area for strategic investments.

Key Takeaways

- Market Value: The Global Wafer Handling System Market is projected to reach USD 2.6 billion by 2033, showing growth from USD 1.2 billion in 2023, with a noteworthy CAGR of 8.0% during the forecast period from 2024 to 2033.

- Product Type Analysis: Atmospheric Wafer Handling System leads with 53.4% market share due to its versatility and adaptability in various semiconductor manufacturing environments.

- Robot Type Analysis: Articulated Robots dominate with 46.5% market share owing to their high flexibility and precision in complex semiconductor manufacturing tasks.

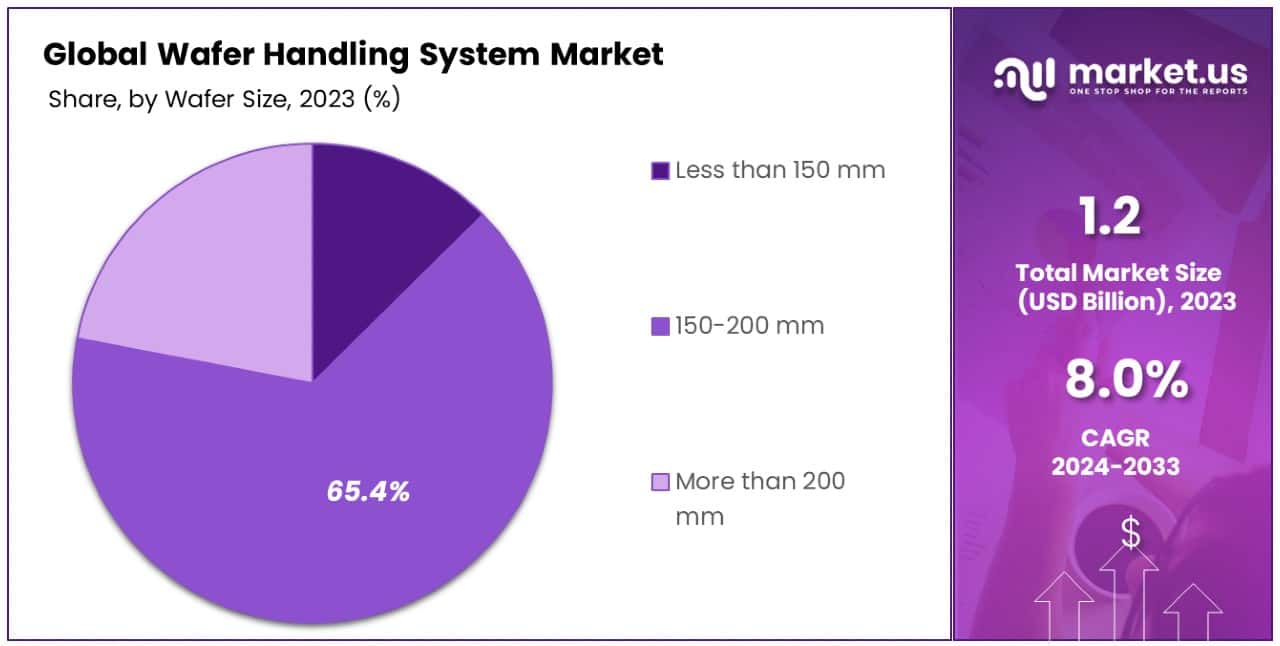

- Wafer Size Analysis: The 150-200 mm wafer size segment dominates with 65.4% market share due to its widespread use in numerous mainstream semiconductor applications.

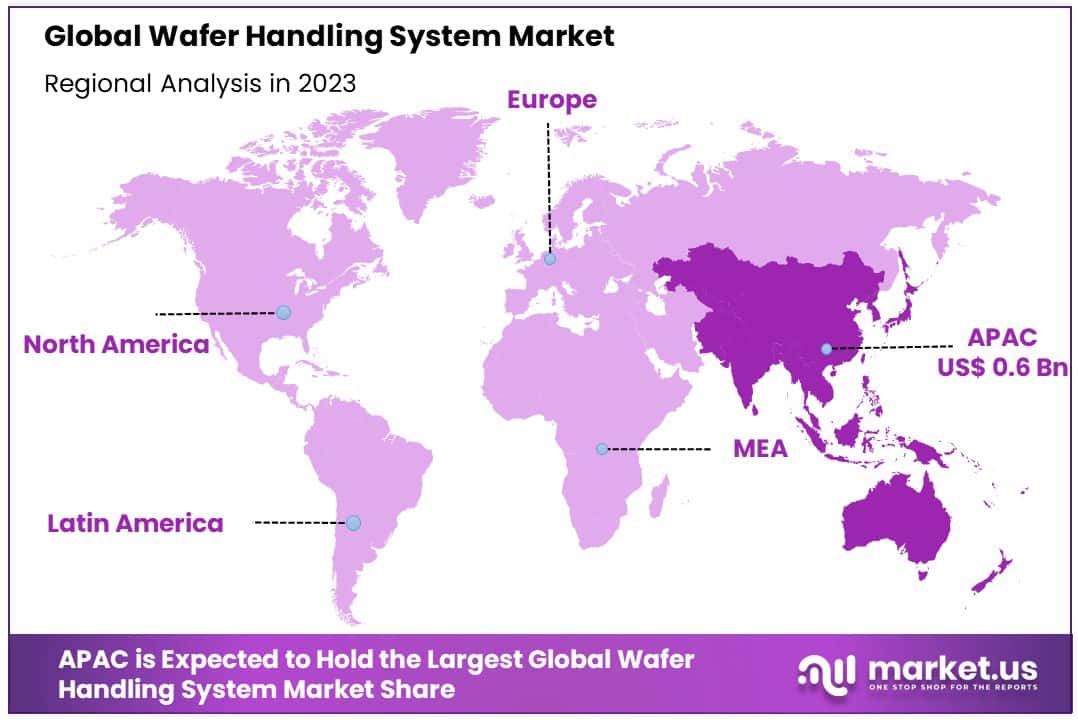

- APAC: Dominates the market with 52.4% market share, driven by the presence of key semiconductor manufacturing hubs and high demand for wafer handling systems in the region’s electronics industry.

- North America: Holds a significant market share of approximately 21.3%, supported by the region’s strong semiconductor manufacturing sector and technological advancements.

- Analyst Viewpoint: Analysts anticipate steady growth in the Wafer Handling System Market, fueled by increasing demand for semiconductor devices across various industries and ongoing technological advancements in semiconductor manufacturing.

- Growth Opportunities: Growth opportunities lie in the development of advanced wafer handling technologies, customization of solutions to meet specific manufacturing needs, expansion into emerging markets, and strategic partnerships with semiconductor manufacturers to enhance product offerings and market presence.

Driving Factors

Increasing Demand for Semiconductor Devices Drives Market Growth

The escalating demand for semiconductor devices is a primary driver for the Wafer Handling System Market. As consumer electronics, including smartphones, computers, and other digital devices, become increasingly integral to daily life, the requirement for advanced semiconductor chips rises correspondingly.

This surge in demand propels semiconductor manufacturers such as Intel, Samsung, and TSMC to expand their production capacities through new fabrication facilities and upgrades to existing ones. These expansions necessitate advanced wafer handling systems to manage the increased throughput and maintain the precision needed in chip manufacturing. The direct correlation between the growth in electronic device consumption and the need for enhanced semiconductor production infrastructure underscores the critical role of wafer handling systems in the industry’s expansion.

Miniaturization of Electronic Components Drives Market Growth

The miniaturization trend in the electronics sector significantly impacts the Wafer Handling System Market. As electronic components become smaller, the complexity of semiconductor chips increases, requiring more sophisticated wafer handling systems. These systems must offer high accuracy and efficiency to handle delicate, smaller wafers throughout the manufacturing process.

Companies like Brooks Automation and Murata Machinery are at the forefront, developing technologies that can support the production of increasingly miniature chips. This trend not only drives the demand for current wafer handling solutions but also spurs innovation within the market, pushing manufacturers to continuously improve the precision and capabilities of their systems.

Adoption of Advanced Node Technologies Drives Market Growth

The shift towards advanced node technologies, such as 7nm, 5nm, and 3nm processes, dictates the need for highly specialized wafer handling systems. These cutting-edge technologies require precise handling tools to ensure accurate wafer positioning and transportation during the semiconductor manufacturing process.

As companies like ASML and Lam Research invest in developing compatible wafer handling systems, the market grows in both capacity and technological advancement. This adaptation to finer technologies not only meets the immediate needs of semiconductor producers but also sets the stage for future industry requirements, ensuring ongoing growth and innovation in wafer handling system solutions. These advancements are critical in maintaining the pace of innovation and production efficiency in the semiconductor industry.

Restraining Factors

Stringent Quality and Safety Standards Restrains Market Growth

The Wafer Handling System Market faces significant constraints due to the stringent quality and safety standards required in semiconductor manufacturing. These standards, as outlined by entities like the International Technology Roadmap for Semiconductors (ITRS), ensure the reliability and performance of semiconductor chips but impose additional complexities and costs for wafer handling system manufacturers.

Compliance with these rigorous standards can lead to increased production expenses, as systems must be designed and tested to meet strict criteria. Failure to adhere to these guidelines not only results in financial burdens from product recalls and legal liabilities but also risks damaging a company’s reputation. This stringent regulatory environment challenges market growth by elevating operational costs and complicating product development.

Skilled Labor Shortage Restrains Market Growth

The shortage of skilled labor significantly impedes the growth of the Wafer Handling System Market. Effective operation and maintenance of wafer handling systems require specialized knowledge and training, yet the semiconductor industry currently faces a gap in skilled personnel.

This shortage hinders the adoption and efficient use of advanced wafer handling systems, as companies must either invest heavily in training programs or recruit skilled workers from other regions, which can be costly and time-consuming. For example, some companies have formed partnerships with educational institutions to bridge this gap, but these efforts are not immediate solutions and contribute to ongoing challenges within the market. This scarcity of qualified workers delays the implementation of new technologies and limits the industry’s capacity to scale operations effectively.

Product Type Analysis

The Atmospheric Wafer Handling System dominates with 53.4% due to its versatility and adaptability in various semiconductor manufacturing environments.

Atmospheric wafer handling systems hold the largest market share within the product type segment of the Wafer Handling System Market, primarily due to their flexibility and efficiency in handling wafers under normal atmospheric conditions. These systems are designed to operate in environments that do not require a vacuum, making them suitable for a wide range of semiconductor manufacturing processes where extreme environmental control is not necessary. This adaptability allows for broader applications across different stages of semiconductor production, contributing to their dominant position in the market.

Additionally, atmospheric systems tend to be less complex and costly compared to vacuum systems, which further enhances their appeal to manufacturers looking for cost-effective solutions without compromising on efficiency. The lower cost of ownership and maintenance, combined with the ease of integration into existing manufacturing lines, significantly drives their adoption.

The remaining sub-segment, the Vacuum Wafer Handling System, although smaller in market share, plays a crucial role in applications requiring stringent contamination control. Vacuum systems are essential in environments where even minimal levels of particulate contamination can result in significant yield losses. As the demand for highly sensitive and advanced semiconductor devices grows, the importance of vacuum wafer handling systems is expected to increase, complementing the growth driven by atmospheric systems.

Robot Type Analysis

Articulated Robots dominate with 46.5% due to their high flexibility and precision in complex semiconductor manufacturing tasks.

Articulated robots, characterized by their rotary joints, offer exceptional flexibility and precision, making them highly suitable for the intricate and delicate processes involved in semiconductor manufacturing. Their ability to maneuver wafers with high degrees of freedom allows for precise placement and handling, which is critical in the production of advanced semiconductor devices. This capability is a key factor in their dominant market share, as manufacturers increasingly seek technologies that can enhance precision and reduce errors in production lines.

The versatility of articulated robots in handling different wafer sizes and types, coupled with their integration capabilities with other systems, bolsters their adoption. These robots can be customized with various end effectors and programming modifications to meet specific manufacturing needs, further driving their prevalence in the industry.

Other robot types, such as Linear Robots, SCARA Robots, Cylindrical Robots, and others, each play vital roles in the market. Linear robots are prized for their straightforward, efficient linear motions, making them ideal for simpler, repetitive tasks. SCARA robots are favored in applications requiring high-speed, precision in horizontal movements. Cylindrical robots offer a balance of compact design and range of motion, suitable for confined spaces. These variations ensure that manufacturers have access to a diverse range of robotic systems that can be tailored to different aspects of semiconductor production, supporting the overall growth of the robot segment in the wafer handling system market.

Wafer Size Analysis

The 150-200 mm segment dominates with 65.4% due to its widespread use in numerous mainstream semiconductor applications.

The 150-200 mm wafer size segment commands the largest share in the wafer size category, primarily due to its extensive application in a multitude of semiconductor devices that form the backbone of current consumer electronics, automotive, and industrial applications. This wafer size strikes an optimal balance between cost-efficiency and device integration capacity, making it particularly attractive for manufacturers focusing on standard performance and cost-effective production.

Moreover, the infrastructure for manufacturing and handling 150-200 mm wafers is well-established in the industry, further easing the integration and operational challenges associated with transitioning to different wafer sizes. This maturity in handling technologies and processes underpins the dominant market position of this segment.

While the less than 150 mm and more than 200 mm wafer sizes cater to niche applications, the former is often used for specialized or older technology products, whereas the latter is increasingly sought after for high-performance, advanced technology applications. The growth in these segments is driven by specific technological advancements and shifts in industry demand, which, while smaller in current market share, indicate significant potential for future expansion as new technologies and needs emerge.

Key Market Segments

By Product Type

- Vacuum Wafer Handling System

- Atmospheric Wafer Handling System

By Robot Type

- Articulated Robots

- Linear Robots

- SCARA Robots

- Cylindrical Robots

- Others

By Wafer Size

- Less than 150 mm

- 150-200 mm

- More than 200 mm

Growth Opportunities

Adoption of Internet of Things (IoT) and Artificial Intelligence (AI) Offers Growth Opportunity

The rapid integration of IoT and AI technologies across various industries is fueling a substantial demand for advanced semiconductor chips. This burgeoning need directly increases the demand for efficient and reliable wafer handling systems, essential for producing high-quality chips at scale. Companies like Qualcomm, NVIDIA, and Intel are at the forefront, significantly investing in developing IoT and AI-driven chips.

For instance, Murata Machinery’s recent collaboration with a top semiconductor producer to craft wafer handling solutions specifically for AI chip production exemplifies this trend. Such partnerships not only highlight the growing market demand but also the potential for wafer handling system manufacturers to innovate and expand their offerings to meet the specific needs of IoT and AI technologies. This sector’s expansion presents lucrative opportunities for technological advancements in wafer handling systems, ensuring their critical role in the next generation of semiconductor manufacturing.

Expansion in Emerging Markets Offers Growth Opportunity

Emerging markets represent a fertile ground for the expansion of the Wafer Handling System Market. While the semiconductor industry has been traditionally concentrated in regions like the United States, Taiwan, South Korea, and Japan, countries such as China, India, and Southeast Asia are rapidly developing their semiconductor manufacturing capabilities.

The Chinese government, for example, has set ambitious targets to boost its domestic semiconductor industry, which spells significant opportunities for wafer handling system manufacturers. As these regions enhance their infrastructure and technological prowess, the demand for sophisticated wafer handling systems is expected to rise. This shift not only opens new markets for existing players but also encourages the development of tailored solutions to meet the unique needs of emerging market environments, thereby driving growth and innovation within the global wafer handling system landscape.

Trending Factors

Automation and Industry 4.0 Are Trending Factors

The movement towards automation and Industry 4.0 is significantly shaping the Wafer Handling System Market. As manufacturing processes become more interconnected and smart factories become the norm, there is an increasing demand for wafer handling systems that are highly automated and capable of integrating with Industry 4.0 technologies. These systems enhance manufacturing efficiency by reducing manual errors, improving throughput, and facilitating real-time monitoring and analysis of production data.

Companies are at the forefront, developing advanced automated wafer handling systems that complement other automated manufacturing systems. This trend not only underscores the shift towards more digitized, efficient, and data-driven manufacturing environments but also highlights the growing need for technologies that can seamlessly connect and communicate within these sophisticated frameworks.

Cleanroom Manufacturing Are Trending Factors

Stringent cleanroom standards are crucial in the semiconductor industry to maintain the purity and quality of semiconductor chips. As these standards become more rigorous, the demand for wafer handling systems that can operate effectively within such environments is growing. These systems must be capable of functioning without introducing contaminants, which is critical in avoiding defects and ensuring high yields.

Companies are leading the way in developing wafer handling systems specifically designed to meet the demanding requirements of cleanroom manufacturing. This trend is driven by the ongoing need to enhance product quality and manufacturing precision, which are paramount in the highly competitive semiconductor industry. The emphasis on cleanroom compatibility in wafer handling systems highlights their pivotal role in maintaining operational excellence and product reliability in chip production.

Regional Analysis

APAC Dominates with 52.4% Market Share

The Asia-Pacific (APAC) region holds a commanding 52.4% share of the Wafer Handling System Market, largely due to its significant semiconductor manufacturing base. Countries like Taiwan, South Korea, and China are global leaders in semiconductor production, hosting major players and extensive manufacturing facilities. The high concentration of semiconductor fabs in the region drives the demand for wafer handling systems, as these facilities require sophisticated equipment to maintain production efficiency and chip quality.

APAC’s dominance in the market is reinforced by its robust electronics industry and governmental support in technology advancements. The region benefits from a well-established supply chain, competitive manufacturing costs, and rapid technological adoption, which collectively enhance its market position. Additionally, the ongoing investments in semiconductor expansion by regional governments and private sectors continue to bolster the demand for advanced manufacturing solutions, including wafer handling systems.

Regional Market Shares:

- North America: North America holds a significant market share of approximately 21.3%. The region’s market strength is supported by advanced technological infrastructure and the presence of leading semiconductor companies.

- Europe: Europe accounts for around 15.2% of the market, driven by its strong focus on research and development and stringent quality control in manufacturing processes.

- Middle East & Africa: The MEA region, while still developing in this sector, has a smaller market share of about 4.1%, showing gradual growth as the technology sector expands.

- Latin America: Latin America has the smallest share at 3.0%, reflecting its nascent stage in semiconductor manufacturing but indicating potential for growth as regional development accelerates.

Key Regions and Countries

- North America

- The US

- Canada

- Mexico

- Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

In the Wafer Handling System Market, several key players shape industry dynamics through strategic innovations and market positioning. Companies like Brooks Automation Inc. and Kawasaki Heavy Industries Ltd. are at the forefront, leveraging their advanced technological capabilities to enhance production efficiency and precision. Brooks Automation, for example, is known for its robust product offerings in automated material handling systems, positioning itself as a leader in both technology and market share.

Nidec Corporation and Rorze Corporation also play critical roles, with Nidec focusing on motor technologies that improve system performance and Rorze expanding its reach through reliable and innovative wafer transport solutions. Entegris Inc. enhances the market with its contamination control products, crucial for maintaining the integrity of wafers during handling.

Newer entrants like Amtech Systems Inc. and Kensington Laboratories LLC contribute with specialized handling solutions that cater to niche market needs, further intensifying competition. Meanwhile, regional players such as Dou Yee Enterprises and Silicon Connection Pte Ltd. focus on meeting the specific requirements of the Asia-Pacific market, which is a significant growth area for the industry.

Together, these companies drive the market through a blend of innovation, strategic global placement, and adaptation to evolving technological demands, ensuring their strong influence and competitive edge in the Wafer Handling System Market.

Market Key Players

- Nidec Corporation

- Kawasaki Heavy Industries Ltd.

- Entegris Inc.

- Brooks Automation Inc.

- Rorze Corporation

- Baumann GmbH

- Amtech Systems Inc.

- Isel Germany AG

- Kensington Laboratories LLC

- Dou Yee Enterprises (S) Pte Ltd.

- Silicon Connection Pte Ltd.

Recent Developments

- On May 2024, mechatronic systemtechnik GmbH inaugurated its cutting-edge Technology Center in Fürnitz, representing a significant investment exceeding EUR 20 million. The new facility spans 6,500m2 across three storeys and includes a state-of-the-art clean room and laboratory, essential for planning, developing, and producing advanced systems for the semiconductor industry.

- On March 2024, Infinitesima completed an investment round to expand production of the Metron3D 300 mm in-line wafer metrology system. This funding will allow the company to meet the growing demand for their next-generation metrology system, which enhances the throughput capability of automated Atomic Force Metrology, enabling sub-nanometer, 3D process control in semiconductor manufacturing.

- Regarding Huawei, on December 2023, the company applied for a patent related to wafer processing technology that enhances wafer alignment efficiency and precision. This move by Huawei signifies a focus on improving wafer processing techniques to achieve higher efficiency and accuracy in semiconductor manufacturing processes, aligning with the industry’s demand for enhanced precision in wafer alignment.

Report Scope

Report Features Description Market Value (2023) USD 1.2 Billion Forecast Revenue (2033) USD 2.6 Billion CAGR (2024-2033) 8.0% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product Type (Vacuum Wafer Handling System, Atmospheric Wafer Handling System), By Robot Type (Articulated Robots, Linear Robots, SCARA Robots, Cylindrical Robots, Others), By Wafer Size (Less than 150 mm, 150-200 mm, More than 200 mm) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Nidec Corporation, Kawasaki Heavy Industries Ltd., Entegris Inc., Brooks Automation Inc., Rorze Corporation, Baumann GmbH, Amtech Systems Inc., Isel Germany AG, Kensington Laboratories LLC, Dou Yee Enterprises (S) Pte Ltd., Silicon Connection Pte Ltd. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is the projected value of the Global Wafer Handling System Market by 2033?The Global Wafer Handling System Market is expected to be worth around USD 2.6 Billion by 2033. The CAGR for the Wafer Handling System Market from 2024 to 2033 is forecasted to be 8.0%.

What are the key components of the Wafer Handling System?The key components include robotic arms, end effectors, and transport systems.

Which region dominates the Wafer Handling System Market?APAC dominates the market with 52.4% market share.

What are the key growth opportunities identified in the Wafer Handling System Market?Adoption of IoT and AI, expansion in emerging markets, automation, and cleanroom manufacturing are key growth opportunities.

Wafer Handling System MarketPublished date: May 2024add_shopping_cartBuy Now get_appDownload Sample

Wafer Handling System MarketPublished date: May 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- Nidec Corporation

- Kawasaki Heavy Industries Ltd.

- Entegris Inc.

- Brooks Automation Inc.

- Rorze Corporation

- Baumann GmbH

- Amtech Systems Inc.

- Isel Germany AG

- Kensington Laboratories LLC

- Dou Yee Enterprises (S) Pte Ltd.

- Silicon Connection Pte Ltd.

- others