Global Predictive Escalator Maintenance AI Market Size, Share Analysis By Maintenance Type (Scheduled Maintenance, Condition-based Maintenance, Predictive Maintenance), By Deployment Mode (On-premises, Cloud-based), By Enterprise Size(Small to Medium Enterprises (SMEs), Large Enterprises), By Application (Residential, Commercial, Industrial), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2025-2034

- Published date: August 2025

- Report ID: 155536

- Number of Pages: 310

- Format:

-

keyboard_arrow_up

Quick Navigation

- Report Overview

- Key Insight Summary

- Role of AI

- Analysts’ Viewpoint

- US Market Size

- Key Trends and Innovations

- Top Growth Factors

- By Maintenance Type

- By Deployment Mode

- By Enterprise Size

- By Application

- Key Market Segments

- Driver Analysis

- Restraint Analysis

- Opportunity Analysis

- Challenge Analysis

- Competitive Analysis

- Recent Developments

- Report Scope

Report Overview

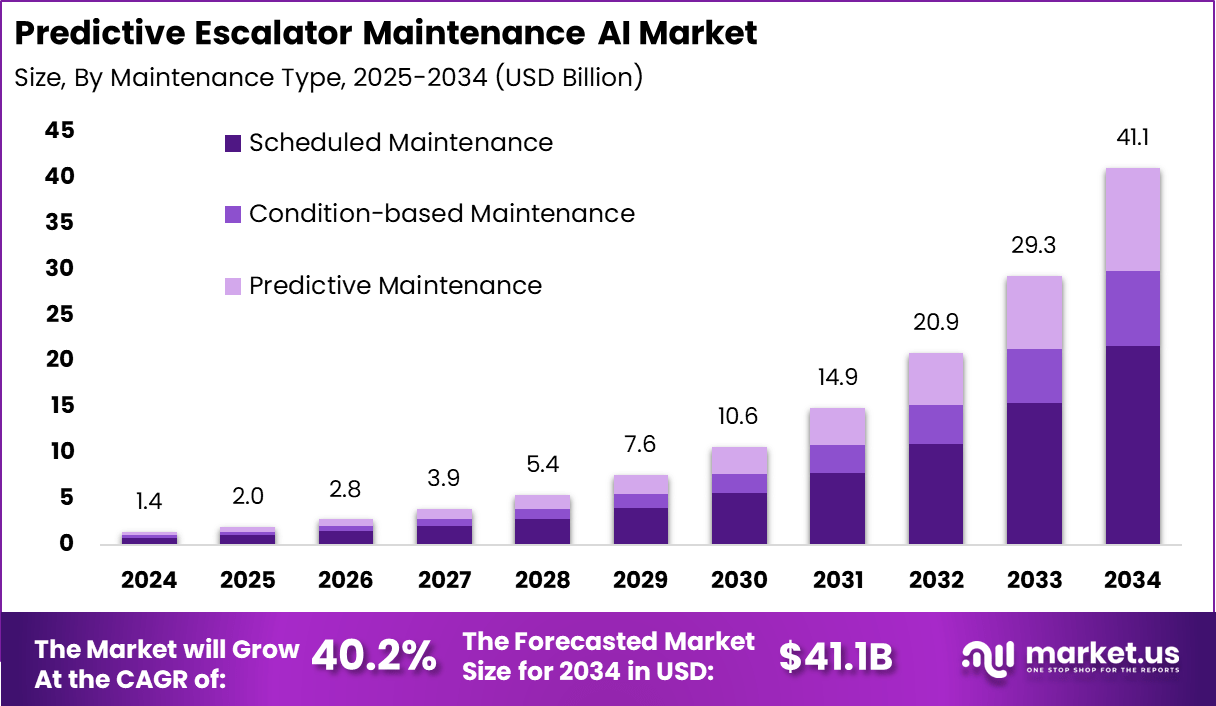

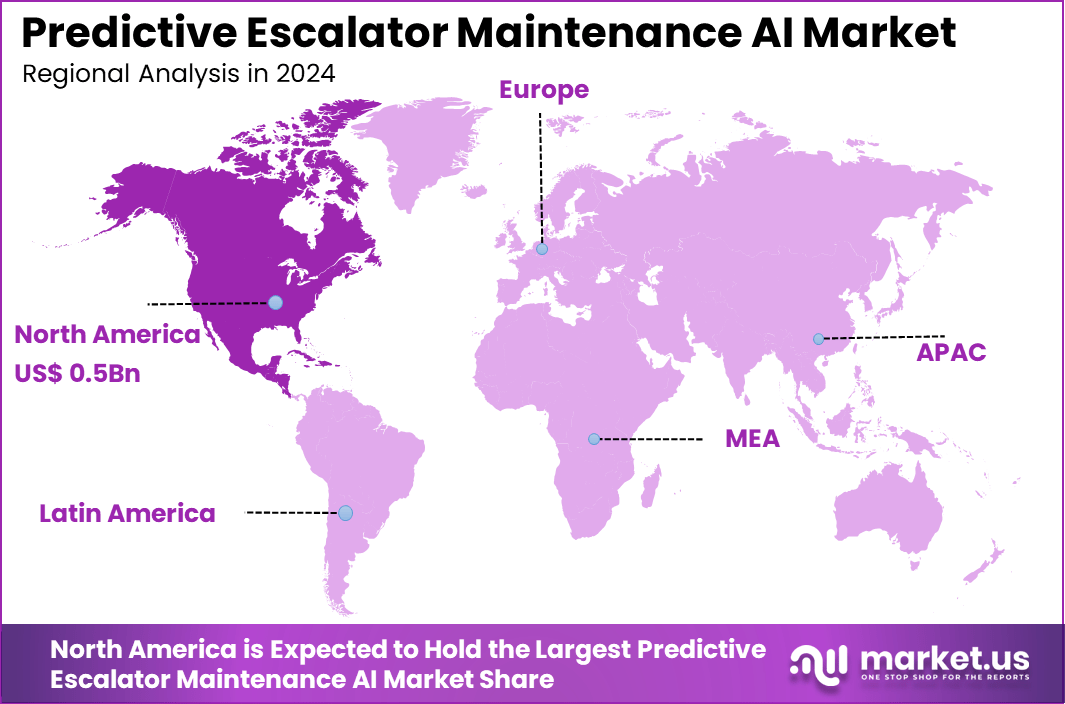

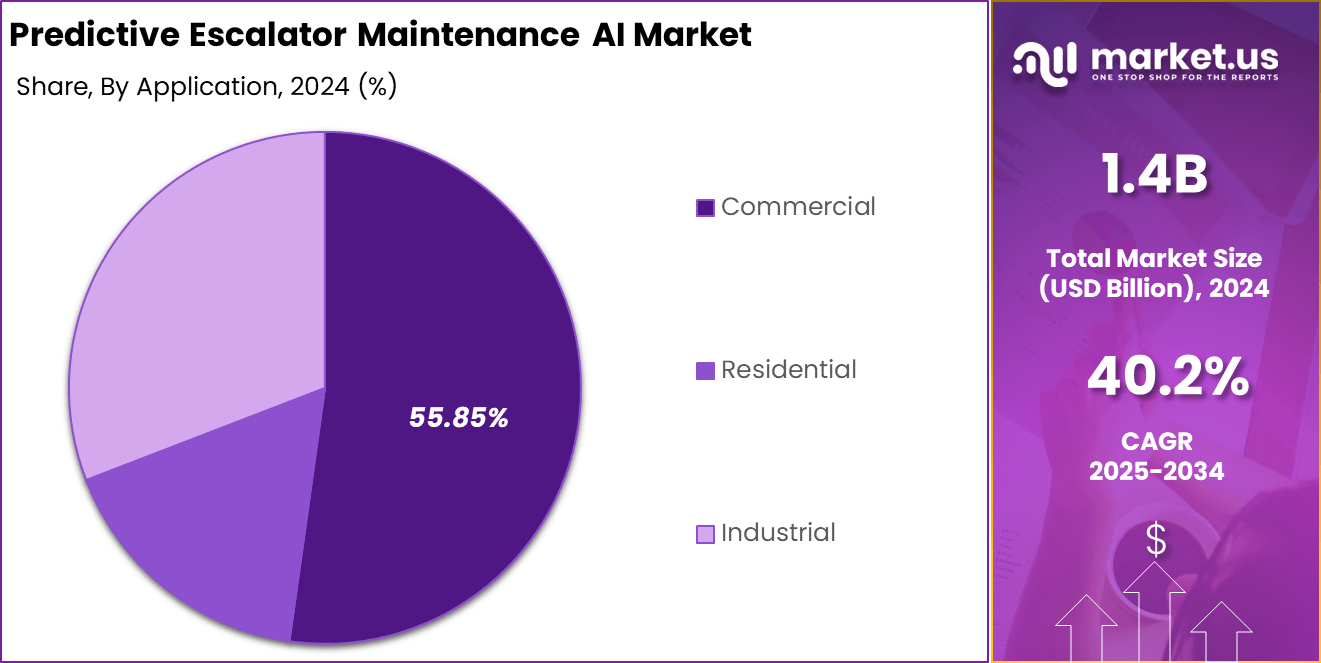

The Global Predictive Escalator Maintenance AI Market size is expected to be worth around USD 41.1 Billion By 2034, from USD 1.4 billion in 2024, growing at a CAGR of 40.2% during the forecast period from 2025 to 2034. In 2024, North America held a dominan market position, capturing more than a 36.6% share, holding USD 0.5 Billion revenue.

Key Insight Summary

- Scheduled maintenance led by maintenance type with 52.8%, showing preference for planned servicing enhanced by predictive AI to prevent costly breakdowns.

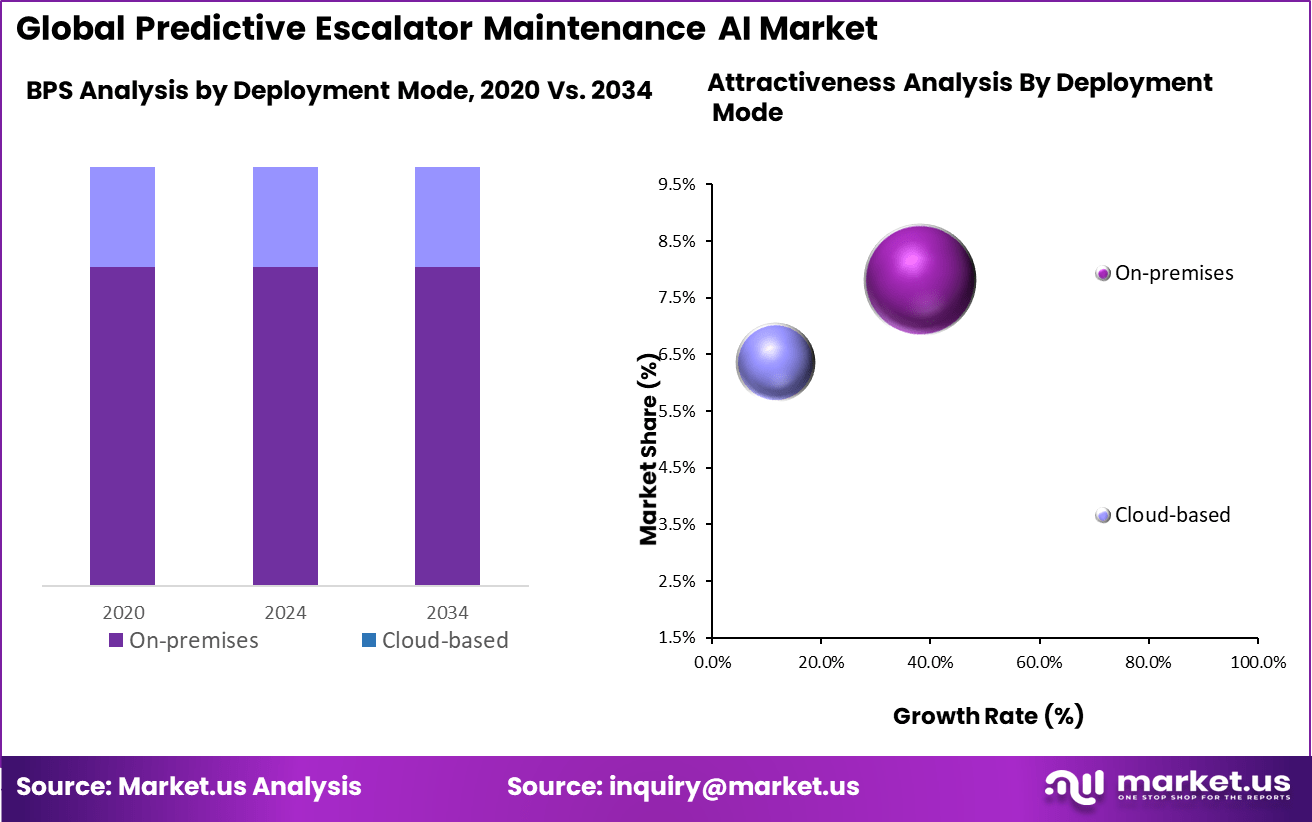

- On-premises deployment held 63.9%, driven by data security needs, operational control, and integration with existing building systems.

- Large enterprises dominated with 66.6%, reflecting the scale and complexity of infrastructure in malls, airports, and corporate facilities.

- Commercial applications accounted for 55.85%, supported by high traffic environments where downtime directly impacts customer experience and safety.

- North America captured 36.6% market share, leveraging advanced facility management practices and high adoption of AI-driven maintenance.

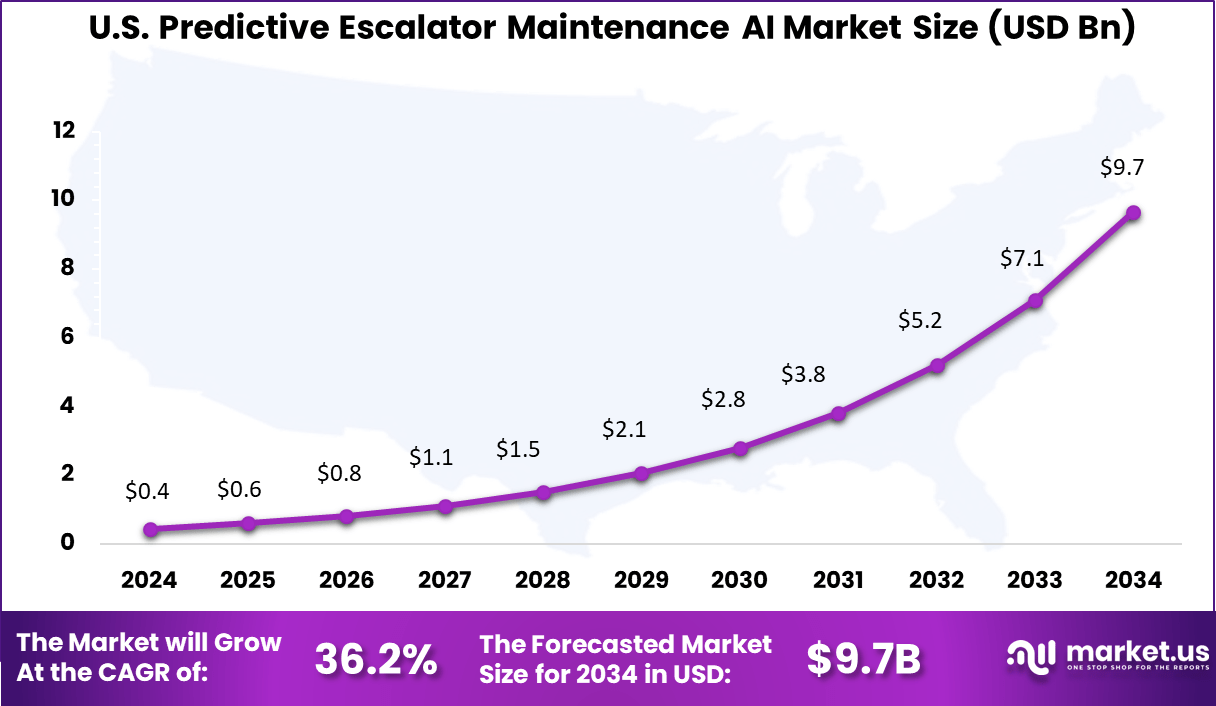

- The U.S. market stood at USD 0.44 billion with a CAGR of 36.2%, indicating rapid growth in AI-based predictive solutions for escalator operations.

The Predictive Escalator Maintenance AI Market focuses on leveraging artificial intelligence to anticipate and prevent escalator malfunctions before they lead to costly breakdowns or safety issues. This market involves AI-powered systems that analyze real-time data collected from sensors embedded in escalator components, such as motors, brakes, and chains.

Key driving factors for this market include the increasing demand for uninterrupted service in high-traffic public and commercial spaces, where escalator downtime can lead to significant inconvenience and revenue loss. Additionally, the growing adoption of IoT sensors and AI analytics in building management systems propels the momentum toward predictive maintenance over traditional reactive approaches.

Role of AI

Role/Function Description Real-Time Equipment Monitoring AI collects data from IoT sensors on escalator components to monitor performance and detect anomalies. Failure Prediction Machine learning models analyze historical and operational data to forecast potential breakdowns. Maintenance Scheduling AI optimizes maintenance timing to prevent unscheduled repairs and minimize service interruptions. Cost Reduction Predicting part wear and failure reduces emergency repairs and extends lifecycle of escalator components. Remote Diagnostics Remote AI-driven diagnosis enables quick interventions without the need for on-site inspections. Data-Driven Insights Analytics inform long-term improvements and enhance reliability of escalator systems. Analysts’ Viewpoint

The market is witnessing increased integration of advanced technologies such as machine learning algorithms, real-time sensor monitoring, and cloud-based analytics. These innovations improve fault detection accuracy and support scalable deployment across different escalator models. Data-driven insights enable maintenance teams to address critical issues promptly and plan preventive actions more effectively.

Rising modernization of infrastructure and the growth of smart buildings are creating strong investment prospects. Public infrastructure and commercial developments are adopting predictive maintenance to enhance asset longevity and ensure operational reliability. Emerging urban markets are also showing potential as they upgrade escalator and elevator systems to meet modern safety and efficiency standards.

Implementing predictive escalator maintenance AI offers multiple operational benefits, including improved asset availability, reduced unscheduled repair costs, and enhanced safety compliance. Maintenance personnel can be utilized more efficiently, leading to fewer disruptions and improved passenger experiences. Organizations gain a competitive edge through better facility management and stronger reputations for service reliability.

US Market Size

The U.S. Predictive Escalator Maintenance AI Market was valued at USD 0.4 Billion in 2024 and is anticipated to reach approximately USD 9.7 Billion by 2034, expanding at a compound annual growth rate (CAGR) of 36.2% during the forecast period from 2025 to 2034.

This rapid growth is being fueled by increasing investments in smart building infrastructure, the adoption of AI-powered condition monitoring systems, and the need to meet stringent safety and operational compliance standards. The U.S. is expected to lead global market growth due to rising demand for predictive maintenance in expanding transit, airport, and commercial infrastructure.

In 2024, North America held a dominant market position, capturing more than 36.6% of the global Predictive Escalator Maintenance AI market and generating approximately USD 0.5 billion in revenue. This leadership is supported by the region’s advanced infrastructure, early adoption of AI-based predictive maintenance solutions, and strong focus on public safety standards.

High foot traffic in commercial buildings, airports, metro stations, and shopping centers has increased the need for proactive maintenance strategies to minimize downtime and prevent accidents. Regulatory bodies in the United States and Canada have established stringent operational safety guidelines, encouraging escalator operators to integrate AI-powered monitoring systems that can detect faults before they escalate into costly breakdowns.

Key Trends and Innovations

Trend/Innovation Description IoT Sensor Integration Use of IoT devices combined with AI analytics for continuous, real-time condition monitoring. Cloud-Based Platforms Scalable, remote monitoring solutions supporting large escalator fleets via cloud technologies. Brand-Agnostic Predictive Solutions Development of AI maintenance systems compatible across various escalator manufacturers. Advanced Failure Prediction AI models forecasting breakdowns weeks in advance enabling proactive part replacements. Industry Collaborations Partnerships between AI firms and facility operators tailor predictive maintenance solutions. Energy Efficiency & Sustainability Incorporation of eco-friendly and energy-saving measures alongside maintenance optimization. Top Growth Factors

Growth Factor Description Urbanization & Infrastructure Growth Rapid urbanization and vertical infrastructure development increase escalator installations worldwide. Smart City & Connected Infrastructure Demand Integration of AI-driven predictive maintenance becomes standard in smart city projects and infrastructure. Operational Cost & Safety Regulations Rising operational expenses and stringent safety standards drive adoption of reliable predictive solutions. Awareness of AI & IoT Benefits Growing recognition of AI and IoT advantages in maintenance efficiency boosts market acceptance. Government Investments Public sector funding for transportation hubs, airports, and commercial facilities supports modernization. By Maintenance Type

In 2024, the Scheduled Maintenance segment holds a leading position in the Predictive Escalator Maintenance AI market with a significant share of 52.8%. Scheduled maintenance remains a preferred approach due to its structured and pre-planned nature, enabling organizations to perform routine checks and servicing before any critical failure occurs.

This proactive approach helps in optimizing maintenance operations by minimizing unexpected equipment breakdowns and enhancing the overall safety and reliability of escalators. The integration of AI to augment scheduled maintenance further improves the accuracy of predictions and scheduling, making maintenance operations more efficient and cost-effective.

Leveraging AI-driven predictive analytics within scheduled maintenance allows for the anticipation of component wear and tear, reducing downtime and extending equipment lifespan. This technology supports data-driven decision-making, enabling maintenance teams to prioritize tasks and allocate resources more effectively.

By Deployment Mode

In 2024, the On-premises deployment mode dominates the Predictive Escalator Maintenance AI market with a substantial share of 63.9%. This is primarily driven by the industry’s focus on data security, real-time processing requirements, and the need for uninterrupted operations.

On-premises solutions provide organizations with greater control over sensitive operational data, ensuring privacy and compliance with regulatory standards, which is especially important for escalator maintenance systems deployed in critical infrastructure and high-traffic commercial environments.

Additionally, on-premises deployment minimizes latency, enabling real-time data analysis and immediate response to maintenance issues, which is crucial for the safety and reliability of escalator systems. By allowing seamless integration with existing legacy systems, businesses can customize solutions without disrupting ongoing operations.

By Enterprise Size

In 2024, Large Enterprises constitute the leading segment in the Predictive Escalator Maintenance AI market, commanding a dominant share of 66.6%. Large enterprises typically have extensive infrastructure with numerous escalator installations, driving a strong demand for advanced predictive maintenance solutions to minimize downtime and optimize operational efficiency.

Their substantial capital and resource capabilities enable them to invest in cutting-edge AI technologies, integrating them into comprehensive maintenance programs that support scalability and sophisticated analytics. Furthermore, large enterprises prioritize risk mitigation, safety, and compliance, which predictive maintenance AI effectively addresses by forecasting failures and optimizing maintenance schedules.

By Application

In 2024, the Commercial application segment dominates the Predictive Escalator Maintenance AI market, capturing a significant share of 55.85%. The commercial sector’s rapid urbanization, increasing foot traffic in malls, airports, office complexes, and transportation centers necessitates reliable and efficient escalator maintenance.

Predictive AI solutions in this space help prevent unscheduled breakdowns, thereby ensuring safety and continuity in daily operations that serve large volumes of people. The adoption of predictive maintenance technology in commercial settings also reflects the growing emphasis on operational efficiency and cost reduction through advanced monitoring and data analytics.

These AI-powered systems facilitate real-time condition monitoring, enabling proactive intervention before failures occur, which reduces costly downtime and enhances the lifecycle of escalator assets. The commercial sector’s focus on smart infrastructure upgrades and customer satisfaction will sustain the robust demand for predictive escalator maintenance AI throughout 2024.

Key Market Segments

By Maintenance Type

- Scheduled Maintenance

- Condition-based Maintenance

- Predictive Maintenance

By Deployment Mode

- On-premises

- Cloud-based

By Enterprise Size

- Small to Medium Enterprises (SMEs)

- Large Enterprises

By Application

- Residential

- Commercial

- Industrial

Regional Analysis and Coverage

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Singapore

- Thailand

- Vietnam

- Rest of Latin America

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Driver Analysis

Demand for Increased Safety, Efficiency, and Cost Reduction

The prime driver of the predictive escalator maintenance AI market is the increasing need to enhance operational safety and reliability in public and private spaces. Escalators are critical for managing vertical transport in airports, malls, metros, and office buildings, where unexpected failures can cause safety hazards and inconvenience large numbers of people.

AI-powered predictive maintenance reduces these risks by identifying wear and tear early, scheduling timely interventions, and minimizing service interruptions. Alongside safety, reducing operational and maintenance costs is a strong incentive – smart diagnostics prevent expensive emergency repairs and extend equipment lifecycle.

Rapid urbanization and escalating foot traffic have increased demand for dependable escalator systems, pushing facility managers to adopt intelligent maintenance solutions. Moreover, regulatory mandates and sustainability goals encourage minimized resource usage and energy-efficient operations that predictive AI supports by optimizing performance metrics and maintenance timing.

Restraint Analysis

High Initial Costs and Complexity of Deployment

Despite the benefits, significant restraints exist due to the high initial investment required for implementing AI-based predictive maintenance systems. Deploying IoT sensors, setting up data analytics platforms, and integrating AI algorithms demand substantial capital expenditure that may deter smaller building operators or those with aging infrastructure.

Targeting retrofitting in older escalator systems with outdated components is particularly challenging, given compatibility issues and scarcity of spare parts. Further complexity arises from the technical expertise required to manage and interpret the predictive analytics effectively. A shortage of skilled personnel capable of handling AI-driven maintenance platforms in the facilities sector can slow adoption.

Opportunity Analysis

Growth in Smart Building Infrastructure and Emerging Markets

The predictive escalator maintenance AI market offers promising opportunities through the ongoing growth of smart building infrastructure worldwide. Increasing adoption of AI and IoT in commercial real estate, airports, transit systems, and public facilities creates substantial demand for predictive maintenance that improves operational efficiency and passenger experience.

Smart cities initiatives and digital twins integration provide pathways to delivering end-to-end predictive asset management solutions that include escalators. Emerging markets – particularly in Asia-Pacific and Latin America – represent major growth areas driven by rapid urbanization, new commercial developments, and government investments in public transit systems.

These regions also offer a lower starting base for digital infrastructure adoption, making them ideal for leapfrogging to AI-based maintenance solutions. Collaborations between AI platform providers, sensor manufacturers, and escalator maintenance service firms are helping accelerate deployment and customization across diverse building types and customer needs.

Challenge Analysis

Ensuring Accuracy, Data Management, and Building Trust

A critical challenge for the predictive escalator maintenance AI market lies in ensuring the reliability and accuracy of AI models. Predictive algorithms require continuous training and validation with high-quality sensor data to avoid false alarms or missed detections that could impact safety or operational costs.

Managing the sheer volume, variety, and velocity of data from distributed escalator sensors demands robust AI infrastructure and efficient data handling protocols. Building trust and acceptance among facility managers and maintenance personnel is another key hurdle. AI-driven insights must be transparent, interpretable, and seamlessly integrated with existing maintenance workflows to encourage adoption.

Competitive Analysis

Schneider Electric and Hexagon AB lead the Predictive Escalator Maintenance AI market with advanced analytics, IoT, and AI monitoring to enhance performance, detect faults, and automate maintenance. Fieldbox and Sensorfy support this growth with modular AI platforms that enable data-driven strategies for high-traffic sites, meeting the need for reduced downtime and improved safety.

N2 Infotech and Siemens expand their reach through intelligent sensors and cloud-based analytics for escalator systems. Teldat Group and Cxociety Pte Ltd focus on connectivity and seamless data integration, while Fieldimp Ltd. delivers scalable AI tools for accurate diagnostics and proactive asset management.

Oracle and Datahoist, LLC strengthen predictive capabilities with AI platforms that refine performance predictions and optimize repair cycles. Emerging players target niche applications with flexible solutions, collectively improving escalator safety, reliability, and operational efficiency through AI-powered maintenance.

Top Key Players in the Market

- Schneider Electric

- Hexagon AB

- Fieldbox

- Sensorfy

- N2 Infotech

- Siemens

- Teldat Group

- Cxociety Pte Ltd

- Fieldimp Ltd.

- Oracle

- Datahoist, LLC

- Others

Recent Developments

- As of mid-2025, Hexagon’s Enterprise Asset Management (EAM) tools are actively helping manufacturers avoid costly escalator and equipment downtime by scheduling maintenance during non-peak hours and improving resource allocation.

- Siemens introduced generative AI functionalities into its Senseye Predictive Maintenance solution in 2025, significantly enriching user interaction and maintenance efficacy. This generative AI supports conversational interfaces that allow maintenance teams to access contextual knowledge rapidly, drawing on past cases to inform decisions.

Report Scope

Report Features Description Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue forecast, AI impact on Market trends, Share Insights, Company ranking, competitive landscape, Recent Developments, Market Dynamics and Emerging Trends Segments Covered By Maintenance Type (Scheduled Maintenance, Condition-based Maintenance, Predictive Maintenance), By Deployment Mode (On-premises, Cloud-based), By Enterprise Size(Small to Medium Enterprises (SMEs), Large Enterprises), By Application (Residential, Commercial, Industrial) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Russia, Netherlands, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, New Zealand, Singapore, Thailand, Vietnam, Rest of Latin America; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Schneider Electric, Hexagon AB, Fieldbox, Sensorfy, N2 Infotech, Siemens, Teldat Group, Cxociety Pte Ltd, Fieldimp Ltd., Oracle, Datahoist, LLC, Others Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three license to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Predictive Escalator Maintenance AI MarketPublished date: August 2025add_shopping_cartBuy Now get_appDownload Sample

Predictive Escalator Maintenance AI MarketPublished date: August 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Schneider Electric

- Hexagon AB

- Fieldbox

- Sensorfy

- N2 Infotech

- Siemens

- Teldat Group

- Cxociety Pte Ltd

- Fieldimp Ltd.

- Oracle

- Datahoist, LLC

- Others