Global Operational Predictive Maintenance Market Report By Component (Software, Services), By Deployment Mode (On-premise, Cloud), By End-User (Automotive, Healthcare, Manufacturing, Energy & Utility, Transportation, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: August 2024

- Report ID: 127615

- Number of Pages: 353

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

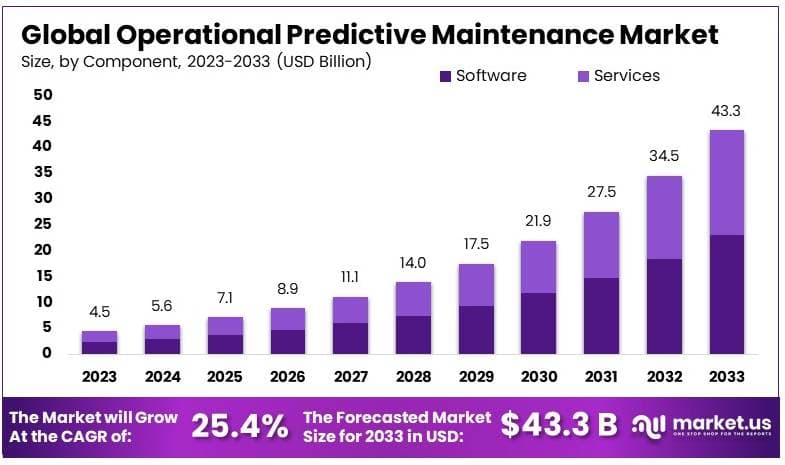

The Global Operational Predictive Maintenance Market size is expected to be worth around USD 43.3 Billion by 2033, from USD 4.5 Billion in 2023, growing at a CAGR of 25.4% during the forecast period from 2024 to 2033.

The Operational Predictive Maintenance Market is revolutionizing how businesses maintain their equipment and operations. Predictive maintenance uses advanced analytics, including artificial intelligence and machine learning, to predict when equipment is likely to fail.

By analyzing data from sensors and other sources, these systems can identify potential issues before they become critical. This approach helps companies avoid unexpected downtime, reduce maintenance costs, and extend the life of their equipment.

The market is expanding as more industries adopt predictive maintenance to improve efficiency and reliability. Manufacturers, energy companies, and transportation firms are particularly interested in these solutions, as they rely heavily on the continuous operation of complex machinery.

As technology continues to evolve, predictive maintenance systems are becoming more accurate and easier to implement. The Operational Predictive Maintenance Market is expected to grow as companies seek to optimize their operations and reduce the risks associated with equipment failures.

The operational predictive maintenance market is rapidly expanding, driven by advancements in machine learning, IoT, and sensor technologies. Companies across asset-intensive industries, such as oil and gas, utilities, and manufacturing, are increasingly adopting predictive maintenance strategies to optimize operations and reduce costs. Approximately 83% of companies in these sectors now implement predictive maintenance, utilizing IoT sensors to continuously monitor equipment health and predict failures.

The benefits of predictive maintenance are significant. Companies that have adopted these strategies report a 30% reduction in maintenance costs and a 70% reduction in equipment breakdowns.

This improvement is largely due to the ability of machine learning algorithms to predict failures with 75-90% accuracy, a precision that increases over time as models are refined with real-world data. The reduction in unexpected downtime has also led to a 25% increase in productivity, underscoring the operational efficiency gains from predictive maintenance.

In large-scale industrial applications, the financial impact is substantial. Predictive maintenance can save up to $30 million annually per facility by preventing unplanned downtime and optimizing maintenance schedules. These savings are not only crucial for profitability but also enhance the reliability and longevity of critical assets.

Government initiatives further support the growth of the predictive maintenance market. For example, the U.S. Department of Energy has invested in research and development programs aimed at improving predictive maintenance for energy infrastructure. These initiatives target a 25% reduction in maintenance costs and a 10% increase in system uptime, reflecting the strategic importance of predictive maintenance in enhancing the efficiency and reliability of national energy systems.

The integration of advanced sensors and IoT technologies plays a pivotal role in this market. A typical manufacturing company might deploy 500 sensors to monitor critical equipment, collecting over 10 million data points per day. This vast amount of data is analyzed using machine learning algorithms to predict potential failures, enabling maintenance teams to take proactive measures and prevent costly disruptions.

The operational predictive maintenance market is set for robust growth as industries continue to prioritize cost reduction and operational efficiency. The combination of technological advancements, proven financial benefits, and government support positions predictive maintenance as a critical component of modern industrial operations.

Key Takeaways

- The Operational Predictive Maintenance Market was valued at USD 4.5 Billion in 2023, and is expected to reach USD 43.3 Billion by 2033, with a CAGR of 25.4%.

- In 2023, Software dominated the component segment with 53.4% due to its essential role in data analysis and predictive algorithms.

- In 2023, Cloud deployment mode led with 56.8% driven by the need for scalable and accessible maintenance solutions.

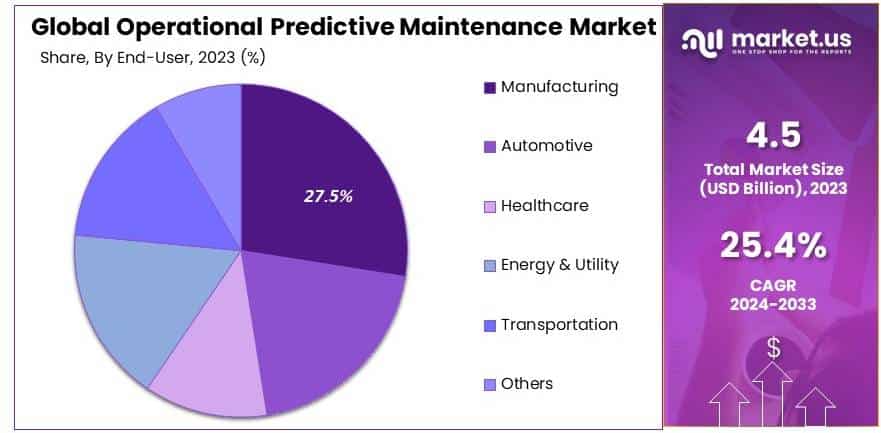

- In 2023, Manufacturing dominated the end-user segment with 27.5% due to the critical need for uptime and efficiency in production lines.

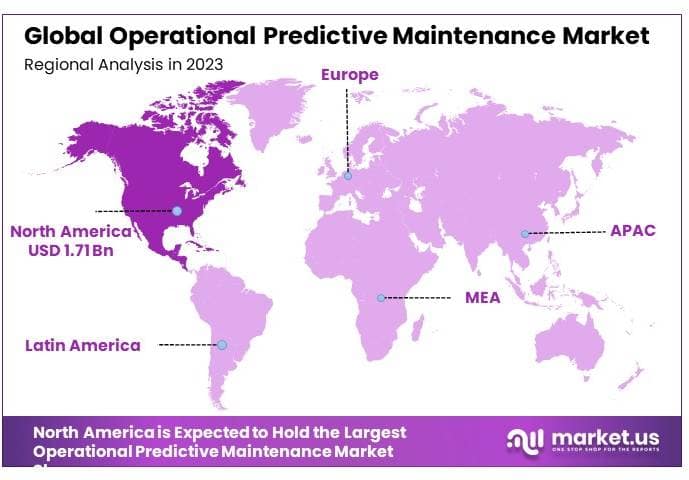

- In 2023, North America dominated the market with 37.9% owing to the region’s strong industrial base and focus on operational efficiency.

Component Analysis

Software dominates with 53.4% due to its essential role in enabling predictive maintenance capabilities.

In the operational predictive maintenance market, the Software component clearly leads, holding a significant market share of 53.4%. This dominance is largely due to the software’s pivotal role in analyzing data and predicting equipment failures before they occur. Predictive maintenance software integrates machine learning algorithms and AI in data analytics to monitor equipment and predict maintenance needs, which significantly reduces downtime and maintenance costs.

While the Software segment leads, the Services segment also plays a critical role by providing necessary support, maintenance, and training for the software. These services ensure that predictive maintenance systems are effectively implemented and maintained, and staff are well-trained to use them. However, the direct impact of software on operational efficiencies and cost reductions in maintenance operations underscores its dominant market position.

As industries increasingly adopt digital transformation practices, the demand for predictive maintenance software is expected to grow, driven by its ability to enhance productivity and sustainability in operations. This growth will likely be supported by advancements in IoT and AI, which improve the software’s effectiveness and accessibility.

Deployment Mode Analysis

Cloud dominates with 56.8% due to its scalability, flexibility, and cost-effectiveness.

Cloud-based deployment models have gained a dominant foothold in the operational predictive maintenance market, accounting for 56.8% of this segment. This preference is attributed to the cloud’s scalability, flexibility, and cost-effectiveness, which are particularly beneficial for predictive maintenance systems. Cloud platforms allow businesses to store vast amounts of data and access advanced analytical tools without significant upfront investments in physical infrastructure.

On-premise deployment, while still used by some organizations that require enhanced control over their data and systems, often involves higher costs and complexity in terms of maintenance and scalability. The shift towards cloud deployment is driven by its ability to provide real-time data access and analytics across multiple locations, essential for organizations with geographically dispersed operations.

The trend towards cloud deployment is expected to continue as more companies realize the benefits of cloud solutions in enabling more agile and responsive maintenance practices. This shift is likely to further enhance the efficiency and cost-effectiveness of maintenance operations across various industries.

End-User Analysis

Manufacturing dominates with 27.5% due to its reliance on heavy machinery and the critical need for minimizing downtime.

The Manufacturing sector emerges as the leading end-user in the operational predictive maintenance market, with a substantial share of 27.5%. This sector’s dominance is due to its heavy reliance on complex machinery and equipment, where downtime can result in significant operational disruptions and financial losses.

Predictive maintenance is crucial in the manufacturing industry as it helps predict equipment failures and schedule maintenance without disrupting production schedules.

Other sectors such as Automotive, Healthcare, Energy & Utility, and Transportation also implement predictive maintenance to enhance their operational efficiency and reduce maintenance costs. Each sector benefits from predictive maintenance by reducing unexpected equipment failures and extending the life of their assets.

The role of predictive maintenance in manufacturing is poised to grow even further as the sector continues to embrace Industry 4.0 technologies. The integration of IoT devices and smart sensors with predictive maintenance software is expected to drive greater efficiencies and support more proactive maintenance strategies, solidifying the sector’s lead in the market.

While Manufacturing remains the dominant sector in operational predictive maintenance, the continued evolution and integration of advanced technologies are likely to enhance the implementation and effectiveness of predictive maintenance across all sectors.

Key Market Segments

By Component

- Software

- Services

By Deployment Mode

- On-premise

- Cloud

By End-User

- Automotive

- Healthcare

- Manufacturing

- Energy & Utility

- Transportation

- Others

Driver

Advancements in AI and IoT Drive Market Growth

The operational predictive maintenance market is significantly driven by advancements in AI and IoT technologies. AI’s ability to predict mechanical failures by processing large datasets and recognizing patterns has reduced equipment downtime and increased operational efficiency.

For instance, machine downtime can cost manufacturers up to $540,000 per hour, making predictive maintenance a crucial investment. IoT devices enhance this process by enabling real-time data collection from machinery through embedded sensors. This integration has been particularly impactful in manufacturing and energy sectors, where equipment failure can result in safety hazards and costly delays.

Government initiatives are also playing a vital role in market growth. The U.S. Department of Energy, for example, has been pushing AI-driven predictive maintenance solutions to enhance energy infrastructure reliability. Additionally, companies such as Siemens have incorporated AI to optimize predictive maintenance systems, offering generative AI tools that anticipate maintenance needs before failures occur.

The growing regulatory pressure for safety and compliance further drives adoption. In industries like aviation and automotive, strict safety regulations require continuous monitoring of critical components to avoid accidents. Predictive maintenance powered by AI has become a necessity, helping organizations comply with these regulations while improving operational efficiency.

Restraint

High Costs and Complex Implementation Restraints Market Growth

The operational predictive maintenance market faces several restraints, primarily driven by high costs and complex implementation processes. The initial setup costs, including sensor installations and software integration, are considerable, making it challenging for smaller businesses to adopt these solutions.

Additionally, there is a shortage of skilled talent capable of managing predictive maintenance technologies. The global shortage of skilled cybersecurity and automation professionals is projected to reach 85 million by 2030. This lack of expertise complicates the adoption of predictive maintenance systems, as companies must invest in both technology and workforce training.

Cybersecurity is another significant concern. With over 72% of companies reporting an increase in cyberattacks in 2023, industries that rely on IoT-enabled maintenance systems are particularly vulnerable. Ensuring robust cybersecurity measures adds to both the cost and complexity of implementing predictive maintenance, especially in sectors like manufacturing, where legacy systems are difficult to secure.

Resistance to change within organizations also slows down adoption. Many businesses still prefer traditional maintenance methods, fearing the risks associated with digital transformation. These factors collectively restrain the market’s growth potential.

Opportunity

Advancements in AI and IoT Provide Opportunities

The operational predictive maintenance market is witnessing various opportunities driven by advancements in AI and IoT technologies. AI-powered solutions, such as those adopted by companies like Vistra, have shown that leveraging real-time data from IoT devices can improve efficiency, saving businesses millions.

Vistra, for example, captured $60 million in one year and identified another $40 million in potential savings by optimizing operations with AI. This technology enables industries like energy and manufacturing to prevent costly equipment failures, reduce downtime, and increase safety.

Government initiatives are also creating opportunities for predictive maintenance solutions. In the U.S., government agencies are investing in AI to improve infrastructure reliability. The Department of Energy is focusing on using AI for grid maintenance, helping to prevent outages and optimize energy production. Additionally, companies such as Shell and E.ON have implemented IoT and AI to enhance safety and streamline maintenance in power generation, reducing accidents and operating costs.

Partnerships between private and public sectors are further unlocking potential. Collaborations like those between Microsoft and Boliden are enhancing the scalability of predictive maintenance through cloud-based solutions, improving site efficiency and operational safety.

Challenge

High Costs and Data Security Challenges Market Growth

The operational predictive maintenance market faces several challenges that limit its growth, primarily due to high costs and data security concerns. Implementing predictive maintenance systems requires significant investment in hardware, software, and the integration of these systems into existing infrastructure.

In addition, the integration of IoT and AI technologies in predictive maintenance generates vast amounts of real-time data. This raises serious concerns about data security and privacy. Industries like energy and manufacturing, where sensitive operational data is involved, must invest heavily in cybersecurity measures to protect against potential breaches.

Another challenge is the lack of standardization across industries. Different sectors often have varying requirements for predictive maintenance, which complicates the development of a one-size-fits-all solution. This lack of uniformity requires companies to customize solutions, increasing both time and cost in the implementation process.

Growth Factors

AI and IoT Advancements Are Growth Factors

The operational predictive maintenance market is experiencing significant growth driven by advancements in artificial intelligence (AI) and the Internet of Things (IoT). AI, through the application of machine learning algorithms, enables real-time fault detection and predictive analytics, leading to improved operational efficiency and reduced equipment downtime. For instance, companies utilizing AI-based predictive maintenance have reported a 20-40% reduction in unplanned downtime.

IoT plays a crucial role by providing real-time monitoring through sensors installed on critical equipment. These sensors gather and analyze large volumes of data, allowing businesses to predict and prevent equipment failures before they occur. In the manufacturing sector, this has led to substantial savings, with companies like Caterpillar reducing fuel costs by 40% and increasing equipment uptime by 90%.

Government initiatives are further promoting AI and IoT adoption. Collaborations like the one between Procter & Gamble and Microsoft are enabling scalable predictive maintenance solutions across global manufacturing sites, improving productivity and sustainability.

Emerging Trends

Digital Twin Technology Is a Latest Trending Factor

Digital twin technology is driving significant growth in the operational predictive maintenance market. This technology allows businesses to create virtual replicas of physical assets, providing a comprehensive view of their operations. By simulating real-time conditions, potential issues can be identified and addressed before they become critical, reducing downtime and maintenance costs.

Another major factor is the rise of 5G services. Faster and more reliable data transmission is crucial for predictive maintenance systems to operate in real-time. This improvement enhances decision-making and operational efficiency across industries.

Additionally, augmented reality (AR) is transforming maintenance processes by providing technicians with instant access to data and visual guides. This enhancement improves accuracy and reduces repair times, leading to fewer errors and faster response rates.

Furthermore, mobile predictive maintenance applications enable teams to monitor equipment remotely. These apps offer alerts and insights on-the-go, adding flexibility and efficiency to maintenance management. Combined, these factors create a proactive maintenance approach that helps companies reduce costs, improve asset longevity, and minimize disruptions.

Regional Analysis

North America Dominates with 37.9% Market Share

North America holds a dominant position in the Operational Predictive Maintenance market with a 37.9% share, translating to USD 1.71 billion. This leadership is driven by the region’s early adoption of IoT and big data technologies, a well-established industrial sector, and significant investments in digital transformation initiatives.

The region’s strong IT infrastructure supports the widespread implementation of predictive maintenance solutions across diverse industries, including manufacturing, energy, and transportation. North America’s proactive approach to embracing advanced analytics and machine learning technologies further enhances its ability to forecast maintenance issues and optimize operations effectively.

The future of North America in the Operational Predictive Maintenance market looks promising, with ongoing advancements in AI and IoT expected to drive further adoption. As industries continue to focus on reducing downtime and maintenance costs, the demand for predictive maintenance solutions is anticipated to grow, potentially increasing the region’s market share.

Regional Overview for Other Regions

- Europe: Europe also has a strong presence in the predictive maintenance market, driven by its manufacturing prowess and stringent regulatory standards regarding equipment efficiency and safety. The region’s focus on sustainability and efficiency continues to drive investments in predictive technologies.

- Asia Pacific: The Asia Pacific region is experiencing rapid growth in this market, fueled by industrialization and the digitalization of manufacturing sectors. Increasing awareness about the benefits of predictive maintenance in reducing operational costs is driving adoption across major economies like China, Japan, and South Korea.

- Middle East & Africa: In the Middle East & Africa, the market is developing gradually, with industries such as oil and gas and mining starting to adopt predictive maintenance technologies to enhance operational efficiency and ensure the safety of aging infrastructure.

- Latin America: Latin America is witnessing moderate growth in the predictive maintenance market. Factors such as industrial modernization and the push towards operational efficiency are driving the adoption of these technologies, particularly in key countries such as Brazil and Mexico.

Key Regions and Countries covered іn thе rероrt

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Russia

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Rest of Asia-Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- GCC

- South Africa

- Israel

- Rest of MEA

Key Players Analysis

The Operational Predictive Maintenance market is led by a few key companies that significantly influence its growth and direction. The top three players in this market are IBM Corporation, SAP SE, and Schneider Electric.

IBM Corporation is a major force in the market, utilizing its Watson AI platform to deliver advanced predictive maintenance solutions. IBM’s strong expertise in data analytics and AI enables companies to predict equipment failures and optimize maintenance schedules. IBM’s global presence and continuous innovation solidify its leadership in this space.

SAP SE is another key player, offering integrated predictive maintenance solutions through its SAP Predictive Maintenance and Service platform. SAP’s solutions are widely adopted across industries, providing real-time insights and helping businesses reduce downtime. SAP’s strong foothold in enterprise software and its focus on innovation give it a significant market influence.

Schneider Electric also plays a crucial role in the market, providing predictive maintenance solutions that focus on energy management and automation. Schneider’s deep industry expertise and commitment to sustainability make its offerings highly valuable in various sectors. Schneider Electric’s strategic positioning as a leader in energy and automation solutions enhances its impact on the market.

These companies drive the operational predictive maintenance market, setting standards and leading innovation. Their strategic positioning, technological advancements, and market influence make them the key players shaping the future of predictive maintenance.

Top Key Players in the Market

- IBM Corporation

- SAS Institute Inc.

- Software AG

- Rockwell Automation

- eMaint by Fluke Corporation

- SAP SE

- Schneider Electric

- SKF

Recent Developments

- Rockwell Automation: Rockwell Automation launched the Asset Risk Predictor, an AI-powered tool designed to predict equipment failures days before they occur. This solution integrates with existing maintenance systems to optimize maintenance schedules and automate work orders.

- SAS Institute: SAS Institute has enhanced its predictive maintenance solutions, now supporting thousands of analytics models to predict equipment failures, optimize maintenance schedules, and reduce downtime. The tools are scalable and versatile for various industrial applications.

- SAP: SAP has collaborated with Petrobras to implement Intelligent Asset Management solutions across the BUZIOS oilfield. This initiative has successfully reduced downtime and improved operational efficiency using SAP’s predictive maintenance tools and machine learning for failure prediction.

Report Scope

Report Features Description Market Value (2023) USD 4.5 Billion Forecast Revenue (2033) USD 43.3 Billion CAGR (2024-2033) 25.4% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Component (Software, Services), By Deployment Mode (On-premise, Cloud), By End-User (Automotive, Healthcare, Manufacturing, Energy & Utility, Transportation, Others) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape IBM Corporation, SAS Institute Inc., Software AG, Rockwell Automation, eMaint by Fluke Corporation, SAP SE, Schneider Electric, SKF Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is the Operational Predictive Maintenance Market?The Operational Predictive Maintenance Market involves solutions and technologies that predict equipment failures and maintenance needs, improving operational efficiency and reducing downtime through data-driven insights.

How big is the Operational Predictive Maintenance Market?The Operational Predictive Maintenance Market was valued at USD 4.5 billion and is expected to grow to USD 43.3 billion, with a CAGR of 25.4% during the forecast period.

What are the key factors driving the growth of the Operational Predictive Maintenance Market?The growth is driven by the increasing need for reducing operational downtime, advancements in sensor technologies and data analytics, and the growing adoption of IoT and machine learning in maintenance strategies.

What are the current trends and advancements in the Operational Predictive Maintenance Market?Trends include the integration of advanced analytics and AI for predictive insights, increased use of IoT sensors for real-time monitoring, and the development of more sophisticated maintenance algorithms.

What are the major challenges and opportunities in the Operational Predictive Maintenance Market?Challenges include the high cost of implementation and the need for accurate data collection and analysis. Opportunities lie in expanding predictive maintenance applications across various industries and improving technology accessibility.

Who are the leading players in the Operational Predictive Maintenance Market?Leading players include IBM Corporation, SAS Institute Inc., Software AG, Rockwell Automation, eMaint by Fluke Corporation, SAP SE, Schneider Electric, and SKF.

Operational Predictive Maintenance MarketPublished date: August 2024add_shopping_cartBuy Now get_appDownload Sample

Operational Predictive Maintenance MarketPublished date: August 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- IBM Corporation

- SAS Institute Inc.

- Software AG

- Rockwell Automation

- eMaint by Fluke Corporation

- SAP SE

- Schneider Electric

- SKF