Global Hybrid Additive Manufacturing Machines Market Size, Share, Growth Analysis By Machine Type (Powder Bed Fusion, Direct Energy Deposition, Material Extrusion, Hybrid CNC-Additive, Others), By Material Type (Titanium Alloys, Aluminum Alloys, Stainless Steel, Nickel Alloys, Ceramics, Others), By End-Use (Aerospace & Defense, Medical, Automotive, Energy, Electronics, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Feb 2026

- Report ID: 160570

- Number of Pages: 299

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

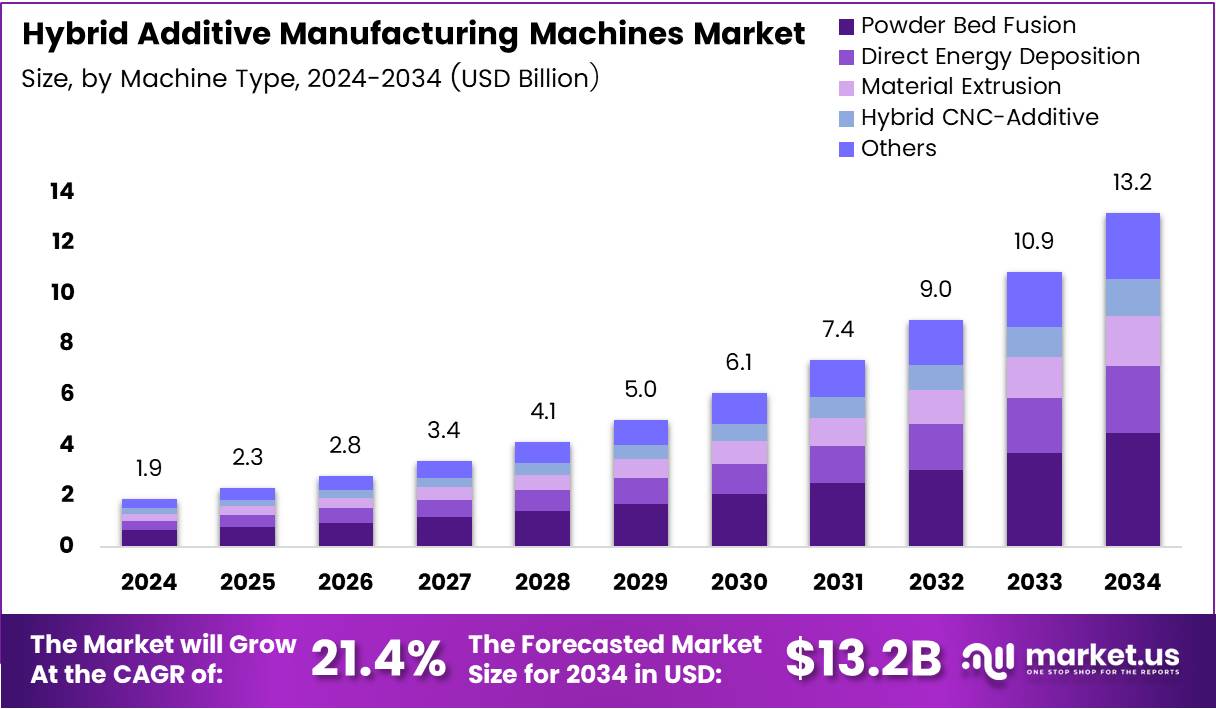

The Global Hybrid Additive Manufacturing Machines Market size is expected to be worth around USD 13.2 Billion by 2034, from USD 1.9 Billion in 2024, growing at a CAGR of 21.4% during the forecast period from 2025 to 2034.

The Hybrid Additive Manufacturing Machines Market integrates additive and subtractive manufacturing in a single setup, enabling precision, flexibility, and high-performance production. It supports complex geometries with reduced lead time and enhanced material efficiency. This market is witnessing rising adoption across aerospace, automotive, and medical sectors due to evolving industrial automation needs.

Moreover, continuous innovation in 3D printing technology and multi-material processing boosts product development. Companies increasingly seek hybrid systems to streamline operations and reduce tooling costs. These machines help achieve superior surface finish and dimensional accuracy, driving their acceptance among manufacturers targeting low-volume, high-value production environments.

Additionally, market growth is supported by rising investments in Industry 4.0 and smart manufacturing initiatives. Governments worldwide promote digital transformation through subsidies and R&D incentives. Such efforts strengthen supply chains, enhance productivity, and foster innovation, ultimately accelerating demand for hybrid additive manufacturing solutions in advanced engineering industries.

Furthermore, emerging economies are investing in advanced manufacturing technologies to enhance competitiveness. Growing awareness about sustainable production and waste reduction drives adoption. The integration of CNC and additive systems ensures energy efficiency, reduced scrap, and material reusability—key factors attracting attention from environmentally conscious manufacturers.

Meanwhile, regulatory bodies are introducing supportive frameworks to standardize hybrid processes. Certifications ensure product quality and safety, building trust among end-users. Compliance with global manufacturing standards further facilitates cross-border trade and encourages foreign investments in industrial modernization programs, thereby expanding the hybrid additive manufacturing ecosystem.

In addition, the market presents strong opportunities in customized part manufacturing and tooling applications. Hybrid machines enable rapid prototyping and complex part reconstruction, helping industries respond faster to design changes. This agility enhances market competitiveness and fuels innovation across aerospace, automotive, defense, and healthcare segments.

Key Takeaways

- The Global Hybrid Additive Manufacturing Machines Market is projected to reach USD 13.2 Billion by 2034, growing from USD 1.9 Billion in 2024 at a CAGR of 21.4% (2025–2034).

- In 2024, Powder Bed Fusion led the By Machine Type segment with a 34.8% share, driven by high-resolution printing and complex geometry capabilities.

- Titanium Alloys dominated the By Material Type segment in 2024, holding a 27.6% share due to their mechanical strength and biocompatibility.

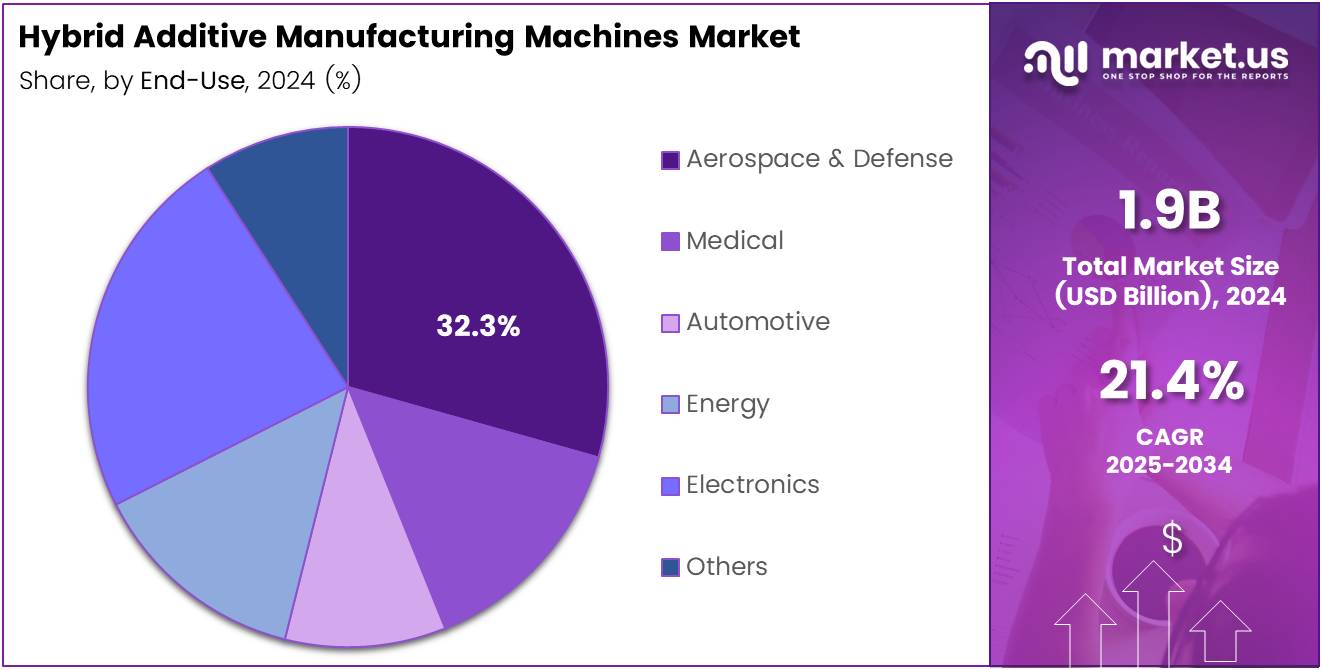

- The Aerospace & Defense sector led the By End-Use segment in 2024 with a 32.3% share, owing to its demand for precision and material efficiency.

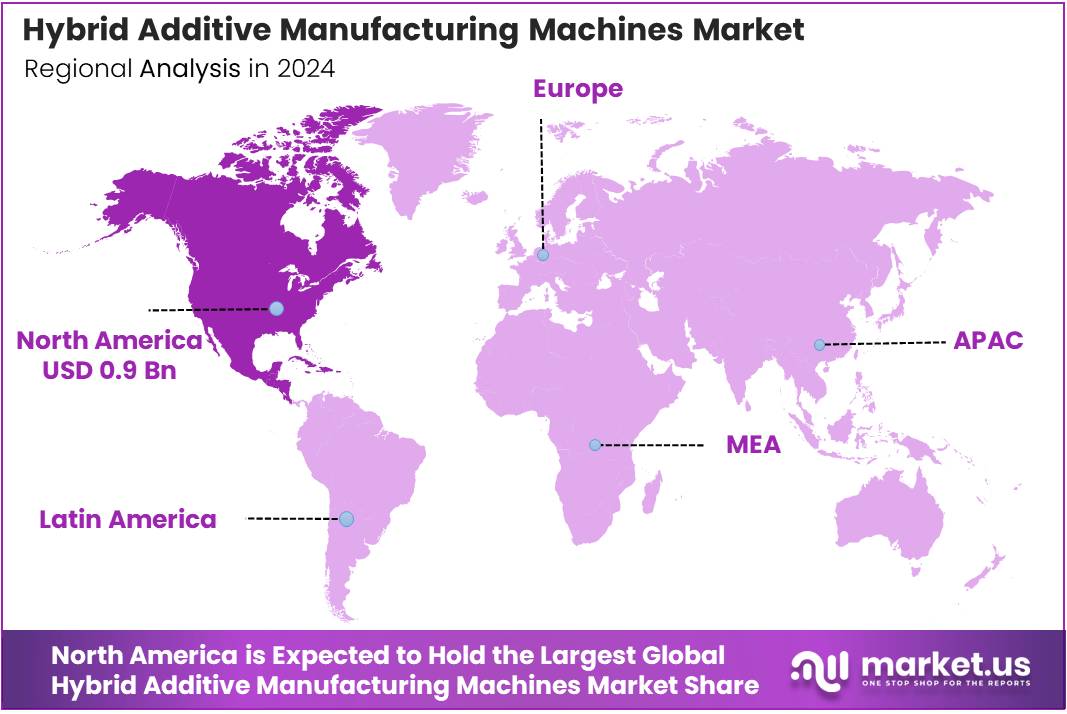

- North America was the leading region with a 48.3% share, valued at USD 0.9 Billion, supported by strong adoption in aerospace, automotive, and defense industries.

By Machine Type Analysis

Powder Bed Fusion dominates with 34.8% due to its precision, scalability, and superior surface finish.

In 2024, Powder Bed Fusion held a dominant market position in the By Machine Type Analysis segment of the Hybrid Additive Manufacturing Machines Market, with a 34.8% share. This technology is widely adopted due to its high-resolution printing capabilities and suitability for complex geometries. Its growing use in aerospace and medical sectors drives significant adoption.

Direct Energy Deposition continues to gain momentum as it allows efficient repair and refurbishment of metal components. Its ability to deposit multiple materials simultaneously enhances product strength and performance, making it ideal for heavy industries. This method’s flexibility and compatibility with large parts support its expanding market presence.

Material Extrusion remains a preferred choice for prototyping and low-cost manufacturing applications. It enables faster production cycles and supports diverse material combinations, particularly in research and design stages. Its simplicity and scalability make it appealing for small-scale enterprises exploring hybrid manufacturing solutions.

Hybrid CNC-Additive systems integrate additive and subtractive technologies for improved accuracy and finish. These machines help in reducing post-processing steps while maintaining dimensional precision, gaining traction across automotive and tooling applications.

Others include emerging technologies tailored for niche applications. They focus on specialized requirements such as composite manufacturing and custom tooling, contributing to technological diversity and innovation in hybrid systems.

By Material Type Analysis

Titanium Alloys dominate with 27.6% due to their superior strength-to-weight ratio and corrosion resistance.

In 2024, Titanium Alloys held a dominant market position in the By Material Type Analysis segment of the Hybrid Additive Manufacturing Machines Market, with a 27.6% share. Their excellent mechanical properties and biocompatibility make them indispensable in aerospace and medical applications where precision and durability are critical.

Aluminum Alloys are favored for their lightweight nature and cost efficiency. They enable faster production and energy savings, particularly in automotive and consumer electronics sectors. The increasing focus on lightweight vehicles and structural optimization drives aluminum’s usage in hybrid systems.

Stainless Steel continues to be a mainstay in industrial manufacturing. Its strength, wear resistance, and affordability make it suitable for tooling, energy, and defense applications. As hybrid machines evolve, stainless steel remains a reliable choice for functional prototypes and end-use parts.

Nickel Alloys gain attention for their heat resistance and structural stability under extreme conditions. They are widely utilized in turbines and energy components, where high performance and longevity are essential. Their compatibility with multi-material deposition enhances design flexibility.

Ceramics are emerging as promising materials in electronics and biomedical fields. Their hardness, insulation properties, and temperature tolerance enable high-precision manufacturing for advanced engineering applications.

Others encompass specialized materials like composites and polymers, addressing niche demands for customized hybrid manufacturing projects.

By End-Use Analysis

Aerospace & Defense dominates with 32.3% due to its demand for lightweight, high-performance parts.

In 2024, Aerospace & Defense held a dominant market position in the By End-Use Analysis segment of the Hybrid Additive Manufacturing Machines Market, with a 32.3% share. The sector relies on hybrid systems for producing complex geometries, reducing material waste, and meeting stringent quality standards.

Medical applications are rapidly growing due to the rising demand for patient-specific implants and surgical tools. Hybrid machines enable customization and biocompatibility, crucial for improving patient outcomes and precision in medical manufacturing.

Automotive manufacturers increasingly adopt hybrid additive technologies for prototyping, tooling, and lightweight components. These systems enhance production efficiency and facilitate design optimization, supporting the industry’s shift toward electrification and sustainability.

Energy sector adoption focuses on turbine blades, valves, and other high-performance parts. Hybrid manufacturing ensures durability, efficient material use, and rapid component repair, aligning with renewable energy initiatives.

Electronics utilize hybrid systems for intricate components requiring miniaturization and precision. The capability to combine multiple materials supports the creation of innovative electronic assemblies.

Others include sectors like construction and education, where hybrid manufacturing drives innovation, training, and small-scale product development.

Key Market Segments

By Machine Type

- Powder Bed Fusion

- Direct Energy Deposition

- Material Extrusion

- Hybrid CNC-Additive

- Others

By Material Type

- Titanium Alloys

- Aluminum Alloys

- Stainless Steel

- Nickel Alloys

- Ceramics

- Others

By End-Use

- Aerospace & Defense

- Medical

- Automotive

- Energy

- Electronics

- Others

Drivers

Rising Adoption of Hybrid Manufacturing for Complex Aerospace and Defense Components Drives Market Growth

The global hybrid additive manufacturing machines market is witnessing strong momentum, primarily driven by the growing need for complex and high-performance components in aerospace and defense industries. These sectors require lightweight, intricate designs with tight tolerances, which hybrid systems can efficiently produce by combining additive and subtractive processes. This integration ensures both structural integrity and precision, supporting the production of mission-critical parts.

Another key driver is the increasing demand for tooling and mold fabrication with shorter lead times. Traditional manufacturing often involves long setup and machining cycles, but hybrid machines allow quick prototyping and production directly from digital designs. This significantly reduces turnaround time and improves flexibility for industries like automotive and industrial equipment.

The growing integration of multi-axis CNC systems with additive modules is further enhancing manufacturing capabilities. Multi-axis systems provide greater design freedom, enabling complex geometries and superior surface finishes. The synergy between CNC precision and additive versatility is boosting adoption across sectors that value customization and performance.

Moreover, advancements in metal powder feedstock quality are improving part consistency, durability, and mechanical properties. Enhanced materials ensure better bonding, reduced porosity, and increased reliability of final products. As a result, manufacturers are gaining confidence in hybrid technologies for both prototyping and end-use parts, further accelerating market expansion.

Restraints

High Initial Investment and Maintenance Cost of Hybrid Manufacturing Systems Limits Market Adoption

Despite the promising benefits, the hybrid additive manufacturing machines market faces certain restraints. One major challenge is the high upfront investment and maintenance cost associated with these advanced systems. Small and medium enterprises often find it difficult to justify the capital expenditure, limiting widespread adoption across industries.

Another critical issue is the lack of standardization across hybrid additive manufacturing platforms. With various vendors offering different system architectures and software ecosystems, interoperability and compatibility remain concerns. This inconsistency can complicate integration and increase the learning curve for operators.

Additionally, the shortage of skilled professionals capable of operating and programming hybrid machines is slowing market growth. These systems demand expertise in both additive and subtractive processes, CAD/CAM programming, and material science. The limited availability of such talent can lead to operational inefficiencies and underutilization of equipment.

Technical challenges in achieving seamless transition between additive and subtractive stages further hinder performance. Ensuring proper alignment, temperature control, and toolpath synchronization is complex and often requires advanced process monitoring. Overcoming these obstacles is essential for delivering consistent part quality and maximizing productivity.

Growth Factors

Expansion of Hybrid Additive Manufacturing in Medical Implants and Orthopedic Devices Creates New Opportunities

The hybrid additive manufacturing machines market is poised for significant growth as applications expand in the medical sector. Hybrid systems are increasingly being used to create patient-specific implants and orthopedic devices that combine intricate internal structures with smooth external surfaces. This capability enhances biocompatibility and performance, opening lucrative opportunities for medical manufacturers.

Rising collaboration between original equipment manufacturers (OEMs) and research institutes for new material development is also driving innovation. Such partnerships aim to improve material properties like strength, corrosion resistance, and thermal stability, enabling more reliable parts for aerospace, defense, and automotive use.

Integration with smart factory and Industry 4.0 ecosystems presents another major opportunity. By connecting hybrid machines with IoT sensors and real-time data analytics, manufacturers can achieve greater visibility, predictive maintenance, and process optimization. This digital integration enhances productivity and reduces downtime.

Furthermore, emerging demand for on-demand production in marine and energy sectors supports market expansion. Hybrid systems allow rapid repair and customization of large, critical components such as turbine blades or propellers, reducing logistics and downtime. This adaptability strengthens their role in decentralized manufacturing environments.

Emerging Trends

Adoption of AI and Digital Twins for Predictive Maintenance and Process Optimization Shapes Market Trends

A key trend shaping the hybrid additive manufacturing machines market is the growing adoption of artificial intelligence (AI) and digital twins. These technologies enable predictive maintenance, process simulation, and real-time optimization, helping manufacturers reduce downtime and improve part quality. By analyzing data from sensors and simulations, companies can fine-tune operations for efficiency.

The development of hybrid machines capable of multi-material fabrication is another significant trend. This capability allows manufacturers to produce components with varied material properties, combining strength, flexibility, or conductivity in a single part. Such innovation expands design possibilities across aerospace, automotive, and electronics industries.

Sustainable manufacturing practices are also gaining traction, with an increasing focus on material efficiency. Hybrid systems minimize waste by depositing material only where needed, while precise machining ensures reduced scrap. This aligns with global efforts toward greener and more resource-efficient production methods.

Lastly, the surge in hybrid additive manufacturing startups offering modular retrofitting solutions is reshaping accessibility for small and medium enterprises. By upgrading existing CNC machines with additive modules, SMEs can adopt hybrid technology without full system replacement. This trend promotes broader market participation and technology democratization.

Regional Analysis

North America Dominates the Hybrid Additive Manufacturing Machines Market with a Market Share of 48.3%, Valued at USD 0.9 Billion

North America holds the leading position in the hybrid additive manufacturing machines market, accounting for a substantial 48.3% share and valued at USD 0.9 Billion. The region’s dominance is driven by the rapid adoption of advanced manufacturing technologies across aerospace, automotive, and defense sectors.

Strong investments in research and development, coupled with the presence of established manufacturing infrastructure, further enhance the region’s leadership. Additionally, supportive government initiatives promoting industrial digitization continue to foster market expansion.

Europe Hybrid Additive Manufacturing Machines Market Trends

Europe is a key contributor to the hybrid additive manufacturing machines market, propelled by a robust industrial base and growing emphasis on sustainable production processes. The region’s focus on innovation, precision engineering, and integration of additive technologies in industrial manufacturing fuels steady growth. Moreover, increased adoption across automotive and aerospace sectors is accelerating the region’s transition towards Industry 4.0 manufacturing capabilities.

Asia Pacific Hybrid Additive Manufacturing Machines Market Trends

Asia Pacific is emerging as one of the fastest-growing regions in the hybrid additive manufacturing machines market. Rapid industrialization, coupled with rising investments in advanced manufacturing facilities, is driving market expansion. Countries such as China, Japan, and South Korea are actively incorporating hybrid manufacturing to improve productivity and achieve high-precision output. The growing focus on cost-effective production and technological innovation is expected to further strengthen regional growth.

Middle East and Africa Hybrid Additive Manufacturing Machines Market Trends

The Middle East and Africa are witnessing gradual growth in the hybrid additive manufacturing machines market, primarily supported by increasing adoption in energy, aerospace, and automotive applications. Government-led diversification strategies and industrial modernization efforts are fostering awareness and investment in advanced manufacturing. While still developing, the region holds promising potential as industries embrace digital transformation.

Latin America Hybrid Additive Manufacturing Machines Market Trends

Latin America’s hybrid additive manufacturing machines market is experiencing moderate growth, driven by rising interest in industrial automation and digital manufacturing. Countries like Brazil and Mexico are gradually adopting hybrid solutions to improve manufacturing efficiency and reduce operational costs. Although adoption is currently limited, growing awareness of technological benefits and supportive policy initiatives are likely to stimulate market opportunities in the near future.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Hybrid Additive Manufacturing Machines Company Insights

The global Hybrid Additive Manufacturing Machines Market in 2024 is witnessing steady growth, driven by increasing adoption of advanced manufacturing solutions that combine additive and subtractive processes for enhanced precision and efficiency. Leading players are focusing on innovation, automation, and strategic collaborations to strengthen their market presence and cater to the growing demand across aerospace, automotive, and healthcare sectors.

DMG MORI Co., Ltd. continues to be a frontrunner with its strong portfolio of hybrid manufacturing systems that integrate milling and laser deposition technologies. The company’s emphasis on digitalization, smart factory solutions, and seamless software integration enables customers to achieve higher productivity and part accuracy. Its hybrid platforms are widely recognized for reliability and adaptability in industrial-grade production.

Mazak Corporation maintains a competitive edge through continuous innovation in multi-tasking hybrid systems that combine additive capabilities with high-performance machining. Its focus on user-friendly interfaces and automation-ready solutions allows manufacturers to enhance throughput and flexibility, making it a key player in the transition toward Industry 4.0 manufacturing environments.

Matsuura Machinery Corporation stands out for its precision engineering and specialized hybrid machines that target high-value applications. The company’s integration of metal additive manufacturing with traditional CNC milling appeals to industries demanding superior surface finish and structural integrity, particularly in aerospace and medical device production.

Stratasys Ltd leverages its deep expertise in additive manufacturing to expand into hybrid systems, offering versatile solutions that bridge prototyping and end-use part manufacturing. With a strong focus on material innovation and software-driven workflows, Stratasys continues to enhance hybrid manufacturing capabilities, supporting customers in achieving greater design freedom and operational efficiency.

Top Key Players in the Market

- DMG MORI Co., Ltd.

- Mazak Corporation

- Matsuura Machinery Corporation

- Stratasys Ltd

- voxeljet AG

- Optomec

- SLM SOLUTIONS GROUP AG

- Materialise

- GE Additive

Recent Developments

- In Mar 2025, Sodick announced its plan to acquire a majority stake in Prima Additive, marking a strategic move to strengthen its position in metal additive manufacturing (AM) technologies. The deal signifies a new chapter in Sodick’s diversification toward advanced hybrid and laser-based AM systems.

- In Aug 2025, Schoeller-Bleckmann Oilfield Equipment (SBO) revealed the acquisition of 3T Additive Manufacturing, expanding its footprint in industrial-grade 3D printing and metal AM services. This acquisition reinforces SBO’s commitment to scaling additive production capabilities across aerospace and energy sectors.

- In 2024, ODeCon introduced the adAM-BASE, a high-speed hybrid additive manufacturing machine integrating laser-based Directed Energy Deposition (DED) with CNC machining. Positioned as a cost-effective entry point, it is priced below ~€300,000, targeting SMEs and research institutions exploring affordable hybrid AM solutions.

Report Scope

Report Features Description Market Value (2024) USD 1.9 Billion Forecast Revenue (2034) USD 13.2 Billion CAGR (2025-2034) 21.4% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Machine Type (Powder Bed Fusion, Direct Energy Deposition, Material Extrusion, Hybrid CNC-Additive, Others), By Material Type (Titanium Alloys, Aluminum Alloys, Stainless Steel, Nickel Alloys, Ceramics, Others), By End-Use (Aerospace & Defense, Medical, Automotive, Energy, Electronics, Others) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape DMG MORI Co., Ltd., Mazak Corporation, Matsuura Machinery Corporation, Stratasys Ltd, voxeljet AG, Optomec, SLM SOLUTIONS GROUP AG, Materialise, GE Additive Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Hybrid Additive Manufacturing Machines MarketPublished date: Feb 2026add_shopping_cartBuy Now get_appDownload Sample

Hybrid Additive Manufacturing Machines MarketPublished date: Feb 2026add_shopping_cartBuy Now get_appDownload Sample -

-

- DMG MORI Co., Ltd.

- Mazak Corporation

- Matsuura Machinery Corporation

- Stratasys Ltd

- voxeljet AG

- Optomec

- SLM SOLUTIONS GROUP AG

- Materialise

- GE Additive