Global Automatic Carton Erector Market Size, Share, Growth Analysis By Type (Vertical Carton Erectors, Horizontal Carton Erectors), By End-User Industry (Food and Beverage, Pharmaceuticals, Consumer Goods, Electronics, Automotive, E-commerce), By Operation Type (Fully Automatic, Semi-Automatic), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Feb 2025

- Report ID: 141034

- Number of Pages: 354

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

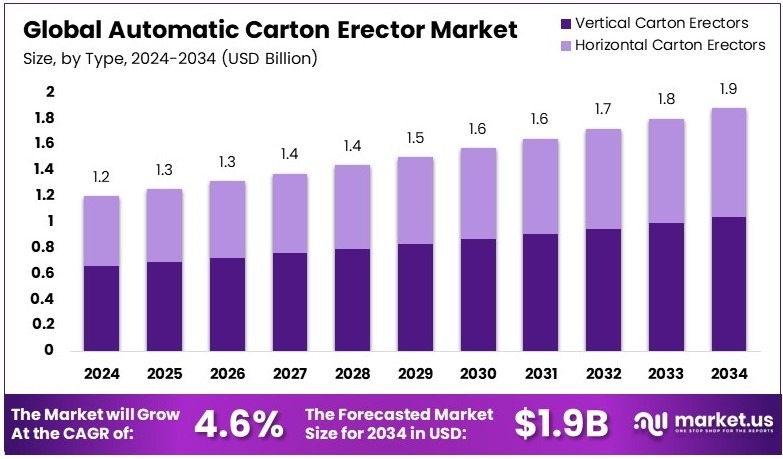

The Global Automatic Carton Erector Market size is expected to be worth around USD 1.9 Billion by 2034, from USD 1.2 Billion in 2024, growing at a CAGR of 4.6% during the forecast period from 2025 to 2034.

An Automatic Carton Erector is a machine used to form, fold, and seal cartons automatically. It streamlines the packaging process by creating boxes from flat sheets and preparing them for filling and sealing. This equipment is widely used in industries for efficient carton handling.

The Automatic Carton Erector Market refers to the demand for machines that automatically form cartons in packaging processes. It includes the sales and use of carton erectors across various industries, particularly those that require efficient and automated packaging solutions in manufacturing and logistics.

Automatic carton erectors have significantly transformed modern packaging lines. These machines, capable of processing up to 30 cartons per minute, are pivotal in boosting efficiency, particularly in sectors that demand rapid production such as food and beverages. Consequently, the market for automatic carton erectors is expanding as businesses increasingly rely on automation to meet production demands.

Furthermore, growth in this market is spurred by several factors. For instance, the push for more efficient production lines at a local scale not only enhances market responsiveness but also allows companies to increase operations without a proportional rise in labor costs. In addition, government regulations aimed at promoting safety and efficiency in manufacturing further drive the adoption of these automated solutions.

Moreover, the competitive landscape of the automatic carton erector market is robust, with manufacturers continually innovating to accommodate a diverse array of carton sizes and types. This versatility opens new opportunities for businesses to customize and integrate these systems into their existing operations, thereby broadening the market’s scope.

However, the impact of automatic carton erectors extends beyond simple market dynamics. Locally, the shift towards automation significantly affects labor patterns, reducing the need for manual packaging assembly.

Meanwhile, governmental investments in automation and smart manufacturing are enhancing this effect, fostering further growth in the sector and encouraging a wider adoption of automated processes. Hence, the trajectory of the automatic carton erector market points towards sustained growth and innovation, driven by ongoing advancements and regulatory support.

Key Takeaways

- The Automatic Carton Erector Market was valued at USD 1.2 Billion in 2024 and is expected to reach USD 1.9 Billion by 2034, with a CAGR of 4.6%.

- In 2024, Vertical Carton Erectors dominated the type segment with 55.0% due to their efficiency in high-speed packaging lines.

- In 2024, Food & Beverage led the end-user industry with 40.0%, driven by increasing demand for packaged food products.

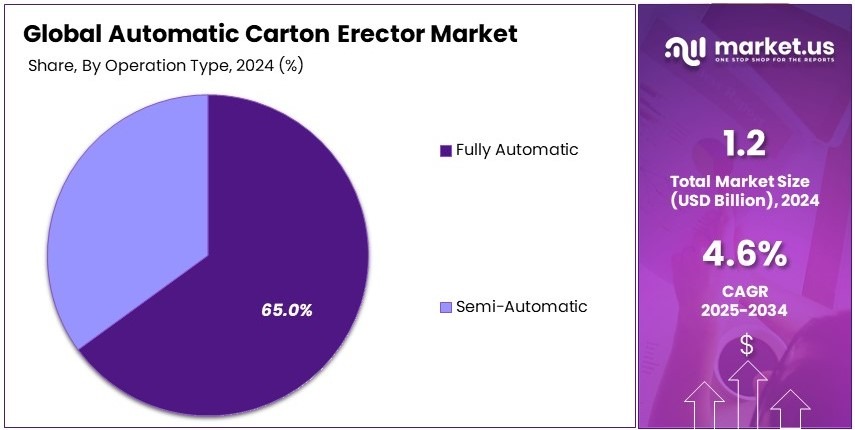

- In 2024, Fully Automatic machines accounted for 65.0%, owing to automation trends and labor cost reductions.

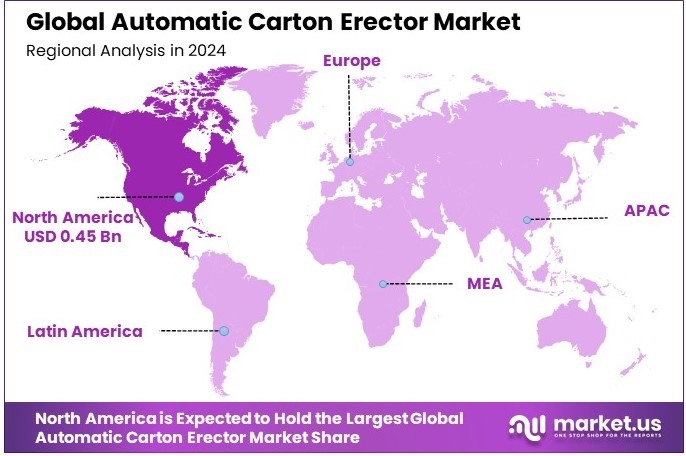

- In 2024, North America was the dominant region with 37.2% valued at USD 0.45 Bn, supported by strong industrial automation growth.

Type Analysis

Vertical Carton Erectors dominate with 55.0% due to higher demand for compact packaging solutions.

Vertical carton erectors are widely used in industries where space efficiency and cost savings are crucial. This sub-segment currently holds a dominant share of the market at 55.0%. The reason for this substantial share lies in the increased demand for packaging systems that maximize space and streamline operations. Vertical carton erectors are more compact, making them ideal for industries that require smaller footprint machines.

Their design allows for faster changeovers and a simplified setup, which is highly valued in fast-paced production environments. The food and beverage industry, in particular, benefits from the speed and efficiency these machines offer in high-volume production lines. Additionally, the trend toward automation in manufacturing processes has further fueled the adoption of vertical carton erectors.

Horizontal carton erectors, while also critical in certain industries, have a smaller market share due to the larger space required for their operations. They tend to be more suitable for high-speed lines in industries like electronics or automotive, but their higher cost and space demands reduce their overall appeal compared to vertical systems.

Despite this, horizontal systems continue to have a strong presence in niche markets, where large, heavy cartons are needed for packaging complex products. While their role is significant, it remains secondary to the dominance of vertical erectors in the overall market.

End-User Industry Analysis

Food & Beverage dominates with 40.0% due to increasing consumer demand for packaged products.

The food and beverage industry holds the largest share of the automatic carton erector market at 40.0%. The demand for packaged products, particularly in the retail sector, drives this trend. Consumers’ preference for ready-to-eat or pre-packaged goods has led to an increase in production requirements for packaging machinery.

Automatic carton erectors, especially vertical models, are highly efficient for food product packaging, as they can handle high volumes with minimal labor input. Furthermore, regulatory requirements for food safety and packaging integrity have spurred growth in this segment, as automated systems offer consistent quality and reduce human error.

Pharmaceuticals follow as the second-largest end-user. The pharmaceutical industry’s need for precise packaging solutions has led to increased adoption of automated erectors. These machines ensure that medicine packaging is consistent and compliant with stringent regulations. The consumer goods segment also plays a significant role, driven by the growing demand for efficient packaging in the mass production of personal care products, cosmetics, and household goods.

Electronics and automotive industries also rely on carton erectors for packaging their products efficiently. However, these industries face more stringent requirements for product protection, and as such, the demand for packaging solutions is somewhat more specialized. The e-commerce sector is rapidly growing as online shopping continues to expand globally. Packaging solutions in this sector are increasingly automated to meet high-volume shipping demands.

Operation Type Analysis

Fully Automatic dominates with 65.0% due to increasing demand for high-efficiency systems.

The fully automatic sub-segment dominates the market with a 65.0% share, driven by the growing trend towards automation across various industries. Fully automatic carton erectors offer higher production speeds, greater reliability, and minimal human intervention.

These systems are preferred in industries that require consistent and high-speed production, such as food and beverage packaging. Automation leads to better efficiency, reduced operational costs, and less downtime, all of which are crucial for companies aiming to maintain competitive advantages in a fast-paced market.

Semi-automatic systems are still crucial in settings where lower volumes and more flexibility are required. These machines are generally easier to operate and maintain, making them ideal for smaller businesses or environments where product types frequently change.

However, their slower speeds and higher labor requirements place them behind fully automatic systems in the overall market growth. As automation continues to grow, the shift towards fully automatic solutions is expected to further intensify, cementing its dominant role in the carton erector market.

Key Market Segments

By Type

- Vertical Carton Erectors

- Horizontal Carton Erectors

By End-User Industry

- Food & Beverage

- Pharmaceuticals

- Consumer Goods

- Electronics

- Automotive

- E-commerce

By Operation Type

- Fully Automatic

- Semi-Automatic

Driving Factors

Surge in Demand for Faster Production Lines Drives Market Growth

The demand for high-speed production lines in consumer goods manufacturing is a major driver for the automatic carton erector market. Manufacturers are increasingly focusing on improving production efficiency and reducing packaging time. As industries scale up their output, the need for faster and more reliable packaging systems grows. This trend leads to a higher adoption of automated systems, including carton erectors.

Additionally, there is a push to expand packaging capabilities to cater to diverse industries. As businesses produce a wider range of products, the ability to handle multiple packaging formats efficiently becomes critical.

Furthermore, the heightened focus on packaging safety standards is pushing manufacturers toward automation. Automated carton erection ensures a higher degree of consistency and minimizes the risk of human error, thereby adhering to stricter safety regulations.

The ongoing labor shortage in the manufacturing sector is also driving the shift toward automation. With fewer workers available, companies are opting for automated systems that can reduce their dependency on human labor, ensuring continuous operation and mitigating workforce challenges.

Restraining Factors

System Integration Challenges and Power Dependency Restrain Market Growth

Despite the benefits, several factors restrain the growth of the automatic carton erector market. A key limitation is the dependency on a consistent power supply. If power outages or fluctuations occur, the functionality and reliability of automated systems may be compromised, which can disrupt production lines.

Additionally, the integration of new automated systems with existing machinery can be challenging. Many manufacturers use legacy systems, which may not be compatible with the latest automation technologies. This creates obstacles for companies looking to upgrade their processes.

Moreover, automated equipment often comes with complex regulatory compliance requirements, especially in industries like food and pharmaceuticals, which demand stringent packaging standards. These requirements can result in delays and additional costs for companies adopting automation.

Lastly, some sectors exhibit resistance to adopting automated systems. In certain industries, businesses still rely heavily on manual processes, and the shift to automation can be met with reluctance due to concerns about job losses and the upfront investment needed.

Growth Opportunities

Modular Solutions and Robotics Offer New Opportunities in Market

Several growth opportunities exist in the automatic carton erector market. One such opportunity is the development of modular and scalable carton erector solutions, particularly targeting small-to-medium enterprises (SMEs). These companies often seek cost-effective solutions to meet their packaging needs without large upfront investments.

Moreover, the application of advanced robotics for carton formation can improve both precision and speed. Robotics enable higher accuracy and faster processing times, which is critical for businesses dealing with high volumes of products.

Another significant opportunity lies in automated systems designed for high-mix, low-volume packaging industries. These industries benefit from automated carton erectors that offer flexibility in handling varying product sizes and types.

Additionally, there is growing demand for after-market services, such as maintenance and system upgrades. As companies continue to invest in automation, they are increasingly seeking reliable support services to ensure optimal performance and minimize downtime. These opportunities allow businesses to provide tailored solutions that cater to the evolving needs of diverse market segments.

Emerging Trends

AI and AMRs Lead the Latest Trends in Market Growth

Several trending factors are influencing the growth of the automatic carton erector market. The rise of AI-enabled systems is a significant trend, as these systems can predict packaging demand patterns with greater accuracy. By leveraging AI, manufacturers can optimize their production schedules and reduce waste.

The integration of autonomous mobile robots (AMRs) for material handling and carton erecting is another major development. AMRs streamline logistics within the production environment, ensuring the efficient movement of materials and finished goods. This innovation not only speeds up the process but also minimizes the risk of human injury in the workplace.

The increased focus on automation to reduce workplace injuries aligns with the broader trend of improving worker safety. The growth in direct-to-consumer packaging has influenced carton erection techniques. With more products being shipped directly to consumers, packaging processes must adapt to meet the higher demands of smaller, more personalized shipments.

Regional Analysis

North America Dominates with 37.2% Market Share

North America holds a dominant 37.2% share of the Automatic Carton Erector Market, accounting for approximately USD 0.45 billion. This dominance is driven by a strong manufacturing base, increased automation demand, and robust supply chain systems. The presence of key players like Bosch, ITW, and others in the U.S. and Canada plays a significant role in the region’s leadership.

The region’s advanced technological infrastructure and early adoption of automation solutions contribute to its high market share. In industries such as food and beverage, pharmaceuticals, and consumer goods, the demand for efficient packaging solutions like automatic carton erectors is growing. Additionally, North America’s significant focus on sustainability and operational efficiency in manufacturing processes has boosted the need for automated systems, which help to reduce labor costs and increase productivity. Furthermore, government incentives for automation and industry 4.0 initiatives support the development and integration of advanced packaging technologies.

Looking ahead, North America’s market presence is expected to remain strong. Increased demand for automated solutions in various sectors, driven by labor shortages and a need for faster production rates, is likely to continue fueling the region’s growth. The expansion of e-commerce and the increasing need for packaging automation will further solidify North America’s position as a leader in the automatic carton erector market.

Regional Mentions:

- Europe: Europe’s market share in the automatic carton erector industry is significant, supported by its focus on sustainability and high manufacturing standards. The region is investing heavily in automation to improve production efficiency, especially in industries like food packaging and pharmaceuticals.

- Asia Pacific: The Asia Pacific region is rapidly adopting automation technologies, with China, Japan, and South Korea leading the way. The booming manufacturing sector and high demand for packaging machinery, driven by e-commerce growth, contribute to the region’s expanding market share.

- Middle East & Africa: The Middle East and Africa are experiencing gradual growth in the automatic carton erector market. The focus on industrial development, particularly in the UAE and South Africa, and the expansion of retail and e-commerce are key drivers for automation adoption in the region.

- Latin America: Latin America is gradually embracing automation solutions, with countries like Brazil and Mexico seeing increased investments in packaging technology. The region’s growth is supported by the rising demand for packaged goods and the drive for operational efficiency in industries such as food and beverage.

Key Regions and Countries Covered in the Report

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Competitive Landscape

The Automatic Carton Erector Market is led by several prominent companies known for their innovation, technology integration, and strong global presence. The top four companies, including Bosch Packaging Technology, Smurfit Kappa, Fischbein, and KHS GmbH, play a significant role in driving market growth.

Bosch Packaging Technology has a solid reputation in the packaging industry, offering automated solutions that enhance productivity and reduce labor costs. Bosch’s expertise lies in providing high-performance, reliable systems for carton erecting, packing, and sealing, which cater to industries such as food, pharmaceuticals, and consumer goods.

Smurfit Kappa, a major player in the packaging sector, is known for its leadership in sustainable packaging solutions. The company specializes in producing eco-friendly, high-efficiency carton erectors. Smurfit Kappa’s vast distribution network and focus on automation in packaging processes give it a significant advantage in the market, especially in Europe and North America.

Fischbein, with a focus on packaging machinery, provides carton erecting solutions that meet the demands of various industries, including agriculture, chemicals, and food processing. Fischbein’s robust machines are recognized for their reliability and efficiency, with an emphasis on high-speed operations and precise carton forming.

KHS GmbH has built a strong presence in the automated packaging market with its advanced machinery for carton erecting and sealing. The company serves a wide range of industries, including beverages, pharmaceuticals, and food, offering efficient and sustainable solutions that cater to growing automation trends.

These companies are well-positioned in the market due to their technological expertise, extensive product portfolios, and commitment to innovation. With a focus on enhancing efficiency, sustainability, and customer-centric solutions, they continue to play a dominant role in shaping the future of the Automatic Carton Erector Market.

These industry leaders are expected to drive further growth as demand for automated, high-efficiency carton erecting solutions increases across global manufacturing and packaging sectors.

Major Companies in the Market

- Bosch Packaging Technology

- Smurfit Kappa

- Fischbein

- KHS GmbH

- A-B-C Packaging Machine Corporation

- Wexxar Packaging

- Duravant

- Star Packaging

- FANUC Corporation

- ProMach, Inc.

- Tetra Pak

- SACMI Group

- Schneider Packaging Equipment Co., Inc.

Recent Developments

- Paxiom: On October 2022, Paxiom showcased its latest automated packaging machine technology at Pack Expo International in Chicago. The company featured innovative products including the VF 1200 high-speed bagging machine, WeightCheQ 0-250 check weigher, PKR Delta robotic cell, and a bulk bagging system.

- Pacteon Group: On October 2024, Pacteon Group is showcasing innovative packaging automation solutions at Pack Expo International. The exhibits include a Collaborative Case Erector-Palletizer, an integrated Single-Lane Empty Can Vacuum Transfer with Laser Coding, and various robotic case packing and palletizing systems.

Report Scope

Report Features Description Market Value (2024) USD 1.2 Billion Forecast Revenue (2034) USD 1.9 Billion CAGR (2025-2034) 4.6% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Vertical Carton Erectors, Horizontal Carton Erectors), By End-User Industry (Food and Beverage, Pharmaceuticals, Consumer Goods, Electronics, Automotive, E-commerce), By Operation Type (Fully Automatic, Semi-Automatic) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Bosch Packaging Technology, Smurfit Kappa, Fischbein, KHS GmbH, A-B-C Packaging Machine Corporation, Wexxar Packaging, Duravant, Star Packaging, FANUC Corporation, ProMach, Inc., Tetra Pak, SACMI Group, Schneider Packaging Equipment Co., Inc. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Automatic Carton Erector MarketPublished date: Feb 2025add_shopping_cartBuy Now get_appDownload Sample

Automatic Carton Erector MarketPublished date: Feb 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Bosch Packaging Technology

- Smurfit Kappa

- Fischbein

- KHS GmbH

- A-B-C Packaging Machine Corporation

- Wexxar Packaging

- Duravant

- Star Packaging

- FANUC Corporation

- ProMach, Inc.

- Tetra Pak

- SACMI Group

- Schneider Packaging Equipment Co., Inc.