Global AI in Manufacturing Market By Component (Software, Hardware, Services), By Technology (Machine Learning, Computer Vision, Natural Language Processing (NLP), Other Technologies), By Application (Process Optimization, Production Planning, Predictive Maintenance, Quality Control and Inspection, Supply Chain Management, Other Applications), By End-Use Industry (Automotive, Food & Beverage , Electronics & Semiconductor, Chemicals, Pharmaceuticals, Metal & Heavy Machinery, Other End-Use Industries), By Region And Key Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends And Forecast 2024-2033

- Published date: Feb. 2024

- Report ID: 115453

- Number of Pages: 279

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

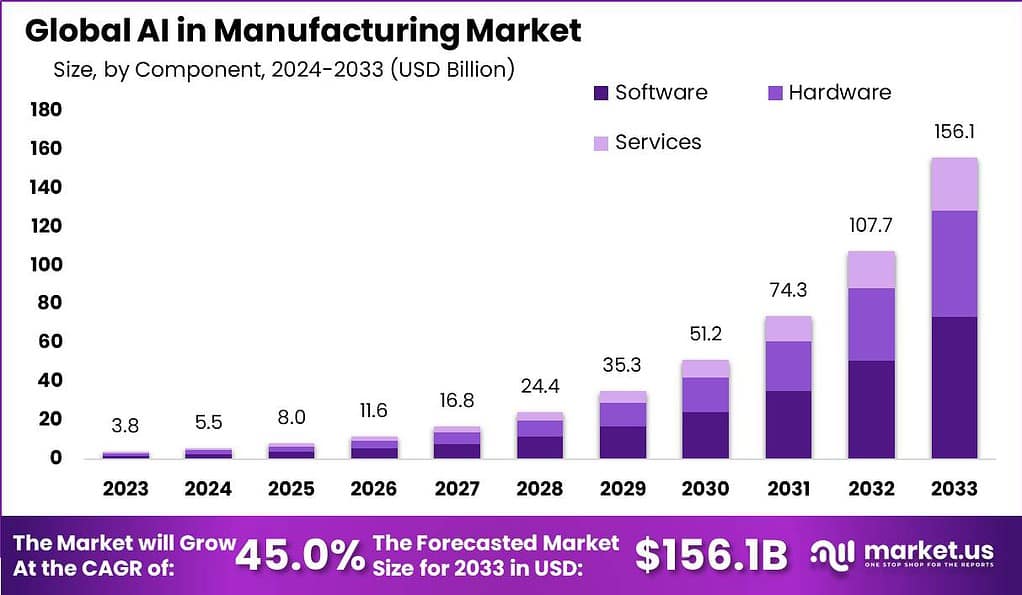

The Global AI in Manufacturing Market size is expected to be worth around USD 156.1 Billion by 2033, from USD 3.8 Billion in 2023, growing at a CAGR of 45% during the forecast period from 2024 to 2033.

AI in Manufacturing refers to the utilization of artificial intelligence technologies and algorithms in various aspects of the manufacturing industry. It involves the integration of machine learning, computer vision, robotics, and data analytics to automate processes, optimize operations, and improve overall efficiency and productivity. AI in Manufacturing has the potential to transform traditional manufacturing processes by enabling predictive maintenance, quality control, demand forecasting, supply chain optimization, and smart production systems.

The artificial intelligence in Manufacturing market is experiencing significant growth as manufacturers recognize the immense value that AI can bring to their operations. The market encompasses a wide range of AI-powered solutions, including machine learning algorithms for predictive maintenance, computer vision systems for quality inspection, and autonomous robots for material handling and assembly tasks.

These technologies enable manufacturers to enhance their decision-making processes, reduce downtime, improve product quality, streamline supply chain operations, and ultimately drive cost savings. Furthermore, the growing demand for customized products and shorter production cycles requires agile and adaptable manufacturing systems, which can be achieved through AI-driven automation and optimization.

According to a groundbreaking study, the adoption of AI in manufacturing has already reached a significant milestone, with 35% of companies leveraging AI in their processes. This demonstrates the tangible impact that AI is having on the industry. The financial implications of AI in manufacturing are projected to be staggering, with the market value of AI in manufacturing expected to soar from $3.8 billion in 2023 to an astounding $24.4 billion by 2028.

Insights from the Manufacturing Institute further emphasize the transformative power of AI in manufacturing. AI-driven decision-support systems have the potential to enhance manufacturing efficiency by an impressive margin of up to 20%. This indicates that AI is not only a buzzword but a practical tool that can significantly improve operational performance and yield substantial benefits for manufacturers.

The study also reveals that manufacturers primarily implement AI in two key functions: maintenance and quality. Approximately 29% of manufacturers leverage AI for maintenance purposes, recognizing the value of predictive maintenance in reducing costs and minimizing breakdowns. AI-driven predictive maintenance has the potential to reduce machinery maintenance costs by up to 25% while resulting in 70% fewer breakdowns.

Furthermore, quality enhancement is another critical aspect where AI plays a significant role. By harnessing AI and smart image recognition, manufacturers can achieve remarkable improvements in product quality and productivity. Employing AI-driven quality testing can lead to a 50% increase in factory productivity, while achieving up to 90% accuracy in detecting defects. This demonstrates the potential of AI to enhance product quality and ensure that manufacturers deliver superior goods to their customers.

Key Takeaways

- Market Growth Projection: The global AI in manufacturing market is estimated to reach a staggering USD 156.1 billion by 2033, showcasing a robust CAGR of 45%.

- Financial Implications: The financial impact of AI in manufacturing is significant, with the market value projected to increase from $3.8 billion in 2023 to an impressive $24.4 billion by 2028, highlighting the industry’s recognition of AI’s value and potential.

- Operational Efficiency: AI-driven decision-support systems have the potential to enhance manufacturing efficiency by up to 20%, indicating that AI is a practical tool capable of significantly improving operational performance and yielding substantial benefits for manufacturers.

- Application Focus: AI is primarily implemented in two key functions within manufacturing: maintenance and quality control. Predictive maintenance leveraging AI technology can reduce machinery maintenance costs by up to 25% and result in 70% fewer breakdowns, while AI-driven quality testing can achieve a 50% increase in factory productivity and up to 90% accuracy in defect detection.

- Segment Analysis: In 2023, the software segment held a dominant market position in AI in manufacturing, capturing over 47.3% share, driven by its crucial role in enabling AI implementation, providing advanced analytics capabilities, and offering flexibility to manufacturers.

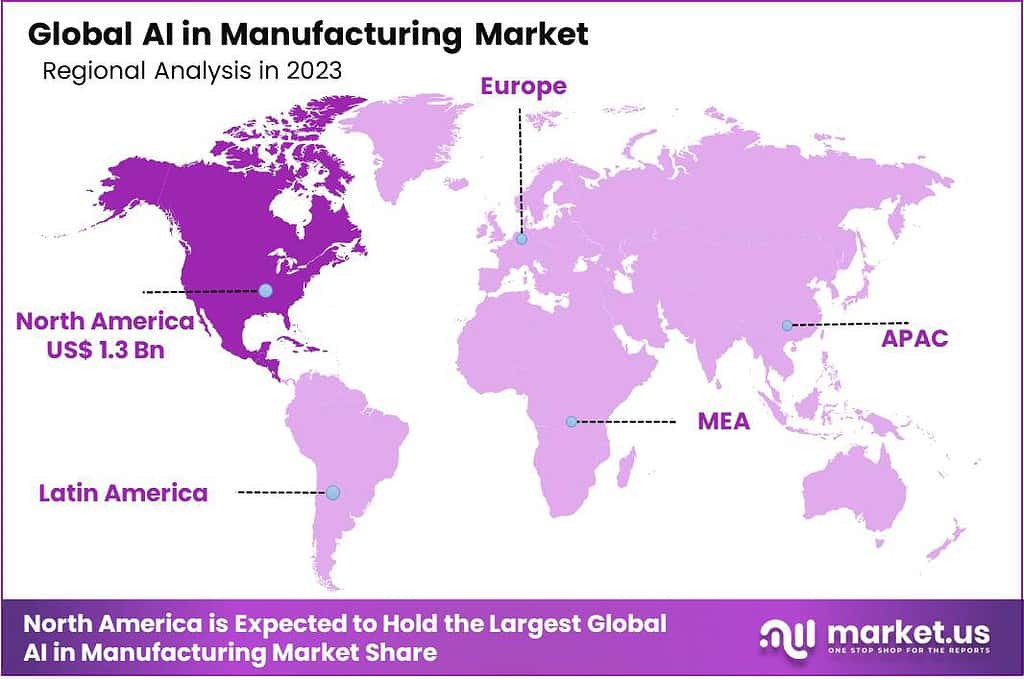

- Regional Dominance: North America led the AI in manufacturing market in 2023, with a dominant market share exceeding 35.1%. This leadership is attributed to factors such as technological advancements, early adoption of AI technologies, robust infrastructure, significant investments in R&D, and favorable government policies promoting digital transformation.

Component Analysis

In 2023, the Software segment held a dominant market position in the AI in Manufacturing market, capturing more than a 47.3% share. The leading position of the Software segment can be attributed to several factors driving its market growth. Firstly, software solutions play a crucial role in enabling the implementation and integration of AI technologies in manufacturing processes.

AI software encompasses various applications, including machine learning algorithms, predictive analytics, data management platforms, and intelligent decision-support systems. These software solutions empower manufacturers to leverage AI capabilities and extract valuable insights from data, optimize operations, and make informed decisions.

Moreover, the Software segment benefits from the increasing demand for advanced analytics and AI-driven applications in manufacturing. The ability to analyze large volumes of data in real-time, identify patterns, and generate actionable insights is essential for manufacturers to improve efficiency, quality, and productivity. AI software solutions provide manufacturers with the tools and algorithms necessary to process and interpret data, enabling them to optimize production processes, detect anomalies, and improve overall performance.

Furthermore, the Software segment offers flexibility and scalability to manufacturers. As the manufacturing industry evolves and embraces digital transformation, software solutions can be easily customized and adapted to meet specific business needs. Manufacturers can select and integrate different AI software components based on their requirements, such as predictive maintenance software, quality control software, or supply chain optimization software. This flexibility allows manufacturers to implement AI technologies gradually and expand their capabilities as needed.

Overall, the leading position of the Software segment in the AI in Manufacturing market can be attributed to its crucial role in enabling AI implementation, providing advanced analytics capabilities, and offering flexibility to manufacturers. With the increasing emphasis on data-driven decision-making and the need for intelligent automation, AI software solutions play a vital role in driving digital transformation and enhancing operational performance in the manufacturing industry.

Technology Analysis

In 2023, the Machine Learning segment held a dominant market position in the AI in Manufacturing market, capturing more than a 42.9% share.

The leading position of the Machine Learning segment can be attributed to several key factors driving its market growth. Firstly, machine learning technology plays a crucial role in enabling data-driven decision-making and process optimization in manufacturing. Machine learning algorithms are designed to analyze vast amounts of data, identify patterns, and make predictions or recommendations based on the available information. This capability empowers manufacturers to optimize production processes, improve product quality, and enhance operational efficiency.

Moreover, machine learning’s ability to continuously learn and adapt from data makes it a powerful tool for manufacturers. As the manufacturing industry generates massive volumes of data from various sources, including sensors, machines, and production lines, machine learning algorithms can extract valuable insights and learn from this data to optimize performance. With each iteration, machine learning models become more accurate and effective, enabling manufacturers to make informed decisions and achieve continuous improvement.

Furthermore, the Machine Learning segment benefits from the integration of AI technologies in multiple areas of manufacturing. Machine learning algorithms are widely used in predictive maintenance, where they analyze sensor data and equipment performance to detect anomalies and predict maintenance needs.

This proactive approach to maintenance can significantly reduce downtime, improve asset utilization, and optimize maintenance schedules. Additionally, machine learning is utilized in quality control processes, where it can analyze visual data from computer vision systems to identify defects or deviations from quality standards, ensuring that only products of high quality reach the market.

Application Analysis

In 2023, the Production Planning segment held a dominant market position in the AI in Manufacturing market, capturing more than a 21.8% share.

The leading position of the Production Planning segment can be attributed to several key factors that drive its market growth. Firstly, production planning is a critical aspect of manufacturing operations as it involves optimizing resources, scheduling activities, and ensuring efficient utilization of assets. AI technologies, specifically machine learning algorithms, enable manufacturers to analyze historical production data, demand forecasts, and other relevant factors to create accurate production plans that minimize costs, reduce lead times, and optimize overall production efficiency.

Moreover, AI-powered production planning solutions offer manufacturers the ability to handle complex variables and uncertainties in real-time. By leveraging machine learning algorithms, manufacturers can incorporate dynamic factors such as demand fluctuations, supply chain disruptions, and resource availability into their production plans. This enables them to make agile and informed decisions, adjust production schedules on-the-fly, and optimize production output based on changing market conditions.

Furthermore, the Production Planning segment benefits from the integration of AI with other manufacturing applications. For example, AI can be combined with predictive maintenance to optimize production planning by considering machine health and maintenance requirements. It can also be integrated with quality control and inspection systems to ensure that production plans align with quality standards and minimize the risk of defects or rework.

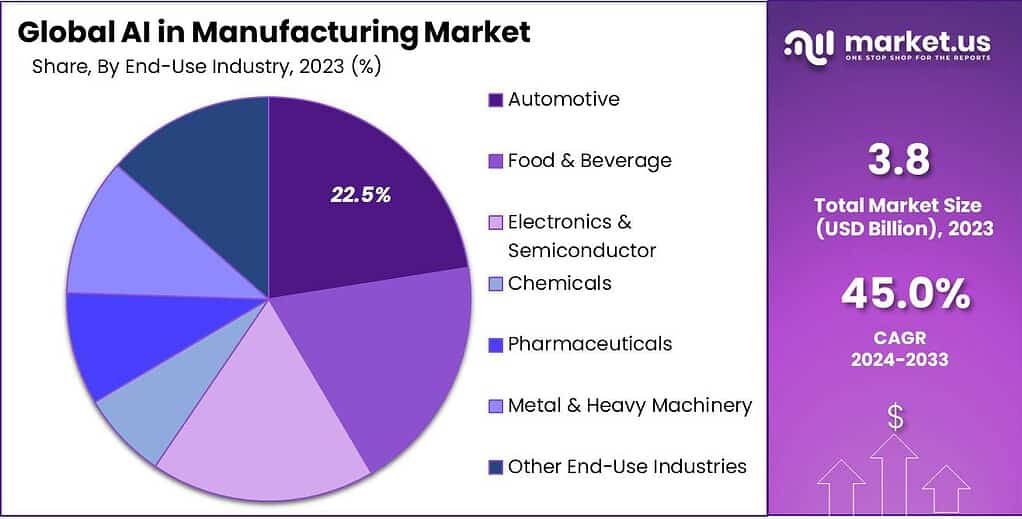

End-Use Industry Analysis

In 2023, the Automotive segment asserted its dominance within the AI in Manufacturing market, securing a substantial market share exceeding 22.5%. This prominent position is primarily attributed to the automotive industry’s relentless pursuit of innovation and efficiency through AI integration across various manufacturing processes.

Specifically, automotive manufacturers leverage AI technologies for a multitude of applications, including predictive maintenance, quality control, and autonomous vehicle development. By harnessing AI-driven analytics and machine learning algorithms, automotive companies can optimize production lines, minimize downtime, and enhance product quality, thereby gaining a competitive edge in a rapidly evolving market landscape.

Moreover, the Automotive segment’s leadership is reinforced by the industry’s increasing emphasis on smart manufacturing practices and Industry 4.0 initiatives. As automotive manufacturers strive to meet stringent quality standards and consumer expectations, AI-enabled technologies play a pivotal role in enabling real-time monitoring and optimization of production processes.

Additionally, the growing demand for electric vehicles (EVs) and connected car technologies further accelerates the adoption of AI in automotive manufacturing. From predictive maintenance of EV components to autonomous driving systems powered by AI algorithms, automotive companies are leveraging AI to drive innovation and redefine the future of mobility.

Key Market Segments

Component

- Software

- Hardware

- Services

Technology

- Machine Learning

- Computer Vision

- Natural Language Processing (NLP)

- Other Technologies

Application

- Process Optimization

- Production Planning

- Predictive Maintenance

- Quality Control and Inspection

- Supply Chain Management

- Other Applications

End-Use Industry

- Automotive

- Food & Beverage

- Electronics & Semiconductor

- Chemicals

- Pharmaceuticals

- Metal & Heavy Machinery

- Other End-Use Industries

Driver

Rising need to handle increasingly large and complex dataset

The rising need to handle increasingly large and complex datasets is a significant driver for the adoption of AI in the manufacturing market. As manufacturing processes become more automated and interconnected, vast amounts of data are generated from various sources such as sensors, machines, and production lines. AI technologies, including machine learning and data analytics, enable manufacturers to extract valuable insights from these datasets, optimize operations, improve product quality, and enhance overall efficiency.

By leveraging AI, manufacturers can make data-driven decisions, predict maintenance needs, and identify patterns that may not be apparent to human operators. This capability to handle and analyze large datasets is crucial in the era of Industry 4.0, where the volume and complexity of data continue to grow.

Restraint

Reluctance among manufacturers to adopt AI-based technologies

Despite the benefits offered by AI-based technologies, there is a reluctance among manufacturers to adopt them. One of the main reasons for this reluctance is the perceived high costs associated with implementing AI solutions. Manufacturers may hesitate to invest in AI technologies due to concerns about the initial investment, integration with existing systems, and ongoing maintenance costs.

Additionally, there may be a lack of awareness or understanding about the potential advantages that AI can bring to their operations. Some manufacturers may also be resistant to change or skeptical about the reliability and accuracy of AI systems, which can hinder their adoption.

Opportunity

Application of AI-driven machine learning and NLP for intelligent enterprise processes

An opportunity lies in the application of AI-driven machine learning and natural language processing (NLP) technologies for intelligent enterprise processes within the automotive industry. AI-powered solutions offer manufacturers the ability to automate and streamline various business operations, from supply chain management to customer service.

By leveraging machine learning algorithms, manufacturers can analyze vast amounts of data to identify patterns, predict trends, and optimize decision-making processes. Additionally, NLP enables automotive companies to extract valuable insights from unstructured data sources such as customer feedback, social media, and text documents.

This facilitates improved communication, personalized customer experiences, and more efficient information retrieval. By embracing AI-driven machine learning and NLP, automotive manufacturers can unlock new levels of operational efficiency, innovation, and competitive advantage in the evolving marketplace.

Challenges

Lack of skilled workforce, especially in developing countries

One of the primary challenges facing the automotive industry in its adoption of AI technologies is the shortage of skilled workforce, particularly in developing countries. The rapid advancement of AI and machine learning requires specialized knowledge and expertise in areas such as data science, programming, and algorithm development.

However, there is a significant gap between the demand for AI talent and the availability of qualified professionals, exacerbating recruitment challenges for automotive manufacturers. Furthermore, the lack of comprehensive educational programs and training initiatives focused on AI further compounds this issue, particularly in regions with limited access to resources and infrastructure.

Addressing the shortage of skilled workforce requires concerted efforts from governments, academia, and industry stakeholders to invest in education, training, and talent development programs tailored to the needs of the automotive sector. Additionally, promoting diversity and inclusion in AI talent recruitment can help foster innovation and drive sustainable growth in the industry.

Regional Analysis

In 2023, North America held a dominant market position in the AI in Manufacturing market, capturing more than a 35.1% share. The demand for AI in Manufacturing in North America was valued at US$ 1.3 billion in 2023 and is anticipated to grow significantly in the forecast period.

The region’s leading position can be attributed to several factors. Firstly, North America has been at the forefront of technological advancements and innovation, with a strong presence of key AI technology providers and manufacturing companies. The region boasts a robust ecosystem that supports research and development in AI, fostering collaborations between academia, industry, and government institutions.

Moreover, North American manufacturers have been early adopters of AI technologies in their operations. The region’s manufacturing sector has recognized the potential of AI in optimizing production processes, improving quality control, and enhancing overall efficiency. The availability of a well-developed infrastructure, including high-speed internet connectivity and advanced manufacturing facilities, has further facilitated the integration and adoption of AI solutions.

Additionally, North America has witnessed significant investments in AI research and development, both from private enterprises and government initiatives. The presence of leading technology hubs such as Silicon Valley in the United States has attracted top talent and encouraged innovation in AI applications for manufacturing. These investments have resulted in the development of cutting-edge AI technologies tailored for the manufacturing industry, giving North American manufacturers a competitive edge in the global market.

Furthermore, favorable government policies and initiatives promoting digital transformation and the adoption of emerging technologies have played a crucial role in North America’s leadership in the AI in Manufacturing market. Government support, such as funding for AI research and development projects and the establishment of AI-focused centers and innovation hubs, has created a conducive environment for the growth and adoption of AI technologies in the manufacturing sector.

Key Regions and Countries Covered in this Report:

- North America

- The US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherland

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

The AI in Manufacturing market is characterized by the presence of several key players who play a pivotal role in driving innovation, shaping industry trends, and influencing market dynamics. These key players encompass a diverse range of companies, including technology giants, niche solution providers, and industrial conglomerates, each contributing unique expertise and capabilities to the market landscape.

One of the prominent key players in the AI in Manufacturing sector is Siemens AG, a global leader in automation, electrification, and digitalization solutions. Siemens offers a comprehensive portfolio of AI-powered software and hardware solutions tailored to the unique needs of manufacturing industries, enabling customers to optimize production processes, improve product quality, and enhance operational efficiency.

Top Market Leaders

- IBM Corporation

- Microsoft Corporation

- Oracle Corporation

- Google LLC

- Siemens AG

- NVIDIA Corporation

- General Electric Company

- Intel Corporation

- Amazon Web Services, Inc.

- ABB Ltd.

- SAP SE

- Cisco Systems, Inc.

- Rockwell Automation, Inc.

- Other Key Players

Recent Developments

1. Siemens AG:

- June 2023: Partnered with NVIDIA to enable the Industrial Metaverse, combining Siemens’ Xcelerator platform with NVIDIA’s Omniverse for real-time AI and physics-based digital twins, aiming to accelerate AI adoption in manufacturing.

- October 2023: Launched Siemens Industrial Copilot, a generative AI assistant co-developed with Microsoft, designed to enhance human-machine collaboration and boost productivity in manufacturing, infrastructure, and other industries.

2. NVIDIA Corporation:

- June 2023: Partnered with Siemens to enable the Industrial Metaverse, providing the AI and real-time simulation capabilities for the platform through their Omniverse technology.

- June 2023: Announced NVIDIA DRIVE Orin, a new AI superchip for autonomous vehicles and robotics, aiming to improve performance and efficiency in manufacturing automation and logistics.

Report Scope

Report Features Description Market Value (2023) US$ 3.8 Bn Forecast Revenue (2033) US$ 156.1 Bn CAGR (2024-2033) 45% Base Year for Estimation 2023 Historic Period 2018-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Component (Software, Hardware, Services), By Technology (Machine Learning, Computer Vision, Natural Language Processing (NLP), Other Technologies), By Application (Process Optimization, Production Planning, Predictive Maintenance, Quality Control and Inspection, Supply Chain Management, Other Applications), By End-Use Industry (Automotive, Food & Beverage , Electronics & Semiconductor, Chemicals, Pharmaceuticals, Metal & Heavy Machinery, Other End-Use Industries) Regional Analysis North America – The U.S. & Canada; Europe – Germany, France, The UK, Spain, Italy, Russia, Netherlands & Rest of Europe; APAC- China, Japan, South Korea, India, Australia, New Zealand, Singapore, Thailand, Vietnam & Rest of APAC; Latin America- Brazil, Mexico & Rest of Latin America; Middle East & Africa- South Africa, Saudi Arabia, UAE & Rest of MEA Competitive Landscape IBM Corporation, Microsoft Corporation, Oracle Corporation, Google LLC, Siemens AG, NVIDIA Corporation, General Electric Company, Intel Corporation, Amazon Web Services Inc., ABB Ltd., SAP SE, Cisco Systems, Inc., Rockwell Automation Inc., Other Key Players Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is AI in Manufacturing?AI in Manufacturing refers to the use of artificial intelligence (AI) technologies such as machine learning, computer vision, and natural language processing to automate and optimize manufacturing processes, improve product quality, and enhance operational efficiency.

How big is AI in Manufacturing Industry?The Global AI in Manufacturing Market size is expected to be worth around USD 156.1 Billion by 2033, from USD 3.8 Billion in 2023, growing at a CAGR of 45% during the forecast period from 2024 to 2033.

What are the Key Applications of AI in Manufacturing?AI is used in manufacturing for predictive maintenance, quality control, supply chain optimization, demand forecasting, and process automation.

What are the Key Drivers of the AI in Manufacturing Market?The key drivers include the increasing adoption of Industry 4.0 technologies, the need for operational efficiency and cost reduction, and the growing demand for smart manufacturing solutions.

What are the Challenges in Implementing AI in Manufacturing?Challenges include data integration and interoperability, the need for skilled AI talent, the complexity of AI algorithms, and the potential for job displacement.

Who are the global artificial intelligence in manufacturing market winners?The major players operating in the artificial intelligence (AI) in manufacturing market are IBM Corporation, Microsoft Corporation, Oracle Corporation, Google LLC, Siemens AG, NVIDIA Corporation, General Electric Company, Intel Corporation, Amazon Web Services Inc., ABB Ltd., SAP SE, Cisco Systems, Inc., Rockwell Automation Inc., Other Key Players

Which region will lead the global artificial intelligence (AI) in manufacturing market?In 2023, North America held a dominant market position in the AI in Manufacturing market, capturing more than a 35.1% share.

AI in Manufacturing MarketPublished date: Feb. 2024add_shopping_cartBuy Now get_appDownload Sample

AI in Manufacturing MarketPublished date: Feb. 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- IBM Corporation

- Microsoft Corporation

- Oracle Corporation

- Google LLC

- Siemens AG

- NVIDIA Corporation

- General Electric Company

- Intel Corporation

- Amazon Web Services, Inc.

- ABB Ltd.

- SAP SE

- Cisco Systems, Inc.

- Rockwell Automation, Inc.

- Other Key Players