Global Wicketed Bagging Machines Market Size, Share, Growth Analysis By Automation Type (Automatic, Semi-Automatic), By Machine Type (Vertical, Horizontal), By Machine Speed (Upto 500 Bags/Hr, 501-2000 Bags/Hr, More Than 2000 Bags/Hr), By End Use (Food, Pharmaceutical, Personal Care & Cosmetics, Others) , By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Aug 2025

- Report ID: 155934

- Number of Pages: 358

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

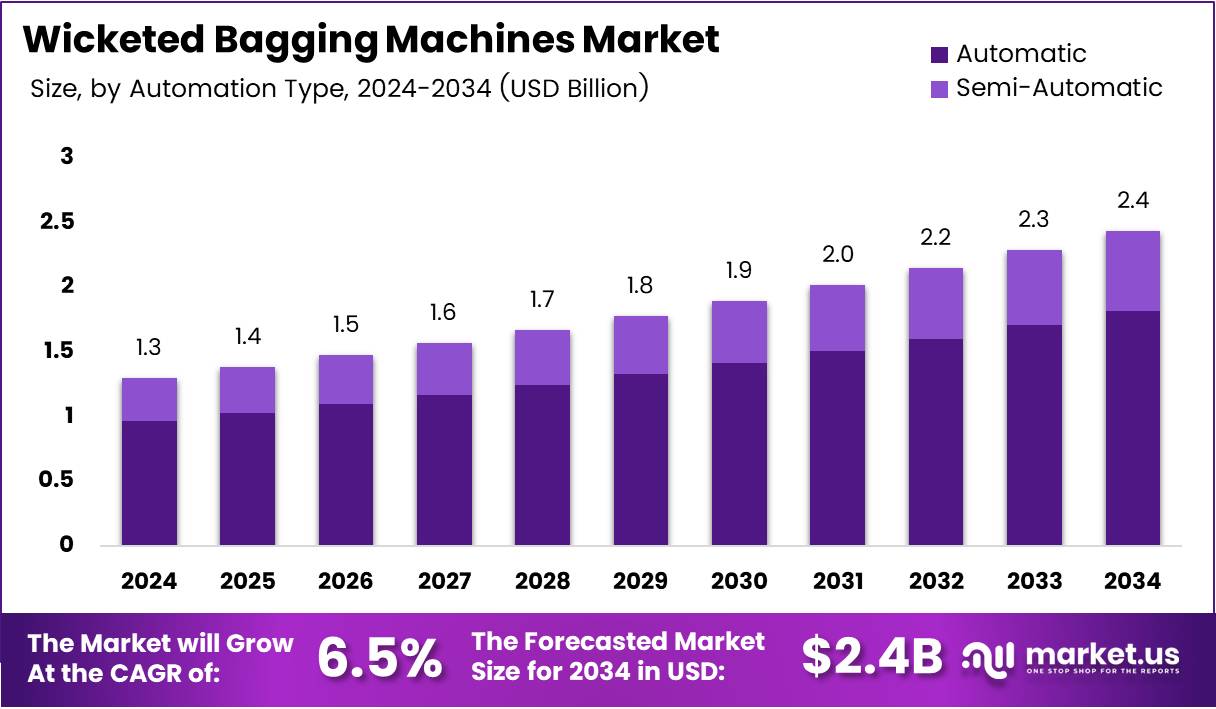

The Global Wicketed Bagging Machines Market size is expected to be worth around USD 2.4 Billion by 2034, from USD 1.3 Billion in 2024, growing at a CAGR of 6.5% during the forecast period from 2025 to 2034.

The Wicketed Bagging Machines market refers to machines used for packaging products into pre-made bags that are attached to a wicket for easy handling. These machines are primarily used in industries such as food, pharmaceuticals, and retail. They automate the bagging process, providing efficiency, precision, and reducing labor costs.

In recent years, the Wicketed Bagging Machines market has witnessed significant growth. As industries shift toward automation to meet increasing demand, the adoption of these machines has soared. By streamlining the packaging process, companies can improve productivity and reduce operational costs, making it a preferred choice for many sectors.

One of the primary drivers of market expansion is the rising demand for packaged food. As consumer preference shifts toward convenience and longer shelf life, companies are investing in automated bagging solutions. These machines offer the ability to package large volumes of products in a short amount of time, making them invaluable in the food industry, where speed and accuracy are essential.

Furthermore, government initiatives to encourage automation in manufacturing processes have fueled growth in the Wicketed Bagging Machines market. Governments worldwide are offering incentives for businesses to adopt advanced machinery, thus reducing human intervention and increasing efficiency. This, in turn, promotes the adoption of wicketed bagging solutions, ensuring compliance with regulatory standards while boosting production.

Opportunities for further market growth lie in the rising demand for eco-friendly packaging solutions. Manufacturers are increasingly seeking ways to reduce waste and use sustainable materials in packaging. Wicketed Bagging Machines, which can accommodate biodegradable and recyclable bags, are expected to play a significant role in this transition toward greener practices.

Additionally, advancements in technology, such as machine learning and IoT integration, are likely to open new opportunities in the Wicketed Bagging Machines market. Smart machines that provide real-time data on performance and efficiency allow companies to optimize their operations further. As the technology evolves, the market is expected to see increased demand for such intelligent packaging systems.

Government regulations are another critical factor influencing the Wicketed Bagging Machines market. With stricter regulations around food safety, product traceability, and labor safety, industries are investing in technologies that comply with these laws. This ensures a safer, more efficient production environment, which is essential for continued growth in the sector.

Key Takeaways

- The Global Wicketed Bagging Machines Market is expected to reach USD 2.4 Billion by 2034, growing at a CAGR of 6.5% from 2025 to 2034.

- Automatic machines dominate the By Automation Type segment, holding 74.5% of the market in 2024.

- Vertical machines lead the By Machine Type segment with a 59.3% market share in 2024.

- 501-2000 Bags/Hr. holds the largest share in the By Machine Speed segment at 53.8% in 2024.

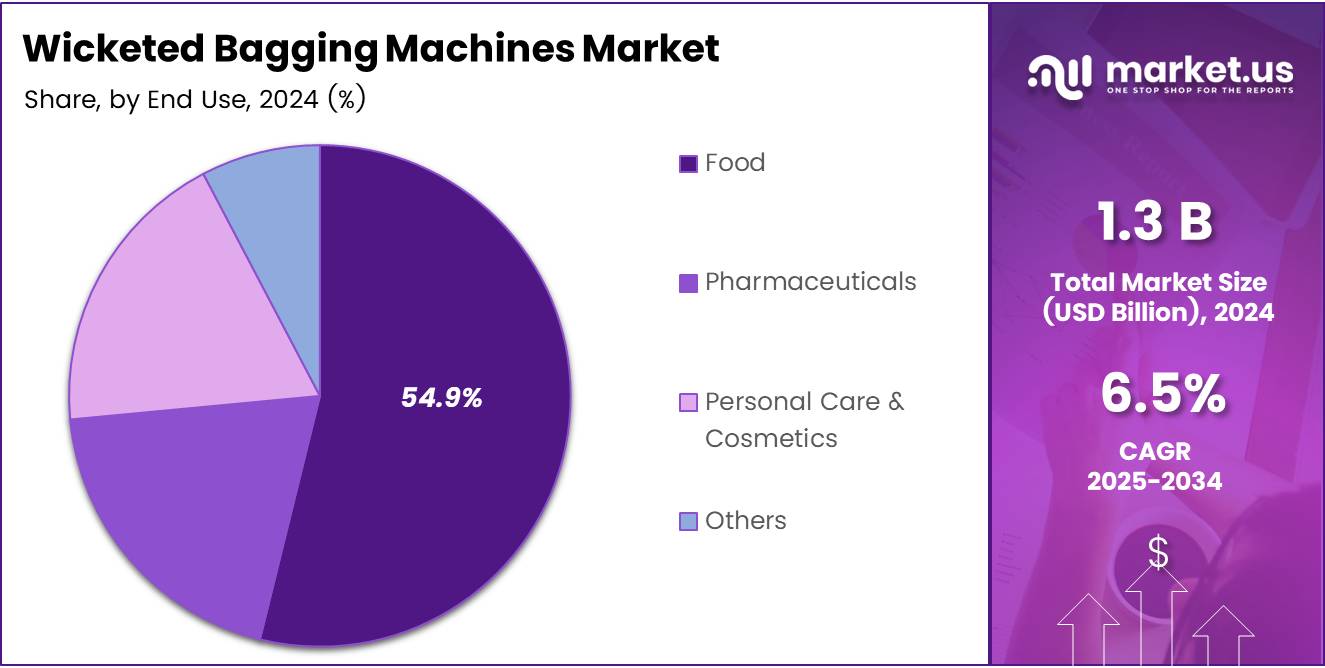

- The Food industry is the leading end-use segment, accounting for 54.9% of the market share in 2024.

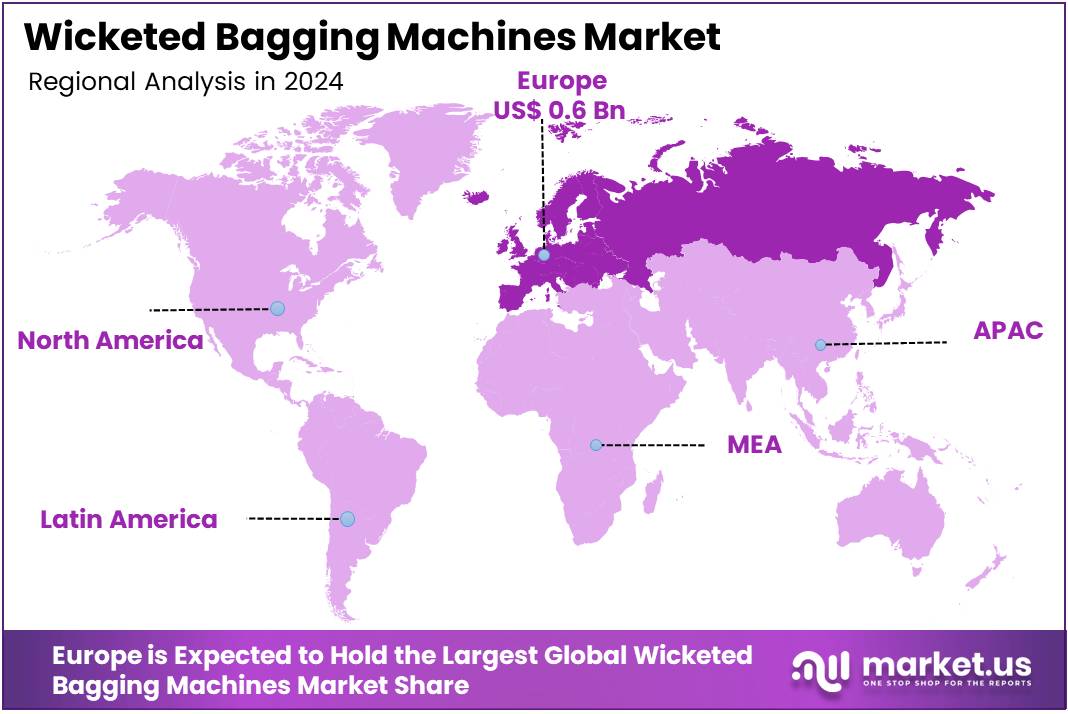

- Europe dominates the market with 48.3% of the market share, valued at USD 0.6 Billion in 2024.

Automation Type Analysis

Automatic systems dominate with 74.5% due to their superior efficiency and reduced labor dependency.

In 2024, Automatic held a dominant market position in By Automation Type Analysis segment of Wicketed Bagging Machines Market, with a 74.5% share. This commanding market presence reflects the industry’s strong preference for automated solutions that deliver consistent performance and operational excellence.

The automatic segment’s leadership stems from its ability to significantly reduce manual intervention while maximizing throughput capabilities. Manufacturing facilities increasingly prioritize automated wicketed bagging systems for their reliability in maintaining consistent bag quality and sealing integrity. These systems offer superior speed control and precision placement, making them ideal for high-volume production environments.

Semi-automatic systems maintain relevance in specific market niches where moderate automation levels meet operational requirements. These solutions provide a balanced approach between manual control and automated efficiency, appealing to manufacturers with varying production volumes. The segment serves businesses seeking cost-effective automation without full-scale investment in completely automated infrastructure.

The market trend clearly favors automation advancement, with manufacturers investing in technologies that enhance productivity while reducing operational costs. This preference drives continuous innovation in automatic wicketed bagging systems, reinforcing their market dominance.

Machine Type Analysis

Vertical machines dominate with 59.3% due to their space efficiency and versatile application capabilities.

In 2024, Vertical held a dominant market position in By Machine Type Analysis segment of Wicketed Bagging Machines Market, with a 59.3% share. This substantial market leadership demonstrates the industry’s preference for vertical configurations that optimize floor space utilization while delivering exceptional bagging performance.

Vertical wicketed bagging machines excel in environments where floor space represents a premium constraint. Their upright design allows manufacturers to maximize production capacity within limited facility footprints. These systems integrate seamlessly with existing production lines, offering flexible installation options that accommodate diverse operational layouts.

The vertical segment’s success relates directly to its superior handling of various bag sizes and materials. These machines demonstrate exceptional versatility in processing different product types, from granular materials to irregularly shaped items. Their gravitational advantage ensures consistent product flow and reliable bag filling, contributing to operational efficiency.

Horizontal systems serve specialized applications where specific product handling requirements demand alternative configurations. While representing a smaller market share, horizontal machines remain essential for certain manufacturing processes that benefit from their unique operational characteristics. The segment continues supporting niche applications where vertical systems may not provide optimal performance solutions.

Machine Speed Analysis

501-2000 Bags/Hr systems dominate with 53.8% due to their optimal balance of productivity and operational flexibility.

In 2024, 501-2000 Bags/Hr. held a dominant market position in By Machine Speed Analysis segment of Wicketed Bagging Machines Market, with a 53.8% share. This speed range represents the industry’s sweet spot, providing manufacturers with efficient throughput capabilities while maintaining operational control and quality standards.

The mid-range speed segment appeals to diverse manufacturing environments that require consistent productivity without overwhelming downstream processing capabilities. These systems offer sufficient capacity for most commercial applications while allowing operators to maintain quality oversight throughout production cycles. The speed range accommodates various product types and packaging requirements effectively.

Upto 500 Bags/Hr systems serve smaller operations and specialized applications where precision takes precedence over volume. These machines excel in environments requiring careful product handling or where batch processing methods align with operational strategies. They provide cost-effective solutions for businesses with moderate production requirements.

More Than 2000 Bags/Hr systems cater to high-volume manufacturing facilities requiring maximum throughput capabilities. These high-speed machines serve large-scale operations where efficiency and volume output represent critical success factors. Advanced automation features ensure consistent performance at elevated production rates, supporting industrial-scale manufacturing requirements.

End Use Analysis

Food sector dominates with 54.9% due to increasing packaged food consumption and stringent packaging requirements.

In 2024, Food held a dominant market position in By End Use Analysis segment of Wicketed Bagging Machines Market, with a 54.9% share. This commanding presence reflects the food industry’s extensive reliance on wicketed bagging solutions for diverse product packaging applications, from fresh produce to processed goods.

The food sector’s dominance stems from evolving consumer preferences toward convenient, portion-controlled packaging formats. Wicketed bags provide excellent product visibility while ensuring freshness preservation and contamination prevention. Food manufacturers increasingly adopt these systems for packaging vegetables, fruits, bakery items, and snack products, driving substantial market demand.

Pharmaceutical applications represent a growing segment where precision and contamination control requirements align perfectly with wicketed bagging capabilities. These systems ensure sterile packaging environments while maintaining product integrity throughout distribution channels. The segment benefits from increasing pharmaceutical production and stringent regulatory compliance requirements.

Personal Care & Cosmetics sectors utilize wicketed bagging for sample distributions, promotional items, and small-format product packaging. These applications leverage the visual appeal and convenience offered by transparent wicketed bags.

Others segment encompasses diverse industrial applications including hardware, automotive parts, and retail merchandise packaging, demonstrating the technology’s versatility across multiple industries.

Key Market Segments

By Automation Type

- Automatic

- Semi-Automatic

By Machine Type

- Vertical

- Horizontal

By Machine Speed

- Upto 500 Bags/Hr

- 501-2000 Bags/Hr

- More Than 2000 Bags/Hr

By End Use

- Food

- Pharmaceutical

- Personal Care & Cosmetics

- Others

Drivers

Increasing Demand for Automated Packaging Solutions Drives Market Growth

The wicketed bagging machines market is experiencing strong growth due to rising demand for automated packaging solutions across industries. Companies are moving away from manual packaging to reduce labor costs and improve efficiency. This shift is particularly evident in manufacturing sectors where consistent packaging quality is essential.

The preference for eco-friendly packaging materials is also boosting market expansion. Businesses are increasingly choosing sustainable options like biodegradable films and recyclable materials for their wicketed bags. This trend aligns with consumer preferences and environmental regulations, creating new opportunities for machine manufacturers.

Machine efficiency and speed improvements are attracting more buyers to upgrade their packaging systems. Modern wicketed bagging machines can handle higher volumes with better precision, reducing waste and operational costs. These technological advances make automation more appealing to small and medium enterprises.

The growing food and beverage industry serves as a major catalyst for market growth. With increasing demand for packaged foods, snacks, and beverages, manufacturers need reliable bagging solutions. Wicketed bagging machines provide the speed and hygiene standards required for food packaging applications.

Restraints

High Initial Investment Costs for Advanced Machines Limit Market Adoption

The wicketed bagging machines market faces significant challenges from high initial investment costs for advanced systems. Small businesses often struggle to justify the substantial upfront expenses, especially when considering additional costs for installation, training, and maintenance. This financial barrier prevents many potential buyers from adopting automated solutions.

Limited availability of skilled operators poses another major constraint for market expansion. Operating modern wicketed bagging machines requires specialized knowledge of automation systems, programming, and troubleshooting. The shortage of qualified technicians increases operational costs and creates dependency on equipment suppliers for support services.

Stringent regulatory standards for packaging materials add complexity to market operations. Companies must ensure their wicketed bagging machines comply with food safety regulations, environmental guidelines, and quality certifications. Meeting these requirements often involves additional testing, documentation, and approval processes that can delay implementation and increase costs.

These regulatory challenges are particularly pronounced in the food and pharmaceutical industries, where contamination risks and safety standards are strictly monitored. Machine manufacturers must continuously update their equipment to meet evolving compliance requirements, which can impact pricing and development timelines.

Growth Factors

Development of Smart Packaging Technologies Creates Growth Opportunities

The wicketed bagging machines market presents exciting growth opportunities through the development of smart packaging technologies. Advanced sensors and monitoring systems are being integrated into machines to provide real-time quality control and predictive maintenance capabilities. These innovations help manufacturers reduce downtime and improve product consistency.

Adoption of sustainable packaging solutions opens new market segments for wicketed bagging machine manufacturers. Companies are increasingly investing in equipment that can handle biodegradable films, compostable materials, and recyclable packaging options. This shift toward environmental responsibility creates demand for specialized machinery.

Integration of artificial intelligence and Internet of Things (IoT) technologies is transforming packaging operations. Smart wicketed bagging machines can optimize production schedules, monitor performance metrics, and automatically adjust settings for different products. These capabilities appeal to manufacturers seeking operational efficiency and data-driven insights.

The convergence of sustainability and technology creates unique positioning opportunities for equipment suppliers. Companies that can offer both eco-friendly packaging capabilities and smart automation features are well-positioned to capture growing market demand from environmentally conscious manufacturers.

Emerging Trends

Shift Towards Customizable Packaging Designs Shapes Market Trends

The wicketed bagging machines market is being shaped by a significant shift towards customizable packaging designs. Manufacturers are demanding flexible equipment that can quickly adapt to different bag sizes, shapes, and printing requirements. This trend reflects the growing need for personalized packaging in competitive consumer markets.

Increasing adoption of paper and biodegradable packaging materials is driving technological innovations in machine design. Equipment manufacturers are developing specialized feeding systems and sealing mechanisms to handle these alternative materials effectively. This evolution supports the industry’s transition away from traditional plastic packaging.

Energy-efficient machinery has become a key purchasing criterion for businesses focused on reducing operational costs and environmental impact. Modern wicketed bagging machines incorporate advanced motor technologies and optimized heating systems that significantly reduce power consumption while maintaining high performance standards.

Growing integration of robotics in packaging lines represents a major trend reshaping the industry. Robotic systems are being combined with wicketed bagging machines to create fully automated packaging solutions. This integration improves consistency, reduces labor requirements, and enables 24/7 operations for high-volume manufacturers seeking maximum productivity.

Regional Analysis

Europe Dominates the Wicketed Bagging Machines Market with a Market Share of 48.3%, Valued at USD 0.6 Billion

Europe holds the dominant position in the Wicketed Bagging Machines Market, with 48.3% of the market share and a valuation of USD 0.6 Billion. The region benefits from a strong industrial base, significant demand in packaging, and continuous technological advancements in machinery. The presence of key manufacturing players and the adoption of automated packaging solutions further drive growth.

North America Wicketed Bagging Machines Market Insights

North America is anticipated to show steady growth in the Wicketed Bagging Machines Market. With a strong emphasis on automation and sustainability, the region’s market is projected to expand due to rising demand across the food and beverage and consumer goods industries. Technological innovations and a shift toward eco-friendly solutions contribute to the market’s upward trajectory.

Asia Pacific Wicketed Bagging Machines Market Trends

Asia Pacific is experiencing rapid growth in the Wicketed Bagging Machines Market, driven by the increasing demand for efficient packaging solutions across industries. The rise in manufacturing activities, particularly in China and India, coupled with the expanding middle-class population, provides strong opportunities for market growth. Moreover, ongoing industrialization in emerging economies fuels demand.

Middle East and Africa Wicketed Bagging Machines Market Growth Prospects

The Middle East and Africa Wicketed Bagging Machines Market is poised for growth, although it remains smaller compared to other regions. Rising infrastructure development, coupled with the demand for packaging solutions in food and beverage sectors, presents substantial growth opportunities. Technological advancements and increased automation adoption are expected to boost the market in the coming years.

Latin America Wicketed Bagging Machines Market Overview

Latin America shows moderate growth in the Wicketed Bagging Machines Market, with increasing demand for packaging solutions in various sectors. The food industry remains a major driver, especially in countries such as Brazil and Argentina. As automation technologies gain traction, the region is expected to witness a gradual rise in the adoption of advanced bagging machines.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Wicketed Bagging Machines Company Insights

The global Wicketed Bagging Machines market in 2024 is shaped by the strong presence of key players that drive innovation and efficiency in packaging solutions.

Euro Machinery is known for its high-performance bagging machines that integrate seamlessly into existing production lines, enhancing productivity and minimizing downtime. Their innovative designs are focused on reducing maintenance costs while optimizing machine lifespan.

WeighPack Systems offers versatile, fully automated bagging systems that cater to industries ranging from food to chemicals. The company has gained a solid reputation for providing reliable, high-speed equipment with a focus on precision and user-friendliness. WeighPack’s bagging solutions are recognized for reducing labor costs and increasing packaging consistency.

Paxiom Group stands out with its diverse portfolio of packaging systems, including advanced wicketed baggers. Their commitment to offering flexible solutions that can accommodate a wide range of bag sizes and materials has positioned them as a major player in the market. Paxiom’s systems are designed to meet the evolving demands of industries requiring high-efficiency packaging solutions.

IMA Group, a renowned leader in automation and packaging machinery, provides state-of-the-art wicketed bagging machines that ensure high throughput and minimal product waste. Their global reach and expertise in engineering allow them to serve a wide variety of sectors, with an emphasis on sustainability and reducing the environmental footprint of packaging processes.

These companies are critical in shaping the competitive dynamics of the market, continuing to drive advancements in automation and efficiency for the global Wicketed Bagging Machines sector.

Top Key Players in the Market

- Euro Machinery

- WeighPack Systems

- Paxiom Group

- IMA Group

- NEWTEC

Recent Developments

- In May 2024, ATS agreed to acquire Paxiom Group, a packaging machine provider, to expand its portfolio in automated packaging solutions. This acquisition strengthens ATS’s presence in the packaging machinery sector, positioning them for increased market share.

- In January 2024, IMA Group acquired the Sarong Packaging Machinery and Packaging Materials divisions, further broadening its packaging solutions and enhancing its global footprint in the flexible packaging sector. The acquisition boosts IMA’s position in the growing demand for advanced packaging technology.

- In December 2024, Starlinger completed the acquisition of the Woven Packaging Division from Windmöller & Hölscher, enhancing its capabilities in woven packaging products. This strategic acquisition positions Starlinger as a leader in the woven bag and packaging market.

Report Scope

Report Features Description Market Value (2024) USD 1.3 Billion Forecast Revenue (2034) USD 2.4 Billion CAGR (2025-2034) 6.5% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Automation Type (Automatic, Semi-Automatic), By Machine Type (Vertical, Horizontal), By Machine Speed (Upto 500 Bags/Hr, 501-2000 Bags/Hr, More Than 2000 Bags/Hr), By End Use (Food, Pharmaceutical, Personal Care & Cosmetics, Others) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape Euro Machinery, WeighPack Systems, Paxiom Group, IMA Group, NEWTEC Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Wicketed Bagging Machines MarketPublished date: Aug 2025add_shopping_cartBuy Now get_appDownload Sample

Wicketed Bagging Machines MarketPublished date: Aug 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Euro Machinery

- WeighPack Systems

- Paxiom Group

- IMA Group

- NEWTEC