Global Robotic Flexible Washer Market By Type(Modular, Standalone), By Application(Oil Stains Removal, Dust Removal, Metal Filings Removal), By End Use(Auto Component Manufacturing, Aerospace & Defense, Heavy Machinery & Metal Working, Other End Uses), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2024-2033

- Published date: April 2024

- Report ID: 18046

- Number of Pages: 333

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

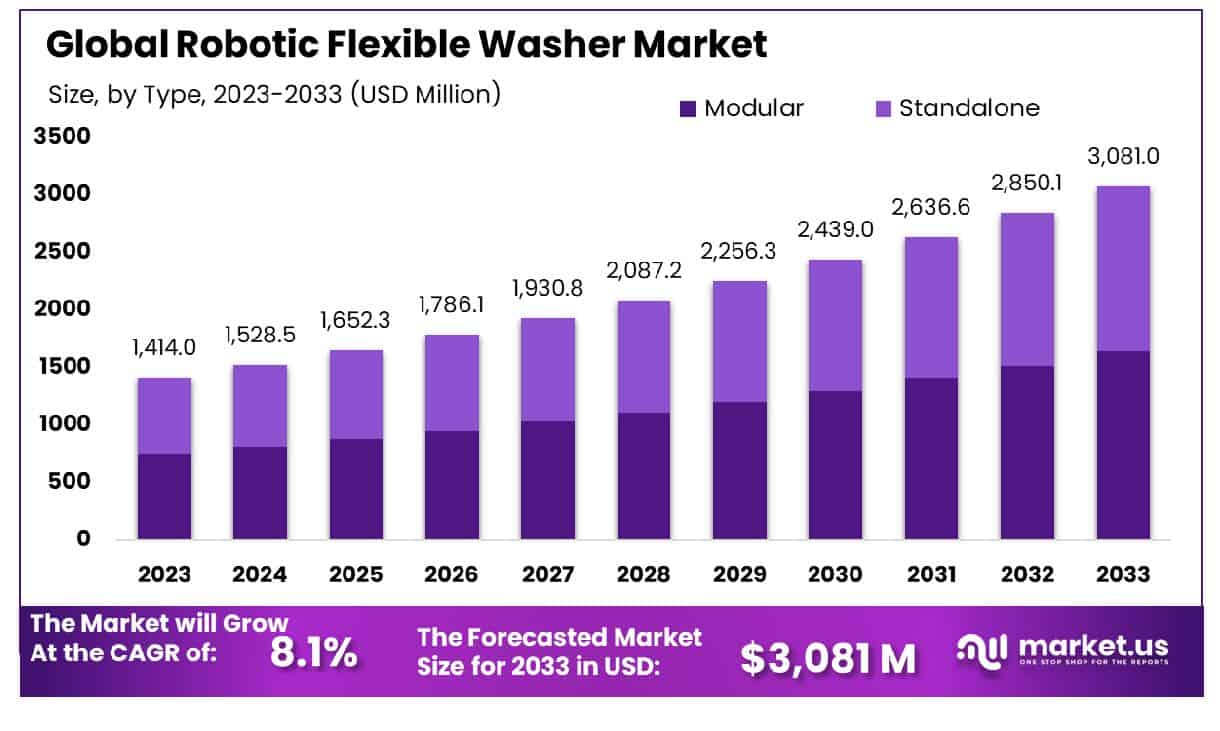

The Global Robotic Flexible Washer Market size is expected to be worth around USD 3081.0 Million by 2033, From USD 1414.0 Million by 2023, growing at a CAGR of 8.10% during the forecast period from 2024 to 2033.

The Robotic Flexible Washer Market encompasses advanced automated cleaning solutions designed for diverse industrial applications. These robotic systems integrate flexible, programmable automation to enhance efficiency and adaptability in cleaning operations across sectors such as automotive, aerospace, and manufacturing.

Characterized by their ability to navigate complex geometries and variable workspaces, these washers significantly reduce labor costs and improve cleaning precision. Strategic deployment of these technologies can lead to improved product quality and operational safety. This market is critical for leaders aiming to leverage cutting-edge automation to drive productivity and maintain competitive advantage in high-stake environments.

The Robotic Flexible Washer market, while poised for evolution, confronts significant challenges and opportunities in the shifting landscape of industrial automation. The industry experienced a notable contraction in North America in 2023, where robot orders plummeted by 30%, totaling 31,159 units. This downturn can largely be attributed to economic sluggishness in the U.S., escalated interest rates, and the repercussions of an over-purchasing spree in 2022 driven by supply chain disruptions.

Conversely, the broader context of global industrial robotics paints a different picture. In 2022, industrial robots saw a record installation of 553,052 units worldwide, with Asia leading at 73%, followed by Europe at 15%, and the Americas at 10%. Notably, China cemented its position as the preeminent market, with annual installations rising by 5% to 290,258 units. Similarly, Japan experienced growth, with installations surging by 9% to 50,413 units, surpassing its pre-pandemic levels.

The Robotic Flexible Washer sector must navigate these complexities by leveraging trends in regional markets and adjusting to macroeconomic pressures. As companies reassess their capital expenditure strategies in response to economic conditions, the demand for flexible robotic solutions is expected to fluctuate. The market’s resilience and future growth will likely hinge on advancements in technology, cost-effectiveness, and the ability to offer tailor-made solutions that address the unique needs of diverse industrial landscapes.

Key Takeaways

- Market Growth: The Global Robotic Flexible Washer Market size is expected to be worth around USD 3081.0 Million by 2033, From USD 1414.0 Million by 2023, growing at a CAGR of 8.10% during the forecast period from 2024 to 2033.

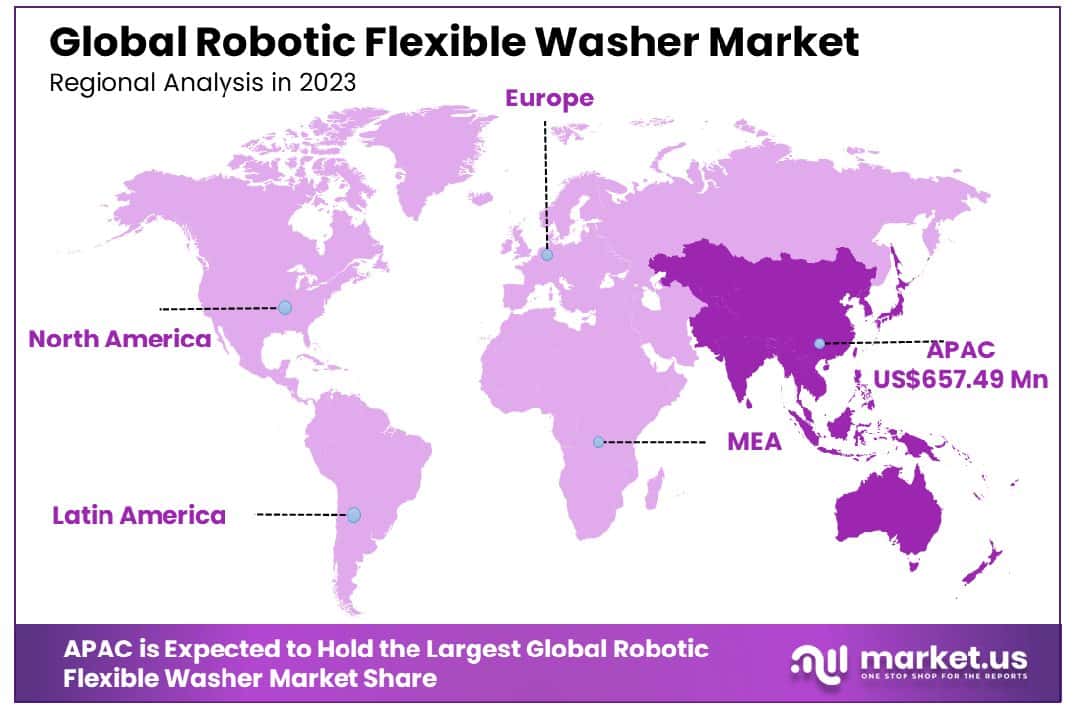

- Regional Dominance: In the Asia-Pacific region, the Robotic Flexible Washer Market dominates with a 46.6% share.

- Segmentation Insights:

- By Type: Modular robotic washers dominate, constituting 53.3% of the market share.

- By Application: Oil stain removal holds a 45.6% market share in applications.

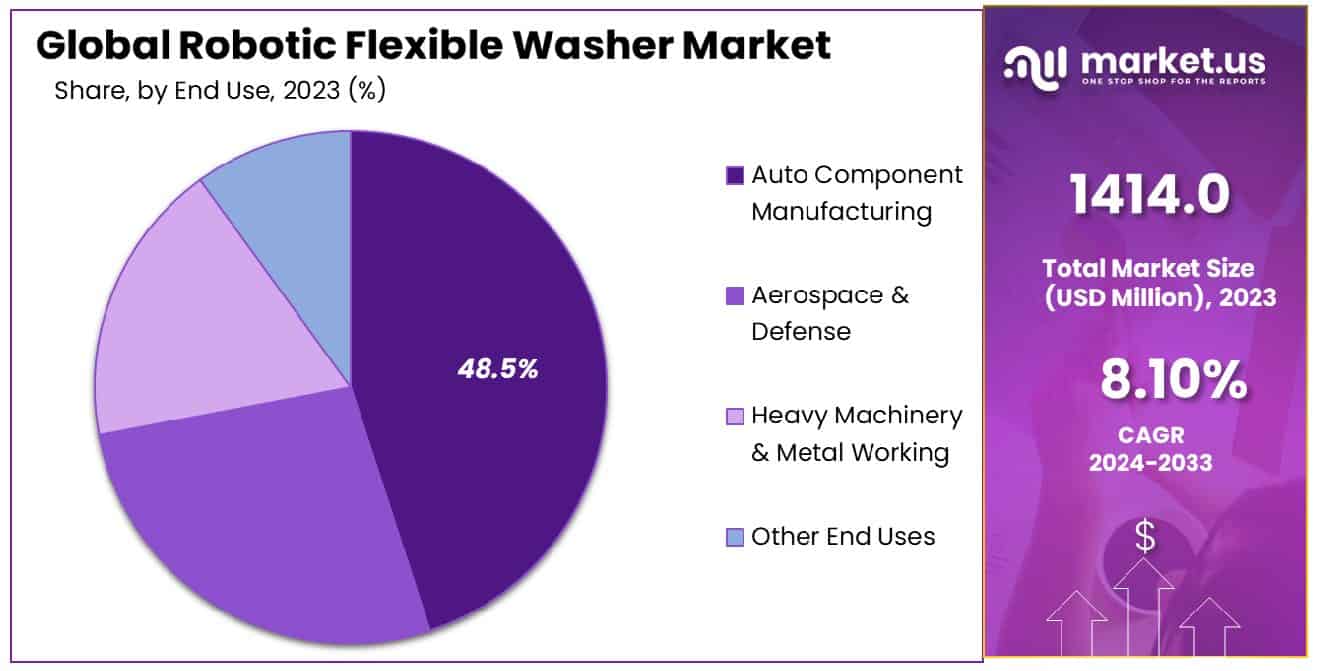

- By End Use: The auto component manufacturing sector accounts for 48.5% of end use.

- Growth Opportunities: In 2023, the global robotic flexible washer market is poised for growth due to rising labor and energy costs, alongside increasing demand for automation in various industries.

Driving Factors

Ensuring Contaminant-Free Operations in Critical Industries

The high demand for contaminant-free equipment and machines significantly drives the growth of the Robotic Flexible Washer Market. In industries where precision and hygiene are paramount, such as pharmaceuticals, food processing, and semiconductors, the necessity for immaculate conditions underlines the critical role of advanced cleaning solutions.

Robotic flexible washers offer consistent, high-quality cleaning that meets stringent regulatory standards and operational protocols. This technology minimizes human error and ensures that the production environments are free from contaminants, directly impacting productivity and compliance with industry regulations.

Addressing Labor Shortages through Automation

A notable shortage of skilled workforce in the manufacturing sector catalyzes the adoption of automated solutions like robotic flexible washers. Manufacturing facilities are increasingly turning to automation to offset labor shortages and enhance operational efficiencies. Robotic washers perform repetitive and labor-intensive cleaning tasks, thereby allowing human resources to be redirected to more skilled operations within the production process.

This shift not only compensates for the labor deficit but also improves the scalability of cleaning operations, crucial for meeting the growing production demand globally.

Expansion Driven by the Electrical and Electronics Industry

The surge in demand for cleanroom robots from the electrical and electronics industry is a pivotal growth vector for the Robotic Flexible Washer Market. In the production of automotive electronic components, where even minute particles can result in product failures, the role of effective cleaning systems becomes indispensable.

Robotic flexible washers provide the necessary precision and consistency required in these controlled environments. As the electronics sector continues to expand, propelled by the consumer demand for more sophisticated gadgets and the proliferation of IoT device management, the demand for these robotic systems is expected to rise, further stimulating market growth.

Restraining Factors

Financial Barriers Stemming from High Initial Costs

High initial investments and installation costs are significant restraining factors for the growth of the Robotic Flexible Washer Market. The acquisition and implementation of robotic systems involve substantial capital, which can deter small to medium-sized enterprises (SMEs) from adopting this technology. These costs include not only the purchase of the robots but also system integration, programming, maintenance, and potential facility modifications to accommodate new machinery.

For companies with limited budgets, the upfront expense can be prohibitive, slowing the rate of adoption and penetration of robotic flexible washers in certain sectors of the market. This financial barrier may limit market growth to larger players who can afford the initial outlay and potentially delay widespread market expansion.

Competitive Dynamics and Market Entry Challenges

The market positioning and competitive strength of key players also serve as restraining factors in the Robotic Flexible Washer Market. Established companies with strong brand recognition and extensive customer bases can dominate the market, making it challenging for new entrants to gain a foothold.

These leading players often benefit from economies of scale, comprehensive service networks, and advanced technology platforms, which can create high entry barriers for smaller or newer competitors. Furthermore, the competitive landscape can limit the diversity of available products and stifle innovation, as new entrants might struggle to compete with the research and development capabilities of these dominant firms.

By Type Analysis

Modular robotic washers dominate the market, constituting 53.3% of the total market share.

In 2023, Modular held a dominant market position in the By Type segment of the Robotic Flexible Washer Market, capturing more than a 53.3% share. This significant share underscores the growing preference for modular robotic solutions within industrial cleaning processes. Modular systems offer versatility and scalability, allowing for customizable configurations to meet varying production demands across diverse industrial sectors.

Standalone robotic washers, although trailing behind Modular systems, retained a notable presence in the market. With a share of approximately 46.7%, standalone units cater to specific applications where a more singular, dedicated approach to washing is preferred. Despite their slightly smaller market share, standalone units remain integral components in industries requiring specialized cleaning solutions or those with constrained operational spaces.

The dominance of Modular systems can be attributed to their inherent flexibility and adaptability. These systems typically comprise modular components that can be easily reconfigured or expanded to accommodate evolving production needs. This flexibility resonates with industries seeking agile solutions capable of adapting to dynamic manufacturing environments.

Furthermore, Modular systems often integrate advanced technologies such as AI-driven optimization and IoT connectivity, enhancing efficiency and enabling predictive maintenance capabilities. These features align with the overarching industry trend towards automation and digitalization, driving the adoption of sophisticated robotic washing solutions.

Looking ahead, the By-type segment of the Robotic Flexible Washer Market is poised for continued growth, fueled by ongoing advancements in modular robotics, increased industrial automation, and the ongoing emphasis on operational efficiency and sustainability.

As industries strive for greater productivity and environmental stewardship, the demand for innovative washing solutions, particularly modular systems, is expected to intensify, shaping the future landscape of industrial cleaning technologies.

By Application Analysis

Oil stain removal stands out as the primary application, representing 45.6% of market demand.

In 2023, Oil Stains Removal held a dominant market position in the By Application segment of the Robotic Flexible Washer Market, capturing more than a 45.6% share. This significant share underscores the critical role of robotic washing solutions in addressing the challenges associated with oil-based contaminants in industrial settings. The efficacy of robotic systems in efficiently removing oil stains from surfaces has propelled their adoption across diverse industries, including manufacturing, automotive, and aerospace.

Following closely behind, Dust Removal accounted for a substantial portion of the market, securing a share of approximately 35.9%. Dust accumulation poses significant operational challenges, leading industries to seek automated solutions capable of effectively mitigating dust-related issues. Robotic washers equipped with specialized brushes, air jets, and suction mechanisms offer precise and thorough dust removal, enhancing product quality and prolonging equipment lifespan.

Metal Filings Removal, while constituting a smaller segment, still commanded a notable share of approximately 18.5%. The presence of metal filings poses risks to machinery performance and product integrity, necessitating efficient cleaning solutions to prevent contamination and equipment damage. Robotic washers equipped with magnetic or suction-based systems excel in removing metal filings from surfaces, ensuring optimal operational efficiency and product quality.

The dominance of Oil stain removal can be attributed to the widespread prevalence of oil-based contaminants in industrial environments, coupled with the critical need for effective cleaning solutions to maintain operational efficiency and regulatory compliance. As industries increasingly prioritize cleanliness, safety, and environmental sustainability, the demand for robotic washers capable of addressing diverse cleaning applications, including oil stain removal, dust removal, and metal filings removal, is expected to surge, driving innovation and market growth in the Robotic Flexible Washer Market.

By End-Use Analysis

Auto component manufacturing emerges as the leading end-use sector, commanding a 48.5% market share.

In 2023, Auto Component Manufacturing held a dominant market position in the By End Use segment of the Robotic Flexible Washer Market, capturing more than a 48.5% share. This substantial share reflects the widespread adoption of robotic washing solutions within the automotive industry to ensure the cleanliness and quality of precision-engineered components. Robotic washers offer manufacturers the ability to streamline production processes, enhance product consistency, and comply with stringent quality standards, driving their widespread adoption in auto component manufacturing.

Following closely behind, Aerospace & Defense accounted for a significant portion of the market, securing a share of approximately 30.2%. The aerospace and defense sectors demand precision cleaning solutions to maintain the integrity and performance of critical components used in aircraft manufacturing, spacecraft, and defense systems. Robotic washers equipped with advanced cleaning technologies play a pivotal role in meeting the rigorous cleanliness requirements of these industries, contributing to improved reliability and safety of aerospace and defense equipment.

Heavy Machinery & Metal Working constituted a notable segment, capturing a share of approximately 16.8%. The heavy machinery and metalworking industries rely on robotic washers to remove contaminants such as oil, grease, and metal shavings from large and complex components. Robotic washing solutions facilitate efficient cleaning of intricate machinery parts, reducing downtime, enhancing equipment longevity, and optimizing operational performance.

Other End Uses, while representing a smaller segment, still held significance in the market, accounting for approximately 4.5%. This category encompasses various industries beyond automotive, aerospace, and heavy machinery, including electronics manufacturing, medical device production, and food processing.

The versatility of robotic washers enables their adoption across diverse end-use applications, driving market expansion and innovation to meet evolving industry needs. As end-use industries prioritize efficiency, quality, and compliance, the demand for robotic flexible washers is poised for sustained growth, catalyzing advancements in industrial cleaning technologies.

Key Market Segments

By Type

- Modular

- Standalone

By Application

- Oil Stains Removal

- Dust Removal

- Metal Filings Removal

By End Use

- Auto Component Manufacturing

- Aerospace & Defense

- Heavy Machinery & Metal Working

- Other End Uses

Growth Opportunities

Surge in Labor and Energy Costs

The global market for robotic flexible washers is poised for significant expansion in 2023, driven in part by a surge in labor and energy costs worldwide. Industries across sectors are grappling with the escalating expenses associated with manual labor and energy consumption.

As a result, companies are increasingly turning to automation solutions to streamline their operations and mitigate rising overheads. Robotic flexible washers offer a cost-effective alternative to traditional labor-intensive cleaning processes, as they require minimal human intervention and consume energy more efficiently.

Increasing Demand for Automation

Furthermore, the growing demand for automation across various industries is a key factor driving the opportunities in the global robotic flexible washer market. As businesses seek to enhance productivity, optimize resource utilization, and improve product quality, they are embracing automation technologies at an unprecedented rate.

Robotic flexible washers enable manufacturers to achieve higher throughput, consistent cleaning results, and greater flexibility in production processes. From automotive and electronics to food and beverage sectors, companies are recognizing the strategic importance of integrating robotic solutions into their operations to stay competitive in the market.

Latest Trends

Evolving Robotics & AI Industry

In 2023, the global robotic flexible washer market is witnessing transformative trends driven by advancements in the robotics and artificial intelligence (AI) sectors. As technology continues to evolve at a rapid pace, robotics solutions are becoming increasingly sophisticated, efficient, and adaptable. This evolution is translating into enhanced capabilities for robotic flexible washers, enabling them to perform intricate cleaning tasks with precision and speed.

Moreover, the integration of AI algorithms enables these robots to learn and adapt to dynamic environments, optimizing cleaning processes and reducing downtime. This convergence of robotics and AI is reshaping the landscape of the global robotic flexible washer market, unlocking new opportunities for innovation and efficiency.

Increase in Application Areas of Clean Room Robots

Another notable trend shaping the global market for robotic flexible washers in 2023 is the expansion of application areas, particularly in clean room environments. With the rising demand for cleanliness and hygiene in industries such as pharmaceuticals, biotechnology, and semiconductor manufacturing, there is a growing need for specialized cleaning solutions that meet stringent cleanliness standards.

Clean room robots equipped with flexible washing capabilities are increasingly being deployed to ensure the cleanliness and sterility of critical production environments. This expansion into clean room applications underscores the versatility and adaptability of robotic flexible washers, positioning them as indispensable assets in industries where hygiene and contamination control are paramount.

Regional Analysis

In the Asia-Pacific region, the robotic flexible washer market commands a significant share of 46.6%.

In the global Robotic Flexible Washer Market, segmented by region into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America, Asia-Pacific emerges as the dominant force, commanding a substantial market share of 46.6%. The region’s dominance is attributed to the rapid industrialization, technological advancements, and increasing adoption of automation solutions across various industries. Specifically, countries like China, Japan, South Korea, and India are driving significant growth in the Asia-Pacific market due to their robust manufacturing sectors and investments in automation technologies.

North America follows closely behind Asia-Pacific, fueled by the presence of key players in the robotics industry and the widespread adoption of advanced manufacturing practices. The region benefits from a strong focus on research and development, fostering innovation and the introduction of cutting-edge robotic flexible washer solutions.

In Europe, the market for robotic flexible washers is characterized by stringent regulations about workplace safety, cleanliness standards, and environmental sustainability. These factors drive the demand for automated cleaning solutions, particularly in industries such as healthcare, pharmaceuticals, and food processing.

The Middle East & Africa region is witnessing steady growth in the adoption of robotic flexible washers, propelled by increasing investments in industrial automation and a growing emphasis on efficiency and productivity improvement across various sectors.

Latin America, while representing a smaller share of the global market, is experiencing a gradual uptick in demand for robotic flexible washers, supported by advancements in manufacturing capabilities and a shift towards automation to remain competitive in the global market landscape.

Key Regions and Countries

- North America

- The US

- Canada

- Mexico

- Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

In 2023, the global Robotic Flexible Washer Market is characterized by the presence of several key players, each contributing uniquely to the industry’s landscape. Among these, companies such as ABB Group, Dynamic Robotic Solutions, and BvL Oberflächentechnik GmbH stand out as frontrunners, leveraging their expertise and innovative solutions to drive market growth and shape industry trends.

ABB Group, a leading multinational corporation renowned for its robotics and automation solutions, plays a pivotal role in advancing the Robotic Flexible Washer Market. With its extensive portfolio of industrial robots and integrated automation systems, ABB Group offers cutting-edge solutions tailored to meet the evolving needs of manufacturing industries worldwide.

Dynamic Robotic Solutions, known for its customizable robotic solutions, brings versatility and adaptability to the market. By offering flexible washer systems that can be tailored to specific applications and production requirements, Dynamic Robotic Solutions caters to diverse industry sectors seeking efficient cleaning solutions.

Similarly, BvL Oberflächentechnik GmbH, with its focus on surface cleaning technologies, contributes significantly to the Robotic Flexible Washer Market. The company’s innovative approaches to surface treatment and cleaning automation address the growing demand for high-quality, environmentally friendly cleaning solutions across industries.

Other notable players such as DurrEcoclean, Elwema Automotive GmbH, and Cleaning Technologies Group also play crucial roles in driving market dynamics through their technological innovations and commitment to delivering reliable and cost-effective cleaning solutions.

Market Key Players

- ABB Group

- Dynamic Robotic Solutions

- BvL Oberflächentechnik GmbH

- DurrEcoclean

- Elwema Automotive GmbH

- Cleaning Technologies Group

- Fives Cinetic Corp

- ADF Systems Ltd.

- Harry Major Machines

- SBS Ecoclean Group

- Fives Group

- Other Key Players

Recent Development

- In April 2024, Boston Dynamics introduces a fully electric Atlas humanoid robot, retiring its hydraulic version. Enhanced agility and strength enable commercial exploration, starting with Hyundai partnership. Innovations set new standards in robotics.

- In April 2024, Collaborative Robotics, a Santa Clara startup, secures $100 million in funding led by General Catalyst, tripling total funding. The company focuses on advancing collaborative robotics technology.

- In March 2024, Cambrian Robotics secured $3.5M Seed+ funding led by Cybernetix Ventures and KST Invest GmbH. Their AI-driven robotic vision software enhances industrial automation, surpassing human capabilities.

Report Scope

Report Features Description Market Value (2023) USD 1414.0 Million Forecast Revenue (2033) USD 3081.0 Million CAGR (2024-2033) 8.10% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type(Modular, Standalone), By Application(Oil Stains Removal, Dust Removal, Metal Filings Removal), By End Use(Auto Component Manufacturing, Aerospace & Defense, Heavy Machinery & Metal Working, Other End Uses) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape ABB Group, Dynamic Robotic Solutions, BvL Oberflächentechnik GmbH, DurrEcoclean, Elwema Automotive GmbH, Cleaning Technologies Group, Fives Cinetic Corp, ADF Systems Ltd., Harry Major Machines, SBS Ecoclean Group, Fives Group, Other Key Players Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is the size of the Global Robotic Flexible Washer Market in 2023?The Global Robotic Flexible Washer Market size is USD 2.6 Million in 2023.

What is the projected CAGR at which the Global Robotic Flexible Washer Market is expected to grow at?The Global Robotic Flexible Washer Market is expected to grow at a CAGR of 8.10% (2024-2033).

List the segments encompassed in this report on the Global Robotic Flexible Washer Market?Market.US has segmented the Global Robotic Flexible Washer Market by geographic (North America, Europe, APAC, South America, and Middle East and Africa). By Type(Modular, Standalone), By Application(Oil Stains Removal, Dust Removal, Metal Filings Removal), By End Use(Auto Component Manufacturing, Aerospace & Defense, Heavy Machinery & Metal Working, Other End Uses)

List the key industry players of the Global Robotic Flexible Washer Market?ABB Group, Dynamic Robotic Solutions, BvL Oberflächentechnik GmbH, DurrEcoclean, Elwema Automotive GmbH, Cleaning Technologies Group, Fives Cinetic Corp, ADF Systems Ltd., Harry Major Machines, SBS Ecoclean Group, Fives Group, Other Key Players

Name the key areas of business for Global Robotic Flexible Washer Market?The China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, Rest of APAC are leading key areas of operation for Global Robotic Flexible Washer Market.

Robotic Flexible Washer MarketPublished date: April 2024add_shopping_cartBuy Now get_appDownload Sample

Robotic Flexible Washer MarketPublished date: April 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- ABB Group

- Dynamic Robotic Solutions

- BvL Oberflächentechnik GmbH

- DurrEcoclean

- Elwema Automotive GmbH

- Cleaning Technologies Group

- Fives Cinetic Corp

- ADF Systems Ltd.

- Harry Major Machines

- SBS Ecoclean Group

- Fives Group

- Other Key Players