Global Healthcare Additive Market By Technology (Stereolithography, Deposition Modeling, Electron Beam Melting, Laser Sintering, Others); By Application-(Medical Implants, Prosthetics, Wearable Devices, Tissue Engineering, Dental, Others); By Material-(Metals and Alloys, Steel, Titanium, Polymers, Nylon, Glass-filled Polyamide, Epoxy Resins, Photopolymers, Plastics, Biological Cells, Biological Cells, Others) By Region, and Key Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: Dec 2023

- Report ID: 74589

- Number of Pages: 228

- Format:

-

keyboard_arrow_up

Quick Navigation

Market Overview

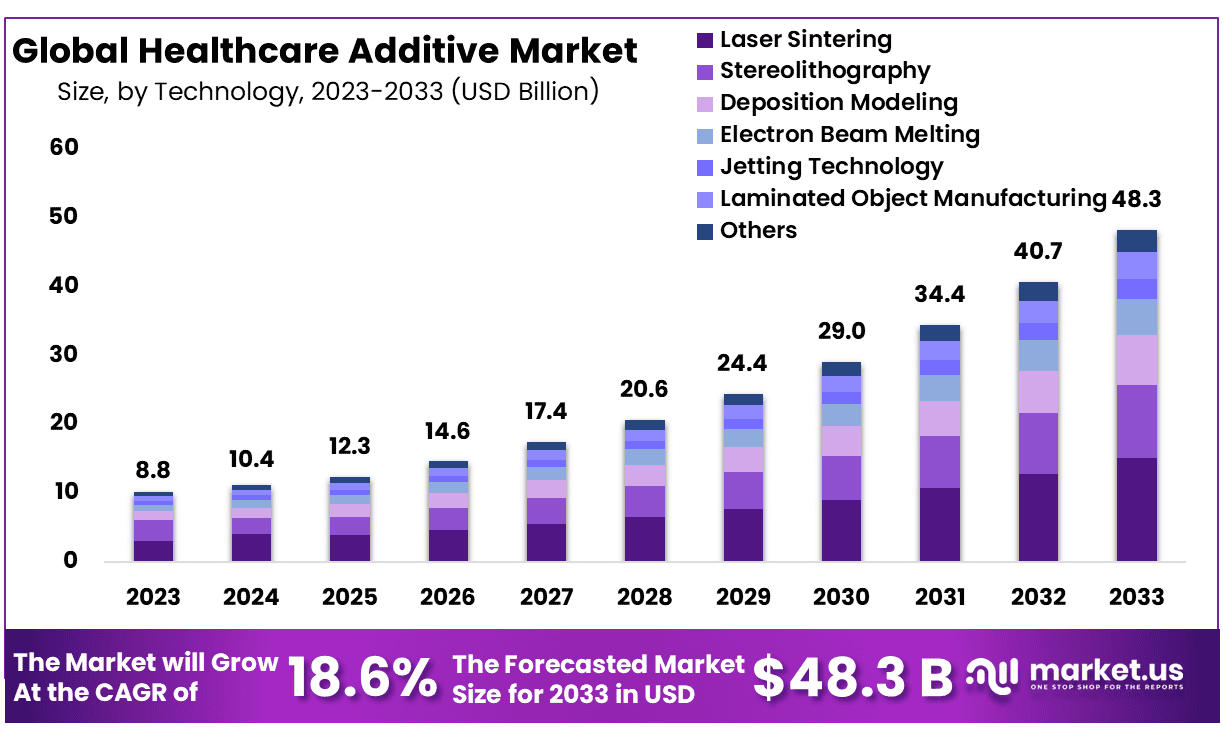

The Global Healthcare Additive Market size is expected to be worth around USD 48.3 Billion by 2033 from USD 8.8 Billion in 2023, growing at a CAGR of 18.6% during the forecast period from 2024 to 2033.

“Additive Manufacturing” (AM) refers to technologies that grow three-dimensional objects one superfine layer at a time. It is also known as 3D Printing and “rapid prototyping.” It removes many of the constraints seen in more traditional manufacturing methods such as milling, casting, forging or fabrication. This has opened-up new possibilities for complex geometries and mass customization of previously unfeasible parts at commercially viable costs.

This technology enables new medical devices that benefit patient care in orthopedics, implantology, and dentistry. It is ideal in making prototypes quickly using 3D CAD and eliminates the lengthy process and high costs associated with the same. It enables the creation of lighter, more substantial parts.

In recent years, communications, imaging, architecture, and engineering have all undergone digital revolutions, and now, AM has brought efficiency to manufacturing operations. This technology has transformed the medical landscape due to the option of having an easily distributed supply-chain. With the increasing pressure on supplying necessary emergency items, the application of AM technology gained popularity.

*Actual Numbers Might Vary In The Final Report

Key Takeaways

- Market Size: Healthcare Additive Market size is expected to be worth around USD 48.3 Billion by 2033 from USD 8.8 Billion in 2023.

- Market Growth: The market growing at a CAGR of 18.6% during the forecast period from 2024 to 2033.

- Technology Analysis: Laser Sintering dominates the Healthcare Additive Market with an impressive 31.2% market share.

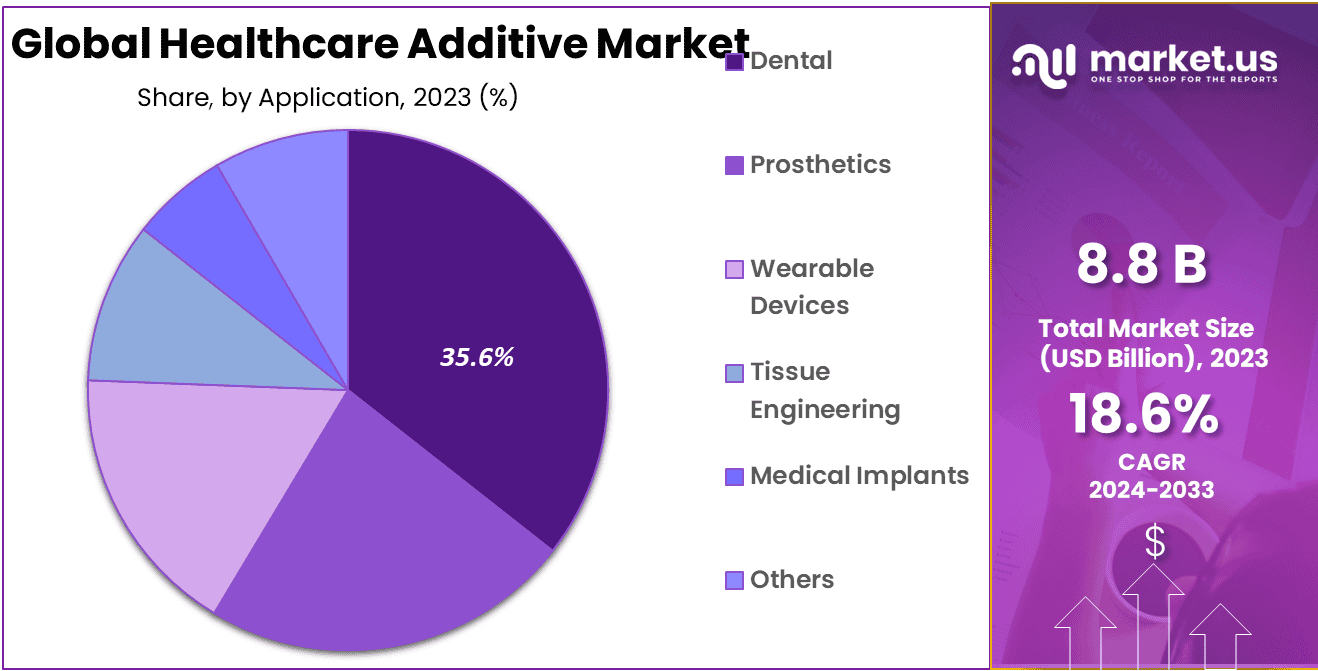

- Application Analysis: Dental contribution, holding a 33.4% market share in 2023.

- Material Analysis: The Healthcare Additive Manufacturing Market presents an ever-evolving scene, with polymers holding 55.5% market share

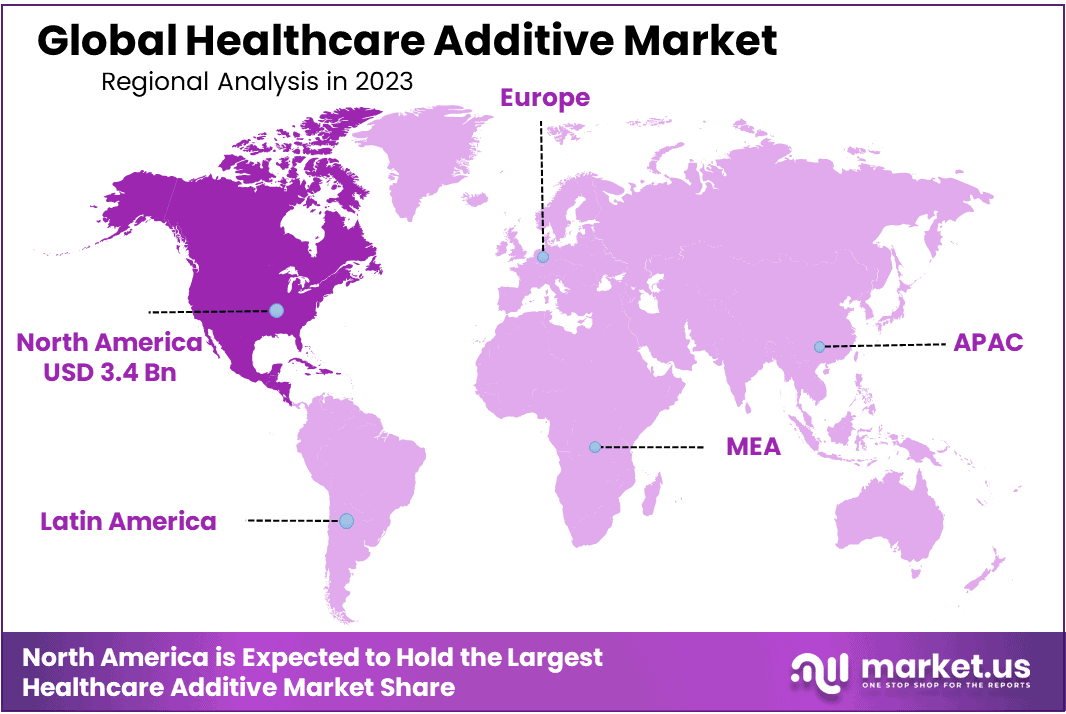

- Regional Analysis: North America commands an impressive market position, boasting a market share of 39.2% and holding ~USD 3.4 Billion revenue.

Technology Analysis

Laser Sintering dominates the Healthcare Additive Market with an impressive 31.2% market share. Utilizing cutting-edge technology, this additive manufacturing method enables the creation of intricate medical components with remarkable precision. Alongside Laser Sintering are other notable technologies like Stereolithography, Deposition Modeling, Electron Beam Melting, Jetting Technology and Laminated Object Manufacturing which all add depth to this market’s diverse offering.

Stereolithography allows for the rapid production of precise prototypes, while Deposition Modeling excels in crafting functional yet long-lasting medical devices. Electron Beam Melting showcases its skill in crafting intricate metal structures – adding technological versatility to the market – while Jetting Technology meets agile healthcare development’s rapid prototyping needs through rapid prototyping capabilities.

Laminated Object Manufacturing’s commitment to improving patient care with additive manufacturing technology cements Laminated Object Manufacturing as the market’s commitment. By joining forces, Healthcare Additive Market marks the dawning of precision, efficiency, and customization in medical device production – ushering in an era that promises precision efficiency & customization in medical device production!

Application Analysis

By Application Analysis, dental contribution, holding a 33.4% market share. Thanks to additive manufacturing technologies used for dentistry components such as crowns and bridges to intricate orthodontic structures. Additive manufacturing provides precise patient-specific solutions, improving both aesthetics and functionality simultaneously.

Beyond dentistry, the Healthcare Additive Market reaches across multiple applications. Medical Implants benefit from additive manufacturing’s capacity to produce customized and biocompatible implants for optimal patient outcomes; prosthetics feature advancements in design and fit which improve mobility and comfort; wearable devices take advantage of additive manufacturing’s agility to provide patient monitoring solutions and treatment adherence systems; Tissue Engineering offers bioprinted tissues for regenerative medicine solutions – these applications demonstrate why Healthcare Additive Market will play such an integral part in shaping personalized and effective healthcare solutions in future healthcare solutions – driving this market!

Material Analysis

The Healthcare Additive Manufacturing Market presents an ever-evolving scene, with polymers holding 55.5% market share – indicative of their prominent role in additive manufacturing processes within healthcare. Beyond polymers, the market offers an array of materials such as metals and alloys such as steel and titanium. Healthcare additive manufacturing boasts an expansive variety of materials such as nylon, glass-filled polyamide, epoxy resins, photopolymers, plastics and biological cells that contribute to its rich repertoire of options.

Each material offers distinct properties and applications to meet the diverse demands of medical industry. This wide variety reflects the ever-advancing advancements and innovations of additive manufacturing technology, creating an ecosystem to meet all aspects of healthcare applications ranging from durable implants to biofabrication of tissues and organs. As Healthcare Additive Manufacturing continues to advance and transform, these diverse materials all contribute towards its progress and transformation.

*Actual Numbers Might Vary In The Final Report

Market Segment

Technology

- Stereolithography

- Deposition Modeling

- Electron Beam Melting

- Laser Sintering

- Jetting Technology

- Laminated Object Manufacturing

- Others

Application

- Medical Implants

- Prosthetics

- Wearable Devices

- Tissue Engineering

- Dental

- Others

Material

- Metals and Alloys

- Steel

- Titanium

- Others

- Polymers

- Nylon

- Glass-filled Polyamide

- Epoxy Resins

- Photopolymers

- Plastics

- Biological Cells

- Others

- Biological Cells

- Others

Driving Factors

Demand for Customized Medical Devices: The Healthcare Additive Market is flourishing thanks to an exploding demand for personalized and tailored medical devices manufactured using additive manufacturing technologies, which enable medical practitioners to tailor solutions specifically tailored for individual patient needs, thus improving treatment outcomes and increasing patient satisfaction.

Advances in Materials Science: Materials science innovations are at the core of market growth. Advancements in biocompatible polymers, metals, and alloys contribute to developing durable healthcare components and expanding additive manufacturing applications.

Rise in Chronic Illnesses: Chronic illnesses worldwide have driven growth of the healthcare additive market. Such conditions often necessitate sophisticated medical treatments; additive manufacturing allows the creation of patient-specific implants and prosthetics, meeting these challenges head on.

Trending Factors

Key Market Trends: The Healthcare Additive Market is characterized by its convergence between additive manufacturing and telehealth services, which aid remote production of medical components for improved healthcare delivery while decreasing physical presence within healthcare facilities.

Focus on Bioprinting Technologies: One trend seen within the market today is an increased emphasis on bioprinting technologies. These advances enable the precise printing of biological tissues and organs, opening the way to revolutionary breakthroughs in regenerative medicine as well as helping address shortages of donor organs.

Rapid Prototyping for Research: Rapid prototyping medical devices has become an increasing trend on the market. Additive manufacturing technology enables fast and cost-effective prototyping, helping accelerate healthcare solutions development while furthering R&D initiatives.

Restraining Factors

Lack of Standardization: The healthcare additive market faces challenges as a result of lack of standardization in additive manufacturing processes. Variation between technologies and materials limits seamless integration and interoperability for widespread adoption in healthcare settings.

Security Concerns: Security issues surrounding digital design files used in additive manufacturing present an obstacle. Protecting intellectual property and maintaining integrity in design files must be tackled to promote wide adoption of additive manufacturing in healthcare.

Limited Reimbursement Policies: Restrictive reimbursement policies hinder market expansion for medical components produced through additive manufacturing, making their adoption even less likely among healthcare providers. Establishing comprehensive reimbursement structures is vital to incentivise healthcare providers to adopt innovative technologies like additive manufacturing.

Growth Opportunities

Expansion in Point-of-Care Manufacturing: One key growth opportunity lies in expanding point-of-care manufacturing using additive technologies. This method allows on-site production of medical devices, shortening lead times and improving accessibility – particularly for remote or underserved healthcare settings.

Collaboration for Research and Development: Partnerships between healthcare institutions, research organizations, and additive manufacturing companies present an exciting growth opportunity. Their joint efforts in research and development may yield novel medical solutions that spur innovation and market expansion.

Integrating Artificial Intelligence (AI): Integrating artificial intelligence (AI) in additive manufacturing represents a promising growth avenue. AI can optimize design processes, increase efficiency and increase precision – opening new possibilities for advanced medical device production.

Regional Analysis

North America commands an impressive market position, boasting a market share of 39.2% and holding ~USD 3.4 Billion revenue in Healthcare Additive Manufacturing. This can be attributed to major companies located there as well as their commitment to developing technology within healthcare sector. To bolster competitive edge and expand market influence, North America utilizes strategic initiatives including collaborations, partnerships, mergers & acquisitions as well as investments in research & development investments – these endeavors promote technological advances while encouraging innovation enhancing overall competitiveness within Healthcare Additive Manufacturing arena.

*Actual Numbers Might Vary In The Final Report

Key Regions and Countries

North America

- The US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Player Analysis

Within our market analysis, we dedicate an entire section to major players. Here, our analysts offer in-depth reviews of each company’s financial statements, product benchmarking and SWOT analyses as well as competitive landscape analyses that evaluate key development strategies, global market share data analysis and an assessment of market positioning for these players.

Market Key Players

- 3D Systems, Inc.

- EnvisionTEC

- RegenHU

- Allevi, Inc.

- EOS GmbH

- Materialise N.V.

- Stratasys Ltd.

- Nanoscribe GmbH

- GPI Prototype and Manufacturing Services, LLC

- 3T Additive Manufacturing Ltd

- Fathom Manufacturing

Recent Developments

- 3D Systems, Inc. recently announced their collaboration with Stryker to develop and market biocompatible 3D printed implants suitable for spinal surgery procedures.

- EnvisionTEC unveiled an advanced 3D printing technology called Micro DLP that is capable of reaching high resolutions while producing features as small as 10 microns in thickness.

- RegenHU was at the forefront of creating a biocompatible hydrogel designed for 3D printing human tissues and organs.

- Allevi, Inc. Made waves when they unveiled an innovative 3D printing technology known as Rapid Powder Deposition (RPD) that boasts speeds up to 10 times faster than standard powder bed fusion technologies.

- EOS GmbH EOS M290 is an advanced metal additive manufacturing system designed specifically for producing medical implants.

- Materialise N.V. unveiled their Mimics Innovation Suite software platform tailored specifically for medical additive manufacturing purposes.

Report Scope

Report Features Description Market Value (2023) USD 8.8 Billion Forecast Revenue (2033) USD 48.3 Billion CAGR (2024-2033) 18.6% Base Year for Estimation 2023 Historic Period 2018-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Technology-(Stereolithography, Deposition Modeling, Electron Beam Melting, Laser Sintering, Jetting Technology, Laminated Object Manufacturing, Others); By Application-(Medical Implants, Prosthetics, Wearable Devices, Tissue Engineering, Dental, Others); By Material-(Metals and Alloys, Steel, Titanium, Others, Polymers, Nylon, Glass-filled Polyamide, Epoxy Resins, Photopolymers, Plastics, Biological Cells, Others, Biological Cells, Others) Regional Analysis North America-US, Canada, Mexico;Europe-Germany, UK, France, Italy, Russia, Spain, Rest of Europe;APAC-China, Japan, South Korea, India, Rest of Asia-Pacific;South America-Brazil, Argentina, Rest of South America;MEA-GCC, South Africa, Israel, Rest of MEA Competitive Landscape 3D Systems, Inc., EnvisionTEC, RegenHU, Allevi, Inc., EOS GmbH, Materialise N.V., Stratasys Ltd., Nanoscribe GmbH, GPI Prototype and Manufacturing Services, LLC, 3T Additive Manufacturing Ltd, Fathom Manufacturing Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

How Do Technological Advancements Impact the Market?Ongoing technological innovations in additive manufacturing contribute to the market's dynamism, enhancing the performance of materials and opening up new possibilities for healthcare applications.

How big is the Healthcare Additive Market?The global Healthcare Additive Market size was estimated at USD 8.8 Billion in 2023 and is expected to reach USD 48.3 Billion in 2033.

What is the Healthcare Additive Market growth?The global Healthcare Additive Market is expected to grow at a compound annual growth rate of 18.6%. From 2024 To 2033

Who are the key companies/players in the Healthcare Additive Market?Some of the key players in the Healthcare Additive Markets are 3D Systems, Inc., EnvisionTEC, RegenHU, Allevi, Inc., EOS GmbH, Materialise N.V., Stratasys Ltd., Nanoscribe GmbH, GPI Prototype and Manufacturing Services, LLC, 3T Additive Manufacturing Ltd, Fathom Manufacturing.

What Does the Market Ecosystem Encompass?The market's evolution results in the formation of a comprehensive ecosystem, addressing multifaceted healthcare requirements and reflecting the industry's commitment to advancing medical solutions.

What Is the Growth Trajectory of the Healthcare Additive Market?The market continues to grow and transform as diverse materials and technological innovations collectively contribute to advancing additive manufacturing within the healthcare sector.

-

-

- 3D Systems, Inc.

- EnvisionTEC

- RegenHU

- Allevi, Inc.

- EOS GmbH

- Materialise N.V.

- Stratasys Ltd.

- Nanoscribe GmbH

- GPI Prototype and Manufacturing Services, LLC

- 3T Additive Manufacturing Ltd

- Fathom Manufacturing