Global Oilfield Roller Chain Market Size, Share, And Enhanced Productivity By Type (Drive Chain, Conveyer Chain, Others), By Material (Carbon Steel, Stainless Steel, Alloy Steel), By Application (Hoisting Operation, Conveyer Chain, Others), By Location (Onshore, Offshore), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: November 2025

- Report ID: 168246

- Number of Pages: 261

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

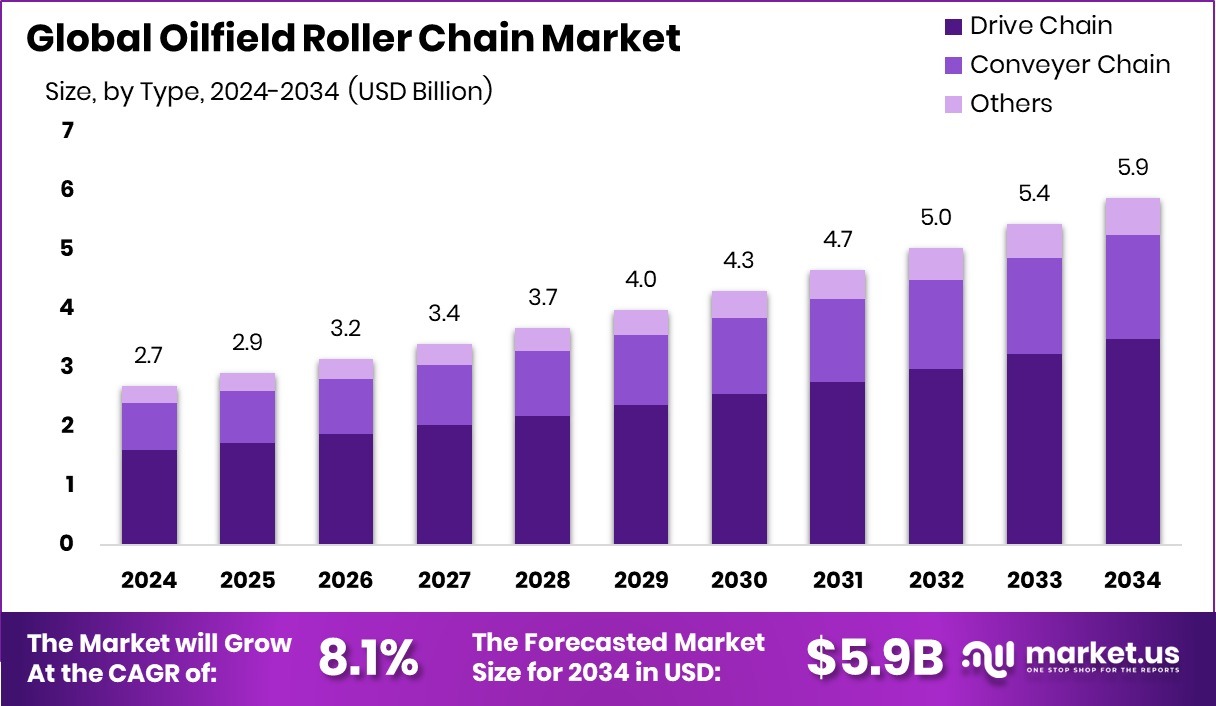

The Global Oilfield Roller Chain Market is expected to be worth around USD 5.9 billion by 2034, up from USD 2.7 billion in 2024, and is projected to grow at a CAGR of 8.1% from 2025 to 2034. Continuous drilling activities keep North America leading at 45.20%, generating USD 1.2 Bn revenue.

Oilfield roller chain is a heavy-duty mechanical chain used to transmit power and motion in oilfield equipment such as drilling rigs, pumping units, conveyors, and rotary systems. It is engineered to perform reliably under extreme loads, abrasive environments, high temperatures, and constant exposure to oil, gas, and drilling fluids.

The oilfield roller chain market covers the production, supply, maintenance, and replacement of these chains across upstream and midstream oil and gas operations. Market growth is supported by steady investment in energy infrastructure and a rising focus on durable, low-maintenance mechanical components that reduce downtime and improve operational safety.

Key growth factors include the modernization of drilling equipment and the increasing emphasis on sustainable industrial materials. Global momentum toward green steel is strengthening supply chains, highlighted by India’s US$569 million green steel support fund, a $186 million Temasek-led round for low-carbon steel innovation, and Tata Steel’s Rs 83 lakh R&D funding for low-carbon technologies.

Demand continues to rise as aging oilfield assets require reliable replacement parts capable of extended service life. Large-scale industrial transitions, including the world’s first major green steel project securing $5 billion in funding and Stegra’s €37 million grant despite remaining gaps, reinforce long-term demand for high-performance steel components.

Opportunities lie in advanced alloys, corrosion-resistant designs, and chains manufactured using low-carbon steel. As energy companies balance operational efficiency with sustainability goals, oilfield roller chains that align with green steel initiatives are expected to see strong future adoption.

Key Takeaways

- The Global Oilfield Roller Chain Market is expected to be worth around USD 5.9 billion by 2034, up from USD 2.7 billion in 2024, and is projected to grow at a CAGR of 8.1% from 2025 to 2034.

- Drive chains dominate the Oilfield Roller Chain Market with a 59.4% share due to reliable power transmission efficiency.

- Carbon steel holds 52.3% market share as it offers cost efficiency, strength, and durability.

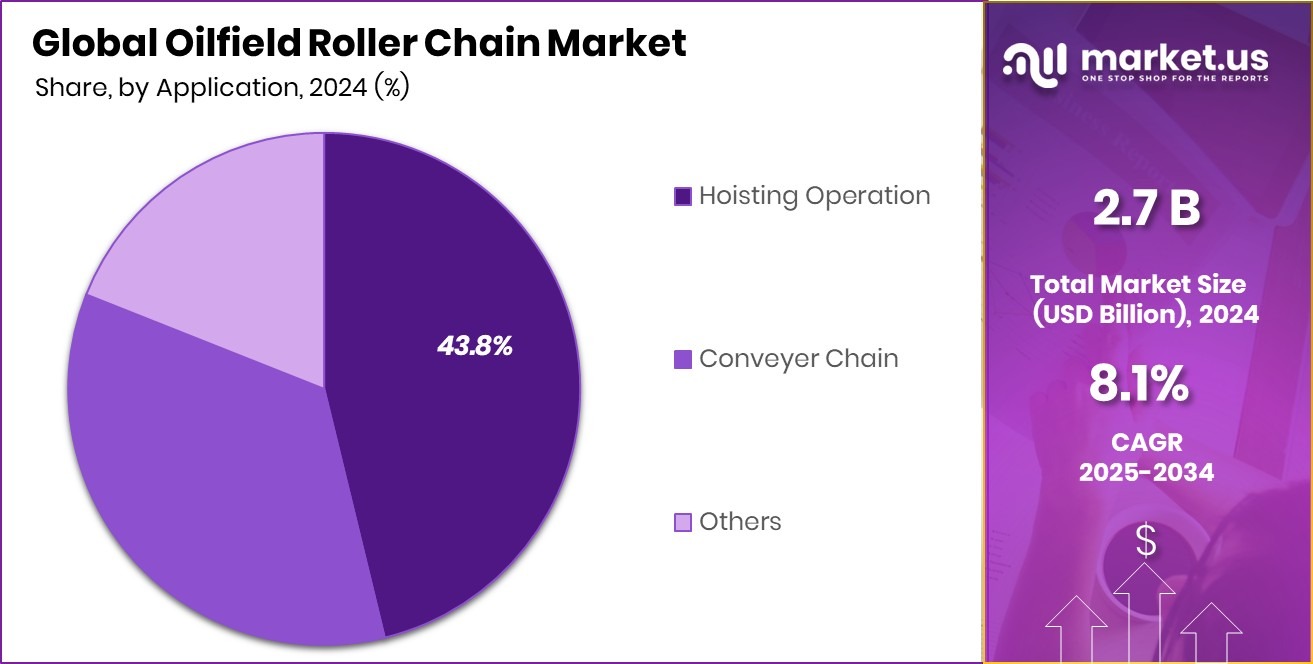

- Hoisting operations account for 43.8 of % demand driven by continuous lifting, load handling, and rig operations.

- Onshore locations lead with 78.5% share, supported by extensive drilling activity and easier maintenance access.

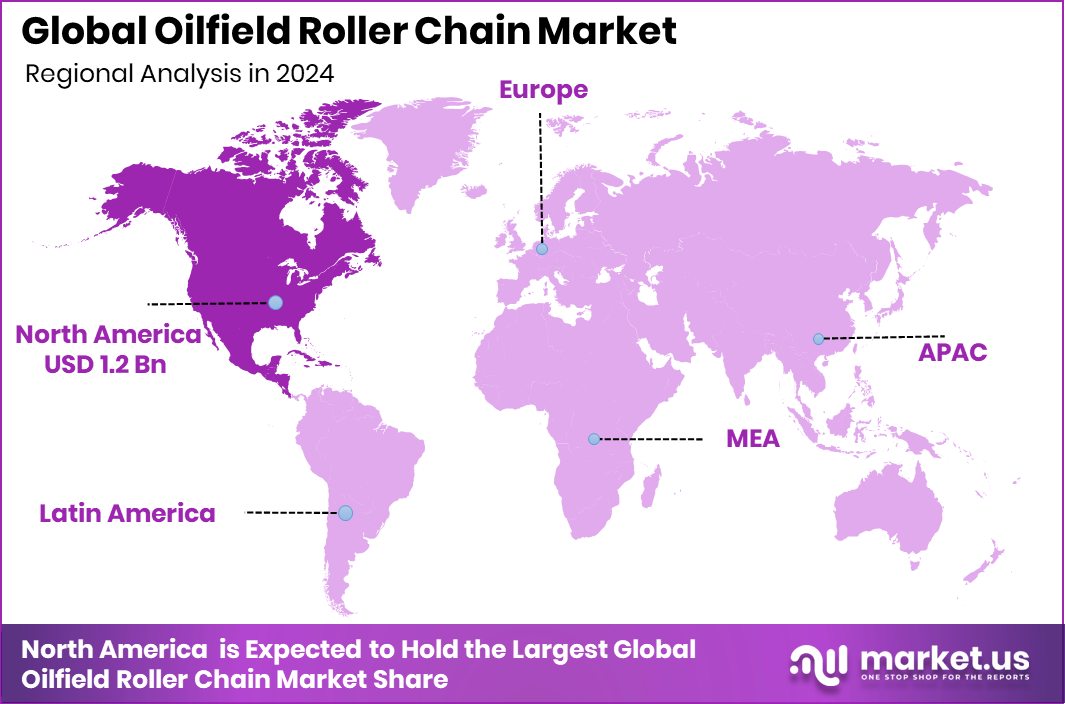

- Strong oilfield infrastructure supports North America’s 45.20% market share, reaching USD 1.2 Bn overall.

By Type Analysis

Drive chain dominated the Oilfield Roller Chain Market with a 59.4% share due to heavy power transmission usage.

In 2024, Drive Chain held a dominant market position in the By Type segment of the Oilfield Roller Chain Market, with a 59.4% share. This leadership is strongly linked to its widespread use in critical oilfield operations where consistent power transmission and mechanical reliability are essential.

Drive chains are commonly installed in drilling rigs, pumping units, and material-handling systems, where equipment runs continuously under high torque and harsh field conditions. Their ability to handle heavy shock loads, maintain alignment, and deliver stable performance makes them a preferred choice for long-term operations.

Moreover, oilfield operators favor drive chains due to their proven durability, ease of installation, and compatibility with existing mechanical systems. As oilfield assets continue to age, the preference for reliable and easy-to-replace drive chain systems has reinforced their dominant 59.4% market position within this segment.

By Material Analysis

Carbon steel dominated the Oilfield Roller Chain Market with a 52.3% share for durability.

In 2024, Carbon Steel held a dominant market position in the By Material segment of the Oilfield Roller Chain Market, with a 52.3% share. This dominance is mainly driven by the material’s strength, toughness, and ability to perform reliably in demanding oilfield environments.

Carbon steel roller chains are widely used in applications that require high load-bearing capacity and long service life under continuous operation. Their resistance to wear, impact, and mechanical stress makes them suitable for drilling and production equipment that operates in challenging field conditions.

Additionally, carbon steel allows consistent manufacturing quality and predictable performance, which supports maintenance planning and operational stability. These advantages have made carbon steel the preferred material choice, securing its leading 52.3% share within the market segment.

By Application Analysis

Hoisting operations dominated the Oilfield Roller Chain Market with a 43.8% share in drilling equipment.

In 2024, Hoisting Operation held a dominant market position in the By Application segment of the Oilfield Roller Chain Market, with a 43.8% share. This strong position is mainly supported by the critical role hoisting operations play in oilfield activities, particularly during drilling, well servicing, and equipment handling.

Roller chains used in hoisting systems must withstand heavy loads, sudden stress, and continuous lifting cycles, making reliability a key requirement. Hoisting operations depend on durable chain systems to ensure smooth vertical movement and safe material handling in harsh working conditions.

Their consistent use across core oilfield processes and the need for dependable performance under load have reinforced the leading 43.8% share of hoisting operations within the application segment.

By Location Analysis

Onshore locations dominated the Oilfield Roller Chain Market with 78.5% share from widespread oilfield activity.

In 2024, Onshore held a dominant market position in the By Location segment of the Oilfield Roller Chain Market, with a 78.5% share. This dominance is closely linked to the high concentration of drilling, production, and maintenance activities taking place in onshore oilfields.

Onshore operations typically involve extensive use of mechanical systems such as pumping units, drilling rigs, and material-handling equipment, all of which rely on roller chains for reliable power transmission. The continuous operation of these systems creates a steady demand for durable and easy-to-maintain chain solutions.

In addition, onshore sites allow more frequent equipment servicing and replacement, supporting higher usage rates. These factors together have secured the leading 78.5% share for onshore locations within the market segment.

Key Market Segments

By Type

- Drive Chain

- Conveyer Chain

- Others

By Material

- Carbon Steel

- Stainless Steel

- Alloy Steel

By Application

- Hoisting Operation

- Conveyer Chain

- Others

By Location

- Onshore

- Offshore

Driving Factors

Rising Equipment Modernization and Strong Alloy Investment

One of the key driving factors of the Oilfield Roller Chain Market is the ongoing modernization of oilfield equipment to improve reliability, safety, and operating efficiency. Oilfield operators are upgrading drilling rigs, pumping systems, and material-handling equipment to reduce breakdowns and maintenance costs. This shift increases the need for durable roller chains that can work under heavy loads, constant motion, and harsh field conditions.

At the same time, stronger and longer-lasting materials are gaining attention, helping chains deliver better performance and longer service life. Financial support for advanced metals is also accelerating product improvements.

A clear example is Alloyed, raising £37 million in new funding for metal alloy development, which supports innovation in high-strength and wear-resistant materials. Such investments encourage the use of improved alloys in roller chains, directly supporting market growth.

Restraining Factors

High Maintenance Costs and Harsh Operating Conditions

A major restraining factor for the Oilfield Roller Chain Market is the high maintenance burden caused by tough operating environments. Oilfield roller chains are exposed to dust, mud, corrosive fluids, heavy loads, and constant motion, which accelerates wear and tear.

Frequent lubrication, inspection, and replacement are often required to avoid unexpected failures. These maintenance needs increase operating costs and create downtime, especially in remote oilfield locations where repairs are time-consuming. Some operators delay replacements or look for alternative systems to manage expenses, which can slow market growth.

Despite efforts to improve material quality, cost pressures remain strong. The UK steel industry receiving £7 million funding for alloy development highlights ongoing work to improve durability, but improvements take time to reach large-scale adoption, keeping maintenance concerns a key restraint.

Growth Opportunity

Advanced Alloy Chains Creating Long-Term Market Demand

A major growth opportunity in the Oilfield Roller Chain Market comes from the development of advanced metal alloys that improve strength, wear resistance, and service life. Oilfield operators are actively looking for chain systems that last longer and reduce shutdowns caused by mechanical failure.

Improved alloys allow roller chains to handle higher loads, resist corrosion, and perform better in extreme temperatures. This creates room for next-generation products that deliver higher value over time. Funding support is accelerating this shift, as shown by Alloyed raising £37 million in funding for metal alloy development.

Such investment helps speed up research, testing, and production of stronger materials suited for heavy industrial use. As these advanced alloys move into commercial use, oilfield roller chains built on them are likely to see wider adoption across operations.

Latest Trends

Growing Use of High-Quality Stainless Steel Chains

One of the latest trends in the Oilfield Roller Chain Market is the growing use of high-quality stainless steel materials to improve strength and corrosion resistance. Oilfield operators are focusing on chains that can perform reliably in wet, corrosive, and high-stress environments for longer periods.

Stainless steel chains reduce rust-related failures and help lower replacement frequency, especially in demanding field locations. This trend is supported by increased investment in stainless steel capacity.

A notable example is AmBank granting RM1.06 billion to Worldwide Stainless for the acquisition of Bahru Stainless, restoring Malaysian ownership of the country’s sole stainless steel manufacturer. Such funding strengthens stainless steel supply and quality, supporting wider adoption of durable roller chains across oilfield operations

Regional Analysis

North America dominates the Oilfield Roller Chain Market with a 45.20% share, valued at USD 1.2 Bn.

North America remains the dominating region in the Oilfield Roller Chain Market, accounting for 45.20% of the global share and valued at USD 1.2 Bn. This leadership is supported by a well-established oilfield infrastructure, a high concentration of onshore drilling activities, and continuous replacement demand for mechanical components. The region’s focus on operational efficiency and equipment reliability sustains steady consumption of roller chains across drilling, pumping, and material-handling applications.

Europe represents a stable regional market, driven by the ongoing maintenance of mature oilfields and strict operational safety practices. The region emphasizes consistent equipment performance and preventive maintenance, which supports regular demand for durable roller chain systems used in established oil and gas operations.

Asia Pacific shows growing market activity due to expanding energy demand and gradual investments in onshore exploration. The region benefits from increased mechanical usage in production sites, where roller chains play a key role in power transmission and hoisting applications across developing oilfield assets.

The Middle East & Africa market is supported by large-scale oilfield operations that rely heavily on mechanical systems operating under extreme conditions. Roller chains are widely used to handle heavy loads and continuous operations, sustaining long-term replacement demand across the region.

Latin America contributes through steady oilfield activities focused on sustaining output from existing fields. Maintenance-driven demand and ongoing operational requirements continue to support roller chain usage across key production areas.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

Flowtools Middle East LLC plays a focused role in supporting oilfield operations through dependable mechanical solutions designed for demanding environments. In 2024, the company stands out for aligning its offerings with harsh operating conditions common in oilfield locations, particularly where durability and resistance to wear are critical. Its approach centers on practical performance, maintenance reliability, and operational continuity, which are key priorities for oilfield clients seeking stable mechanical transmission solutions.

Emerson Bearing Company maintains a strong analytical and application-driven position in the oilfield roller chain space. In 2024, the company’s strength lies in its deep technical understanding of bearing and chain performance under heavy loads. It supports oilfield users by emphasizing correct product selection, improved operational life, and reduced downtime. This advisory-focused model helps operators improve system efficiency while managing long-term equipment reliability.

Zhejiang Gidi Industrial Chain Co., Ltd. remains notable in 2024 for its manufacturing-driven presence in industrial and oilfield chain solutions. The company demonstrates capability in producing roller chains suited for continuous operation and high mechanical stress. Its focus on consistent quality, scalable production, and adaptation to industrial standards positions it as a dependable supplier for oilfield applications requiring stable power transmission and long service life.

Top Key Players in the Market

- Flowtools Middle East LLC

- Emerson Bearing Company

- Zhejiang Gidi Industrial Chain Co., Ltd.

- Daido Kogyo Co. Ltd.

- Tsubakimoto Chain Co

- Renold Plc

- Diamond Chain Company

- Rombo

- Rexnord Corporation

- Wippermann jr. GmbH

Recent Developments

- In December 2024, Tsubakimoto announced a strategic acquisition of a manufacturing company in Germany — described as “Europe’s First Industrial Steel Chain Manufacturing Base.”

- In September 2024, Renold acquired Mac Chain Company Ltd. (operating in the US/Canada), expanding its geographic footprint in North America and broadening its chain business reach.

Report Scope

Report Features Description Market Value (2024) USD 2.7 Billion Forecast Revenue (2034) USD 5.9 Billion CAGR (2025-2034) 8.1% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Drive Chain, Conveyer Chain, Others), By Material (Carbon Steel, Stainless Steel, Alloy Steel), By Application (Hoisting Operation, Conveyer Chain, Others), By Location (Onshore, Offshore) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – GCC, South Africa, Rest of MEA Competitive Landscape Flowtools Middle East LLC, Emerson Bearing Company, Zhejiang Gidi Industrial Chain Co., Ltd., Daido Kogyo Co. Ltd., Tsubakimoto Chain Co, Renold Plc, Diamond Chain Company, Rombo, Rexnord Corporation, Wippermann jr. GmbH Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Oilfield Roller Chain MarketPublished date: November 2025add_shopping_cartBuy Now get_appDownload Sample

Oilfield Roller Chain MarketPublished date: November 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Flowtools Middle East LLC

- Emerson Bearing Company

- Zhejiang Gidi Industrial Chain Co., Ltd.

- Daido Kogyo Co. Ltd.

- Tsubakimoto Chain Co

- Renold Plc

- Diamond Chain Company

- Rombo

- Rexnord Corporation

- Wippermann jr. GmbH