Global Twist Tie Machines Market Size, Share, Growth Analysis By Machine Type (Automatic, Manual), By Operating Speed (Less than 100 bags/min, 101 to 150 bags/min, 150 bags & above), By Compatibility (Plastic Twist Ties, Metal Twist Ties, Paper Twist Ties), By Application (Food & Beverage, Wire Harnessing, Chemical, Glass & Ceramics, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Aug 2025

- Report ID: 155889

- Number of Pages: 382

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

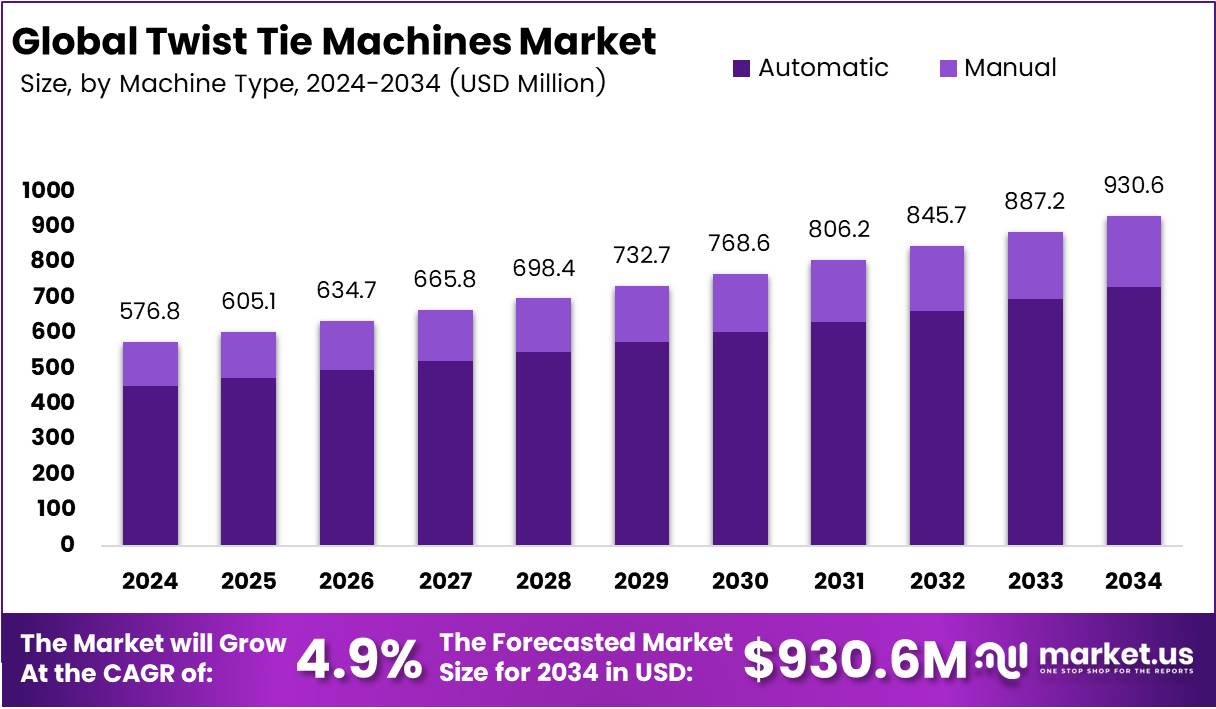

The Global Twist Tie Machines Market size is expected to be worth around USD 930.6 Million by 2034, from USD 576.8 Million in 2024, growing at a CAGR of 4.9% during the forecast period from 2025 to 2034.

The Twist Tie Machines Market is witnessing significant growth as industries continue to rely on automation for packaging processes. Twist tie machines play a vital role in various sectors, including food, pharmaceuticals, and agriculture, offering efficient and cost-effective solutions for sealing bags and bundles. These machines provide a streamlined process, reducing manual labor and improving overall productivity.

The growth of the market is attributed to the rising demand for automated packaging solutions. As the food and beverage industry expands globally, the need for fast and reliable sealing technologies increases. Additionally, the growing preference for sustainable packaging materials has led to a surge in the demand for twist tie machines, which offer an eco-friendly option compared to alternatives like plastic seals.

Furthermore, government investments in the manufacturing and automation sectors are expected to drive market growth. In many regions, governments are providing incentives for businesses to adopt advanced technologies, including twist tie machines, to enhance production efficiency and reduce operational costs. These investments aim to support innovation and increase competitiveness in the global market.

Opportunities in the Twist Tie Machines Market also arise from the continuous advancements in machine technology. With the development of more efficient, user-friendly models, companies are now able to implement twist tie machines in diverse applications. Additionally, there is an increasing trend toward customization, allowing businesses to meet specific sealing requirements in different industries. This is contributing to the market’s expansion as new applications are being discovered regularly.

As the market evolves, regulations related to packaging and automation are becoming increasingly important. Stringent regulations surrounding food safety and quality control are pushing industries to adopt automated sealing technologies. Twist tie machines, with their ability to provide consistent, tamper-evident seals, are becoming the preferred choice for packaging in regulated markets.

Key Takeaways

- The Global Twist Tie Machines Market is projected to reach USD 930.6 Million by 2034, growing at a CAGR of 4.9% from 2025 to 2034.

- Automatic Twist Tie Machines dominated the market in 2024 with a share of 78.4% due to their high speed and operational efficiency.

- Twist Tie Machines operating at 101 to 150 bags/min held a market share of 48.5% in 2024, offering a balance of efficiency and productivity.

- Plastic Twist Ties led the market in 2024 with a share of 56.8% due to their strength, versatility, and cost-effectiveness.

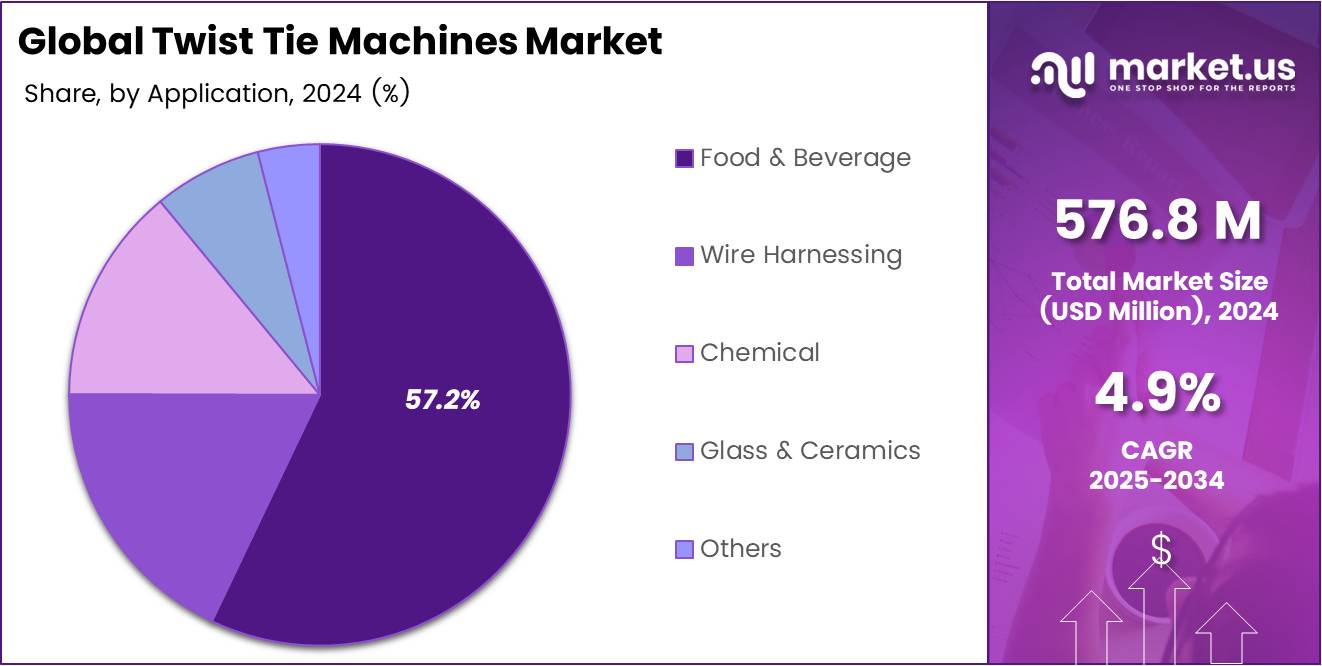

- The Food & Beverage industry accounted for 57.2% of the market share in 2024, driven by packaging requirements for perishable items.

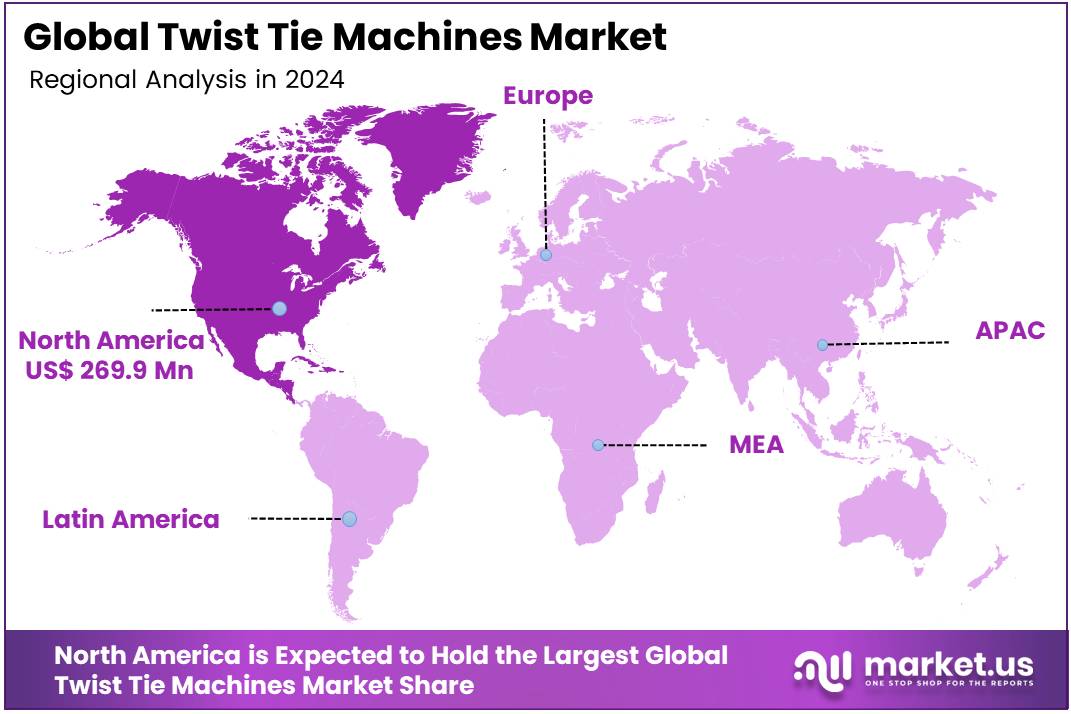

- North America held a dominant market share of 46.8% in 2024, valued at USD 269.9 Million, fueled by demand in packaging and food industries.

Machine Type Analysis

Automatic Twist Tie Machines dominate with 78.4% market share, driven by their efficiency and high automation levels.

In 2024, Automatic Twist Tie Machines held a dominant market position in the Twist Tie Machines Market, with a share of 78.4%. This segment is favored for its high speed and operational efficiency, making it ideal for industries with large-scale packaging requirements. Automatic machines require minimal human intervention, ensuring consistent production output and reducing labor costs.

On the other hand, Manual Twist Tie Machines hold a smaller share of the market. These machines are often used in smaller-scale operations where cost-effectiveness is a priority, but they are less efficient than automatic models.

The market’s preference for automation is expected to continue due to the growing demand for higher productivity in manufacturing settings. Automatic machines, offering greater precision and fewer operational errors, are likely to maintain their market leadership in the coming years.

Operating Speed Analysis

101 to 150 bags/min dominates with a 48.5% share due to its balanced efficiency and productivity in industrial applications.

In 2024, Twist Tie Machines operating at 101 to 150 bags/min held a dominant market position, with a share of 48.5%. This operating speed range provides an optimal balance of efficiency and productivity, making it highly preferred by industries seeking consistent output with moderate speed. Machines within this category are typically versatile and capable of meeting the needs of various packaging sectors.

Machines that operate at speeds of less than 100 bags/min cater to smaller-scale operations or specialized applications, holding a relatively smaller market share. These machines are typically more affordable but are less capable of meeting high-volume demand.

Meanwhile, machines that operate at speeds of 150 bags & above cater to large-scale production environments. Although they offer the highest productivity, their cost and specialized applications restrict their widespread adoption.

As the demand for packaging solutions in high-volume industries continues to grow, machines operating between 101 to 150 bags/min will remain a key player in the market.

Compatibility Analysis

Plastic Twist Ties lead the market with a dominant 56.8% share, offering durability and cost-effectiveness for packaging applications.

In 2024, Plastic Twist Ties held a dominant market position in the Twist Tie Machines Market, with a share of 56.8%. This material’s popularity stems from its strength, versatility, and cost-effectiveness. Plastic twist ties provide reliable closure for a wide range of packaging applications, making them the most widely used option in the market.

Metal Twist Ties, while durable, account for a smaller portion of the market. These ties offer superior strength but come at a higher cost, limiting their adoption to specific industrial uses that demand stronger closure.

Paper Twist Ties hold a niche market share. While they are environmentally friendly and preferred for eco-conscious packaging solutions, their adoption is comparatively limited due to lower durability and strength compared to plastic and metal options.

The ongoing shift towards sustainability may influence future market dynamics, but plastic twist ties are expected to maintain their dominant market share.

Application Analysis

Food & Beverage sector leads with 57.2% share, driven by its extensive use of twist tie machines for packaging.

In 2024, the Food & Beverage industry held a dominant position in the Twist Tie Machines Market with a share of 57.2%. This sector’s significant market share is attributed to the extensive use of twist ties for packaging perishable items, such as bakery products, snacks, and other food goods. The demand for efficient and cost-effective packaging solutions in this sector continues to drive growth.

The Wire Harnessing industry follows, utilizing twist tie machines for bundling and securing wires, though its market share is considerably smaller. Similarly, the Chemical and Glass & Ceramics sectors use twist tie machines for packaging purposes but to a lesser extent than the food industry.

While these other industries contribute to market growth, the Food & Beverage sector remains the primary driver, expected to continue leading the market due to increasing consumer demand for packaged food products and the efficiency of twist ties in food packaging.

Key Market Segments

By Machine Type

- Automatic

- Manual

By Operating Speed

- Less than 100 bags/min

- 101 to 150 bags/min

- 150 bags & above

By Compatibility

- Plastic Twist Ties

- Metal Twist Ties

- Paper Twist Ties

By Application

- Food & Beverage

- Wire Harnessing

- Chemical

- Glass & Ceramics

- Others

Drivers

Growing Demand for Packaged Food Products Drives Market Growth

The twist tie machines market is experiencing significant growth due to several key factors that are reshaping the packaging industry. The increasing demand for packaged food products is a primary driver, as consumers seek convenient and ready-to-eat options in their busy lifestyles. This trend has pushed food manufacturers to invest in efficient packaging solutions, creating a steady demand for twist tie machines.

Manufacturing processes are becoming increasingly automated across industries, with companies looking to reduce labor costs and improve production efficiency. Twist tie machines fit perfectly into this automation trend, offering consistent and reliable packaging solutions that minimize human intervention while maximizing output speed.

The need for efficient packaging solutions has never been more critical as businesses face pressure to reduce packaging time and costs while maintaining product quality. Twist tie machines provide a cost-effective solution that ensures secure closure of bags and packages with minimal material waste.

Consumer preferences are shifting toward eco-friendly packaging alternatives as environmental awareness grows. Modern twist tie machines are adapting to this trend by working with biodegradable and recyclable materials, making them attractive to environmentally conscious manufacturers who want to meet consumer expectations while maintaining operational efficiency.

Restraints

Limited Availability of Skilled Labor Restricts Market Growth

Despite the positive growth drivers, the twist tie machines market faces several significant challenges that could limit its expansion potential. The limited availability of skilled labor represents a major constraint, as operating and maintaining these sophisticated machines requires specialized technical knowledge. Many manufacturing facilities struggle to find qualified technicians who can effectively manage twist tie machine operations, leading to production delays and increased operational costs.

Technological limitations in product customization present another significant restraint for market growth. Many existing twist tie machines lack the flexibility to accommodate diverse packaging requirements across different industries. This limitation forces manufacturers to invest in multiple specialized machines rather than versatile solutions, increasing capital expenditure and operational complexity.

Environmental concerns over plastic waste are becoming increasingly important as governments and consumers push for sustainable packaging alternatives. Traditional twist ties often contain plastic components that contribute to environmental pollution, creating regulatory pressure and consumer resistance. This concern is forcing manufacturers to redesign their products and processes, which requires substantial investment in research and development.

These restraints collectively create challenges for market participants, requiring strategic planning and investment to overcome barriers while maintaining competitive positioning in the evolving packaging industry landscape.

Growth Factors

Integration of Smart Technology in Packaging Creates New Market Opportunities

The twist tie machines market presents numerous growth opportunities that forward-thinking companies can capitalize on to expand their market presence. The integration of smart technology in packaging represents a transformative opportunity, with Internet of Things (IoT) sensors and artificial intelligence enabling real-time monitoring of machine performance, predictive maintenance, and quality control. These smart features help manufacturers optimize production efficiency while reducing downtime and operational costs.

Government initiatives promoting sustainable packaging create significant market expansion opportunities. Regulatory bodies worldwide are implementing policies that encourage the use of environmentally friendly packaging materials and processes. Companies that align their twist tie machine offerings with these sustainability requirements can access new market segments and benefit from government incentives and support programs.

Collaboration with packaging companies for innovation opens doors to developing cutting-edge solutions that meet evolving market needs. Strategic partnerships enable twist tie machine manufacturers to combine their technical expertise with packaging companies’ market knowledge, resulting in innovative products that address specific industry challenges and customer requirements.

These opportunities require proactive investment in research and development, strategic partnerships, and technology adoption. Companies that successfully leverage these growth opportunities can establish competitive advantages and capture larger market shares in the expanding packaging automation sector.

Emerging Trends

Development of Biodegradable Twist Ties Shapes Market Trends

Several trending factors are currently shaping the twist tie machines market, reflecting broader changes in manufacturing technology and consumer preferences. The development of biodegradable twist ties represents a major trend driven by environmental consciousness and regulatory requirements. Manufacturers are investing in machines capable of handling eco-friendly materials like paper-based and compostable twist ties, creating new market segments focused on sustainable packaging solutions.

The adoption of Industry 4.0 technologies in manufacturing is transforming twist tie machine operations through advanced automation, data analytics, and connected systems. These technologies enable real-time production monitoring, predictive maintenance, and seamless integration with existing manufacturing execution systems, improving overall operational efficiency and product quality.

The growth of e-commerce and online retail has created new packaging requirements that favor twist tie solutions for their simplicity and cost-effectiveness. Online retailers need efficient packaging methods that protect products during shipping while minimizing packaging costs and material usage, making twist tie machines increasingly attractive for e-commerce fulfillment operations.

Rising preference for flexible packaging solutions reflects consumer demand for convenient, portable, and resealable packaging options. Twist tie machines are adapting to accommodate various flexible packaging formats, from small snack bags to large agricultural product packages, expanding their application range and market potential across diverse industries.

Regional Analysis

North America Dominates the Twist Tie Machines Market with a Market Share of 46.8%, Valued at USD 269.9 Million

In 2024, North America held the dominant market share of 46.8% in the Twist Tie Machines Market, valued at USD 269.9 Million. The region is expected to continue its lead, driven by strong demand in packaging and food industries. With technological advancements and increased automation in production processes, North America maintains its competitive edge.

Europe Twist Tie Machines Market Trends

Europe represents a significant portion of the global Twist Tie Machines Market, with countries such as Germany and France leading the market due to their well-established manufacturing industries. The adoption of automation in packaging operations is expected to drive growth, enhancing productivity in the region.

Asia Pacific Twist Tie Machines Market Trends

Asia Pacific holds a rapidly growing market for Twist Tie Machines, primarily driven by the increasing demand from emerging economies such as China and India. The growing food and beverage sectors, alongside rising industrialization, contribute to the expansion of the market, positioning the region for substantial growth.

Middle East and Africa Twist Tie Machines Market Insights

The Middle East and Africa region is experiencing steady growth in the Twist Tie Machines Market, attributed to improving industrial infrastructure and a growing demand for packaging solutions. The region’s expanding retail and food processing industries are expected to further fuel market demand.

Latin America Twist Tie Machines Market Developments

Latin America presents a developing market for Twist Tie Machines, with steady growth projected in countries like Brazil and Mexico. The increasing use of automated systems in packaging and the rise in food production are key factors contributing to the gradual market expansion in this region.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Twist Tie Machines Company Insights

The global Twist Tie Machines market is highly competitive, with several key players contributing to its growth. Chengdu Huitong Packing Machine has established itself as a leading player in the industry, known for its innovative packaging solutions. The company’s focus on advanced technology and high-quality machinery enables it to offer efficient and reliable twist tie machines tailored to various packaging needs.

International Plastics Inc is another significant player in the market, providing a wide range of packaging solutions, including twist tie machines. The company’s strong emphasis on customer satisfaction and product customization has allowed it to build a loyal client base, particularly in the retail and industrial packaging sectors.

IPS Packaging has gained a notable market share through its comprehensive range of packaging machinery, including twist tie machines. Known for its commitment to product durability and superior performance, IPS Packaging’s solutions are designed to meet the needs of both small and large-scale packaging operations, contributing to its growing presence in the market.

Kunshan Yuanhan Electronic Equipment stands out for its focus on the integration of electronic technology in its packaging solutions. By providing automated and precision-engineered twist tie machines, the company has positioned itself as a strong competitor in the market, meeting the demand for high-efficiency, low-maintenance packaging equipment.

These key players are pivotal in shaping the competitive landscape of the global Twist Tie Machines market in 2024, with each contributing distinct advantages in terms of technology, customer satisfaction, and market penetration.

Top Key Players in the Market

- Chengdu Huitong Packing Machine

- International Plastics Inc

- IPS Packaging

- Kunshan Yuanhan Electronic Equipment

- Paxiom

- Plas-Ties, Co.

- Tach-It

Recent Developments

- In April 2024, JJG Aero secured a $12M funding boost from CX Partners to accelerate its innovative aerospace technology solutions and expand its operational capacity in the industry.

- In November 2024, IonKraft raised €3.5M in equity funding to advance its mission of promoting sustainability and driving the circular economy within the packaging industry.

- In May 2024, ATS announced an agreement to acquire Paxiom Group, a prominent packaging machine provider, marking a significant step in strengthening its position in the packaging solutions market.

Report Scope

Report Features Description Market Value (2024) USD 576.8 Million Forecast Revenue (2034) USD 930.6 Million CAGR (2025-2034) 4.9% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Machine Type (Automatic, Manual), By Operating Speed (Less than 100 bags/min, 101 to 150 bags/min, 150 bags & above), By Compatibility (Plastic Twist Ties, Metal Twist Ties, Paper Twist Ties), By Application (Food & Beverage, Wire Harnessing, Chemical, Glass & Ceramics, Others) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape Chengdu Huitong Packing Machine, International Plastics Inc, IPS Packaging, Kunshan Yuanhan Electronic Equipment, Paxiom, Plas-Ties, Co., Tach-It Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- Chengdu Huitong Packing Machine

- International Plastics Inc

- IPS Packaging

- Kunshan Yuanhan Electronic Equipment

- Paxiom

- Plas-Ties, Co.

- Tach-It