Global Torsion Tester Market Size, Share, Growth Analysis By Type (Electromechanical Torsion Testers, Electric Torsion Testers, Servo Hydraulic Torsion Testers), By Frequency Range (Below 10 Hz, 10-15 Hz, Above 15 Hz), By Material Type (Metal, Plastic, Wood, Composite), By End Use (Medical, Building & Construction, Automotive, Aerospace, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Sep 2025

- Report ID: 157059

- Number of Pages: 349

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

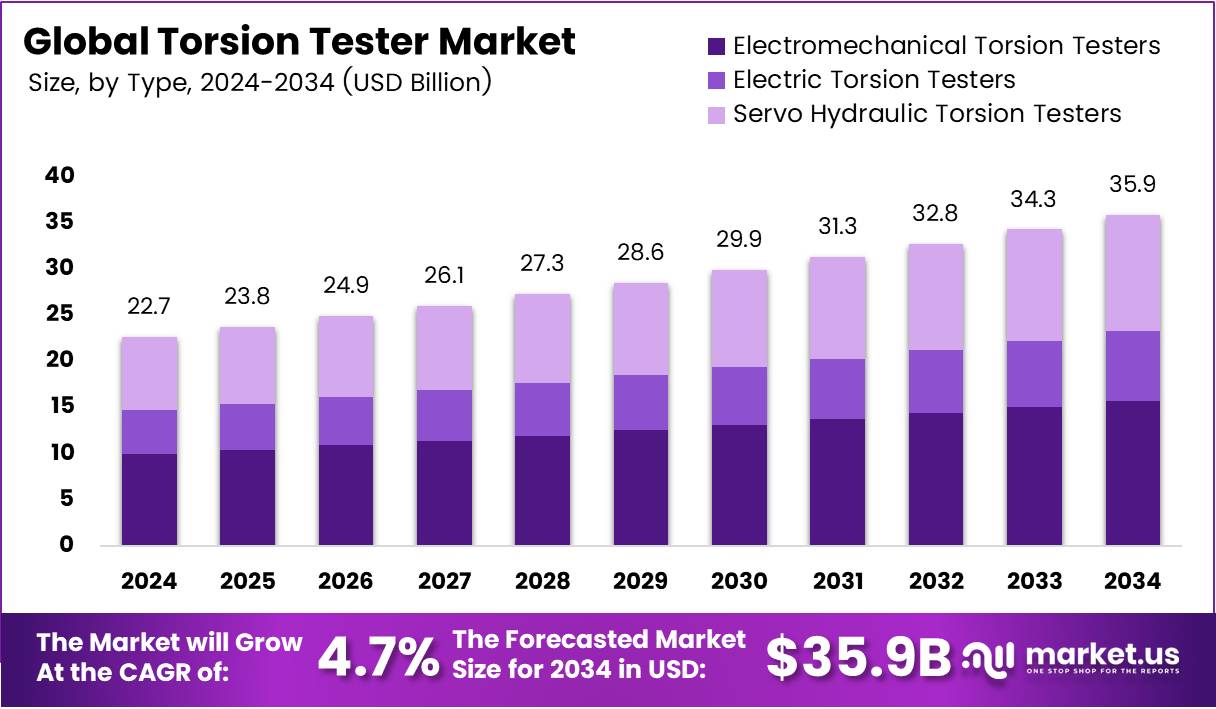

The Global Torsion Tester Market size is expected to be worth around USD 35.9 Billion by 2034, from USD 22.7 Billion in 2024, growing at a CAGR of 4.7% during the forecast period from 2025 to 2034.

The Torsion Tester Market involves equipment used to measure the torsional strength and rigidity of materials and products. It is crucial in industries such as automotive, aerospace, and manufacturing, where the testing of materials’ ability to withstand twisting forces is essential. As a result, the market is expanding with increasing industrial needs.

The growth of the Torsion Tester Market is largely driven by the continuous advancements in manufacturing processes and material sciences. With industries like automotive and aerospace requiring precise measurements of material durability, the demand for high-performance torsion testing equipment is set to rise. This sector is poised for significant growth due to technological innovation and rising material testing standards.

The increasing adoption of automated and digitalized testing systems is another key factor accelerating market growth. Automation ensures higher accuracy and reduces human error, making torsion testers essential in quality control processes. Additionally, digitalization allows for more precise data analysis, which is crucial for industries that rely on stringent quality standards.

There is a significant opportunity in emerging markets as industries in regions such as Asia Pacific and Latin America ramp up production capabilities. With growing manufacturing sectors in countries like China and India, the demand for torsion testing equipment is expected to grow rapidly. This creates new avenues for market expansion and innovation.

Government investment in infrastructure and manufacturing sectors also plays a vital role in boosting the market. Governments are increasingly funding industrial advancements, particularly in developing countries, which in turn drives the need for testing equipment like torsion testers. This support fosters innovation and enhances industry standards globally.

Furthermore, the growing importance of regulatory compliance across industries adds a layer of opportunity for the Torsion Tester Market. Regulatory bodies require strict testing of materials to ensure they meet safety and durability standards. This compliance demand ensures a steady market for torsion testing equipment in both developed and emerging markets.

Key Takeaways

- The Global Torsion Tester Market is projected to reach USD 35.9 Billion by 2034, growing at a CAGR of 4.7% from 2025 to 2034.

- Electromechanical Torsion Testers dominated the By Type Analysis segment in 2024, holding a 43.8% market share.

- The 10-15 Hz frequency range led the By Frequency Range Analysis segment in 2024, with a 49.3% share.

- Metal dominated the By Material Type Analysis segment in 2024, holding a 51.1% market share.

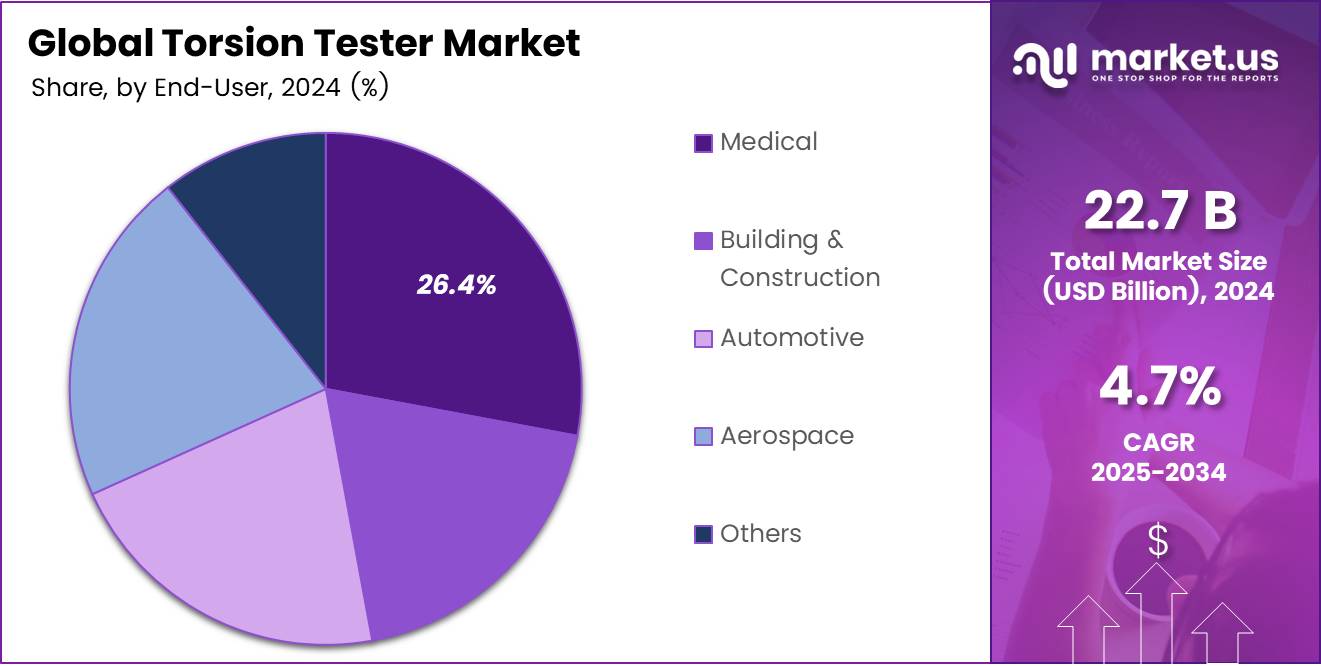

- The Medical sector led the By End Use Analysis segment in 2024, with a 26.4% market share.

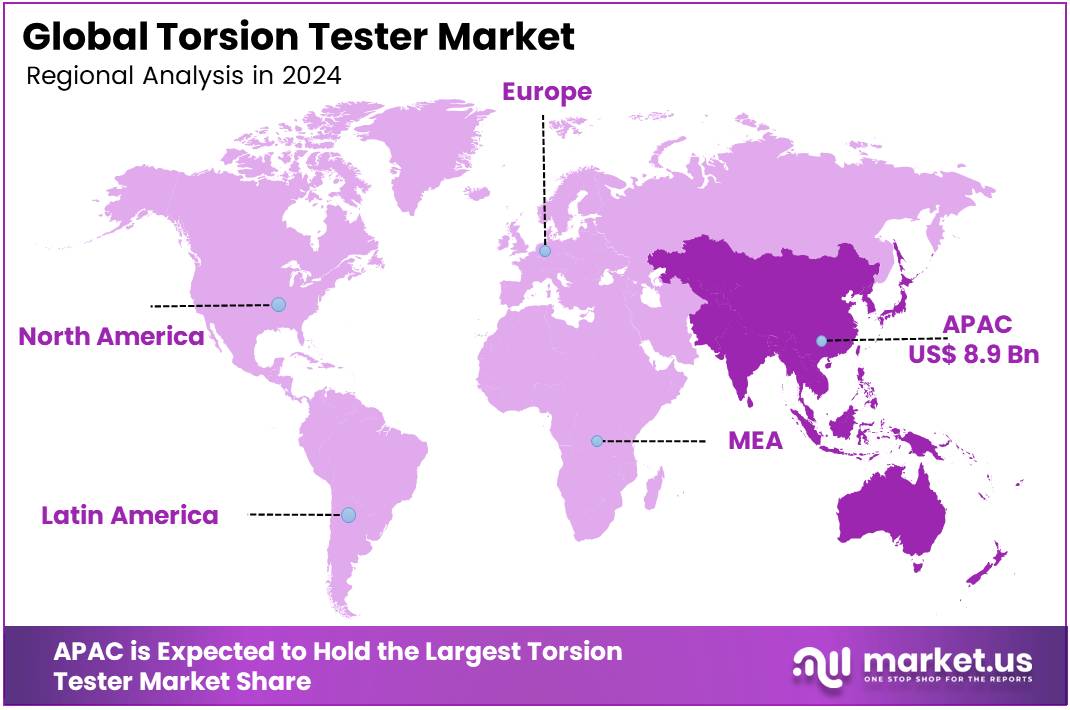

- Asia Pacific held the largest share of the torsion tester market in 2024, valued at USD 8.9 billion, with a 39.4% market share.

Type Analysis

In 2024, Electromechanical Torsion Testers held a dominant market position in the By Type Analysis segment of Torsion Tester Market, with a 43.8% share. These testers are widely preferred due to their precision and reliability in testing materials for torsional strength and stiffness. Their versatility and ability to handle a wide range of materials make them the go-to choice for most industries.

Electric Torsion Testers followed, offering a more compact and energy-efficient alternative, and accounted for a substantial share of the market. They are ideal for smaller testing setups and are expected to grow in demand due to their increasing applications in laboratories and small-scale production.

Servo Hydraulic Torsion Testers, though having a smaller share compared to the other types, are gaining traction in industries requiring high-load testing. Their use in more specialized applications continues to expand, but they remain a niche segment within the overall market.

Frequency Range Analysis

In 2024, 10-15 Hz held a dominant market position in the By Frequency Range Analysis segment of Torsion Tester Market, with a 49.3% share. This frequency range is particularly effective for standard material testing, providing optimal precision in torsion measurement for a wide variety of industries. Its broad applicability across different test settings drives its market share dominance.

The Below 10 Hz frequency range is expected to see moderate growth, particularly in industries where very slow, low-frequency testing is required for specific materials. This range is typically used in research and development settings, where detailed analysis is necessary.

Meanwhile, the Above 15 Hz range, although holding a smaller share, serves specialized applications requiring high-speed torsion testing. Its growth is linked to advances in materials science and high-performance testing applications.

Material Type Analysis

In 2024, Metal held a dominant market position in the By Material Type Analysis segment of Torsion Tester Market, with a 51.1% share. Metals are the most tested material in torsion testing due to their widespread use across industries such as automotive, aerospace, and manufacturing. Their mechanical properties, such as elasticity and strength, require extensive testing to ensure product reliability.

The Plastic segment, although smaller, is witnessing growth as more industries require torsion testing for lightweight and flexible materials, especially in the automotive and consumer goods sectors.

Wood and Composite materials represent niche segments in the torsion testing market. While wood is used less frequently for torsion testing, it remains crucial for applications in construction and furniture industries. Composites, however, are gaining traction, especially in the aerospace and automotive sectors, where high-strength, lightweight materials are increasingly in demand.

End Use Analysis

In 2024, Medical held a dominant market position in the By End Use Analysis segment of Torsion Tester Market, with a 26.4% share. The medical industry relies heavily on torsion testing for ensuring the safety and durability of medical devices, surgical instruments, and prosthetics. The growing demand for high-precision testing in this field is a key driver for the segment’s market share.

The Building & Construction industry also presents significant demand for torsion testing, driven by the need for testing the structural integrity of materials like steel and concrete.

The Automotive industry continues to leverage torsion testers for testing the strength of components such as axles and gears. The growth of electric vehicles is also pushing the demand for torsion testing in automotive applications.

Aerospace and Others segments, while smaller, remain important due to the specialized nature of torsion testing in high-performance materials used in aircraft and space vehicles.

Key Market Segments

By Type

- Electromechanical Torsion Testers

- Electric Torsion Testers

- Servo Hydraulic Torsion Testers

By Frequency Range

- Below 10 Hz

- 10-15 Hz

- Above 15 Hz

By Material Type

- Metal

- Plastic

- Wood

- Composite

By End Use

- Medical

- Building & Construction

- Automotive

- Aerospace

- Others

Drivers

Rising Demand for Precision Testing Equipment in Aerospace Component Validation Drives Market Growth

The torsion tester market is gaining momentum due to its essential role in aerospace component validation. Aerospace industries demand high-precision testing equipment to ensure the durability and reliability of critical parts. Torsion testers help manufacturers comply with strict safety standards and performance requirements, boosting adoption in this sector.

The automotive industry is increasingly adopting torsion testers as advanced materials such as composites and lightweight alloys are used in vehicle design. Automotive R&D teams rely on these testers to validate torsional strength and performance. This trend supports innovation in safer and more efficient vehicles, expanding the use of torsion testing technology.

Investments in industrial automation and quality assurance systems are further propelling market demand. As industries modernize their manufacturing processes, torsion testers are becoming integral to automated testing solutions. Companies focus on reducing product failures, improving efficiency, and meeting quality certifications, creating a steady growth path for the market.

Academic and research institutions are also expanding their use of torsion testers. Universities and laboratories employ these systems to study new materials and validate research outcomes. With the increasing focus on material science and engineering education, the academic adoption of torsion testers is strengthening market opportunities worldwide.

Restraints

Limited Awareness Among SMEs About Torsion Testing Applications Restrains Market Growth

Despite the benefits of torsion testers, limited awareness among small and medium enterprises (SMEs) acts as a restraint. Many SMEs do not fully understand the advantages of torsion testing or lack the financial capacity to adopt advanced equipment, slowing broader market penetration.

Another barrier is the lack of standardized testing protocols across industries. While large sectors like aerospace and automotive rely on strict standards, other industries do not have uniform guidelines. This inconsistency creates confusion and slows the adoption of torsion testers in smaller markets, limiting potential growth.

The market also faces challenges due to dependency on skilled technicians. Accurate interpretation of torsion tests requires experienced operators with deep technical knowledge. The shortage of skilled professionals in many regions delays adoption, as companies hesitate to invest in equipment without reliable expertise for its operation.

High training and labor costs add to these concerns. Businesses must invest in both equipment and skilled personnel, which increases overall expenses. This dependency makes torsion testers less attractive for cost-sensitive companies, creating a long-term restraint for the market’s expansion across emerging regions.

Growth Factors

Integration of IoT and AI-Based Analytics in Torsion Testing Systems Creates Opportunities

The integration of IoT and AI-based analytics in torsion testing systems is opening new opportunities. Smart testing equipment provides real-time data monitoring, predictive insights, and enhanced test accuracy. This trend is expected to appeal to industries seeking digital transformation and advanced quality assurance.

Emerging manufacturing hubs are expanding their demand for testing equipment. Countries in Asia Pacific and Latin America are investing in local manufacturing and quality systems. These regions are increasingly adopting torsion testers to ensure compliance with global standards, driving growth opportunities for equipment providers.

Torsion testers are also gaining new applications in the medical device sector. Durability testing for implants, surgical instruments, and other devices is becoming more important to meet regulatory requirements. This creates a promising niche for torsion testers in the healthcare industry, adding to market expansion.

The development of portable and compact torsion testers is another growth driver. Portable models allow field applications, making testing more convenient for industries with remote operations. This innovation is expected to attract small laboratories and on-site inspection teams, broadening the customer base for torsion tester manufacturers.

Emerging Trends

Shift Towards Fully Automated and Digital Torsion Testing Solutions is a Key Market Trend

A key trend shaping the torsion tester market is the shift towards fully automated and digital solutions. Automation reduces manual errors, improves efficiency, and ensures repeatable results. This transformation is driving industries to upgrade traditional testing systems with modern digital platforms.

Collaboration between universities and industries for material innovation is also trending. Academic research on advanced composites, lightweight alloys, and sustainable materials relies heavily on torsion testing. Such partnerships accelerate technology transfer, fostering innovation in torsion tester applications across different industries.

The adoption of hybrid torsion testers is rising, supporting multiple test configurations in one system. These versatile machines save costs and time by allowing different testing modes on a single platform. This trend reflects growing customer preference for flexible and adaptable testing solutions.

Sustainability is emerging as a major driver of new testing requirements. Industries are adopting recyclable and eco-friendly materials, which must undergo rigorous durability validation. Torsion testers are being adapted to meet these sustainability standards, reinforcing their importance in modern material testing.

Regional Analysis

Asia Pacific Dominates the Torsion Tester Market with a Market Share of 39.4%, Valued at USD 8.9 Billion

In 2024, Asia Pacific held the largest share of the torsion tester market at 39.4%, reaching a value of USD 8.9 billion. This dominance is attributed to rapid industrialization, rising automotive production, and strong investments in aerospace and defense testing facilities. Growing R&D expenditure in China, India, and Japan further supports the demand for precision testing instruments.

North America Torsion Tester Market Outlook

North America remains a significant market due to its advanced testing infrastructure and strong presence of aerospace and automotive industries. The US contributes the majority of demand with robust investments in automation and quality assurance systems. Rising focus on material innovation continues to fuel the adoption of torsion testers.

Europe Torsion Tester Market Trends

Europe is projected to show steady growth, driven by strong manufacturing bases in Germany, France, and the UK. The region benefits from strict quality regulations and a growing emphasis on sustainability, which is prompting industries to adopt reliable testing equipment. Expansion in automotive electrification also supports regional market advancement.

Middle East and Africa Torsion Tester Market Insights

The Middle East and Africa market is expanding moderately, supported by investments in oil & gas, construction, and material testing sectors. Governments are increasingly encouraging industrial diversification, which creates opportunities for testing equipment adoption. However, limited awareness and infrastructure challenges restrict faster penetration.

Latin America Torsion Tester Market Overview

Latin America is witnessing gradual growth, with Brazil and Mexico leading in automotive and aerospace component testing. The market is benefiting from increasing foreign investments and the rise of local manufacturing hubs. Economic fluctuations remain a challenge but growing R&D activities support long-term demand.

United States Torsion Tester Market Highlights

The US accounts for a substantial portion of the North American market due to its advanced aerospace and automotive R&D ecosystem. Strong government support for innovation, combined with rapid adoption of automated testing systems, ensures continued market strength. The country also plays a key role in setting global testing standards.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Torsion Tester Company Insights

In 2024, the global torsion tester market reflected steady contributions from established players, each focusing on product innovation, customer-centric solutions, and expanding their global reach. These companies are strengthening their presence through advanced testing technologies and industry-focused offerings, contributing significantly to overall market competitiveness.

Shimadzu Corporation continues to maintain a strong presence in the torsion tester market by integrating advanced precision technologies into its equipment. The company’s focus on automation and accuracy in mechanical testing is enhancing its adoption across industries such as aerospace and automotive.

Test Resources has positioned itself as a key supplier of versatile torsion testing solutions, catering to both research institutions and industrial laboratories. Their emphasis on customizable test systems allows them to serve niche applications, thereby boosting their relevance in academic and commercial sectors.

FORM+TEST GmbH is strengthening its foothold with European engineering expertise, focusing on robust designs and user-friendly controls. The company is gaining traction by supplying reliable torsion testers for quality assurance processes in materials research and manufacturing environments, where durability and precision remain critical.

Gotech Testing Machines Inc. is expanding its market influence by offering a wide portfolio of testing instruments that include torsion testers. Its competitive pricing and global distribution networks are helping the company penetrate emerging markets, making it a preferred option for cost-sensitive industries seeking dependable testing solutions.

Together, these companies underscore the competitive landscape by driving technological advancement, enhancing affordability, and meeting the rising demand for precision testing across diverse industrial applications.

Top Key Players in the Market

- Shimadzu Corporation

- Test Resources

- FORM+TEST GmbH

- Gotech Testing Machines Inc.

- Qualitest

- International Inc.

- Illinois Tool Works Inc.

- Tinius Olsen TMC

- Nordson Corporation

Recent Developments

- In Apr 2025, IPCO AB, a wholly owned subsidiary of FAM AB, acquired New Era Converting Machinery Inc., strengthening its portfolio in web converting equipment manufacturing. This acquisition is aimed at expanding IPCO’s market reach and product capabilities.

- In Jan 2025, Butech Bliss announced the acquisition of LM Equipment & Design and Lehmann Mills, enhancing its product portfolio in metal processing and milling solutions. The move is expected to expand its technical expertise and customer base.

- In May 2025, Sun Acquisitions facilitated the sale of Miami Machine, Inc., based in Ohio, to Moore Manufacturing, LLC. This transaction supports Moore Manufacturing’s growth strategy while ensuring Miami Machine’s legacy continues under new ownership.

- In Sep 2024, Metso broadened its offerings through the acquisition of Diamond Z and Screen Machine Industries. This acquisition strengthens Metso’s position in the mobile crushing, screening, and recycling equipment market.

- In Nov 2024, Stellar Industries expanded its product line with the acquisition of Elliot Machine Works. This move enhances Stellar’s capabilities in mobile service truck solutions and strengthens its market presence.

Report Scope

Report Features Description Market Value (2024) USD 22.7 Billion Forecast Revenue (2034) USD 35.9 Billion CAGR (2025-2034) 4.7% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Electromechanical Torsion Testers, Electric Torsion Testers, Servo Hydraulic Torsion Testers), By Frequency Range (Below 10 Hz, 10-15 Hz, Above 15 Hz), By Material Type (Metal, Plastic, Wood, Composite), By End Use (Medical, Building & Construction, Automotive, Aerospace, Others) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape Shimadzu Corporation, Test Resources, FORM+TEST GmbH, Gotech Testing Machines Inc., Qualitest, International Inc., Illinois Tool Works Inc., Tinius Olsen TMC, Nordson Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- Shimadzu Corporation

- Test Resources

- FORM+TEST GmbH

- Gotech Testing Machines Inc.

- Qualitest

- International Inc.

- Illinois Tool Works Inc.

- Tinius Olsen TMC

- Nordson Corporation