Global Precast Concrete Market By Product Type (Foundations, Structural Beams, Slabs, Walls, and Other Product Types), By Applications(Structural Building Components, Architectural Building Components, Transportation Products, Waste & Water Handling Products), By End-User(Residential, Non-Residential), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2023-2032

- Published date: Oct 2023

- Report ID: 13411

- Number of Pages: 218

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

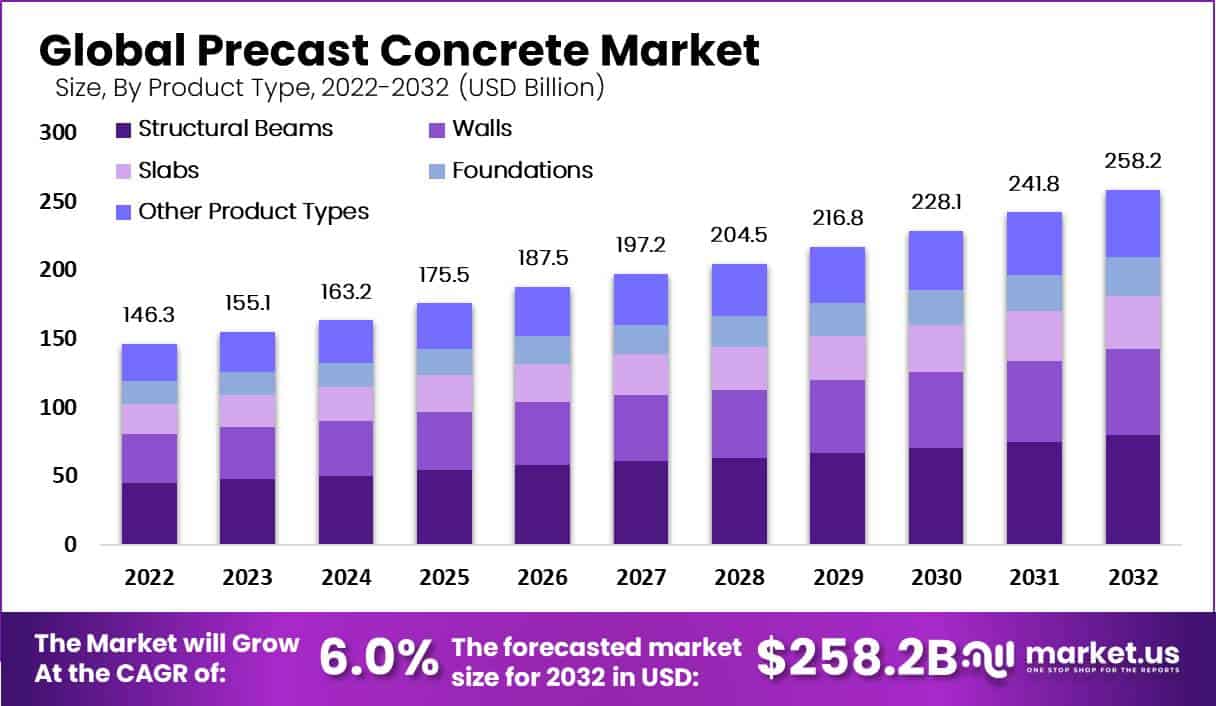

In 2022, the Global Precast Concrete market size was valued at USD 146.3 Billion and is supposed to reach a valuation of USD 258.2 Billion by 2032. Between 2023 and 2032, this market is estimated to register the highest CAGR of 6.0%.

Precast concrete is made by casting concrete in a reusable mold. The concrete is then cured on-site and transported to the site. This makes it more efficient than traditional onsite casting. The molds can be reused several times before being replaced. Cast concrete products can be cured in a controlled environment that is monitored closely.

Casting concrete products at ground level offers many advantages, such as better control over the material quality, safer workmanship, and greater safety. This concrete type is becoming more popular due to increasing urbanization and construction activities.

This market has grown due to the shift in the construction industry towards modern, sustainable, cost-effective, and eco-friendly construction methods. The market will continue to grow due to the increasing number of construction projects in developing nations that are aimed at modernizing their infrastructure.

Key Takeaways

Market Growth: The Precast Concrete market was valued at USD 146.3 billion in 2022 and is projected to reach USD 258.2 billion by 2032, with a Compound Annual Growth Rate (CAGR) of 6.0% between 2023 and 2032. This signifies substantial growth in the market.

Precast Concrete Defined: Precast concrete involves casting concrete in reusable molds, curing it off-site, and then transporting it to the construction site. This method is more efficient than traditional on-site casting and allows for controlled environment curing.

Driving Growth: Quality Precast concrete offers higher quality due to better industrial management. Speed It has a faster construction time compared to traditional concrete.

Restraining Factors: High Cost: The initial investment, equipment, molds, and skilled labor make precast concrete expensive.

Trending Factors: Precast concrete reduces construction time and labor costs, making it more affordable. Specialty concrete and technology innovations are contributing to market growth. Precast technology is faster and produces high-quality structures.

Product Type Analysis: The structural Beams segment dominates the market due to its extensive use in infrastructure for commercial and residential purposes.

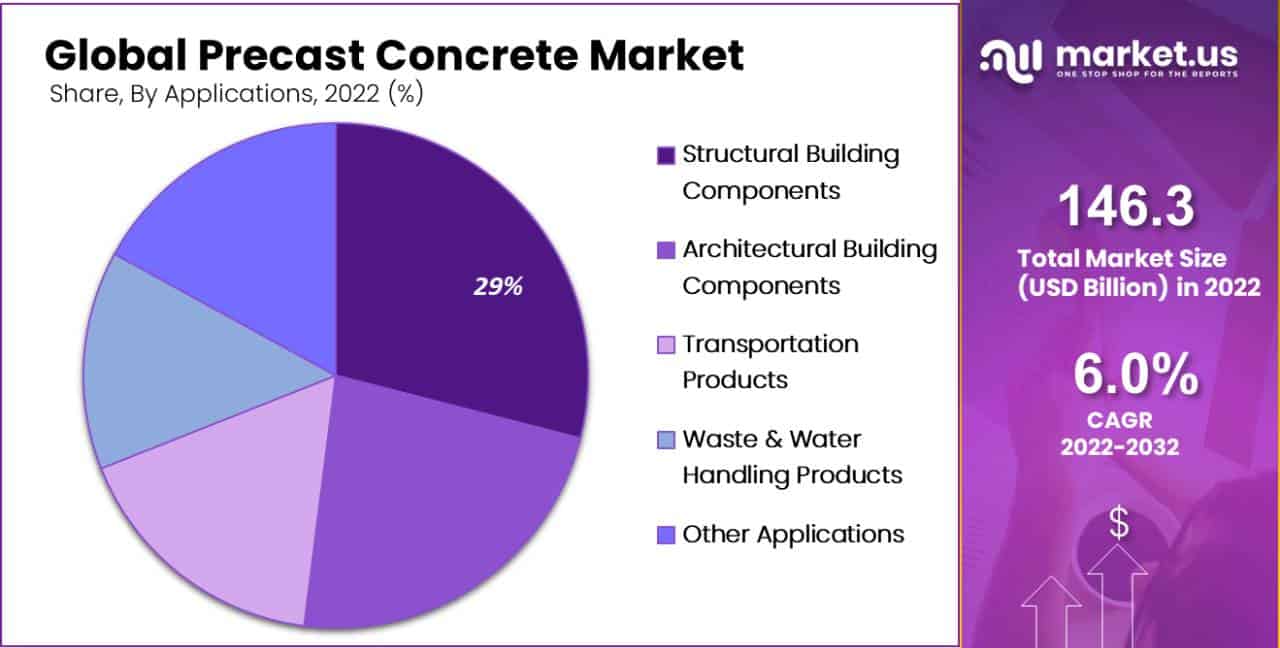

Applications Analysis: Structural Building Components: High demand for precast products used in the construction of commercial and residential structures. Architectural Building Components: Precast concrete walls see increased demand due to flexibility and profitability.

End-User Analysis: Non-Residential: This segment dominates the market, driven by investments in commercial spaces, infrastructure, and public facilities. Residential: Growth is attributed to the increasing global population and investments in real estate development.

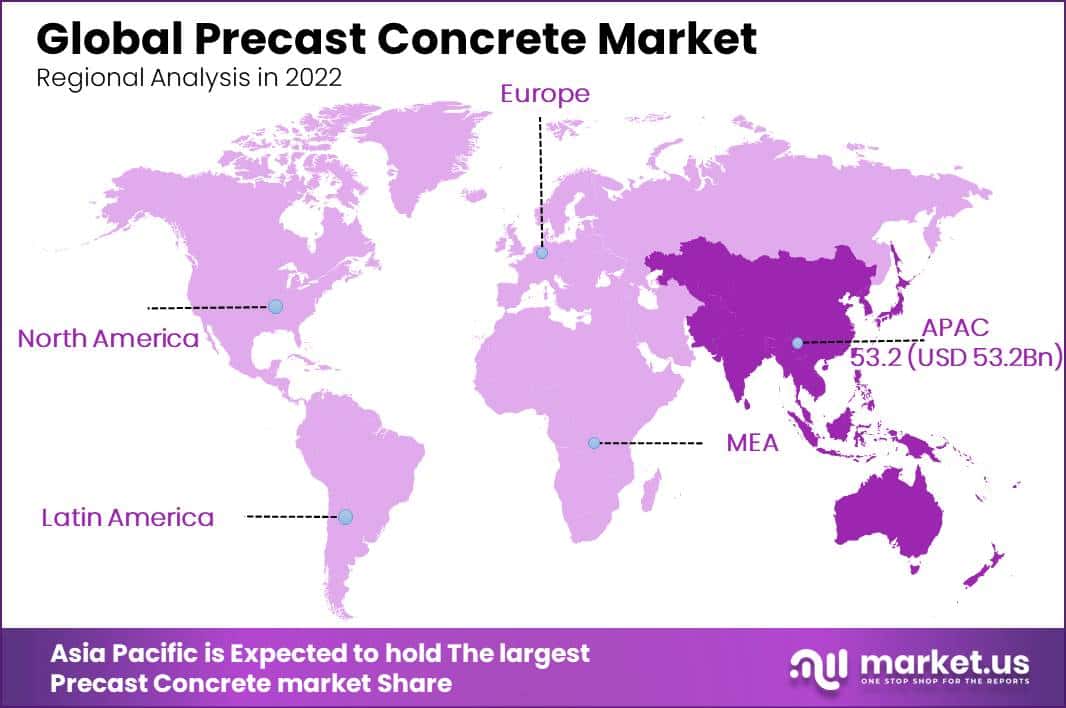

Regional Dominance: Asia Pacific: The Asia Pacific region leads the global precast concrete market, covering 36.4% of the market.

Key Players: Major market players include Boral, LafargeHolcim, CEMEX, and more.

Driving Factors

Advantages of Precast Concrete are Driving the Market.

Precast concrete offers many advantages over cast concrete on site. Precast concrete has a greater quality than traditional methods. Precast concrete has a higher quality because of its excellent industrial management. Precast concrete has a faster construction time than traditional concrete. Precast concrete can reduce the overall construction time by about one-third.

A typical home system can be installed in less time than one day. Precast concrete makes it easy to install wall panels and other components. This saves time and effort.

Precast concrete constructions are durable and are expected to increase demand. Precast concrete products are in high demand. This trend is expected to continue over the forecast period.

Prefabrication, also known as offsite construction, involves the creation of civil and structural components in a manufacturing plant and then the transport of the entire assembly to the construction site. Precast structures are made from precast concrete and are hardened before being used in construction.

Precast concrete is a key component of offsite construction. Because it is faster and less wasteful, offsite construction is becoming more popular in the construction industry. It can be done regardless of weather conditions.

Precast concrete is used to build bridges and flyovers. Prefabricated deck slabs and pillars are transported to the job site by cranes using trained labor. Over the forecast period, offsite construction will be a major driver for development in the precast concrete sector.

The regulatory landscape is constantly changing. Therefore, it is expected that more environmentally sustainable and compliance-oriented building processes will increase prospects and revenue in established markets like North America and Western Europe.

In the post-COVID era, it is likely that offsite housing construction will increase. England is currently experiencing housing shortages as a result.

Construction activity has been halted by the introduction of COVID-19 and lockdown. Preventative measures and strong tracking will help to contain the pandemic. Precast concrete is safe and can be inspected in-house for quality control, which lowers the defect rate.

The improved manufacturing and recycling capabilities of precast concrete also reduce construction waste and pollutant emissions. Precast Concrete Market growth is expected to be driven by the previously mentioned advantages of precast concrete.

Restraining Factors

High Cost and Lack of Skill are Restraining the Precast Concrete Market Growth.

Precast concrete is more cost-effective than traditional concrete. However, it is not widely used in developing countries due to the high investment.

Precast concrete is expensive because of the high cost of the gear and molds needed for its fabrication. Complex technology and highly skilled workers are required to manufacture precast concrete items.

The large initial investment will likely limit growth over the long term. Even though the cost of precast concrete production is declining, there are still significant costs that could limit the Precast Concrete Market.

Precast concrete must be transported to the site because it is made in factories. Due to the heavy precast components and the manpower required to transport the product, the cost of transportation is high.

The precast building has some downsides. The cost of precast construction will rise due to the need for skilled labor and supervision, which is more expensive than traditional methods. Producers are also more likely to have to pay higher land costs.

Storage sites that can store precast concrete components must be large enough for them to be properly stored. They should also be big enough to allow for transport trucks and equipment to move around.

Precast pieces can be damaged if they are not properly stored and stacked. The storage and stacking of units should be covered to prevent accidental damage or discoloration.

Product Type Analysis

Precast Concrete Structural Beams Dominate the Market.

In terms of market revenue, the structural beams segment accounted for the largest share. Structural beams are used extensively in infrastructures for commercial and residential purposes.

Due to rapid global urbanization and increasing residential and commercial development, the market for columns and beams is expected to expand.

Structural beams are essential for supporting the building’s weight and providing a safe load route between the slab and the foundations. Both residential and commercial use precast columns and beams.

Precast columns can also lower the cost of building materials and allow for greater crane capacities to lift large precast concrete modules.

Precast concrete’s benefits, along with the increasing public and private investment into infrastructure projects, especially in developing countries in South America, Asia-Pacific, and the Middle East, will likely drive demand for precast beams during the projected period.

Precast concrete walls allow for greater flexibility in design and increase profitability. This will drive the demand for precast building components during the forecast period.

There will be an increase in the number of apartments, shops, schools, hospitals, schools, and shopping centers as cities expand. Due to its high durability and low maintenance costs, the Precast Concrete wall will see significant growth during the forecast period.

Applications Analysis

Structural Building Components are in High Demand in the Precast Concrete Market.

Due to the high demand from the construction sector, the segment of structural building components is expected to dominate the product segment. This category includes many precast products used in the construction of commercial and residential structures.

Precast slabs, façade, as well as other products are being used in increasing numbers for the construction of industrial and manufacturing businesses. This market will be driven by the increased use of structural building components in affordable housing.

Global industrialization and the increasing number of malls, hotels, and hospitals are expected to drive product segment growth during the forecast period. Precast structural components are very attractive because they require minimal or no maintenance.

This will increase product demand over the forecast period. Precast concrete columns, beams, and other components can help reduce the cost of building materials. Precast concrete is more durable and helps in construction, which results in strong demand for both residential and commercial construction.

It is expected that the revenue for architectural buildings will continue to grow. Precast concrete walls will increase the demand for architectural buildings over the forecast period due to their flexibility and greater profitability.

As cities grow, there will be more offices, hospitals, schools, and shopping malls. There will also be more apartments and parking garages.

Precast concrete will see a significant rise in rail applications due to its high durability and track elasticity. The precast concrete industry will also benefit from improved ride quality, lower lifecycle costs, and better geometric retention of rail tracks. This is essential for large freight lines and high speeds. It is also expected to be more environmentally friendly.

End-User Analysis

Non-Residential Segment Dominates over Residential Segment in Precast Concrete Market.

The largest share of precast concrete was accounted for by the non-residential market. This is due to increased investment in countries in commercial spaces and flyovers, roads, education institutes, hospitals, and roads.

The forecast period will see a rise in non-residential segments due to the demand for stadiums, sports complexes, and airports.

The forecast period saw significant growth in the residential segment. Market growth will be driven by the increasing global population and investments made in infrastructure and real estate development.

The market will grow significantly if governments take proactive steps to provide affordable housing for the poorest members of society.

Market Key Segments

Product Type

- Foundations

- Structural Beams

- Slabs

- Walls

- Other Product Types

Application

- Structural Building Components

- Architectural Building Components

- Transportation Products

- Waste & Water Handling Products

- Other Applications

End-user

- Residential

- Non-Residential

Opportunity

Rising Tourism and Construction are Creating Opportunities in the Precast Concrete Market.

Precast concrete is being used to make grave liners, burial vaults, and other structures. Precast Concrete Market share is less in the funeral and burial industry.

It does, however, have a steady share of the entire precast concrete market. To protect the cascade against ground settling and earth weight, the burying industry requires large concrete cages.

Precast concrete’s upper sector is expected to be a major player in areas with a majority of Christian residents. Hotel construction is one of the main Precast Concrete industry routes. Due to the rapid growth in the tourist industry, there is a demand for new hotels.

This contributes to global employment creation and economic growth. This trend is a positive sign for both hotel and construction businesses, as the potential of the tourist industry is enormous. This will lead to healthy competition as vendors in the tourism business will likely concentrate on offering residents amenities such as comfortable stays.

The most visited tourist destinations on the planet are Europe and the Middle East. Europe is the region that receives the most tourists. Thailand is a popular destination for tourists in the Asia-Pacific region. These factors will drive demand for precast concrete products in lodging, hotels, restaurants, and other commercial buildings during the forecast period.

Transportation infrastructure is another area that will see precast concrete grow. Global urbanization has led to a greater need for better transportation infrastructure. As governments develop strategies to meet this demand, the transport infrastructure industry will grow dramatically over the coming years. Large amounts of traffic are expected to come from China and India.

Trending Factors

Precast concrete can be used to reduce construction time. Precast concrete can also be reduced in time, which reduces labor costs. Precast components can be made in controlled environments, such as factories.

This allows for easy changes and monitoring in real time. Precast construction uses fewer resources than cast-in-situ construction. It also produces less waste on both the construction site and the manufacturing plant.

Precast construction allows for the production of individual parts of a structure before the foundation is completed. While modular structures can be completed and put up in as little as four to eight weeks, traditional on-site buildings take twice the time to build a similar-sized structure.

Because of the increased quality and productivity, reduced construction time, and lower trash production, this building method is cheaper and, therefore, more affordable for end users.

Specialty concrete is a key area of expertise for major players. This helps expand their product range for precast concrete producers. Precast concrete requires high strength, durability, and an excellent off-form finish.

These requirements were met by key players when supplying concrete materials for concrete products, residential walls, and large infrastructure projects. They may also offer low CO2 or green star compliance blends.

This is done while maintaining early strength performance through their own product line. These are steps that will increase output and boost the market.

Precast technology is faster than traditional building methods and has a higher quality and longer life span because it is made in controlled environments. A number of prominent companies have set up precast concrete centers and fabrication yards in areas close to major cities and other project locations.

These businesses can deliver cost-effective solutions and meet tight deadlines. They can work to design for electric installation, underfloor heating mats, and piping into the precast module. Many notable firms have achieved success in the design and manufacture of precast solutions as well as industrial equipment. To increase their prestressed concrete market share, they are focusing on expanding their businesses.

Regional Analysis

Asia Pacific Region Dominates the Global Precast Concrete Market.

36.4% of the global precast concrete market is covered by the Asia Pacific region, which makes the Asia Pacific the leading region in the global precast concrete market. The strength of the region’s industrial base is what has driven its rapid growth. Many well-known companies have made a significant contribution to expanding the market.

The Asia Pacific precast concrete market has huge potential because of the growing focus on modular and sustainable building and significant investments in rehabilitation projects in countries like India, China, Japan, Indonesia, and Japan.

Other factors that are contributing to market expansion in the Asia Pacific include increased urbanization, expanding residential, commercial, and infrastructure sectors, easy accessibility to raw materials, low labor costs, and low production costs.

Europe accounted for the second largest revenue share. The Nordic countries were among the first to adopt precast technology. The product is expected to be widely adopted in Europe’s construction industry during the forecast period.

Private investments in emerging economies are responsible for Europe’s GDP growth. It is expected that the region will experience significant growth due to the recovery in the construction industry and the increasing product penetration.

Germany is the largest construction market due to high investment in the sector. This is due to factors such as favorable government incentives and digitization.

Over the forecast period, the North American market will experience moderate growth. Technological advances in the building and construction industry are driving North America’s precast concrete market growth.

Single-family homes are in high demand, especially in Florida, Georgia and North Carolina. The U.S. has a strong manufacturing base and a large industrial base that has contributed to an increase in non-residential buildings, especially in the U.S.

Key Regions and Countries

- North America

- The US

- Canada

- Mexico

- Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Player Analysis

To expand the precast concrete market, major market players are investing a lot in R&D. Market players also take a variety of strategic steps to increase their global footprint.

These include new product launches and contracts & agreements, mergers & acquisitions, better investments, collaboration & strategic partnerships, and better investments.

To survive and expand in a highly competitive market, the precast concrete industry’s competitors must provide cost-effective products.

There are many players in the industry offering a wide range of products, which leads to fierce competition. The presence of major players in developed countries like North America, Europe, and parts of the Asia Pacific region (including Australia) is a testament to their strength.

The global industry is characterized by high levels of forward and reverse integration, which has made it difficult for new players to enter the market.

Market Key Players

- Boral

- LafargeHolcim

- Gulf Precast

- Olson Precast Company

- Larsen & Toubro Limited

- CEMEX

- Forterra

- Tindall Corporation

- Spancrete

- Elementbau Osthessen GmbH & Co., ELO KG

- Bouygues Construction

- Balfour Beatty

- Oldcastle Precast

- Other Key Players

Recent Developments

- In January 2021, LafargeHolcim signed a contract to acquire Firestone Building Products (FSBP), a leader in commercial roofing and building envelope solutions based out of the United States. This acquisition marks a major step in LafargeHolcim’s growth as a global leader in environmentally friendly building solutions.

- In January 2022, Tindall Corporation was North America’s largest supplier of precast concrete products. The company has announced that it will soon be split into Tindall Building Systems Group and Tindall Infrastructure Group.

Report Scope

Report Features Description Market Value (2022) US$ 146.3 Bn Forecast Revenue (2032) US$ 258.2 Bn CAGR (2023-2032) 6.0% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Product Type – Foundations, Structural Beams, Slabs, Walls, and Other Product Types; By Applications – Structural Building Components, Architectural Building Components, Transportation Products, Waste and Water Handling Products, and Other Applications; By End-User – Residential and Non-Residential. Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; the Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Boral, LafargeHolcim, Gulf Precast, Olson Precast Company, Larsen & Toubro Limited, CEMEX, Forterra, Tindall Corporation, Spancrete, Elementbau Osthessen GmbH & Co., ELO KG, Bouygues Construction, Balfour Beatty, Oldcastle Precast, and Other Key Players. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

How big is the Global Precast Concrete market?In 2022, the Global Precast Concrete market was valued at US$ 146.3 Billion and it is projected to reach a valuation of US$ 258.2 Billion by 2032.

How is the future for the growth of the Precast Concrete market?The Precast Concrete market is expected to grow due to increasing urbanization, construction activities, and the demand for modernizing infrastructure in developing nations.

What are the different types in the Precast Concrete market?The Precast Concrete market includes product types such as foundations, structural beams, slabs, walls, and other product types.

Which product type dominates the Precast Concrete market?The structural beams segment dominates the Precast Concrete market in terms of market revenue.

Which applications have high demand in the Precast Concrete market?The structural building components segment has high demand in the Precast Concrete market, driven by the construction of commercial and residential structures.

What are the key drivers of the Precast Concrete market?The advantages of precast concrete, such as quality control, faster construction, and durability, are major drivers of the market. The shift towards modern, sustainable, and eco-friendly construction methods also contributes to market growth.

What are the current trends in the Precast Concrete market?The use of precast concrete to reduce construction time, the focus on specialty concrete for better quality, and the establishment of precast concrete centers near project locations are some of the current trends in the market.

What are the key players in the Precast Concrete market?Some key players in the Precast Concrete market include Boral, LafargeHolcim, Gulf Precast, Olson Precast Company, Larsen & Toubro Limited, CEMEX, Forterra, Tindall Corporation, Spancrete, Elementbau Osthessen GmbH & Co., ELO KG, Bouygues Construction, Balfour Beatty, Oldcastle Precast, and others.

-

-

- Boral

- LafargeHolcim

- Gulf Precast

- Olson Precast Company

- Larsen & Toubro Limited

- CEMEX

- Forterra

- Tindall Corporation

- Spancrete

- Elementbau Osthessen GmbH & Co., ELO KG

- Bouygues Construction

- Balfour Beatty

- Oldcastle Precast