Global Metaverse in Manufacturing Market By Technology (Augmented Reality (AR), Virtual Reality (VR), Mixed Reality (MR)), By Application (Product Design and Development, Production and Operations Management, Supply Chain Management, Quality Control and Assurance), Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: May 2024

- Report ID: 119871

- Number of Pages: 331

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

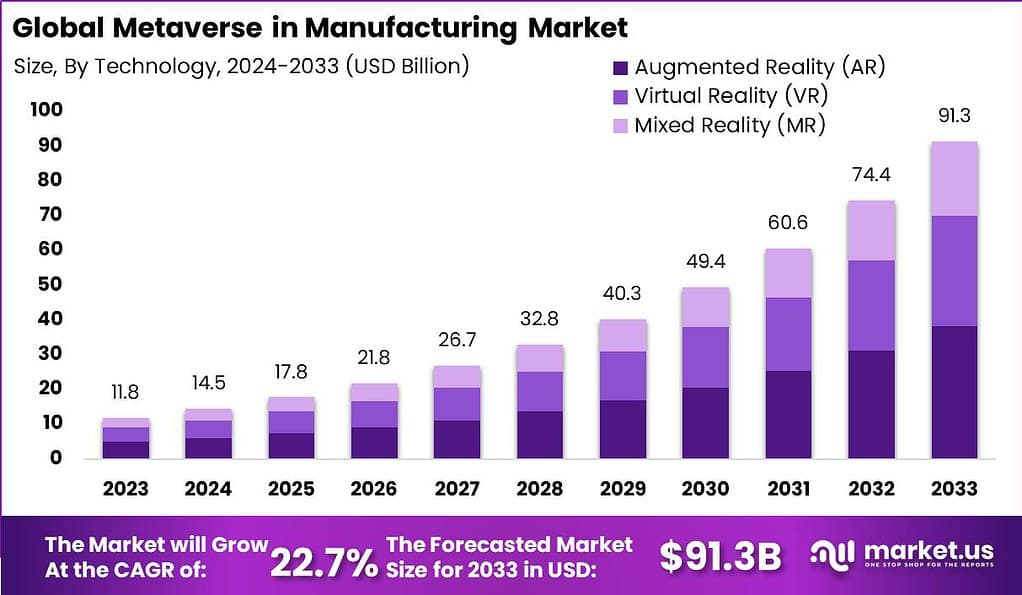

The Global Metaverse in Manufacturing Market size is expected to be worth around USD 91.3 Billion By 2033, from USD 11.8 Billion in 2023, growing at a CAGR of 22.7% during the forecast period from 2024 to 2033.

The concept of the metaverse in manufacturing refers to the integration of virtual environments with physical manufacturing processes. This integration can enhance design, production, and training within the industry. By utilizing virtual and augmented reality, manufacturers can create digital twins of their facilities, simulate production processes, and optimize operations without the need for physical prototypes. This technology allows for real-time collaboration among teams, regardless of their physical location, leading to improved efficiency and reduced costs.

The market for the metaverse in manufacturing is experiencing significant growth. This expansion can be attributed to the increasing demand for advanced manufacturing techniques and the need for more efficient production methods. The market is supported by investments in virtual reality (VR) and augmented reality (AR) technologies, which are crucial for developing immersive virtual environments.

However, the integration of metaverse technologies in manufacturing also presents significant challenges. These include the high costs of VR and AR technologies, the need for substantial IT infrastructure, and concerns regarding data security and privacy. Additionally, the steep learning curve associated with these advanced technologies can be a barrier to adoption, especially for traditional manufacturing workforces.

Despite these challenges, the market offers considerable opportunities for new entrants. Innovators and startups can carve out niches by developing user-friendly, scalable, and secure metaverse solutions tailored to the unique needs of manufacturers. There is also potential for significant collaboration with established industry players to foster the development of new standards and best practices in metaverse implementations.

A recent survey conducted by PwC reveals that a significant 78% of manufacturing executives are convinced that applications within the metaverse enhance collaboration among global teams. This enhanced collaboration is credited with leading to expedited decision-making processes. The potential of the metaverse to streamline and accelerate corporate operations is becoming increasingly evident, positioning it as a pivotal tool in global business strategies.

Furthermore, a case study from a prominent automotive manufacturer underscores the efficiency of metaverse technologies in the realm of product design. By integrating metaverse simulations, the company has reported a substantial 20% reduction in prototype iterations. This improvement not only signifies a decrease in time and resources spent during the design phase but also suggests a shift towards more cost-effective and agile product development practices within the industry.

Key Takeaways

- The Metaverse in Manufacturing Market size is expected to be worth around USD 91.3 Billion By 2033, growing at a CAGR of 22.7% during the forecast period from 2024 to 2033.

- In 2023, the Augmented Reality (AR) segment held a dominant position in the metaverse in manufacturing market, capturing more than a 41.8% share.

- In 2023, the Product Design and Development segment held a dominant market position in the metaverse in manufacturing, capturing more than a 34.3% share.

- In 2023, North America held a dominant position in the metaverse in manufacturing market, capturing more than a 35.2% share.

- The global metaverse market is Expected to Accumulate a Value of USD 2,346.2 Billion by 2032 from USD 94.1 Billion in 2023; Registering a CAGR of 44.4% in the Forecast Period 2023 to 2032.

Technology Analysis

In 2023, the Augmented Reality (AR) segment held a dominant position in the metaverse in manufacturing market, capturing more than a 41.8% share. This leadership is primarily due to AR’s ability to overlay digital information onto the real world, enhancing the precision and efficiency of manufacturing processes.

AR tools assist workers in complex assembly tasks by providing real-time, hands-free access to data and guidance directly within their field of vision. This not only speeds up the production process but also reduces errors, leading to higher quality outcomes and lower costs. Additionally, AR is crucial in maintenance and training, where visual instructions and simulations help to improve skill retention without the physical constraints of traditional methods.

The appeal of AR in manufacturing also extends to its scalability and ease of integration compared to other immersive technologies. Unlike Virtual Reality (VR), which requires a completely virtual environment, AR can be implemented using smartphones and tablets, reducing the initial investment and encouraging adoption among small to mid-sized enterprises. Furthermore, as the technology continues to advance, the cost of AR devices is decreasing, making it more accessible to a broader range of manufacturers.

This segment’s growth is further propelled by the ongoing development of AR applications tailored specifically for manufacturing needs. These applications are becoming more sophisticated, offering more detailed and context-sensitive information to users, which enhances operational efficiency. As AR technology evolves, its integration into manufacturing processes is expected to deepen, potentially increasing its market share and solidifying its position as the leading technology in the metaverse in manufacturing.

Application Analysis

In 2023, the Product Design and Development segment held a dominant market position in the metaverse in manufacturing, capturing more than a 34.3% share. This segment leads due to the critical role the metaverse plays in enhancing the design and development phase of manufacturing. Utilizing virtual and augmented reality technologies, engineers and designers can create, test, and refine product designs in a completely virtual space.

This allows for rapid prototyping, where modifications to designs can be made instantly and tested without the need for costly and time-consuming physical prototypes. The ability to visualize and interact with a product design in a 3D space also enhances creativity and problem-solving, leading to more innovative and efficient design outcomes.

The significant market share of this segment is further supported by the collaborative opportunities it offers. Teams spread across different geographies can work together in a shared virtual space, discussing and manipulating product designs in real-time. This not only speeds up the development process but also ensures that the final product is more aligned with the diverse insights and expertise of a global team.

Such collaboration was particularly crucial in maintaining project timelines and quality during the disruptions caused by global events such as the COVID-19 pandemic. As technology advances, the tools and platforms available for product design and development in the metaverse are becoming more sophisticated, providing even more detailed simulations and analyses.

This ongoing technological evolution is expected to continue driving the growth of this segment, further cementing its position as a leader in the metaverse in manufacturing market. The integration of artificial intelligence for automated design improvements and machine learning for predictive modeling are trends that are likely to enhance the utility and prevalence of metaverse technologies in this area.

Key Market Segments

By Technology

- Augmented Reality (AR)

- Virtual Reality (VR)

- Mixed Reality (MR)

By Application

- Product Design and Development

- Production and Operations Management

- Supply Chain Management

- Quality Control and Assurance

Driver

Enhanced Collaboration and Efficiency

One significant driver for the adoption of the metaverse in manufacturing is the enhanced collaboration and efficiency it facilitates. By integrating virtual environments, manufacturers can bring together teams from across the globe in real-time, simulating and optimizing production processes without physical or geographical limitations. This technology enables seamless interaction between designers, engineers, and production staff, allowing for immediate feedback and iterative design changes.

The ability to conduct virtual trials and troubleshoot in a digital space reduces downtime and speeds up the time to market, significantly enhancing productivity. As companies increasingly prioritize agility and responsiveness, the demand for such collaborative platforms is expected to grow, driving further integration of metaverse technologies in manufacturing processes.

Restraint

High Initial Costs and Complexity

A major restraint in the adoption of the metaverse within the manufacturing sector is the high initial investment required for the necessary hardware and software, alongside the complexity of integrating these technologies into existing systems. Setting up a fully functional metaverse environment involves substantial expenditures on advanced VR and AR equipment, robust IT infrastructure, and secure data storage solutions.

Additionally, the integration process can be complex, requiring significant changes to current workflows and possibly leading to downtime or disruptions in production. These factors can be particularly daunting for smaller manufacturers with limited budgets, which may hinder the widespread adoption of metaverse technologies in the industry.

Opportunity

Training and Skill Development

The metaverse presents a significant opportunity in the area of training and skill development within the manufacturing industry. Virtual and augmented reality platforms allow for the creation of detailed, immersive training programs that can simulate real-world manufacturing scenarios without the risks associated with physical training. This can be particularly beneficial for training employees on expensive or hazardous equipment, allowing them to gain proficiency before operating actual machinery.

Furthermore, the scalability of such programs means that training can be standardized and deployed across multiple locations, ensuring consistency in skills and knowledge. As the workforce continues to evolve, the demand for such innovative training solutions is likely to increase, presenting a substantial growth opportunity for the metaverse in manufacturing.

Challenge

Data Security and Privacy Concerns

A significant challenge facing the integration of the metaverse in manufacturing is ensuring data security and privacy. The use of virtual and augmented reality technologies involves the generation, storage, and transmission of large volumes of sensitive data. This data can include proprietary design information, detailed factory layouts, and personal information of employees.

Protecting this information from cybersecurity threats is paramount, as any breach could lead to intellectual property theft, operational disruptions, or even safety risks. Manufacturers must invest in robust cybersecurity measures and develop comprehensive data governance policies to mitigate these risks, which can be a complex and costly process.

Growth Factors

- Digital Transformation and Smart Manufacturing: The rapid advancement and adoption of smart manufacturing technologies have laid a solid foundation for the integration of metaverse technologies in the industry. This technological groundwork facilitates improved efficiency and innovation, enabling manufacturers to leverage virtual environments for design, training, and operations management.

- Integration of Advanced Technologies: Manufacturers are increasingly implementing foundational technologies like AI, 5G, and the Internet of Things, which are crucial for supporting the functionalities of the metaverse. This integration is enhancing data connectivity and operational agility across manufacturing processes.

- Increasing Demand for Immersive Training and Simulation: Virtual Reality (VR) and Augmented Reality (AR) technologies are being widely adopted for creating realistic training simulations and prototyping, which reduce costs and time-to-market for new products. This not only improves the skillset of the workforce but also enhances product quality and innovation.

- Global Collaboration: The metaverse enables seamless collaboration across geographically dispersed teams, allowing for real-time interaction and cooperation, which is especially crucial in a globalized manufacturing landscape. This connectivity helps in maintaining continuous innovation and operational efficiency despite physical distances.

Emerging Trends

- Rise of Mixed Reality (MR): MR technology, which combines elements of VR and AR, is gaining traction for its ability to provide a seamless blend of digital and real-world elements. This is particularly useful in tasks that require a high degree of spatial awareness and manipulation, enhancing the interaction between digital content and physical operations.

- Adoption in Diverse Manufacturing Sectors: As MR and VR technologies mature, they are being adopted across various manufacturing sectors, including automotive and aerospace, where they can aid in everything from design to maintenance and remote assistance.

- Growth of Digital Twins: The use of digital twins is becoming more prevalent, enabling manufacturers to create virtual replicas of physical systems. This is instrumental in optimizing manufacturing processes and product lifecycle management, providing significant cost savings and agility.

- Expansion of Remote Operations: The metaverse facilitates the management of manufacturing operations remotely, enhancing the ability to monitor, control, and make decisions from afar. This trend is growing as companies continue to expand their digital infrastructure to support more sophisticated metaverse applications.

Regional Analysis

In 2023, North America held a dominant position in the metaverse in manufacturing market, capturing more than a 35.2% share. This leadership is largely attributed to the region’s robust technological infrastructure and the early adoption of advanced technologies, including virtual reality (VR), augmented reality (AR), and artificial intelligence (AI).

North American companies are pioneers in integrating digital twins and immersive technologies into manufacturing processes, which significantly enhances operational efficiency and product innovation. The presence of major technology companies that invest heavily in R&D, such as Google, Microsoft, and Meta, also propels the development of metaverse technologies in this region.

Moreover, the emphasis on industry 4.0 and smart manufacturing solutions in North America further drives the integration of the metaverse in manufacturing. Governments and private sectors are collaboratively promoting the adoption of digital technologies to maintain competitiveness in the global market. Initiatives to boost manufacturing capabilities through digital transformation are widespread, which supports the growth of the metaverse in manufacturing.

The robust network infrastructure, high internet penetration, and a culture that rapidly embraces technological advancements are pivotal in maintaining North America’s leading position in the market. With continuous investments in tech development and supportive regulatory frameworks, North America is expected to sustain its market dominance and may even increase its market share in the coming years.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

The metaverse in manufacturing has emerged as a transformative force, with several key players shaping its trajectory. Microsoft Corporation is at the forefront, leveraging its extensive cloud infrastructure and development platforms to support robust metaverse environments. Unity Technologies and NVIDIA Corporation are pivotal in rendering high-fidelity virtual spaces, crucial for detailed and immersive manufacturing simulations.

PTC Inc. and Siemens AG bring to the table advanced industrial IoT and digital twin technologies that integrate seamlessly with metaverse applications, enhancing real-time operations and remote collaboration. Autodesk Inc. and EON Reality Inc. contribute with powerful 3D design tools and virtual reality solutions that streamline the design and prototyping processes within the manufacturing sector.

Top Key Players in the Market

- Microsoft Corporation

- Unity Technologies

- NVIDIA Corporation

- PTC Inc.

- Siemens AG

- Autodesk Inc.

- EON Reality Inc.

- Magic Leap Inc.

- HTC Corporation

- Oculus VR (Facebook Technologies LLC)

- Samsung Electronics Co. Ltd.

- Alphabet Inc. (Google)

- Varjo Technologies

- Marxent Labs LLC

- Other Key Players

Recent Developments

- In January 2022, Hyundai Motor Company teamed up with Unity Technologies to develop a new digital-twin factory called Meta-Factory. This innovative project uses the metaverse to improve how plants operate. It creates a virtual space where people can come together to solve problems creatively within an interactive digital environment.

- In November 2021, the Korea Advanced Institute of Science & Technology (KAIST) launched a unique project: a virtual plastic screw factory in the metaverse. Here, customers can put on virtual reality headsets to see and interact with the factory’s operations as if they were really there. This virtual factory allows users to operate machines and get a realistic feel for the manufacturing process, all within a simulated setting.

Report Scope

Report Features Description Market Value (2023) USD 11.8 Bn Forecast Revenue (2033) USD 91.3 Bn CAGR (2024-2033) 22.7% Base Year for Estimation 2023 Historic Period 2019-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Technology (Augmented Reality (AR), Virtual Reality (VR), Mixed Reality (MR)), By Application (Product Design and Development, Production and Operations Management, Supply Chain Management, Quality Control and Assurance) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Russia, Netherlands, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, New Zealand, Singapore, Thailand, Vietnam, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – South Africa, Saudi Arabia, UAE, Rest of MEA Competitive Landscape Microsoft Corporation, Unity Technologies, NVIDIA Corporation, PTC Inc., Siemens AG, Autodesk Inc., EON Reality Inc., Magic Leap Inc., HTC Corporation, Oculus VR (Facebook Technologies LLC), Samsung Electronics Co. Ltd., Alphabet Inc. (Google), Varjo Technologies, Marxent Labs LLC, Other Key Players Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three license to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is the Metaverse in manufacturing?The Metaverse in manufacturing refers to the integration of virtual and augmented reality technologies into various aspects of manufacturing processes, such as design, simulation, training, maintenance, and collaboration.

How big is Metaverse in Manufacturing Market?The Global Metaverse in Manufacturing Market size is expected to be worth around USD 91.3 Billion By 2033, from USD 11.8 Billion in 2023, growing at a CAGR of 22.7% during the forecast period from 2024 to 2033.

What technologies are involved in creating the Metaverse for manufacturing?Technologies involved in creating the Metaverse for manufacturing include virtual reality (VR), augmented reality (AR), mixed reality (MR), 3D modeling and simulation software, Internet of Things (IoT) sensors, cloud computing, and advanced data analytics.

Who are the prominent players operating in the metaverse in manufacturing market?Microsoft Corporation, Unity Technologies, NVIDIA Corporation, PTC Inc., Siemens AG, Autodesk Inc., EON Reality Inc., Magic Leap Inc., HTC Corporation, Oculus VR (Facebook Technologies LLC), Samsung Electronics Co. Ltd., Alphabet Inc. (Google), Varjo Technologies, Marxent Labs LLC, Other Key Players

Which are the driving factors of the metaverse in manufacturing market?Driving factors of the Metaverse in Manufacturing Market include the need for enhanced product design and prototyping, demand for immersive training simulations, remote collaboration requirements, and the drive for predictive maintenance and real-time monitoring.

Which region will lead the global metaverse in manufacturing market?In 2023, North America held a dominant position in the metaverse in manufacturing market, capturing more than a 35.2% share.

Metaverse in Manufacturing MarketPublished date: May 2024add_shopping_cartBuy Now get_appDownload Sample

Metaverse in Manufacturing MarketPublished date: May 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- Microsoft Corporation

- Unity Technologies

- NVIDIA Corporation

- PTC Inc.

- Siemens AG

- Autodesk Inc.

- EON Reality Inc.

- Magic Leap Inc.

- HTC Corporation

- Oculus VR (Facebook Technologies LLC)

- Samsung Electronics Co. Ltd.

- Alphabet Inc. (Google)

- Varjo Technologies

- Marxent Labs LLC

- Other Key Players