Global Laser Marking For Packaging Market Size, Share, Growth Analysis By Technology (Fiber Laser Marking, CO2 Laser Marking, UV Laser Marking, Others), By Packaging Material (Plastic & Polymer, Paper & Cardboard, Metal, Glass, Others), By Application (Product Identification, Traceability & Anti-counterfeiting, Branding & Logos, Regulatory Compliance), By End-Use Industry (Food & Beverage, Pharmaceuticals & Healthcare, Cosmetics & Personal Care, Automotive, Electronics, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Dec 2025

- Report ID: 170390

- Number of Pages: 199

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

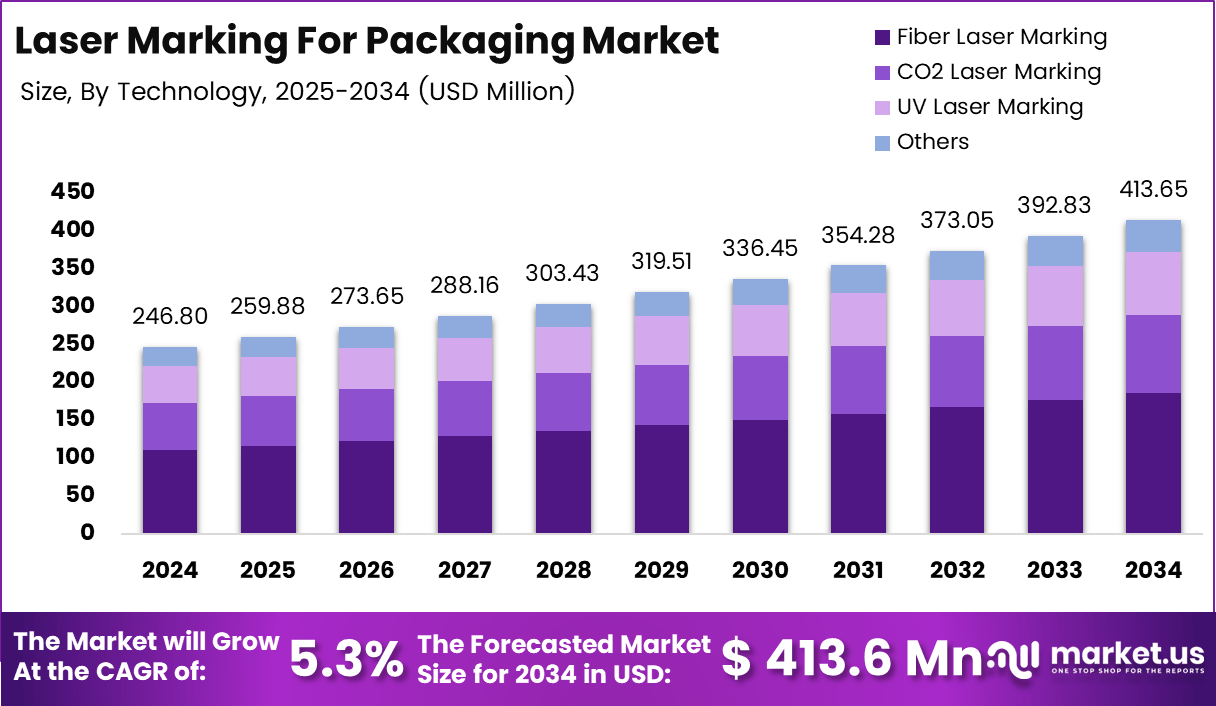

The Global Laser Marking For Packaging Market size is expected to be worth around USD 413.6 million by 2034, from USD 246.8 million in 2024, growing at a CAGR of 5.3% during the forecast period from 2025 to 2034.

The laser marking for the packaging market refers to the use of laser technology to create permanent codes, symbols, and graphics directly on packaging surfaces. From an analyst perspective, this market addresses rising demand for durability, compliance, and traceability across regulated and high-volume packaging environments, while supporting both operational efficiency and long-term cost optimization.

From a growth standpoint, laser marking for packaging is expanding as manufacturers prioritize non-consumable, contact-free marking solutions. Consequently, adoption is increasing across food, beverage, pharmaceuticals, and personal care packaging lines, driven by automation, sustainability targets, and the need to reduce downtime associated with inks, solvents, and frequent maintenance interventions.

In terms of opportunity, laser marking systems offer strong alignment with smart packaging and digital manufacturing initiatives. As a result, packaging producers are integrating laser solutions with ERP, serialization, and quality inspection platforms. Moreover, governments are encouraging traceability and anti-counterfeiting through labeling regulations, indirectly accelerating investments in advanced laser-based packaging identification technologies.

Regulatory frameworks also influence market momentum. Packaging regulations increasingly emphasize permanent, legible, and tamper-resistant coding to support recalls and consumer safety. Therefore, laser marking aligns well with compliance requirements across multiple jurisdictions, while supporting clean manufacturing objectives promoted through environmental and waste reduction policies.

According to manufacturer technical documentation, modern laser marking systems support both stationary and mark-on-the-fly installations, enabling marking speeds of up to 1300 characters per second in automated environments. Furthermore, compact designs with combined laser head and controller weights below 25 kilograms improve integration flexibility, representing approximately 44 percent lower weight compared to traditional fiber laser systems.

Additionally, the same technical sources indicate support for line speeds reaching 900 meters per minute, depending on configuration and material compatibility. These systems operate within the 1.04 to 1.09 micrometer wavelength range and meet CE, TÜV NRTL, FCC, ROHS, and CFRH FDA compliance standards, reinforcing suitability for regulated packaging applications.

From an analyst viewpoint, these performance attributes strengthen the market’s value proposition by enabling high-speed, compliant, and space-efficient deployment. Consequently, the laser marking for the packaging market is positioned for sustained adoption as manufacturers modernize packaging lines, pursue digitalization, and respond to evolving regulatory and sustainability-driven production requirements.

Key Takeaways

- The global Laser Marking For Packaging Market is projected to reach USD 413.6 million by 2034, expanding from USD 246.8 million in 2024 at a CAGR of 5.3%.

- Fiber Laser Marking is the leading technology segment, accounting for 44.9% of the total market share due to high speed and automation compatibility.

- Plastic & Polymer packaging represents the dominant material segment with a market share of 46.7%, driven by widespread use in flexible and rigid packaging.

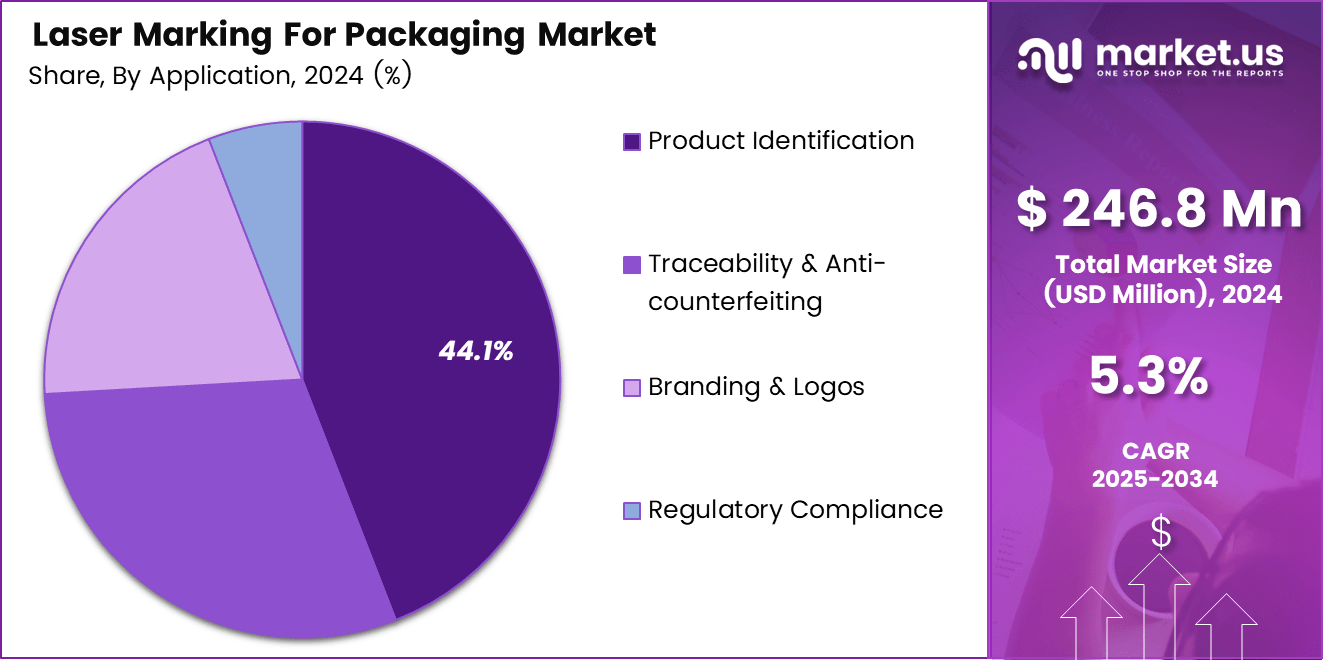

- Product Identification is the largest application segment, holding 44.1% share as demand for permanent and legible coding increases.

- Food & Beverage is the leading end-use industry, contributing 38.2% of overall market demand due to high-volume packaging needs.

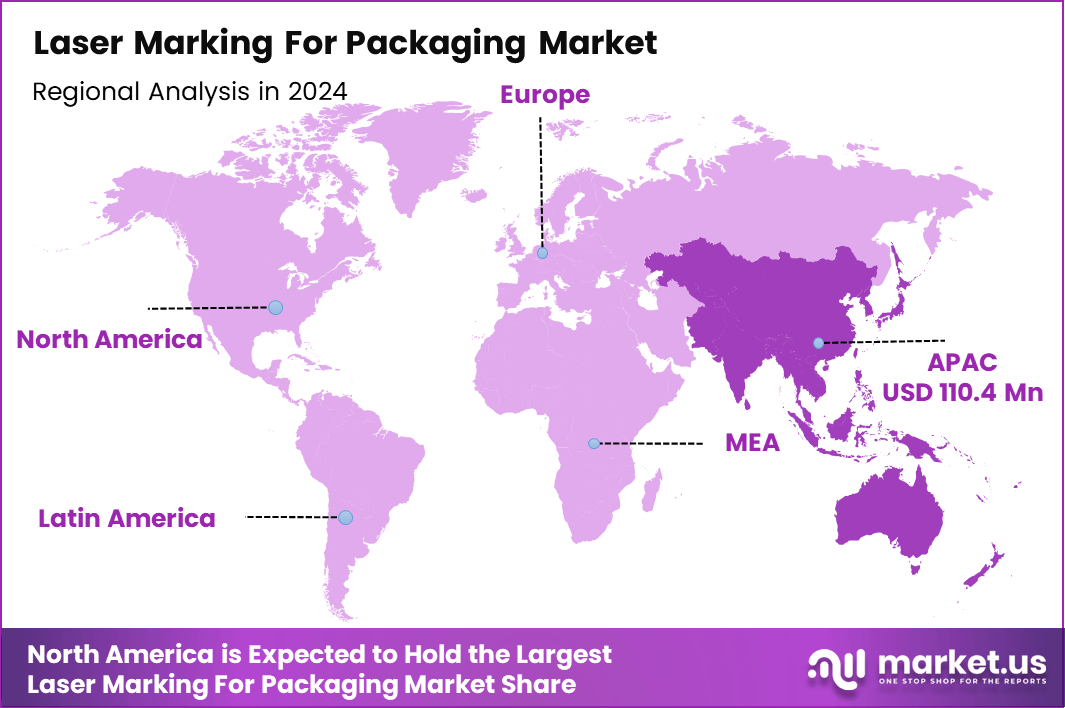

- Asia Pacific is the dominant regional market with a 44.9% share, valued at USD 110.4 million, supported by large-scale manufacturing activity.

By Technology Analysis

Fiber Laser Marking dominates with 44.9% due to its precision, speed, and compatibility with automated packaging lines.

In 2024, Fiber Laser Marking held a dominant market position in the By Technology Analysis segment of the Laser Marking for Packaging Market, with a 44.9% share. Moreover, this technology is widely adopted for high-speed packaging environments, as it delivers permanent, high-contrast marks while supporting continuous production workflows and minimal maintenance requirements.

CO2 Laser Marking continues to hold relevance, particularly in applications involving organic packaging substrates. Additionally, this technology supports non-contact marking on cartons and films, enabling consistent coding quality. As packaging volumes grow, CO2 systems remain preferred where cost efficiency and material compatibility are prioritized.

UV Laser Marking is increasingly applied in specialized packaging lines that require ultra-fine and low-heat marking. Furthermore, its ability to minimize material damage supports sensitive packaging formats. This technology is gradually expanding across regulated industries, demanding precise and clean marking outcomes.

Other laser technologies address niche packaging needs, including customized marking requirements. Consequently, these systems support flexibility across varied production scales. While adoption remains limited, they complement mainstream technologies by enabling tailored marking solutions for complex packaging environments.

By Packaging Material Analysis

Plastic & Polymer dominates with 46.7% owing to its extensive use across flexible and rigid packaging formats.

In 2024, Plastic & Polymer held a dominant market position in the By Packaging Material Analysis segment of the Laser Marking For Packaging Market, with a 46.7% share. Moreover, laser marking supports permanent, ink-free coding on plastic surfaces, aligning with sustainability and traceability requirements across packaging supply chains.

Paper & Cardboard packaging benefits from laser marking due to its compatibility with recyclable materials. Additionally, this method eliminates ink usage while enabling clean labeling. As demand for eco-friendly packaging rises, laser marking adoption continues to strengthen within paper-based packaging formats.

Metal packaging applications rely on laser marking for durability and resistance to environmental exposure. Furthermore, permanent marking enhances product identification across industrial and premium packaging. This segment supports consistent branding and compliance labeling in high-stress packaging conditions.

Glass packaging adopts laser marking for high clarity and long-term identification. Consequently, it supports premium packaging aesthetics and regulatory labeling. Other materials address emerging packaging substrates, enabling broader laser marking integration across diverse material compositions.

By Application Analysis

Product Identification dominates with 44.1% driven by rising demand for clear and permanent product coding.

In 2024, Product Identification held a dominant market position in the By Application Analysis segment of the Laser Marking For Packaging Market, with a 44.1% share. Moreover, laser marking ensures legible batch codes, dates, and serial numbers, supporting efficient inventory management and supply chain transparency.

Traceability & Anti-counterfeiting applications benefit from laser marking through secure and tamper-resistant identification. Additionally, permanent marks support authentication initiatives across regulated industries. As brand protection becomes critical, adoption of laser-based traceability continues to increase steadily.

Branding & Logos applications utilize laser marking to enhance visual appeal and brand consistency. Furthermore, high-precision marking supports customized packaging designs without consumables. This application segment aligns with premiumization trends across consumer packaging markets.

Regulatory Compliance applications depend on laser marking for accuracy and permanence. Consequently, it ensures compliance with labeling standards while reducing operational errors. This application remains essential across industries requiring strict packaging documentation.

By End-Use Industry Analysis

Food & Beverage dominates with 38.2% supported by high volume packaging and strict labeling requirements.

In 2024, Food & Beverage held a dominant market position in the By End-Use Industry Analysis segment of the Laser Marking For Packaging Market, with a 38.2% share. Moreover, laser marking supports hygienic, ink-free coding, aligning with food safety regulations and high-speed production demands.

Pharmaceuticals & Healthcare packaging adopts laser marking for precise and permanent labeling. Additionally, it supports serialization and compliance with regulatory standards. This industry values laser marking for its accuracy, reliability, and ability to reduce contamination risks.

Cosmetics & Personal Care applications leverage laser marking to enhance packaging aesthetics and traceability. Furthermore, it supports premium branding while ensuring durability. As product differentiation increases, laser marking continues to gain relevance within this segment.

Automotive, Electronics, and Other industries apply laser marking for durable identification and component traceability. Consequently, these sectors benefit from long-lasting marks that withstand handling and storage conditions, supporting operational efficiency and compliance needs.

Key Market Segments

By Technology

- Fiber Laser Marking

- CO2 Laser Marking

- UV Laser Marking

- Others

By Packaging Material

- Plastic & Polymer

- Paper & Cardboard

- Metal

- Glass

- Others

By Application

- Product Identification

- Traceability & Anti-counterfeiting

- Branding & Logos

- Regulatory Compliance

By End-Use Industry

- Food & Beverage

- Pharmaceuticals & Healthcare

- Cosmetics & Personal Care

- Automotive

- Electronics

- Others

Drivers

Rising Adoption of Permanent, Tamper-Resistant Product Identification Drives Market Growth

From an analyst perspective, the laser marking for the packaging market is strongly driven by the need for permanent and tamper-resistant product identification. Manufacturers across food, pharmaceuticals, and consumer goods increasingly focus on traceability to protect brands and ensure product authenticity. Laser marking creates permanent codes that cannot be removed without damaging the packaging, improving trust across supply chains.

Another major driver is growing regulatory pressure for clear, legible, and non-removable coding on both primary and secondary packaging. Authorities demand accurate batch numbers, expiry dates, and compliance codes, making laser marking a reliable solution. This supports consistent readability even in harsh storage or transport conditions.

The rising preference for non-contact and ink-free marking also fuels adoption. Laser systems eliminate inks and solvents, reducing consumable costs and waste generation. As sustainability goals become important, packaging producers favor cleaner technologies with lower environmental impact.

Additionally, expanding use of automated packaging lines increases demand for high-speed and low-maintenance marking technologies. Laser systems integrate easily into automated environments, supporting continuous operations with minimal downtime.

Restraints

High Initial Capital Investment Limits Wider Adoption

Despite strong growth drivers, high upfront investment remains a key restraint in the laser marking for packaging market. Industrial-grade laser systems require significant capital spending, which can discourage cost-sensitive manufacturers, especially smaller players with limited budgets.

Limited compatibility of certain laser types with heat-sensitive or multilayer packaging materials also restricts adoption. Some materials may discolor or deform under laser exposure, requiring careful system selection and testing, which adds complexity to deployment.

The requirement for skilled operators further acts as a restraint. Laser marking systems need technical expertise for setup, calibration, and optimization. A lack of trained personnel can slow adoption and increase reliance on external service support.

From an analyst’s viewpoint, these challenges mainly affect early-stage adopters, although ongoing advancements are gradually reducing these barriers.

Growth Factors

Rising Demand for Sustainable Packaging Creates New Growth Opportunities

Growth opportunities in the laser marking for packaging market are expanding alongside demand for sustainable and recyclable packaging formats. Laser marking supports eco-friendly packaging by removing the need for inks, labels, and additional materials, aligning well with circular economy goals.

Increasing penetration of smart packaging and serialization initiatives also presents strong opportunities. Regulated industries require advanced coding for tracking, authentication, and digital connectivity, where laser marking provides permanent and high-quality data carriers.

Small and mid-sized manufacturers are gradually adopting laser marking to achieve long-term operational cost savings. Although initial costs are higher, reduced consumables and maintenance deliver benefits over time.

Analysts note that these factors collectively create a favorable environment for wider market expansion.

Emerging Trends

Shift Toward Fiber Laser Technology Shapes Market Trends

One of the key trending factors in the laser marking for packaging market is the shift toward fiber and UV laser systems. These technologies offer higher precision, faster speeds, and better material flexibility compared to traditional systems.

Integration of laser marking with vision inspection and digital packaging platforms is also increasing. This improves code verification, reduces errors, and supports data-driven packaging operations.

There is a growing focus on micro-marking and high-resolution graphics, particularly for premium and branded packaging. Laser systems enable fine details without compromising package integrity.

Additionally, Industry 4.0 enabled laser systems with remote monitoring and predictive maintenance are gaining traction, helping manufacturers improve efficiency and reduce unexpected downtime.

Regional Analysis

Asia Pacific Dominates the Laser Marking for Packaging Market with a Market Share of 44.9%, Valued at USD 110.4 Million

Asia Pacific holds the leading position in the laser marking for packaging market, accounting for 44.9% share and generating approximately USD 110.4 Million in value. The region benefits from large-scale manufacturing activity, rapid expansion of packaged food, pharmaceuticals, and consumer goods industries, and increasing adoption of automated packaging lines. Strong focus on traceability, export compliance, and cost-efficient, non-contact marking solutions further supports sustained demand across emerging and developed economies within the region.

North America Laser Marking For Packaging Market Trends

North America represents a technologically mature market driven by strict packaging regulations and high emphasis on product safety and traceability. The region shows strong adoption of laser marking systems across food, beverage, and pharmaceutical packaging due to demand for permanent, high-precision coding. Continuous upgrades in smart factories and automation-focused packaging infrastructure are supporting stable market expansion.

Europe Laser Marking For Packaging Market Trends

Europe demonstrates steady growth supported by stringent regulatory frameworks related to labeling, serialization, and environmental sustainability. Manufacturers across the region increasingly prefer ink-free and low-waste marking technologies to align with circular economy goals. The presence of advanced packaging standards and a strong focus on anti-counterfeiting solutions contribute to consistent regional demand.

Middle East and Africa Laser Marking For Packaging Market Trends

The Middle East and Africa market is gradually expanding, driven by growing investments in food processing, pharmaceuticals, and industrial packaging sectors. Adoption of laser marking is supported by rising awareness around product authentication and longer shelf life requirements. Infrastructure development and modernization of packaging facilities are expected to improve regional uptake over time.

Latin America Laser Marking For Packaging Market Trends

Latin America is witnessing moderate growth as manufacturers increasingly shift toward automated and compliant packaging solutions. Rising exports of packaged food, beverages, and personal care products are encouraging the use of permanent marking technologies. Regulatory alignment with international trade standards and gradual industrial automation are key factors shaping regional market progression.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Laser Marking For Packaging Company Insights

Videojet Technologies Inc. holds a strong position in the global laser marking for packaging market in 2024, driven by its focus on high-speed, reliable, and low-maintenance laser systems designed for continuous production environments. From an analyst perspective, the company’s emphasis on seamless line integration, remote monitoring, and service support enables packaging manufacturers to improve uptime, enhance traceability, and reduce total operating costs across high-volume applications.

Domino Printing Sciences pic continues to strengthen its market standing through flexible and modular laser marking platforms that cater to diverse packaging formats and materials. Analysts observe that Domino’s investments in intuitive software interfaces and smart connectivity features support faster changeovers and easier operator adoption. This approach aligns well with the growing demand for automated, sustainable, and digitally connected packaging lines in regulated industries.

Markem-Imaje differentiates itself by offering integrated laser marking solutions that support compliance, brand protection, and consistent code quality across complex packaging substrates. From a market viewpoint, its strong software-driven control and precision marking capabilities help manufacturers meet strict labeling standards while maintaining operational efficiency. The company’s focus on end-to-end coding ecosystems supports long-term customer retention.

Trumpf GmbH + Co. KG is recognized for its advanced fiber laser technology, delivering high precision, durability, and energy efficiency for demanding packaging environments. Analysts highlight Trumpf’s strong engineering expertise and ongoing innovation in automation-ready laser systems as key strengths. These capabilities enable packaging producers to achieve permanent, high-contrast markings with reduced maintenance and waste, supporting productivity and sustainability goals.

Top Key Players in the Market

- Videojet Technologies Inc.

- Domino Printing Sciences pic

- Markem-Imaje

- Trumpf GmbH + Co. KG

- Han’s Laser Technology Industry Group Co., Ltd.

- Keyence Corporation

- Cajo Technologies

- Coherent Inc.

- IPG Photonics Corporation

Recent Developments

- In Apr 2025, Fonon Quantum Technologies acquired Beamer Laser Marking Systems, marking its expansion into the industrial laser equipment market. The acquisition broadens Fonon’s technology capabilities and strengthens its position in precision laser marking and manufacturing solutions.

- In Sep 2025, Laser Photonics closed the acquisition of Beamer Laser Marking Systems, including its manufacturing equipment, inventory, customer contracts, intellectual property, and key personnel. Beamer’s operations were integrated into LPC’s Florida facility, with order shipments commencing to support expanded industrial laser production.

Report Scope

Report Features Description Market Value (2024) USD 246.8 million Forecast Revenue (2034) USD 413.6 million CAGR (2025-2034) 5.3% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Technology (Fiber Laser Marking, CO2 Laser Marking, UV Laser Marking, Others), By Packaging Material (Plastic & Polymer, Paper & Cardboard, Metal, Glass, Others), By Application (Product Identification, Traceability & Anti-counterfeiting, Branding & Logos, Regulatory Compliance), By End-Use Industry (Food & Beverage, Pharmaceuticals & Healthcare, Cosmetics & Personal Care, Automotive, Electronics, Others) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape Videojet Technologies Inc., Domino Printing Sciences pic, Markem-Imaje, Trumpf GmbH + Co. KG, Han’s Laser Technology Industry Group Co. Ltd., Keyence Corporation, Cajo Technologies, Coherent Inc., IPG Photonics Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited Users and Printable PDF)  Laser Marking For Packaging MarketPublished date: Dec 2025add_shopping_cartBuy Now get_appDownload Sample

Laser Marking For Packaging MarketPublished date: Dec 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Videojet Technologies Inc.

- Domino Printing Sciences pic

- Markem-Imaje

- Trumpf GmbH + Co. KG

- Han's Laser Technology Industry Group Co., Ltd.

- Keyence Corporation

- Cajo Technologies

- Coherent Inc.

- IPG Photonics Corporation