Global Laser Displacement Sensor Market By Type (Above 300mm, 100mm-300mm, Below 100mm), End-Use Industry (Manufacturing, Automotive, Electronics, Aerospace & Defense, Other End-Use Industries), By Region and Key Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

- Published date: August 2024

- Report ID: 18763

- Number of Pages: 363

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

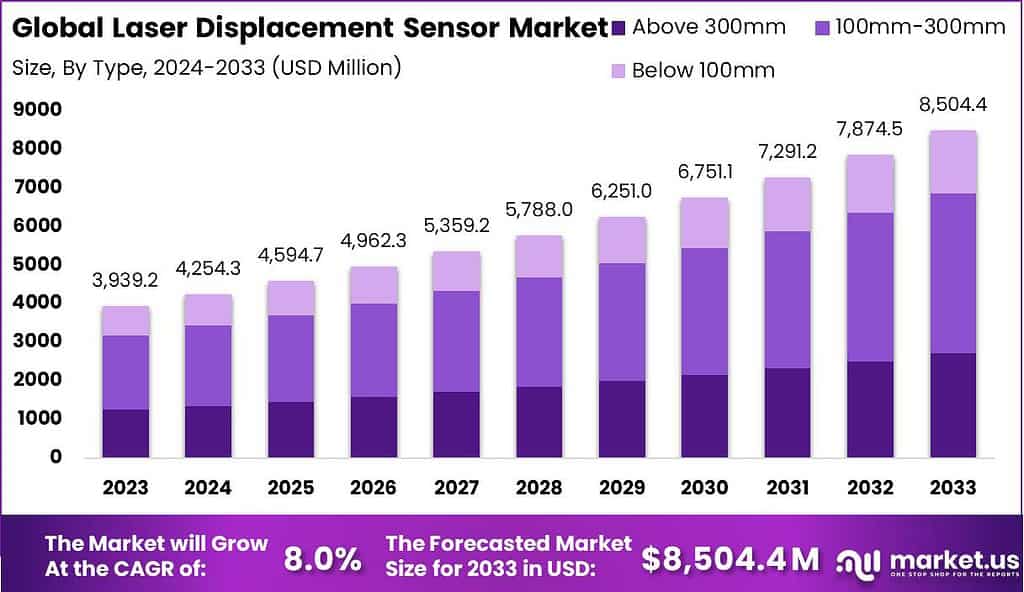

The Global Laser Displacement Sensor Market size is expected to be worth around USD 8,504.4 Million by 2033, from USD 3,939.2 Million in 2023, growing at a CAGR of 8.0% during the forecast period from 2024 to 2033.

A laser displacement sensor is a high-precision device used to measure distance and position by projecting a laser beam onto a target and analyzing the reflection. The sensor determines the displacement by calculating the distance between the sensor and the surface based on the angle or position of the reflected laser beam. These sensors are valued for their accuracy, speed, and non-contact nature, making them ideal for various applications, including automation, robotics, and quality control in manufacturing processes.

The global market for laser displacement sensors is experiencing significant growth, driven by the increasing adoption of automation across various industries such as automotive, electronics, and manufacturing. The demand for high-precision components and the push towards Industry 4.0 are further propelling the market forward. Additionally, advancements in laser technology and the integration of IoT capabilities into sensors are opening new applications and enhancing sensor performance.

Furthermore, the growing trend towards smart factories and Industry 4.0 initiatives presents opportunities for laser displacement sensors. These sensors are integral components of intelligent manufacturing systems, enabling real-time monitoring, control, and optimization of production processes. By integrating laser displacement sensors with other automation technologies, manufacturers can achieve greater precision, productivity, and flexibility in their operations.

However, the laser displacement sensor market also faces challenges that need to be addressed. One challenge is the complexity of integrating and calibrating laser displacement sensors in different industrial environments. Ensuring accurate measurements and reliable performance requires expertise in sensor installation, alignment, and configuration, which can be a barrier for some users.

Another challenge is the cost of high-quality laser displacement sensors, especially for small and medium-sized enterprises. The initial investment and maintenance costs associated with advanced laser sensors may deter some businesses from adopting these technologies, limiting their widespread adoption in certain industries.

Accoridng to worldmetrics survey, it is evident from recent data that a significant majority of laser sensors utilized in automated machinery rely on 2D or 3D technology, comprising over 60% of usage. Furthermore, the United States holds a substantial share of the laser sensors market within North America, accounting for approximately 25%. This indicates a robust engagement with laser sensor technology in various industrial applications across the region.

Key Takeaways

- The market size for laser displacement sensors is projected to increase from USD 3,939.2 Million in 2023 to USD 8,504.4 Million by 2033. This represents a compound annual growth rate (CAGR) of 8.0% over the forecast period from 2024 to 2033.

- 100mm-300mm: In 2023, the 100mm-300mm range segment was the largest, commanding a significant market share of 48.9%.

- Above 300mm: The segment for sensors with ranges above 300mm also held a substantial market share, accounting for 31.9%.

- Automotive: The automotive industry emerged as the leading consumer of laser displacement sensors, holding a dominant share of 33.3% in 2023.

- Manufacturing: The manufacturing sector also accounted for a significant portion of the market, with a share of 23.9%.

- Asia-Pacific: Asia-Pacific led the regional markets with the highest share, capturing 38.7% and generating revenue of USD 1,524.4 million.

- North America: North America also maintained a strong market presence, securing 30.1% of the market share in 2023

Asia-Pacific Market Growth

In 2023, Asia-Pacific (APAC) held a dominant market position in the Laser Displacement Sensor Market, capturing more than a 38.7% share and generating USD 1,524.4 million in revenue. The region’s leadership can be attributed to several key factors.

The rapid industrialization and technological advancements in countries such as China, Japan, and South Korea have significantly driven the demand for laser displacement sensors in various applications, including automotive, electronics, and manufacturing sectors. These countries have seen substantial investments in automation and precision measurement technologies, further fueling market growth.

Moreover, the strong presence of major manufacturers in APAC, coupled with favorable government policies promoting industrial automation, has contributed to the region’s dominance. The increasing adoption of smart manufacturing practices and the rising demand for high-precision equipment in the electronics and semiconductor industries have also played a crucial role in the market’s expansion.

Additionally, the growing emphasis on quality control and inspection processes across various industries in APAC has heightened the need for advanced displacement sensors, boosting market demand. The availability of a skilled workforce and the relatively low production costs in APAC have attracted significant investments from global players, further reinforcing the region’s market position.

Type Analysis

In 2023, the 100mm-300mm segment held a dominant market position in the laser displacement sensor market, capturing more than a 48.9% share. This segment’s leadership can be attributed to its versatility and wide applicability across various industrial applications where precision is crucial but extreme long-range measurement is not necessary.

Sensors in this range are particularly suited for tasks in automotive assembly, where they can effectively measure the displacement and alignment of components with sufficient range to accommodate different assembly setups. Moreover, the 100mm-300mm range strikes a balance between short-range precision and long-range capabilities, making it ideal for use in electronics manufacturing and packaging industries.

These sensors provide the accuracy required for inspecting small and medium-sized components, a common requirement in the production of consumer electronics and other compact devices. Their ability to operate efficiently over a moderate range also ensures they can be adapted for a variety of manufacturing processes without the need for multiple sensor types, simplifying the automation infrastructure and reducing costs.

The popularity of this segment is further bolstered by the increasing push towards automation and data-driven quality control in manufacturing. As industries seek more advanced and reliable sensor technologies to improve production accuracy and reduce waste, the 100mm-300mm laser displacement sensors are well-positioned to meet these needs. Their ability to deliver precise measurements at a practical range makes them a favored choice among manufacturers aiming to enhance operational efficiency and product quality.

Meanwhile, the Above 300mm segment also holds a significant share of the market, accounting for 31.9%. This segment is primarily driven by industries that require large-scale measurements with less emphasis on extremely high precision but more focus on range, such as construction and heavy machinery. In these sectors, the ability to accurately measure larger distances is crucial for tasks such as site surveys, large equipment positioning, and structural assessments.

This segment benefits from the advancements in laser technology that have improved the range and durability of sensors, making them more adaptable to harsh environmental conditions typically found in outdoor or heavy industrial settings. As the global construction industry continues to expand and modernize, the demand for reliable and efficient large-range measurement solutions is anticipated to increase, further supporting the growth of the Above 300mm laser displacement sensor segment.

End-Use Industry

In 2023, the Automotive segment held a dominant market position within the laser displacement sensor industry, capturing more than a 33.3% share. This significant market share can be largely attributed to the automotive industry’s ongoing advancements in automation and precision manufacturing. Laser displacement sensors are essential for modern automotive production lines, where they ensure the accuracy of assembly processes, alignment of parts, and quality control across the manufacturing cycle.

The surge in the adoption of electric vehicles (EVs) and autonomous vehicles (AVs) has particularly amplified the need for these sensors. As manufacturers strive to meet stringent safety and performance standards, laser displacement sensors are increasingly used for critical measurements, such as chassis alignment, engine part fitting, and the precise installation of sensors and cameras in AVs. These applications underscore the vital role of laser displacement sensors in enhancing the reliability and efficiency of automotive production.

Additionally, the push towards Industry 4.0 within the automotive sector has led to the integration of smart sensors into manufacturing processes. These smart laser displacement sensors collect and analyze data in real-time, enabling predictive maintenance, process optimization, and enhanced automation. The ability of these sensors to adapt to various materials and complex geometries also makes them indispensable in automotive R&D, where precision is paramount.

Meanwhile, the Manufacturing segment also holds a substantial portion of the laser displacement sensor market, accounting for 23.9% in 2023. This significant market share is driven by the widespread application of these sensors in diverse manufacturing environments, where precision and efficiency are paramount. Laser displacement sensors are integral to automating quality control processes, monitoring production lines, and ensuring the accuracy of manufactured components.

In sectors such as metal fabrication, plastics, and consumer goods, laser displacement sensors play a critical role in measurements for material thickness, surface profile, and dimensional accuracy. Their ability to deliver precise and reliable data in real-time makes them invaluable for maintaining the high standards required in modern manufacturing. Additionally, these sensors facilitate the implementation of adaptive manufacturing techniques, where real-time adjustments are made to production processes based on the sensor data, enhancing overall productivity and reducing waste.

Key Market Segments

Type

- Above 300mm

- 100mm-300mm

- Below 100mm

End-Use Industry

- Manufacturing

- Automotive

- Electronics

- Aerospace & Defense

- Other End-Use Industries

Driver

Automation in Manufacturing

The primary driver for the growth of the laser displacement sensor market is the increasing automation across various industries, particularly in manufacturing. As industries strive for precision and efficiency, laser displacement sensors are crucial for non-contact measurement of dimensions and distances on production lines.

These sensors are integral in automating quality control processes, enhancing productivity, and reducing waste, thus driving their demand significantly. The ongoing trend towards Industry 4.0, which emphasizes digital technologies and smart manufacturing, further bolsters this demand as companies seek more intelligent and automated solutions.

Restraint

Supply Chain Disruptions

One major restraint affecting the laser displacement sensor market is the vulnerability of supply chains, exacerbated by global disruptions such as the COVID-19 pandemic. The reliance on specific components and raw materials, often sourced from different parts of the world, poses a significant challenge.

Disruptions can lead to production delays, increased costs, and reduced market responsiveness. Moreover, stringent government regulations related to manufacturing and exports further complicate the supply chain dynamics, impacting the timely availability of sensors and their components.

Opportunity

Expansion into New Markets

Emerging markets present a significant opportunity for the expansion of the Laser Displacement Sensor market. As countries in regions such as Asia-Pacific and Latin America continue to industrialize, the demand for advanced manufacturing technologies is expected to rise.

These regions offer a vast customer base and substantial scope for growth, especially in sectors like automotive, consumer electronics, and construction. Establishing a presence in these markets could be strategically beneficial for laser displacement sensor manufacturers, as they could leverage lower operational costs and increase their global market penetration

Challenge

Technological Adaptation and Integration

A significant challenge in the laser displacement sensor market is the need for continuous technological advancement and integration compatibility. As industries evolve and new technologies emerge, sensors must adapt to operate efficiently within increasingly complex and automated systems.

The rapid pace of technological change requires ongoing research and development to ensure that laser displacement sensors can seamlessly integrate with new manufacturing technologies and IoT devices. This necessity for constant innovation demands substantial investment and poses a challenge for companies aiming to maintain competitive in a swiftly advancing market.

Growth Factors

The laser displacement sensor market is primarily driven by the increasing demand for automation across various sectors, including automotive, electronics, and manufacturing. This trend is reinforced by the ongoing shift towards Industry 4.0, which emphasizes the integration of digital technologies into industrial operations, enhancing both efficiency and precision in processes.

Additionally, the versatility and cost-efficiency of laser displacement sensors, which allow for accurate measurements in diverse applications, are key contributors to market growth. These sensors are pivotal in applications requiring high precision, such as positioning and quality control, which further stimulates their demand.

Emerging Trends

Emerging trends in the laser displacement sensor market include the growing adoption of these sensors in consumer electronics and smart manufacturing settings. The miniaturization of electronic components and the increasing complexity of designs in consumer electronics have elevated the need for precise measurement solutions, thus pushing the demand for laser displacement sensors.

Another significant trend is the integration of IoT capabilities into these sensors, allowing for real-time data collection and analysis, which is crucial for predictive maintenance and process optimization. Additionally, advancements in sensor technology, such as improvements in laser beam quality and data processing capabilities, are enabling more precise and reliable measurements across various industrial applications.

Regional Analysis

In 2023, Asia-Pacific (APAC) held a dominant market position in the Laser Displacement Sensor Market, capturing more than 38.7% of the global share. This significant lead can be attributed to the region’s robust manufacturing sector, particularly in countries like China, Japan, and South Korea, which are key players in electronics and automotive production.

North America accounted for a substantial 30.1% of the market share, driven by the region’s advanced industrial infrastructure and strong presence in the aerospace and defense sectors. The increasing focus on quality control and manufacturing accuracy in the United States and Canada also contributes to the region’s market growth.

Europe held a market share of 22.9%, with Germany, France, and the United Kingdom leading in automotive and industrial automation. The emphasis on Industry 4.0 and the integration of advanced measurement technologies in manufacturing processes are key factors driving the adoption of laser displacement sensors in this region.

Latin America captured 5.8% of the market, with growing industrialization and investments in manufacturing sectors in countries like Brazil and Mexico. The demand for precision measurement in these emerging economies is expected to grow steadily.

Finally, the Middle East & Africa accounted for 2.5% of the global market share. While the adoption of laser displacement sensors is still in its nascent stages in this region, the ongoing development of infrastructure and the gradual shift towards automation in industries such as oil and gas, and construction, are expected to create growth opportunities in the coming years.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Key Players Analysis

The Laser Displacement Sensor Market is distinguished by the participation of several leading companies that play crucial roles in shaping the industry’s landscape. Micro-Epsilon Messtechnik GmbH & Co. KG and OPTEX GROUP CO., LTD are renowned for their precision and innovation in sensor technology.

AMETEK Inc., a giant in electronic instruments and electromechanical devices, significantly contributes to technological advancements in this field. Cognex Corporation and Banner Engineering Corp. are pivotal in integrating intelligent sensing technologies that enhance automation capabilities across various industries.

Additionally, Schmitt Industries Inc. emphasizes the development of sensors that offer high accuracy and reliability, while Panasonic Corporation and Keyence Corporation are pivotal in driving growth through their robust research and development efforts.

Honeywell International Inc. is recognized for its durable and efficient sensors suited for harsh industrial environments. Delta Electronics Inc. and Omron Corporation are at the forefront of incorporating energy-efficient and highly scalable sensor solutions.

Top Market Leaders

- Micro-Epsilon Messtechnik GmbH & Co. KG

- OPTEX GROUP CO. LTD

- AMETEK Inc.

- Cognex Corporation

- Banner Engineering Corp.

- Schmitt Industries Inc.

- Panasonic Corporation

- Keyence Corporation

- Honeywell International Inc.

- Delta Electronics Inc.

- Omron Corporation

- SICK AG

Recent Developments

- In January 2023, OPTEX launched a new line of high-precision laser displacement sensors aimed at industrial automation applications.

- Cognex introduced a new generation of its laser displacement sensors in June 2023, focusing on improved accuracy and faster data processing for industrial applications.

- Banner Engineering launched a new series of laser displacement sensors with enhanced sensitivity and longer range capabilities in April 2023.

- Schmitt Industries updated its laser displacement sensor product line in July 2023, adding features for better integration with automated systems.

- Panasonic released its latest laser displacement sensor models in February 2023, targeting automotive and electronics manufacturing sectors.

Report Scope

Report Features Description Market Value (2023) USD 3,939.2 Mn Forecast Revenue (2033) USD 8,504.4 Mn CAGR (2024-2033) 8.0% Base Year for Estimation 2023 Historic Period 2018-2022 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Type (Above 300mm, 100mm-300mm, Below 100mm), End-Use Industry (Manufacturing, Automotive, Electronics, Aerospace & Defense, Other End-Use Industries) Regional Analysis North America – The U.S. & Canada; Europe – Germany, France, The UK, Spain, Italy, Russia, Netherlands & Rest of Europe; APAC- China, Japan, South Korea, India, Australia, New Zealand, Singapore, Thailand, Vietnam & Rest of APAC; Latin America- Brazil, Mexico & Rest of Latin America; Middle East & Africa- South Africa, Saudi Arabia, UAE & Rest of MEA Competitive Landscape Micro-Epsilon Messtechnik GmbH & Co. KG, OPTEX GROUP CO. LTD, AMETEK Inc., Cognex Corporation, Banner Engineering Corp., Schmitt Industries Inc., Panasonic Corporation, Keyence Corporation, Honeywell International Inc., Delta Electronics Inc., Omron Corporation, SICK AG Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) Frequently Asked Questions (FAQ)

What is a laser displacement sensor?A laser displacement sensor is a non-contact measurement device that uses laser technology to accurately determine the distance between the sensor and the target object. It is widely used in industrial automation, robotics, and quality control applications.

How big is Laser Displacement Sensor Market?The Global Laser Displacement Sensor Market size is expected to be worth around USD 8.7 Billion by 2033, from USD 4.0 Billion in 2023, growing at a CAGR of 8.1% during the forecast period from 2024 to 2033.

What are the primary advantages of laser displacement sensors?Laser displacement sensors offer high accuracy, fast measurement speeds, non-contact operation, immunity to environmental conditions such as dust and ambient light, and versatility for measuring various surfaces and materials.

Who are the key players in the Laser Displacement Sensor Market?Some key players operating in the Laser Displacement Sensor Market include Delta Electronics Inc., Panasonic Corporation, Sick AG, Omron Corporation, Keyence Corporation, LMI Technologies Inc., Micro-Epsilon Messtechnik GmbH & Co. KG, Cognex Corporation, MTI Instruments Inc., Banner Engineering Corp., Zygo Corporation, Other Key Players

What factors are driving the growth of the laser displacement sensor market?The increasing adoption of automation in manufacturing, demand for precision measurement in industries such as automotive, electronics, and aerospace, and advancements in sensor technology are driving the growth of the laser displacement sensor market.

What are the challenges facing the laser displacement sensor market?Challenges include cost constraints for high-end sensors, complexity in integrating sensors into existing systems, limitations in measuring certain materials or surfaces, and competition from alternative technologies.

Laser Displacement Sensor MarketPublished date: August 2024add_shopping_cartBuy Now get_appDownload Sample

Laser Displacement Sensor MarketPublished date: August 2024add_shopping_cartBuy Now get_appDownload Sample -

-

- Micro-Epsilon Messtechnik GmbH & Co. KG

- OPTEX GROUP CO. LTD

- AMETEK Inc.

- Cognex Corporation

- Banner Engineering Corp.

- Schmitt Industries Inc.

- Panasonic Corporation

- Keyence Corporation

- Honeywell International Inc.

- Delta Electronics Inc.

- Omron Corporation

- SICK AG