Global Sleeves Market Size, Share, And Enhanced Productivity By Product Type (Insulating Sleeves, Exothermic Sleeves (Slurry Sleeves, High-density Sleeves)), By Application (Steel Casting, Aluminum Casting, Cast Iron, SG Iron, Brass and Bronze, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: February 2026

- Report ID: 177015

- Number of Pages: 326

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

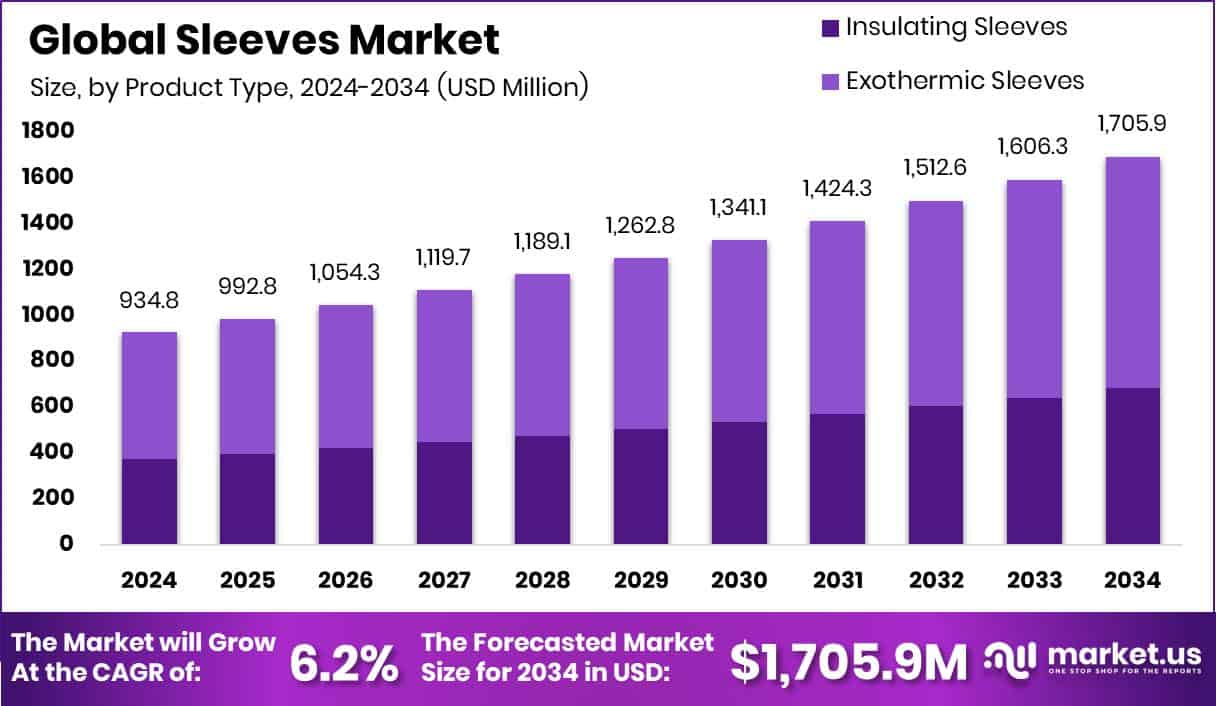

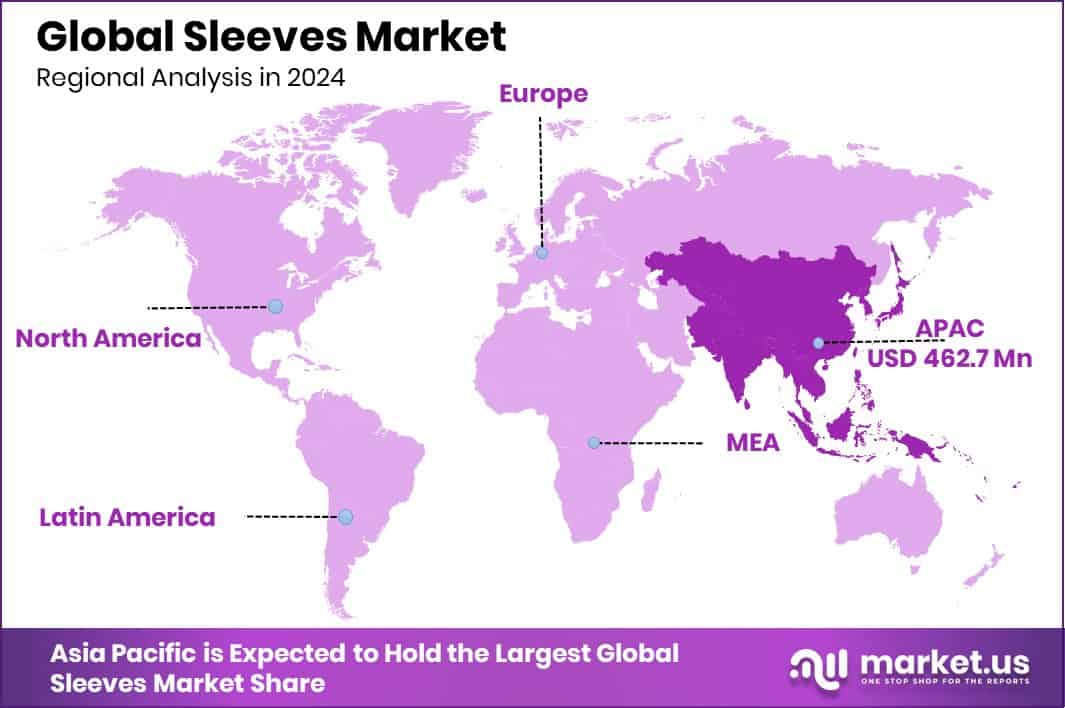

The Global Sleeves Market is expected to be worth around USD 1,705.9 million by 2034, up from USD 934.8 million in 2024, and is projected to grow at a CAGR of 6.2% from 2025 to 2034. Growing foundry demand pushed Asia Pacific to 49.5% and USD 462.7 Mn.

The Sleeves Market centers on specialized components used in metal casting to control solidification and improve feeding efficiency. Sleeves are refractory or insulating materials placed around risers to retain heat, reduce heat loss, and ensure defect-free castings. They help maintain molten metal temperature longer, supporting proper directional solidification in steel, aluminum, cast iron, SG iron, brass, and bronze applications. The Sleeves Market includes several product types such as insulating sleeves, exothermic sleeves, slurry sleeves, and high-density sleeves, each designed to optimize casting performance for different alloys and casting environments.

Growth in this market is supported by rising casting output and increasing focus on manufacturing quality. The aluminum segment, in particular, is seeing significant development. Strong industry commitments, such as the U.S. aluminum sector investing over $10+ billion and AFS receiving $4 million for aluminum casting performance research, indicate growing momentum that indirectly strengthens demand for sleeves used in aluminum casting processes.

Demand continues to rise as lightweighting, high-performance alloys, and efficiency-driven manufacturing expand globally. Funding initiatives such as Alloy Enterprises, raising $26 million, along with an additional $4.3 million, highlight rapid movement toward advanced aluminum manufacturing, where controlled feeding systems remain essential.

Opportunities also emerge through recycling and sustainability trends. Companies like Sortera, scaling aluminum recycling systems with $45 million in funding, and Golden Aluminum advancing its Nexcast project with $22 million, suggest long-term growth potential. As aluminum and specialty alloys gain prominence, the need for reliable sleeve systems continues to strengthen across diverse casting applications.

Key Takeaways

- The Global Sleeves Market is expected to be worth around USD 1,705.9 million by 2034, up from USD 934.8 million in 2024, and is projected to grow at a CAGR of 6.2% from 2025 to 2034.

- Exothermic Sleeves dominate the Sleeves Market with a strong 59.2% share globally in 2025.

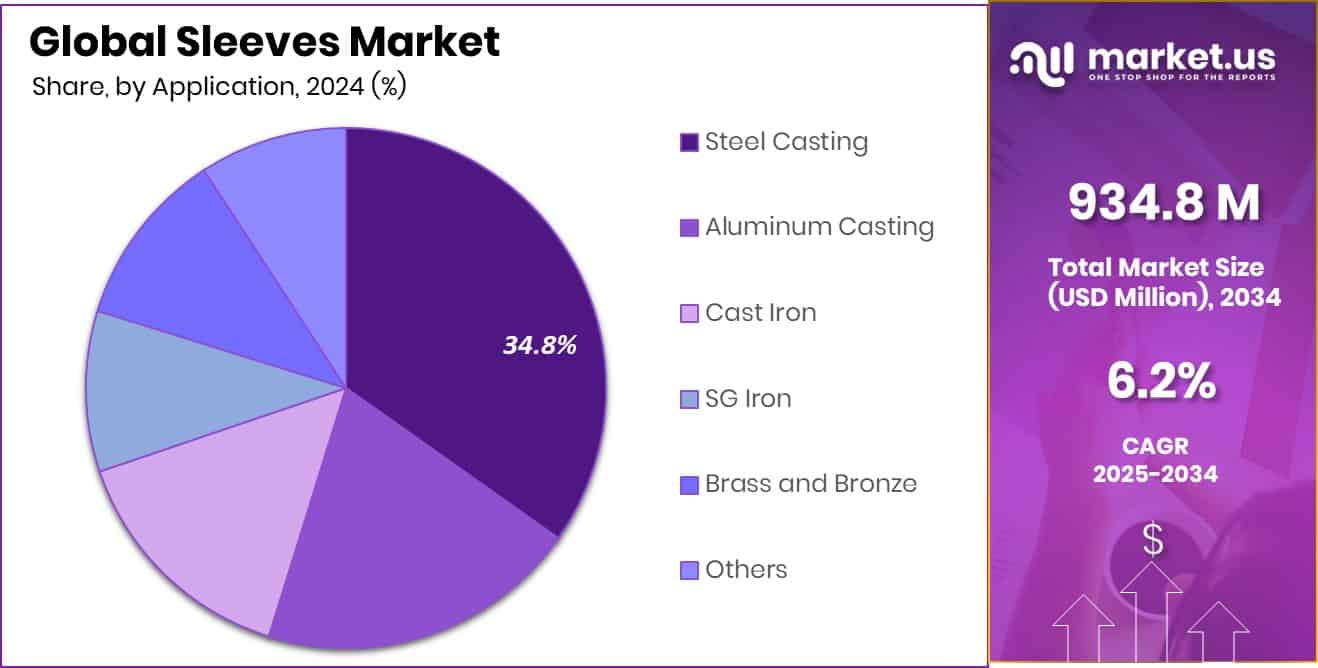

- Steel Casting applications significantly influence the Sleeves Market, contributing a notable 34.8% overall demand share.

- Strong manufacturing expansion helped the Asia Pacific maintain 49.5%, valued at USD 462.7 Mn.

By Product Type Analysis

The Sleeves Market grows as exothermic sleeves achieve a strong 59.2% share.

In 2024, the Sleeves Market saw Exothermic Sleeves secure a dominant position with a strong 59.2% share, reflecting their widespread adoption across foundries seeking better efficiency and reduced metal wastage. These sleeves enhance feeding efficiency by generating additional heat, ensuring superior directional solidification during casting. Their consistent performance, compatibility with different alloys, and ability to minimize shrinkage defects make them a preferred choice for large-scale industrial applications.

As foundries continue to modernize operations, exothermic variants are increasingly valued for their role in improving casting yield and reducing rework rates. Continuous innovations in insulating materials and sustainability-driven research further support their growing demand, strengthening their foothold within the global Sleeves Market.

By Application Analysis

Steel casting leads the Sleeves Market with a notable 34.8% contribution.

In 2024, Steel Casting emerged as a leading application segment in the Sleeves Market, capturing 34.8% of total demand. Manufacturers increasingly rely on sleeves to ensure optimal feeding performance, reduce porosity, and maintain high structural integrity in steel components. With steel castings used extensively across heavy machinery, automotive systems, construction equipment, and energy infrastructure, the need for reliable feeding aids has intensified.

Sleeves play a crucial role in achieving consistent quality in thick-section and high-temperature steel molds, supporting efficiency while lowering production defects. Their ability to handle thermal stress and maintain dimensional accuracy has strengthened adoption across global steel foundries. As industries expand capacity, sleeve consumption in steel casting continues to rise steadily.

Key Market Segments

By Product Type

- Insulating Sleeves

- Exothermic Sleeves

- Slurry Sleeves

- High-density Sleeves

By Application

- Steel Casting

- Aluminum Casting

- Cast Iron

- SG Iron

- Brass and Bronze

- Others

Driving Factors

Rising demand for high-quality metal castings

The Sleeves Market continues to grow as the demand for high-quality metal castings increases across industries seeking better accuracy and fewer defects. This demand is further supported by advancements in digital and rapid casting technologies. Magnus Metal raising $74 million in funding highlights how modern digital casting platforms are gaining traction and influencing upstream components like sleeves.

Similarly, Foundry Lab securing $8 million to produce metal castings using microwave-based methods reflects the push toward faster and more efficient foundry workflows. As casting operations expand and adopt innovative production methods, the need for reliable insulating and exothermic sleeves grows, making these advancements an important driver for the market’s long-term development.

Restraining Factors

High material costs limit broader adoption

Despite market growth, high material costs continue to limit broader adoption of advanced sleeves, especially among small and mid-scale foundries. Rising costs affect procurement decisions and often delay modernization plans. External investments in other manufacturing areas, such as the state contributing $10 million for the redevelopment of a central Pennsylvania manufacturing plant, can shift budget priorities away from casting materials.

Additionally, major funding like CN – ROX Motor securing $1 billion in strategic investment from Weiqiao Pioneering draws financial attention toward alternative manufacturing technologies. These factors collectively create pressure on foundries managing tight budgets, thereby slowing wider sleeve adoption.

Growth Opportunity

Expanding aluminum casting projects boost demand

Opportunities in the Sleeves Market are expanding as aluminum casting projects grow worldwide, supported by strong interest in lightweight components. Increasing global investment is also reshaping casting technologies, creating a positive environment for sleeve demand.

For example, Magnus Metal’s $74 million Series B funding to digitize metal casting demonstrates how modern digital processes require precise feeding systems, strengthening the need for high-performance sleeves. Similarly, Israel’s Magnus Metal securing another $74 million for its digital casting process shows the industry’s shift toward accuracy, automation, and reduced waste. As aluminum and advanced metal casting projects scale, sleeves gain greater relevance in supporting these evolving production methods.

Latest Trends

Rising use of sustainable sleeve material

Sustainable materials are becoming a central trend in the Sleeves Market as industries look for eco-friendly and thermally stable solutions. The market is increasingly shaped by innovations targeting reduced waste, improved feeding efficiency, and lower environmental impact. This shift aligns with broader technological changes, as seen in reports that Magnus Metal aims to revamp the 4,000-year-old method of making metal parts through digital casting.

Such modernization efforts heighten interest in optimized sleeve materials that can handle new temperatures, alloy types, and production speeds. With sustainability and modernization progressing together, sleeves designed with greener and more efficient formulations are gaining stronger market relevance.

Regional Analysis

Asia Pacific led the Sleeves Market with 49.5%, reaching USD 462.7 Mn revenue.

Asia Pacific dominated the global Sleeves Market with a 49.5% share, valued at USD 462.7 Mn, supported by strong foundry activity and the region’s high-volume steel and metal casting production. North America showed stable demand driven by industrial applications and steady casting output, with manufacturers focusing on enhancing casting quality for automotive and heavy machinery sectors.

Europe maintained a consistent market contribution supported by established metal processing industries and adherence to stringent casting quality standards. The Middle East & Africa region reflected moderate growth, influenced by ongoing industrial development and increasing adoption of sleeves in steel casting operations. Latin America continued to grow gradually as regional foundries expanded production capacities and strengthened sleeve usage to improve casting efficiency.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

INEXO Cast Metal Solutions Pvt. Ltd. continued strengthening its presence by focusing on engineered feeding solutions designed to improve casting quality and reduce defects. Its emphasis on product consistency and customer-centric customization positioned the company as a dependable supplier for foundries aiming to enhance yield and operational reliability.

Meanwhile, Cangzhou Sefu Ceramic New Materials Co., Ltd. contributed to market growth through its expanding portfolio of ceramic-based sleeves and related casting auxiliaries. The company’s capability to cater to varied alloy requirements made it a preferred choice for foundries seeking durability and thermal efficiency in sleeve applications. Its manufacturing strength supported wider regional adoption, particularly among small- and mid-scale casting units.

ASK Chemicals maintained a strong industry influence through continuous development of high-performance exothermic and insulating sleeve technologies. The company’s focus on process optimization and defect reduction aligned well with global casting trends. Its established technical expertise and diversified product range reinforced its position as a key enabler of efficiency and quality within the Sleeves Market.

Top Key Players in the Market

- INEXO Cast Metal Solutions Pvt. Ltd.

- Cangzhou Sefu Ceramic New Materials Co., Ltd.

- ASK Chemicals

- Vesuvius plc

- INTOCAST AG

- Shengquan Group

- Freeman (Japan) Co., Ltd.

- TOCHU Corporation

- Kore Mart Limited

- KITANI Corporation

Recent Developments

- In February 2025, Vesuvius completed the acquisition of PiroMET, a refractory and robotics business based in Turkey. This move expands Vesuvius’s capabilities in refractory technologies, supporting its role in high-temperature casting and metal flow applications. The acquisition strengthens Vesuvius’s position in the strategic EEMEA (Europe, Middle East & Africa) region.

- In January 2024, ASK Chemicals unveiled ECOCAST ONE, a new feeding solution, at the International Foundry Exhibition in India. This product aims to improve metal feeding performance and can help foundries reduce casting defects. The company showcased other foundry-related innovations from its Ranjangaon site in Pune, including binders and coating technologies for steel and iron casting.

Report Scope

Report Features Description Market Value (2024) USD 934.8 Million Forecast Revenue (2034) USD 1,705.9 Million CAGR (2025-2034) 6.2% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product Type (Insulating Sleeves, Exothermic Sleeves (Slurry Sleeves, High-density Sleeves)), By Application (Steel Casting, Aluminum Casting, Cast Iron, SG Iron, Brass and Bronze, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – GCC, South Africa, Rest of MEA Competitive Landscape INEXO Cast Metal Solutions Pvt. Ltd., Cangzhou Sefu Ceramic New Materials Co., Ltd., ASK Chemicals, Vesuvius plc, INTOCAST AG, Shengquan Group, Freeman (Japan) Co., Ltd., TOCHU Corporation, Kore Mart Limited, KITANI Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- INEXO Cast Metal Solutions Pvt. Ltd.

- Cangzhou Sefu Ceramic New Materials Co., Ltd.

- ASK Chemicals

- Vesuvius plc

- INTOCAST AG

- Shengquan Group

- Freeman (Japan) Co., Ltd.

- TOCHU Corporation

- Kore Mart Limited

- KITANI Corporation