Global Fumed Silica Market Size, Share Analysis Report By Type (Hydrophilic, Hydrophobic), By Production Process (Flame Hydrolysis, Plasma/Arc Vapor Oxidation), By Function (Rheology Control/Thickening, Anti-settling/Anti-caking, Reinforcement/Filler), By Application (Silicone Elastomers, Paints, Coatings and Inks, Adhesives and Sealants, UPR and Composites, Others), By End-use (Building and Construction, Electrical and Electronics, Automotive and Transportation, Personal Care and Beauty, Food and Beverages, Pharmaceuticals, Others) , By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: Oct 2025

- Report ID: 161391

- Number of Pages: 298

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

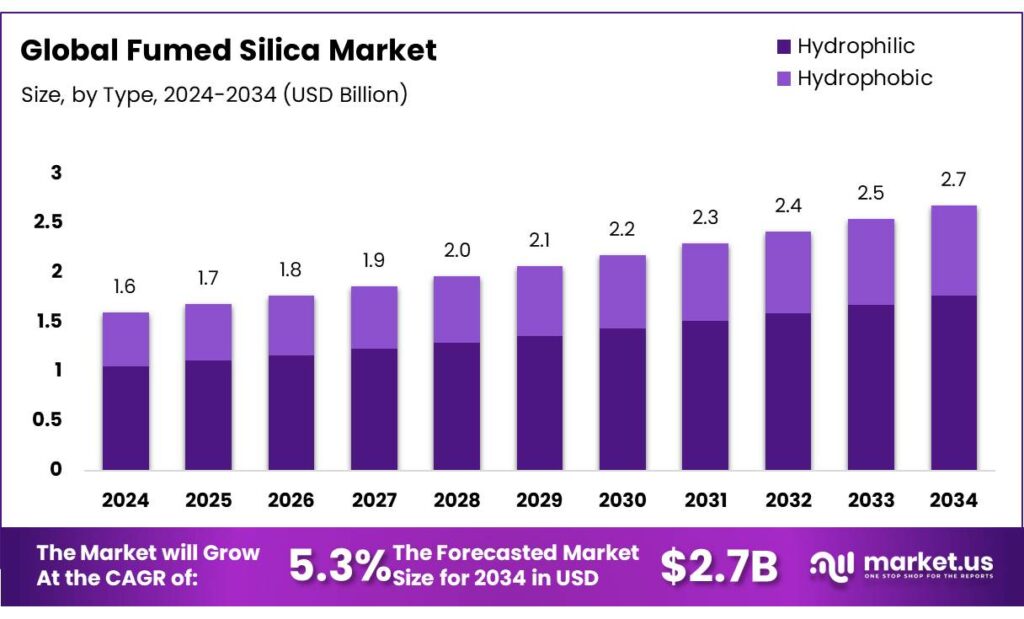

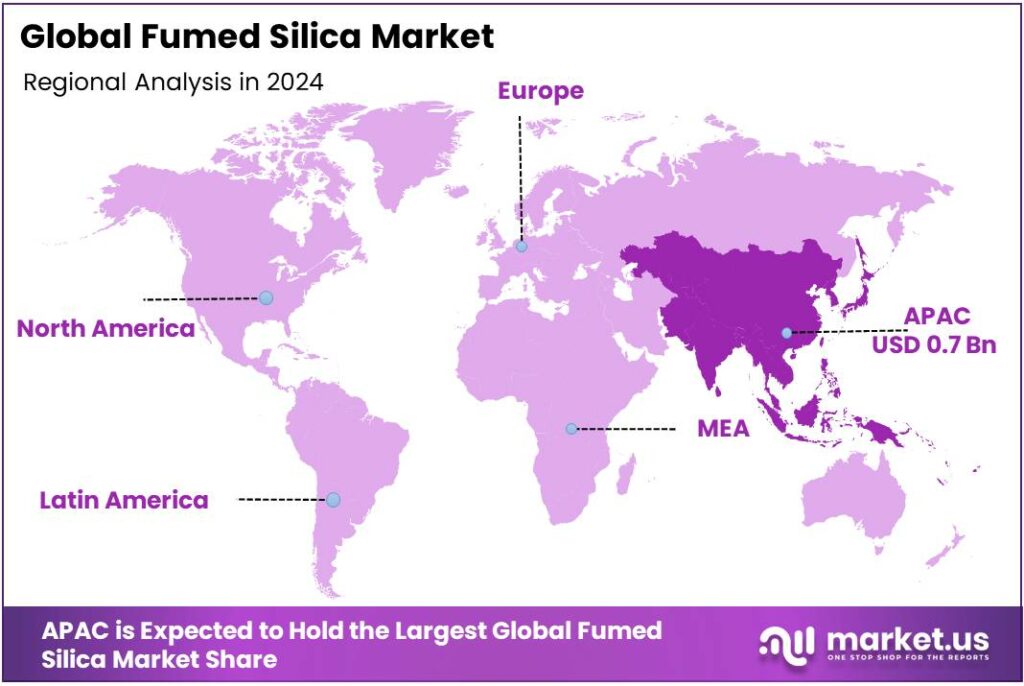

The Global Fumed Silica Market size is expected to be worth around USD 2.7 Billion by 2034, from USD 1.6 Billion in 2024, growing at a CAGR of 5.3% during the forecast period from 2025 to 2034. In 2024 Asia Pacific held a dominant market position, capturing more than a 46.8% share, holding USD 0.7 Billion in revenue.

Fumed silica, also known as pyrogenic silica, is a high-purity, amorphous form of silicon dioxide produced through the flame hydrolysis of silicon tetrachloride or quartz. Its unique structure—comprising submicron-sized spherical particles that agglomerate into branched chains—imparts exceptional properties such as high surface area, low bulk density, and thixotropic behavior. These characteristics make fumed silica an indispensable additive across various industries, including paints and coatings, pharmaceuticals, cosmetics, adhesives, sealants, and food processing.

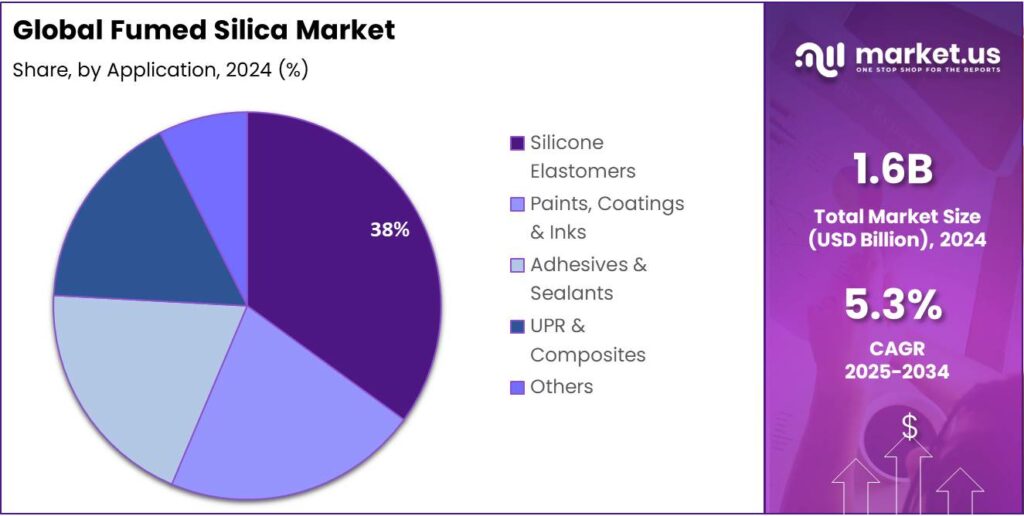

The industrial scenario for fumed silica is marked by robust demand across various applications. In 2024, the adhesives and sealants segment accounted for 29% of the market share, driven by their essential role in construction and automotive industries. The paints and coatings sector also exhibits significant growth, with fumed silica enhancing the rheological properties of coatings, thereby improving performance and application ease

Driving factors for short- to medium-term growth have been identified as the rising need for high-performance coatings and lightweight composites, expansion of personal-care formulations that require flow control, and increased pharmaceutical production that deploys fumed silica as an excipient and flow aid. The market has also been supported by innovations in hydrophobic surface treatments of fumed silica that enable new functional coatings and sealants. Reported production/demand volumes reached approximately 285 thousand tonnes in 2024 according to one industry analysis, which underlines the commodity-scale yet specialty character of the product.

Government initiatives are also contributing to market growth. For instance, in 2023, the U.S. government allocated USD 100 million under the Advanced Manufacturing Initiative to support the development of advanced materials, including fumed silica. This initiative aims to enhance domestic production capabilities and reduce dependency on imports, promoting innovation and competitiveness in the market. Similarly, the Infrastructure Investment and Jobs Act, signed into law in 2021, is expected to inject USD 1 trillion into infrastructure projects, significantly driving the demand for construction materials, including those utilizing fumed silica.

Key Takeaways

- Fumed Silica Market size is expected to be worth around USD 2.7 Billion by 2034, from USD 1.6 Billion in 2024, growing at a CAGR of 5.3%.

- Hydrophilic held a dominant market position, capturing more than a 65.9% share of the global fumed silica market.

- Flame Hydrolysis held a dominant market position, capturing more than an 89.5% share of the fumed silica.

- Rheology Control/Thickening held a dominant market position, capturing more than a 46.8% share of the fumed silica market.

- Silicone Elastomers held a dominant market position, capturing more than a 37.7% share of the fumed silica.

- Building & Construction held a dominant market position, capturing more than a 32.3% share of the fumed silica.

- Asia Pacific region held a dominant position in the global fumed silica market, capturing more than a 46.8% share, valued at approximately USD 0.7 billion.

By Type Analysis

Hydrophilic Fumed Silica dominates with 65.9% share in 2024

In 2024, Hydrophilic held a dominant market position, capturing more than a 65.9% share of the global fumed silica market. This strong presence can be attributed to its excellent dispersion properties, high surface area, and ability to improve the viscosity and stability of various industrial formulations. Hydrophilic fumed silica is extensively used in coatings, adhesives, sealants, and rubber products, where uniform distribution and thixotropic behavior are essential for product performance.

Manufacturers increasingly preferred hydrophilic variants due to their compatibility with water-based systems, making them ideal for environmentally friendly and low-VOC applications. Looking ahead into 2025, the demand for hydrophilic fumed silica is expected to remain robust, supported by growing industrial production and rising adoption in automotive and construction sectors, ensuring its continued dominance in the market.

By Production Process Analysis

Flame Hydrolysis leads with 89.5% share in 2024

In 2024, Flame Hydrolysis held a dominant market position, capturing more than an 89.5% share of the fumed silica production segment. This method has become the preferred choice due to its ability to produce high-purity, fine, and uniform particles, which are critical for industrial applications requiring precise performance. The process ensures superior surface area and excellent dispersibility, making it highly suitable for use in coatings, adhesives, sealants, and rubber reinforcement.

Manufacturers favored flame hydrolysis for its consistency and scalability, which support large-volume production while maintaining product quality. Looking into 2025, the reliance on flame hydrolysis is expected to continue, driven by increasing industrial demand and the ongoing need for high-performance fumed silica across various sectors, securing its position as the leading production method.

By Function Analysis

Rheology Control/Thickening dominates with 46.8% share in 2024

In 2024, Rheology Control/Thickening held a dominant market position, capturing more than a 46.8% share of the fumed silica market. This function is highly valued for its ability to regulate viscosity and improve the flow properties of liquids and pastes, making it essential in coatings, adhesives, sealants, and personal care products.

Manufacturers increasingly relied on fumed silica for rheology control due to its efficiency in preventing settling, sagging, and phase separation, ensuring product stability and consistent performance. In 2025, the demand for fumed silica in rheology control applications is expected to maintain a steady growth, supported by expanding industrial production and rising adoption in water-based formulations, highlighting its continued importance as a key functional segment.

By Application Analysis

Silicone Elastomers lead with 37.7% share in 2024

In 2024, Silicone Elastomers held a dominant market position, capturing more than a 37.7% share of the fumed silica applications segment. This strong adoption is driven by the material’s exceptional reinforcement properties, which enhance mechanical strength, flexibility, and thermal stability in silicone-based products. Fumed silica is widely incorporated into elastomers used in automotive components, electrical insulation, and industrial seals, where durability and consistent performance are critical.

Manufacturers favored fumed silica for its ability to improve tensile strength and resistance to wear and tear, ensuring longer-lasting and high-quality end products. Moving into 2025, the use of fumed silica in silicone elastomers is expected to grow steadily, supported by expanding demand in industrial, automotive, and construction sectors, cementing its position as a leading application segment.

By End-use Analysis

Building & Construction leads with 32.3% share in 2024

In 2024, Building & Construction held a dominant market position, capturing more than a 32.3% share of the fumed silica end-use segment. This significant share is driven by the material’s ability to enhance the performance of cement, concrete, and coatings, providing improved strength, durability, and resistance to shrinkage and cracking. Fumed silica is increasingly used in high-performance building materials, such as self-leveling floors, grouts, and waterproofing solutions, where consistency and long-term stability are essential.

Throughout the year, manufacturers in the construction sector relied on fumed silica to meet the rising standards for sustainable and resilient structures. Looking ahead to 2025, demand from the building and construction industry is expected to continue growing steadily, supported by ongoing infrastructure development and urban expansion, ensuring fumed silica remains a key material in this sector.

Key Market Segments

By Type

- Hydrophilic

- Hydrophobic

By Production Process

- Flame Hydrolysis

- Plasma/Arc Vapor Oxidation

By Function

- Rheology Control/Thickening

- Anti-settling/Anti-caking

- Reinforcement/Filler

By Application

- Silicone Elastomers

- Paints, Coatings & Inks

- Adhesives & Sealants

- UPR & Composites

- Others

By End-use

- Building & Construction

- Electrical & Electronics

- Automotive & Transportation

- Personal Care & Beauty

- Food & Beverages

- Pharmaceuticals

- Others

Emerging Trends

Growing Demand for Clean-Label Food Additives

The increasing consumer preference for natural and transparent ingredients in food products is driving the demand for clean-label additives. Fumed silica, recognized as E551, is gaining traction in this segment due to its natural origin and multifunctional properties. Derived from silicon dioxide, fumed silica is a naturally occurring compound found in sand, quartz, and other minerals. Its use in food products aligns with the clean-label trend, as it is a simple, recognizable ingredient that meets consumer expectations for transparency and naturalness.

Regulatory bodies have recognized the safety of fumed silica as a food additive. The European Food Safety Authority (EFSA) has concluded that silicon dioxide (E551) is safe for use in food products within the established limits. This regulatory approval further supports the adoption of fumed silica in clean-label food products, as manufacturers seek ingredients that are both functional and compliant with food safety standards.

Drivers

Enhancing Food Quality and Safety with Fumed Silica

Fumed silica, recognized as food additive E551, plays a pivotal role in the food industry by ensuring the quality and safety of powdered products. Its primary function is as an anti-caking agent, preventing the formation of lumps and ensuring the free-flowing nature of powders. This is particularly crucial in products like powdered milk, spices, and drink mixes, where moisture absorption can lead to clumping and spoilage. By coating the surface of powder particles, fumed silica reduces interparticle interactions and absorbs moisture, fats, and oils, thereby preventing caking and lumping.

Regulatory bodies such as the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) have recognized the safety of fumed silica as a food additive. According to EFSA, silicon dioxide (E551) is considered safe when used in accordance with good manufacturing practices. This endorsement has facilitated its widespread adoption in the food industry.

In addition to its anti-caking properties, fumed silica contributes to the texture and stability of food products. It is used in the formulation of food-grade thickeners and stabilizers, enhancing the mouthfeel and consistency of products like sauces and dressings. Furthermore, its ability to absorb moisture extends the shelf life of products, reducing waste and improving food security.

Restraints

Regulatory Scrutiny and Emerging Health Concerns

While fumed silica (E 551) is widely recognized for its role as an anti-caking agent in the food industry, recent studies have prompted a closer examination of its safety, particularly concerning its nanoparticle form. The European Food Safety Authority (EFSA) has acknowledged uncertainties regarding the characterization of E 551 particles, noting that some may fall within the nano range (less than 100 nm). This raises questions about their potential to penetrate biological barriers and accumulate in tissues, which could pose health risks.

A study published in Environmental Health Perspectives highlighted that chronic exposure to nano-sized E 551 particles might impair the intestinal immune system, potentially increasing the risk of developing celiac disease in genetically predisposed individuals. The research indicated that prolonged exposure led to heightened intestinal inflammation and reduced tolerance to dietary proteins in mice, suggesting that similar effects could occur in humans.

Despite these findings, EFSA has concluded that E 551 does not raise safety concerns for any population group at current usage levels. However, the authority has recommended lowering the maximum limits for lead, mercury, and arsenic in E 551 and setting a maximum limit for aluminum to mitigate potential exposure to toxic elements.

For consumers, especially those with sensitivities or autoimmune conditions, it may be prudent to limit the intake of processed foods containing E 551. Opting for fresh, whole foods and checking ingredient labels can help reduce exposure to this additive.

Opportunity

Expanding Applications of Fumed Silica in Food Products

Fumed silica, known as E551, is a versatile food additive primarily used as an anti-caking agent in powdered and granular foods. Its ability to prevent clumping and improve flowability has made it indispensable in products like powdered milk, spices, instant soups, and drink mixes. As global food consumption patterns evolve, particularly with the increasing demand for convenience foods, the role of fumed silica is expanding beyond traditional applications.

In the European Union, the European Food Safety Authority (EFSA) has re-evaluated the safety of silicon dioxide (E551) as a food additive. The EFSA concluded that E551 does not raise safety concerns for any population group at the reported uses and use levels, including infants under 16 weeks of age. This regulatory approval has facilitated the broader adoption of fumed silica in various food applications.

Furthermore, the increasing emphasis on food quality and safety is prompting manufacturers to explore innovative uses of fumed silica. For instance, its application in food supplements is expanding, as it serves as an effective carrier and anti-caking agent in powdered formulations. The versatility of fumed silica allows it to be utilized in a wide range of food products, enhancing their stability and shelf life.

As consumer preferences shift towards more convenient and long-lasting food options, the demand for additives like fumed silica is expected to rise. Its proven safety profile, coupled with its functional benefits, positions fumed silica as a key ingredient in the development of innovative food products. Manufacturers are increasingly recognizing the value of fumed silica in meeting consumer demands for quality, convenience, and safety in food products.

Regional Insights

Asia Pacific leads with 46.8% share in 2024

In 2024, the Asia Pacific region held a dominant position in the global fumed silica market, capturing more than a 46.8% share, valued at approximately USD 0.7 billion. This substantial market presence is attributed to the region’s rapid industrialization, robust manufacturing capabilities, and increasing demand across various end-use sectors, including construction, electronics, and automotive industries.

China emerged as the largest consumer of fumed silica within the region, accounting for a significant portion of the market share. The country’s expansive industrial base, coupled with substantial investments in infrastructure development, has driven the demand for high-performance materials such as fumed silica. Additionally, China’s emphasis on technological advancements and self-reliance in semiconductor manufacturing has further bolstered the need for fumed silica in electronic packaging applications.

Key Regions and Countries Insights

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

Cabot Corporation is a leading manufacturer of fumed silica, serving industries such as automotive, paints and coatings, and personal care. The company emphasizes high-performance solutions with enhanced dispersibility, surface area, and purity. In 2024, Cabot maintained its competitive edge by investing in research and development to introduce specialized grades of fumed silica tailored for advanced applications. Its global distribution network and focus on sustainability have helped it capture significant market share while meeting increasing demand in Asia, North America, and Europe.

Evonik Industries AG is a global leader in specialty chemicals, including fumed silica, offering products with high purity, surface area, and reinforcing properties. Its fumed silica is widely applied in coatings, elastomers, adhesives, and personal care products. In 2024, Evonik focused on innovation, sustainability, and technological excellence to expand its product portfolio. The company’s strong R&D capabilities and global presence helped maintain its competitive advantage, particularly in Europe, North America, and Asia, serving industrial sectors requiring high-performance and reliable materials.

Gelest Inc. specializes in advanced fumed silica and silicone-based materials for electronics, coatings, and healthcare applications. The company emphasizes precision-engineered products with controlled particle size, high purity, and excellent dispersibility. In 2024, Gelest strengthened its market position through innovation, tailored solutions, and expansion into high-demand industrial sectors. Its focus on research and development, coupled with strong technical support, has allowed it to meet specialized industrial requirements while maintaining global competitiveness and ensuring high-quality standards across its fumed silica offerings.

Top Key Players Outlook

- AMS Applied Material Solutions

- Cabot Corporation

- China-Henan Huamei Chemical Co.,Ltd.

- DONGYUE GROUP

- Evonik Industries AG

- Gelest Inc.

- Henan Xunyu Chemical Co., Ltd.

- Heraeus Group

- HPQ Silicon Inc.

- Kemitura

Recent Industry Developments

In 2024, Gelest continued to strengthen its market position by focusing on innovation and expanding its production capabilities. A significant development was the completion of a new 50,000-square-foot production facility in Morrisville, Pennsylvania, which was finalized in September 2024.

Cabot opened a new production facility in Texas in January 2025, increasing its annual fumed silica output by 15,000 tons.

Report Scope

Report Features Description Market Value (2024) USD 1.6 Bn Forecast Revenue (2034) USD 2.7 Bn CAGR (2025-2034) 5.3% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Hydrophilic, Hydrophobic), By Production Process (Flame Hydrolysis, Plasma/Arc Vapor Oxidation), By Function (Rheology Control/Thickening, Anti-settling/Anti-caking, Reinforcement/Filler), By Application (Silicone Elastomers, Paints, Coatings and Inks, Adhesives and Sealants, UPR and Composites, Others), By End-use (Building and Construction, Electrical and Electronics, Automotive and Transportation, Personal Care and Beauty, Food and Beverages, Pharmaceuticals, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – GCC, South Africa, Rest of MEA Competitive Landscape AMS Applied Material Solutions, Cabot Corporation, China-Henan Huamei Chemical Co.,Ltd., DONGYUE GROUP, Evonik Industries AG, Gelest Inc., Henan Xunyu Chemical Co., Ltd., Heraeus Group, HPQ Silicon Inc., Kemitura Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)

-

-

- AMS Applied Material Solutions

- Cabot Corporation

- China-Henan Huamei Chemical Co.,Ltd.

- DONGYUE GROUP

- Evonik Industries AG

- Gelest Inc.

- Henan Xunyu Chemical Co., Ltd.

- Heraeus Group

- HPQ Silicon Inc.

- Kemitura