Quick Navigation

Overview

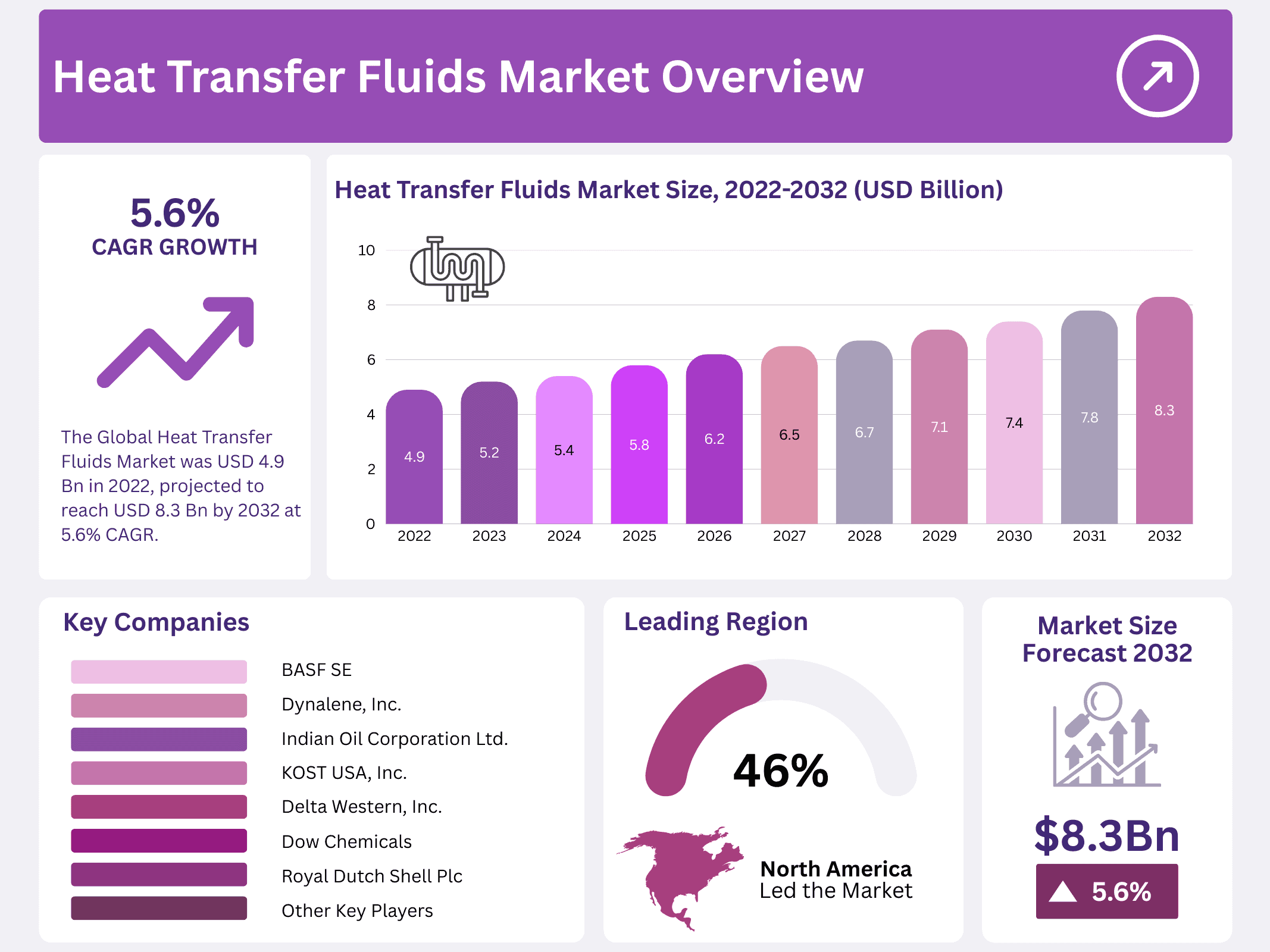

New York, NY – February 04, 2026 – The Heat Transfer Fluids Market reached USD 4.9 billion in 2022 and is projected to grow steadily, reaching USD 8.3 billion by 2032. This reflects a healthy CAGR of 5.6% between 2023 and 2032, indicating rising adoption across industrial applications that depend on efficient temperature regulation.

Heat transfer fluids are essential materials used to move heat from one point to another in controlled systems. They find extensive use in chemical processing units, oil and gas operations, power generation, HVAC systems, and various industrial heating or cooling processes. Their ability to maintain stable thermal performance under extreme temperatures makes them crucial for modern industrial operations.

The market growth is driven by increasing demand for advanced thermal management technologies and the global shift toward energy-efficient industrial solutions. Rapid industrialization in emerging economies, along with greater emphasis on operational efficiency and safety, continues to boost the need for high-performance heat transfer fluids across multiple sectors.

Key Takeaways

- The Global Heat Transfer Fluids Market was USD 4.9 billion in 2022, projected to reach USD 8.3 billion by 2032 at 5.6% CAGR, driven by industrial temperature regulation needs.

- The Mineral Oils segment captured 33.7% revenue share in 2022 due to affordability, availability, thermal stability, and use in HVAC and low-temperature industrial processes.

- The Oil & Gas application led with 26.4% market share, vital for crude oil processing, hydrocarbon separation, natural gas cooling, and pipeline temperature control.

- North America holds 46.2% global market share, fueled by strong chemical, oil & gas, automotive, and manufacturing sectors, mature infrastructure, and high-tech adoption.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2022) | USD 4.9 Billion |

| Forecast Revenue (2032) | USD 8.3 Billion |

| CAGR (2023-2032) | 5.6% |

| Segments Covered | By Type (Silicone Fluids, Aromatic Fluids, Mineral Oils, Glycol-Based Fluids, Other Types), By Application (Oil & Gas, Chemical, Concentrated Solar Power, Food & Beverages, Plastics, Pharmaceutical, HVAC, Other Applications) |

| Competitive Landscape | BASF SE, Dynalene, Inc., Indian Oil Corporation Ltd., KOST USA, Inc., Delta Western, Inc., Hindustan Petroleum Corporation Ltd., Royal Dutch Shell Plc, Dow Chemicals, Other Key Players |

Key Market Segments

By Type Analysis

The Mineral Oils segment held the largest revenue share in the Heat Transfer Fluids Market in 2022, capturing 33.7% of the global market. Mineral oils remain widely used due to their affordability, easy availability, and suitability for low-temperature heating applications. They are commonly utilized in HVAC systems and various industrial processes where the fluid does not come into contact with food or other sensitive materials. Their strong thermal stability, broad operating temperature range, and efficient heat transfer capabilities further strengthen their dominance in the market.

The Glycol-Based segment is recognized as the fastest-growing type from 2022 to 2031. These fluids—typically formulated using ethylene glycol or propylene glycol—are preferred in systems requiring cooling or heating below freezing temperatures. They offer reliable performance across temperatures ranging from –50°C to 175°C, combined with low viscosity, strong thermal stability, and enhanced heat transfer properties. Glycol-based fluids are widely used in refrigeration, cooling systems, HVAC operations, and various industrial processes. Their non-toxic characteristics also make them suitable for applications in food and beverage processing.

By Application Analysis

The Oil & Gas segment leads the Heat Transfer Fluids Market by application, accounting for 26.4% of the market share. Heat transfer fluids play a critical role in crude oil processing, where they help maintain controlled temperatures and support the separation of hydrocarbons into different components. These fluids are also essential for cooling natural gas during processing and ensuring stable temperatures in machinery and pipelines.

In offshore operations, heat transfer fluids are used to regulate equipment temperatures and prevent the formation of hydrates or wax deposits in subsea pipelines. Additionally, they support enhanced oil recovery techniques such as steam injection, where maintaining heat in the reservoir is vital for improved oil flow and overall extraction efficiency.

Regional Analysis

North America remains the most lucrative market in the global heat transfer fluids industry, holding the largest market share of 46.2%. The region benefits from a strong industrial base, with well-established chemical, oil and gas, automotive, and manufacturing sectors that consistently require advanced thermal management solutions. Its mature infrastructure and high level of technological adoption further support the demand for efficient and high-performance heat transfer fluids.

Asia-Pacific is identified as the fastest-growing region in the heat transfer fluids market. The rapid industrialization across key economies such as China, India, and Southeast Asian nations is significantly fueling the demand for reliable heat transfer solutions. Growth in the chemical, oil and gas, automotive, and manufacturing industries continues to create strong market momentum.

Additionally, the expanding middle-class population and rising consumption of a wide range of consumer products are contributing to increased industrial output across the region. This, in turn, is driving the need for efficient heat transfer fluids to support production, processing, and temperature-sensitive industrial systems.

Top Use Cases

- Automotive Applications: Heat transfer fluids are vital in vehicles for managing engine temperatures and ensuring reliable performance. They act as coolants to prevent overheating and as lubricants for smooth gear shifts. As a market research analyst, I observe their growing role in electric cars for battery thermal control, supporting the shift toward greener transportation options and extended vehicle durability.

- HVAC Systems: In heating, ventilation, and air conditioning setups, these fluids efficiently move heat or cold to create comfortable indoor spaces. They are commonly used in buildings, hospitals, and data centers for energy-saving climate control. From a market viewpoint, their adoption rises with the demand for sustainable infrastructure, aiding in reduced operational costs and better environmental practices.

- Solar Energy Systems: Heat transfer fluids capture sunlight’s energy in concentrated solar plants, transferring it to produce power and enable storage for later use. They boost system efficiency in renewable setups. As an analyst, I see this application expanding with the global push for clean energy, fostering innovation in thermal management for reliable electricity generation.

- Chemical Processing: These fluids provide precise temperature regulation in chemical reactors and distillation units, ensuring safe and effective production of materials like plastics and drugs. They help maintain consistent operations in manufacturing. Market trends highlight their importance in expanding industrial sectors, where they support quality output and process optimization for competitive advantages.

- Food and Beverage Industry: In food processing, heat transfer fluids aid in heating, cooling, and preserving products like dairy and meats to meet safety standards. They are key in breweries and cold storage for quality control. Analysts note that rising consumer preferences for ready-to-eat items drive demand, emphasizing their role in efficient supply chains and regulatory compliance.

Recent Developments

1. BASF SE

- BASF has advanced its Dynalene HF series, focusing on high-performance, non-toxic glycol-based fluids for extreme temperature ranges (-60°C to 180°C), emphasizing sustainability and energy efficiency. Recent R&D targets renewable feedstocks and enhanced thermal stability for concentrated solar power and electric vehicle battery cooling. BASF also promotes fluid recycling initiatives to support circular economy goals.

2. Dynalene, Inc.

- Dynalene recently expanded its HC (Hydrocarbon) and white oil-based heat transfer fluid lines, designed for low-viscosity and high thermal stability in indirect cooling/heating applications. Developments include fluids for hydrogen cooling, data center immersion cooling, and improved oxidation inhibitors for longer fluid life. The company emphasizes custom-engineered solutions for emerging industrial and energy storage sectors.

3. Indian Oil Corporation Ltd.

- Indian Oil has launched “CoolTherm”—a new range of synthetic and mineral oil-based heat transfer fluids for solar thermal, industrial process heating, and cryogenic applications. Recent efforts have integrated IoT-based fluid monitoring systems to optimize performance and prevent degradation. The company focuses on indigenization to reduce imports and caters to India’s growing renewable energy and chemical processing sectors.

4. KOST USA, Inc.

- KOST USA introduced “KOST Therm FS”—a non-toxic, non-flammable fluorinated fluid for single-phase immersion cooling of electronics and high-heat-flux applications. Recent innovations target direct-contact cooling in data centers and electric vehicle power electronics, emphasizing superior dielectric properties and low environmental impact. The company also provides fluid analysis services to extend operational lifespan.

5. Delta Western, Inc.

- Delta Western, as a key distributor in Alaska and the Pacific Northwest, has expanded its portfolio with MultiTherm and Paratherm fluids, focusing on cold-climate applications. Recent developments include supplying low-pour-point fluids for arctic industrial facilities, fishing vessels, and remote renewable energy installations. The company enhances technical support and fluid testing services to ensure reliability in harsh environments.

Conclusion

Heat Transfer Fluids stand out for their broad versatility in handling thermal needs across industries, from renewables to manufacturing. Their ability to improve efficiency and support sustainable practices makes them essential for future growth, adapting to evolving demands in energy management and production processes.