Quick Navigation

Overview

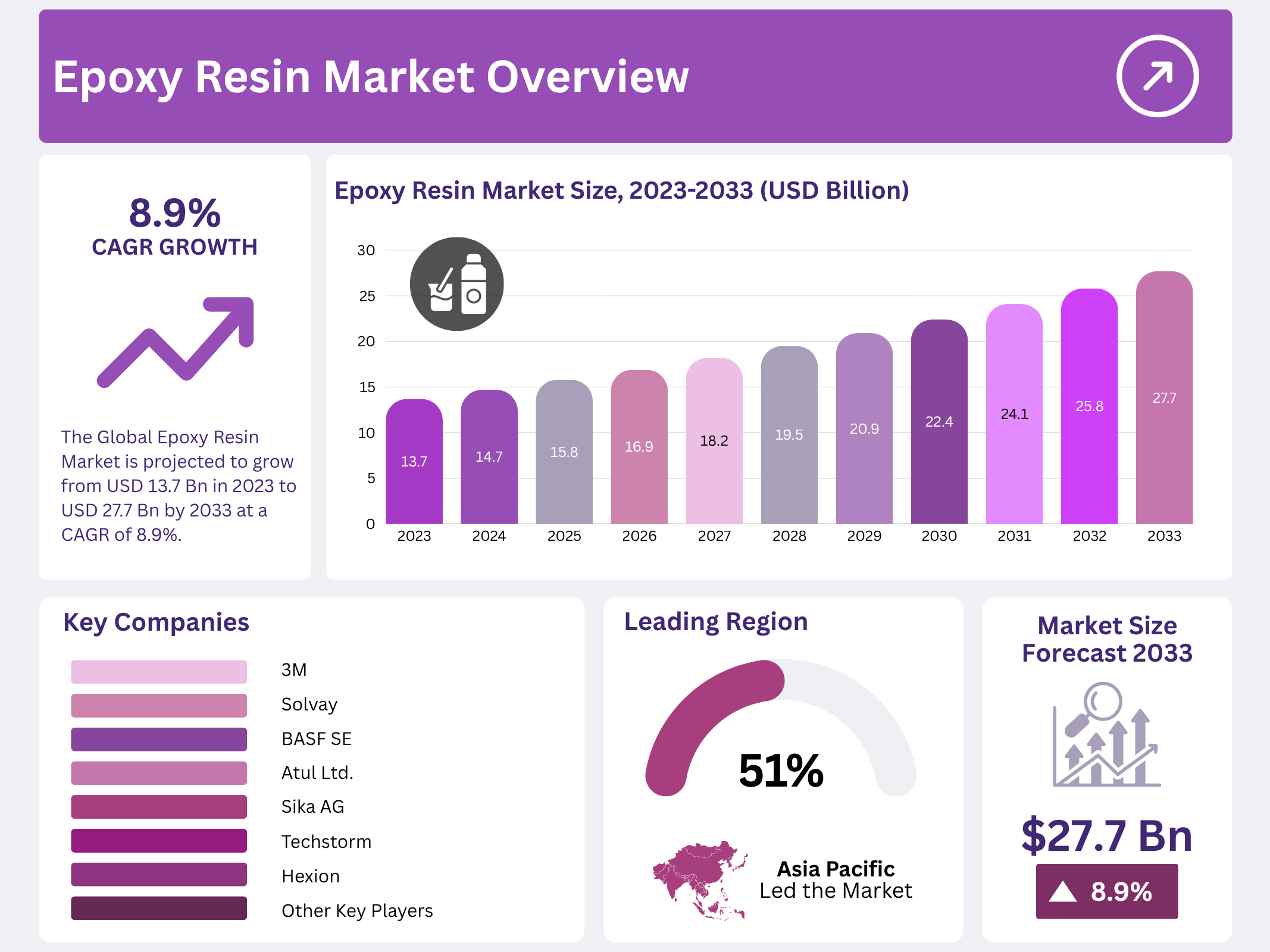

New York, NY – November 19, 2025 – The Global Epoxy Resin Market is projected to reach USD 27.7 billion by 2033, increasing from USD 13.7 billion in 2023 at a steady CAGR of 8.9% between 2023 and 2033. Epoxy resin is a plastic material produced from chemicals known as epoxides. It is formed by mixing two key components—a resin and a hardener—which react chemically to create a strong, solid material. This reaction gives epoxy its well-known toughness and stability.

Epoxy resins are widely valued for their high strength and exceptional resistance to heat, pressure, and chemicals. These properties make them ideal for use in coatings, adhesives, composites, and mold casting. They are also essential in the production of fiber-reinforced plastics used in skis, boats, automotive components, and various industrial products. Their versatility keeps them relevant across multiple sectors that demand durable, long-lasting materials.

The epoxy resin market represents the industrial ecosystem involved in producing, purchasing, and selling epoxy-based products. Major chemical companies manufacture various resins and hardeners, while numerous end-user industries—including construction, automotive, aerospace, paints, and electronics—use these materials in their products. With strong demand from these sectors, the market has shown consistent growth over recent years, and experts expect this upward trend to continue over the next five years.

Key Takeaways

- The Global Epoxy Resin Market is projected to grow from USD 13.7 billion in 2023 to USD 27.7 billion by 2033 at a CAGR of 8.9%.

- The Solid Epoxy Resin segment led the market with over 52.1% revenue share due to superior durability, thermal stability, and chemical/moisture resistance.

- The Paints & Coatings segment dominated in 2023 with more than 37.7% global market share, driven by excellent corrosion resistance and long-lasting high-gloss finish.

- Asia Pacific held the largest share (>51.5%) in 2023, generating USD 7.0 billion in revenue, and is expected to grow the fastest during the forecast period.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 13.7 Billion |

| Forecast Revenue (2033) | USD 27.7 Billion |

| CAGR (2023-2033) | 8.9% |

| Segments Covered | By Physical Forms (Liquid, Solid, Solution), By End-use Industry (Paints & Coatings, Wind Turbines, Composites, Construction, Electrical & Electronics, Adhesives, Others) |

| Competitive Landscape | 3M, Aditya Birla Management Corp. Pvt. Ltd., Atul Ltd., BASF SE, Solvay, Huntsman International LLC, Kukdo Chemical Co., Ltd., Olin Corporation, Sika AG, Nan Ya Plastics Corp., Jiangsu Sanmu Group Co., Ltd., Jubail Chemical Industries LLC, China Petrochemical & Chemical Corporation (SINOPEC), Hexion, Kolon Industries, Inc., Techstorm, Nagase & Co., Ltd. |

Key Market Segments

By Physical Form

The Solid Epoxy Resin segment dominated the market, accounting for more than 52.1% of total revenue. This leadership position stems from its superior durability, thermal stability, and excellent resistance to chemicals and moisture. Solid epoxy resins deliver outstanding adhesion and mechanical strength, making them the material of choice across demanding applications in construction, electrical & electronics, adhesives, and advanced composites. Manufacturers particularly value solid forms for their ease of storage, extended shelf life, and straightforward handling during processing.

By End-Use

The Paints & Coatings segment emerged as the clear leader in 2023, commanding over 37.7% of the global market share. Epoxy-based paints and coatings are prized for their exceptional corrosion resistance, chemical durability, and ability to deliver a high-gloss, long-lasting finish. These properties have cemented their widespread adoption in automotive refinishing, marine protection, industrial maintenance, and architectural applications.

The Wind Energy (Wind Turbines) segment also recorded notable growth and remains a high-value niche. Epoxy resins are critical in the fabrication of lightweight, high-strength rotor blades capable of enduring extreme mechanical stress and environmental conditions. With ongoing global investment in renewable energy infrastructure, demand from the wind turbine sector is projected to grow steadily in the coming years.

The Composites industry represented another major consumer of epoxy resins in 2023. Thanks to their excellent strength-to-weight ratio and fatigue resistance, epoxy systems are indispensable in aerospace components, automotive parts, sporting goods, and other high-performance composite structures.

Regional Analysis

In 2023, the Asia Pacific dominated the global epoxy resin market with a commanding share of over 51.5%. The region generated USD 7.0 billion in revenue and is expected to record the fastest growth throughout the forecast period. This leadership position is the result of several powerful drivers. Rapid urbanization and large-scale infrastructure projects in countries like China and India have significantly increased demand for epoxy resins in construction applications, including coatings, adhesives, sealants, and flooring systems.

Asia Pacific’s position as the world’s electronics manufacturing powerhouse continues to drive consumption of epoxy resins for encapsulation and circuit board production. The region’s booming wind energy sector—led by China, the global leader in installed wind capacity—relies heavily on advanced epoxy systems for manufacturing durable rotor blades. Additionally, access to low-cost raw materials, competitive labor, and proactive industrial policies have attracted major producers to expand their manufacturing footprint in the region, further strengthening its market dominance.

Europe, in contrast, maintained a mature yet highly significant market presence in 2023. The region benefits from a well-established industrial base and a strong emphasis on sustainability and regulatory compliance. Demand remains robust in the automotive and aerospace sectors, where lightweight epoxy composites are critical for improving fuel efficiency and performance. Strict environmental regulations across the EU have accelerated the adoption of eco-friendly formulations, such as waterborne, low-VOC, and bio-based epoxy resins.

Top Use Cases

- Coatings for Protection: Epoxy resin works great as a tough coating on floors and surfaces in homes, factories, and garages. It sticks well to concrete and metal, keeping out water, chemicals, and daily wear. This makes spaces last longer and look shiny without needing fixes often, saving time and effort for builders and owners.

- Adhesives for Bonding: In building and fixing things, epoxy resin acts as a super-strong glue that joins wood, metal, or plastic pieces firmly. It holds up against shakes and pulls, perfect for tools, shelves, or repairs. Craftspeople love it because it dries clear and hard, giving projects a clean, lasting finish without mess.

- Composites in Vehicles: Car and plane makers use epoxy resin to mix with fibers for lightweight, strong parts like bodies or wings. It helps make rides smoother and safer by cutting weight while boosting strength against bumps and heat. This keeps fuel use low and parts reliable over long trips or flights.

- Electronics Insulation: Epoxy resin shields tiny wires and chips in phones, computers, and gadgets from dust, moisture, and shocks. It wraps parts snugly to stop short circuits and keep heat in check, making devices run smoothly and safely for years. Tech folks pick it for easy use and a reliable guard in crowded circuits.

- Art and Crafts Creation: Hobbyists pour epoxy resin over wood, photos, or flowers to make shiny tables, jewelry, or wall art that glows with color. It seals items tightly against scratches and spills, turning simple ideas into eye-catching pieces. Beginners find it fun and forgiving, as it levels smoothly for pro-like results at home.

Recent Developments

1. 3M

3M is strategically exiting the epoxy resin adhesives market, having sold its advanced epoxy-based Transcend line to IPC in late 2023. This move is part of 3M’s broader corporate spin-off of its Health Care business into Solventum, allowing it to focus on core markets. Their remaining development efforts are now concentrated on other material sciences, moving away from dedicated epoxy resin innovation for electronics and aerospace.

2. Aditya Birla Management Corp. Pvt. Ltd. (Grasim Industries)

Aditya Birla Group, through Grasim Industries, is making a major entry into the epoxy resins market with a new manufacturing facility in India. This significant investment aims to reduce the country’s import dependency and cater to the growing domestic demand from sectors like paints, coatings, composites, and wind energy. The project is a key part of their foray into the paints business and broader petrochemical portfolio.

3. Atul Ltd.

Atul Ltd. is expanding its Epoxy Resin and Hardener manufacturing capacity at its Atul site in Gujarat, India. This brownfield expansion is designed to meet rising demand from both domestic and international markets, particularly for applications in coatings, composites, and adhesives. The project reinforces their integrated product portfolio and commitment to the specialty chemicals sector, strengthening their position in the supply chain.

4. BASF SE

BASF is heavily focused on developing sustainable epoxy resin solutions. Recent developments include bio-based curing agents like Baxxodur ECO and collaborations to create epoxy systems for recyclable carbon fiber composites. They are also advancing water-based epoxy systems for can coatings to meet regulatory demands. These innovations align with their strategic emphasis on the circular economy and reducing the carbon footprint across the value chain.

5. Solvay

Solvay is pioneering high-performance and sustainable epoxy formulations. A key development is their launch of “Rizepox”, a new brand identity for their comprehensive epoxy resin and hardener portfolio. They are also innovating in thermoplastic and toughened epoxy systems for aerospace and automotive composites, focusing on materials that offer better recyclability and lighter weight to support the energy transition and electric vehicle markets.

Conclusion

Epoxy Resin is a powerhouse material that’s quietly shaping everyday life and big industries alike. Its knack for sticking, shielding, and strengthening surfaces opens doors in building sturdy homes, crafting zippy cars, and powering smart gadgets, all while folks chase greener ways to build. With shifts toward lighter, tougher, and earth-friendlier options, this resin keeps evolving to fit what people need next, promising steady buzz in workshops and factories worldwide.