Gas Nitriding Furnace Market Infographics Description

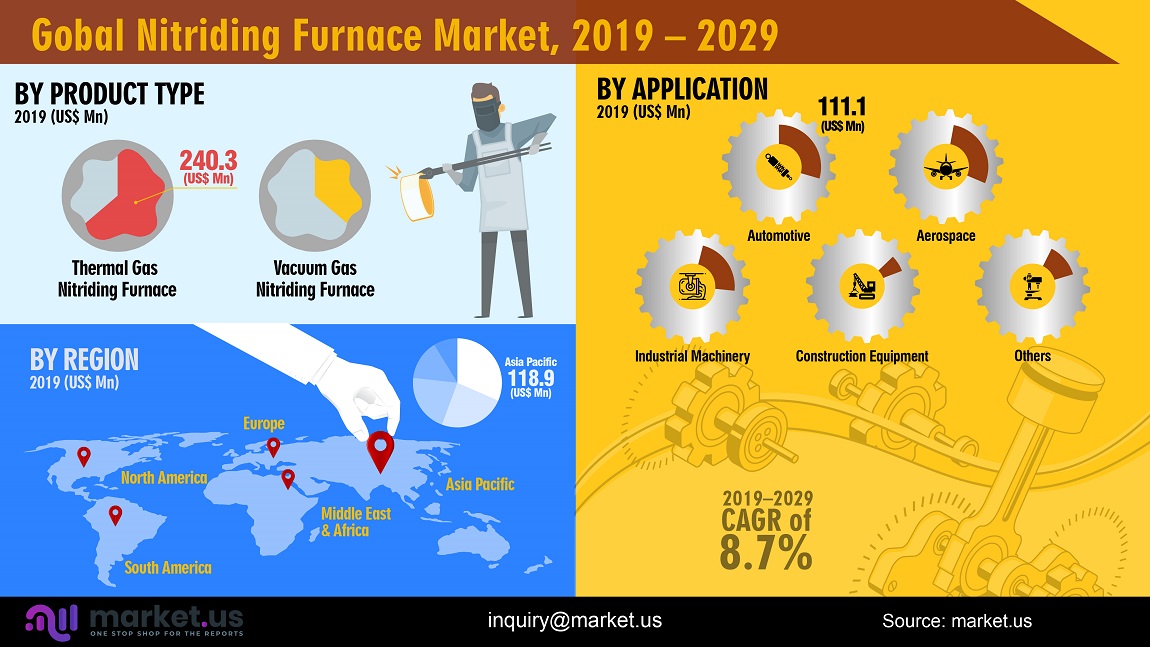

- The Global Gas Nitriding Furnace Market size is expected to be worth around USD 2.9 Billion by 2033, From USD 1.7 Billion by 2023

- The market growing at a CAGR of 5.40% during the forecast period from 2024 to 2033.

- North America holds a 29% share of the global gas nitriding furnace market.

- Vacuum Gas Nitriding Furnace dominates, holding 47% market share.

- Automotive sector leads, representing 35% of applications.

- The global gas nitriding furnace market is expanding due to advancements in post-oxidation technologies and rising demand from the tool and die industry for wear-resistant tools.

- Increasing emphasis on energy-efficient solutions, including advanced insulation, temperature control, and furnace monitoring systems, is a key market driver, responding to growing environmental concerns and cost reduction needs.

- The market has numerous established players who are focusing on product development, strategic partnerships, and technological advancements to stay competitive.

Gas Nitriding Furnace Growth Drivers

- Increasing Demand for Automotive Components: Gas nitriding furnaces are extensively used in the automotive industry to enhance the wear resistance and fatigue life of metal parts. As the global automotive sector continues to grow, especially with the rise in manufacturing of electric vehicles that require durable components, the demand for gas nitriding processes is expected to surge.

- Advancements in Aerospace Applications: The aerospace industry relies on gas nitriding for critical components that must withstand extreme conditions. The increasing production of aircraft and the rising demand for maintenance of aging fleets contribute to the growth of the gas nitriding furnace market.

- Emphasis on Product Durability and Longevity: Industries such as construction and machinery are emphasizing longer-lasting components to reduce maintenance costs and enhance safety. Gas nitriding furnaces provide a cost-effective solution to achieve these goals by improving the surface hardness and corrosion resistance of metal parts.

- Technological Innovations in Furnace Design: Recent technological advancements in furnace designs that offer better temperature uniformity, controlled atmospheres, and efficient gas usage are promoting the adoption of gas nitriding systems. These innovations help in achieving more precise and reliable nitriding processes, driving their demand across various sectors.

- Regulatory and Environmental Compliance: Increasing regulations regarding emissions and environmental sustainability are pushing industries to adopt cleaner and more energy-efficient manufacturing processes. Gas nitriding furnaces are being designed to meet these stringent standards, making them more appealing to environmentally conscious companies.

Strategic Developments in the Gas Nitriding Furnace Market

- Expansion of Manufacturing Facilities: Several companies are expanding their manufacturing capabilities globally to cater to the growing demand for nitrided components. This expansion is not just in terms of physical facilities but also through the adoption of advanced manufacturing technologies that enhance production efficiency and quality.

- Mergers and Acquisitions: Key players in the market are engaging in mergers and acquisitions to broaden their technological expertise and market reach. These strategic moves allow companies to enhance their product offerings and cater to a larger customer base across different geographical regions.

- Increased R&D Investments: Companies are investing heavily in research and development to innovate and improve gas nitriding technologies. These investments are focused on developing furnaces that can provide more uniform case depths, better nitride layer properties, and lower operational costs.

- Collaborations with Automotive and Aerospace Sectors: Strategic partnerships with major automotive and aerospace manufacturers are crucial developments in the market. These collaborations are aimed at developing specialized nitriding solutions that meet the specific requirements of these industries, thus ensuring deeper market penetration.

- Adoption of IoT and Automation: The integration of IoT and automation technologies in gas nitriding furnaces is a significant trend. These technologies facilitate real-time monitoring and control of the nitriding process, leading to higher precision, reduced errors, and minimal human intervention, thereby increasing overall operational efficiency.