Global Water-Based and Low-Migration Inks for Food Packaging Market Size, Share, Growth Analysis By Ink Type (Acrylic Water-based, Maleic Resin Water-based, Bio-based Polyurethane Water-based, Shellac / Natural-based, Latex Dispersion Water-based, and Others), By Printing Process (Flexographic Printing, Gravure Printing, Digital inkjet Printing, Offset Printing, and Screen PRINTING), By Packaging Substrate (Flexible packaging films, Paper And paperboard cartons, Rigid packaging, Labels and Wraps, and Others), By End-use (Bakery and Confectionery, Dairy Products, Ready-to-eat Meals and Meal Kits, Meat, Poultry and Seafood, Fruits and Vegetables, and Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2025-2034

- Published date: Nov 2025

- Report ID: 167836

- Number of Pages: 395

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

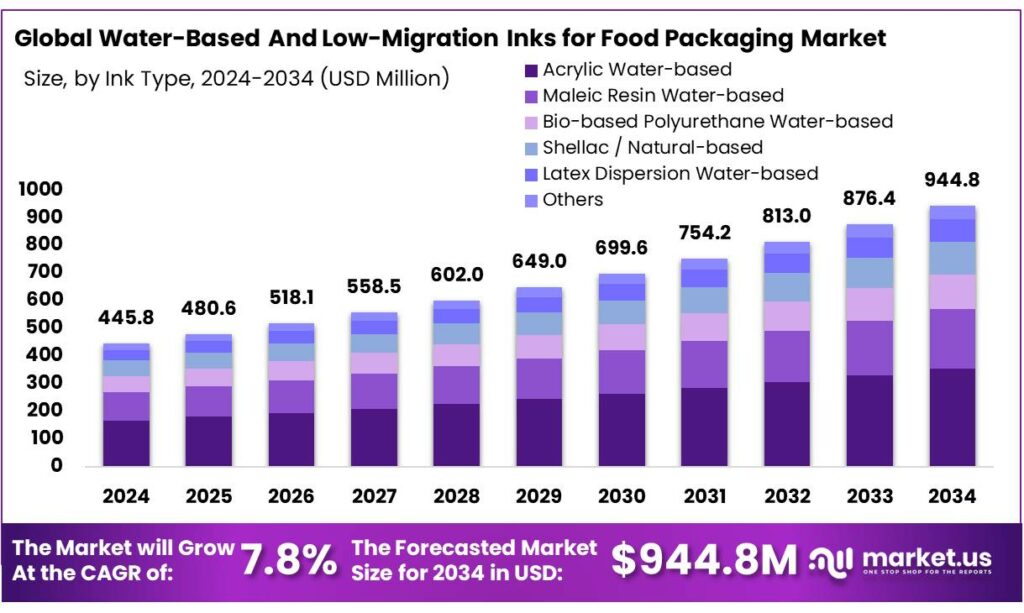

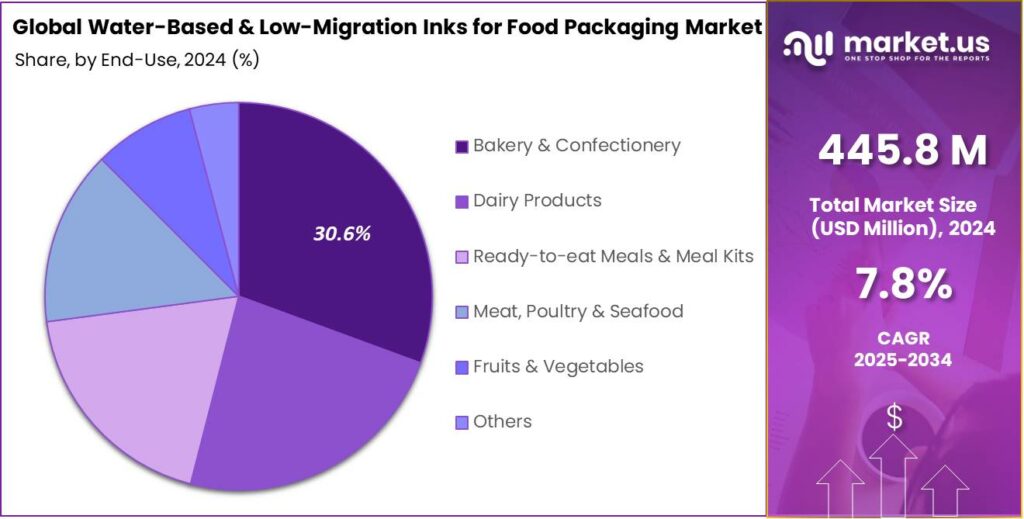

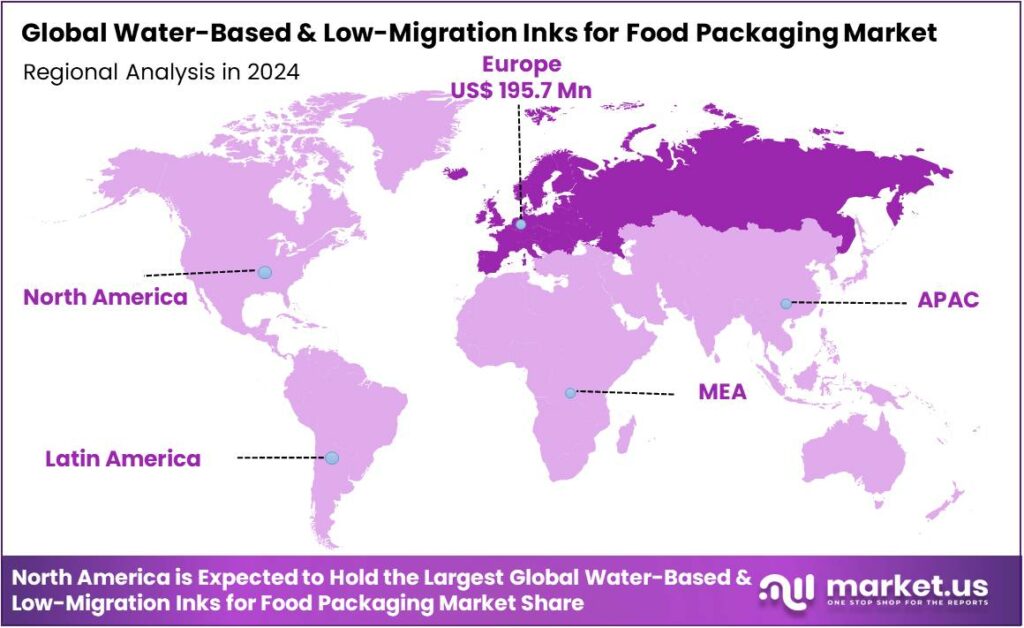

The Global Water-Based and Low-Migration Inks for Food Packaging Market size is expected to be worth around USD 944.8 Million by 2034, from USD 445.8 Million in 2024, growing at a CAGR of 7.8% during the forecast period from 2025 to 2034. In 2024, North America held a dominan market position, capturing more than a 42.9% share, holding USD 185.7 Million revenue.

Water-based low-migration inks are specialized water-based inks for food packaging designed to minimize the risk of ink components migrating into the food. They are formulated to meet strict safety regulations by using high-molecular-weight components and are often required to be printed and cured correctly to prevent contamination. These inks are an eco-friendly option, often odorless, and are gaining traction as international standards evolve to include green solutions.

The market has seen significant growth driven by increasing regulatory pressure and consumer demand for safer, more sustainable packaging solutions. The trend toward acrylic water-based inks, known for their relatively strong adhesion, durability, and environmental benefits, is especially prominent in flexible packaging, which offers high functionality and versatility for various food types, particularly bakery and confectionery products.

Flexographic printing remains the preferred method for these inks due to its speed, cost-effectiveness, and ability to handle different substrates, particularly flexible films. While challenges such as adhesion issues, longer drying times, and higher costs remain, the shift toward water-based inks continues to align with the growing emphasis on sustainability and consumer safety. The ongoing demand for low-migration, eco-friendly packaging solutions is expected to propel the market forward in the near future.

- According to the European Food Safety Authority (EFSA), low-migration (LM) inks reduce harmful substance migration by over 80% compared to traditional inks, effectively minimizing potential health hazards. In 2022, the EU’s RASFF notification system revealed that 34% of food contamination incidents in packaged food were related to the migration of packaging inks.

Key Takeaways

- The global water-based and low-migration inks for food packaging market was valued at US$445.8 million in 2024.

- The global water-based and low-migration inks for food packaging market is projected to grow at a CAGR of 7.8% and is estimated to reach US$944.8 million by 2034.

- Based on the types, acrylic inks dominated the market, with 6% of the total global market.

- Among the substrates, flexible packaging films are the most utilized in the water-based and low-migration inks for the food packaging market, with 4% of the market share.

- Based on printing processes, water-based and low-migration inks are used for the flexographic printing, thus leading the market with 7% of share.

- The bakery and confectionery industry accounted for the largest revenue share, which is 6%, among the end-uses.

- Europe was at the forefront of the water-based and low-migration inks for the food packaging market, accounting for 9% of the total global consumption.

Type Analysis

Acrylic Water-Based Inks Dominate the Water-Based and Low-Migration Inks for Food Packaging Market.

The water-based and low-migration inks for the food packaging market are segmented based on ink types as acrylic water-based, maleic resin water-based, bio-based polyurethane water-based, shellac / natural-based, latex dispersion water-based, and others. The acrylic water-based inks dominate the market, comprising around 37.6% of the shares, due to their comparatively strong adhesion, versatility, and ability to provide a smooth, durable finish on a wide range of substrates, including plastics and paper. Unlike maleic resin-based or bio-based polyurethane inks, which can sometimes have limited adhesion to certain surfaces or require additional curing processes, acrylic inks offer more consistent performance in high-speed printing operations.

Additionally, they exhibit excellent resistance to smudging and fading, ensuring a longer life of the print. Compared to natural-based or latex dispersion inks, acrylic formulations are less prone to issues such as drying time variability and are more stable under various environmental conditions. Their low migration potential, combined with compliance with food safety regulations, makes them ideal for packaging that directly contacts food, ensuring both safety and functionality. This combination of performance, ease of use, and regulatory compliance makes acrylic water-based inks ideal solutions in various cases.

Printing Process Analysis

Water-Based and Low-Migration Inks for Food Packaging Are Majorly Used in Flexographic Printing Processes.

On the basis of printing process, the water-based and low-migration inks for the food packaging market are segmented into flexographic printing, gravure printing, digital inkjet printing, offset printing, and screen printing. Among these, 49.7% of the revenue in the water-based and low-migration inks for food packaging market is generated by the flexographic printing process. It is the most commonly used method for water-based low-migration inks due to its adaptability, speed, and cost-effectiveness, particularly for large-volume food packaging production. In addition, it is ideal for printing on a wide variety of substrates, including flexible films, paper, and corrugated materials, which are frequently used in food packaging.

Similarly, it allows for precise control over ink application, ensuring consistent coverage while minimizing the risk of ink migration. Unlike gravure, which is more suited for high-quality, high-volume production with solvent-based inks, flexography handles water-based inks more efficiently without compromising print quality. Furthermore, its ability to handle intricate designs on both large and small runs makes it a preferred choice over digital inkjet or offset printing. These advantages, coupled with lower operational costs, make flexographic printing the go-to technology for producing food-safe packaging with water-based low-migration inks.

Substrate Analysis

Flexible Packaging Films Are Predominantly Used as a Substrate for Water-Based and Low-Migration Inks for Food Packaging.

Based on substrates, the water-based and low-migration inks for the food packaging market are segmented into flexible packaging films, paper & paperboard cartons, rigid packaging, labels & wraps, and others. The flexible packaging films, as a substrate, dominated the market with 36.4% of the market share, as they offer excellent barrier properties, flexibility, and the ability to conform to complex shapes, which is crucial for protecting food products.

These films, such as polyethylene (PE), polypropylene (PP), and polyester (PET), provide a superior seal to prevent moisture, oxygen, and light from affecting the contents, ensuring longer shelf life. Additionally, flexible films are lightweight, cost-effective, and easy to transport, making them an ideal choice for high-volume food packaging. Compared to rigid packaging such as paperboard cartons or glass containers, flexible films are better suited for high-speed production processes such as flexographic printing, which is commonly used with water-based inks.

End-Use Analysis

The Bakery and Confectionery Sector Held a Dominant Position in the Water-Based and Low-Migration Inks for Food Packaging Market.

Based on the end-uses of the water-based and low-migration inks for food packaging, the market is divided into bakery and confectionery, dairy products, ready-to-eat meals and meal kits, meat, poultry and seafood, fruits and vegetables, and others. In 2024, the bakery and confectionery sector held a dominant market position, capturing more than 30% of the market share. The inks are most commonly used for bakery and confectionery packaging, as these products typically have fewer packaging requirements compared to items such as dairy or meat.

These products often have a longer shelf life, which allows for more flexibility in packaging materials and inks. In contrast, products such as dairy, meat, and ready-to-eat meals often require more robust, specialized packaging with higher barrier properties to preserve freshness and prevent contamination. These products may also have more direct interaction with the packaging material, demanding inks with even stricter migration controls, often prompting the use of alternative ink technologies. Foods that are high in fat, water, or acid are more likely to extract chemical components from packaging materials and inks. Such food products often use inks made from approved color additives.

Key Market Segments

By Ink Type

-

- Acrylic Water-based

- Maleic Resin Water-based

- Bio-based Polyurethane Water-based

- Shellac / Natural-based

- Latex Dispersion Water-based

- Others

By Printing Process

-

- Flexographic printing

- Gravure printing

- Digital inkjet printing

- Offset printing

- Screen printing

By Packaging Substrate

-

- Flexible packaging films

- Paper & paperboard cartons

- Rigid packaging

- Plastics Containers

- Metal Cans

- Glass Jars & Bottles

- Labels & wraps

- Others

By End-Use

-

- Bakery and Confectionery

- Dairy Products

- Ready-to-eat Meals and Meal Kits

- Meat, Poultry, and Seafood

- Fruits and Vegetables

- Others

Drivers

Regulatory and Safety Concerns Drive the Water-Based and Low-Migration Inks for Food Packaging Market.

Regulatory and safety concerns have significantly influenced the adoption of water-based and low-migration inks in the food packaging industry. As food safety standards become stricter globally, the demand to eliminate harmful chemicals in packaging materials has driven a shift toward inks that minimize the risk of contamination. In the United States, the Food and Drug Administration (FDA) regulates substances that may come into direct or indirect contact with food, mandating compliance with strict limits on the migration of potentially harmful chemicals.

- Similarly, the European Union enforces Regulation (EC) No. 1935/2004, which requires that materials in contact with food must not transfer constituents in quantities that could endanger human health.

Water-based low-migration inks, which are free from solvents, are increasingly favored for printing on food packaging. These inks reduce the chances of harmful chemicals migrating from packaging to food, addressing growing consumer concerns over food safety. These inks are formulated and made in accordance with the EuPIA (European Printing Ink Association) Good Manufacturing Practices (GMP).

- This regulation, along with Swiss Ordinance SR 817.023.21, which lists permitted substances in printing inks, has further encouraged manufacturers to adopt safer alternatives and reformulate their products.

Restraints

Potential Adhesion Issues Might Pose a Challenge for the Water-Based and Low-Migration Inks for Food Packaging Market.

While water-based and low-migration inks offer significant benefits in terms of food safety and environmental impact, they present some challenges for the food packaging industry. One of the primary issues faced by these inks is adhesion, as water-based inks tend to have a weaker bond to non-porous surfaces such as certain plastics and films. This might cause poor print quality and raise the requirement for additional coatings, which can complicate the manufacturing process.

Additionally, water-based inks generally have longer drying times compared to solvent-based inks, which can lead to slower production speeds and higher costs in high-volume printing operations. Similarly, this delay in drying can increase the risk of smudging or the transfer of ink onto other surfaces during handling. Moreover, the cost of formulating low-migration inks, which are specifically designed to prevent harmful substances from leaching into food, is often higher than traditional ink formulations due to the specialized raw materials and production processes required. For companies looking to balance quality, cost, and compliance, these challenges can be a significant hurdle.

Opportunity

Increased Consumer Demand for Safer Packaging Solutions Creates Opportunities in the Water-Based and Low-Migration Inks for Food Packaging Market.

Increased consumer demand for safer and more sustainable packaging solutions has opened up significant opportunities for water-based and low-migration inks in food packaging. With rising awareness about health and environmental impacts, consumers are now more cautious about what comes into contact with their food. This has led to a shift in the packaging industry, where food manufacturers and packaging companies are prioritizing inks that minimize the risk of chemical migration. For instance, Nestlé requires all suppliers to meet stringent internal packaging safety standards, influencing upstream suppliers to adopt low migration inks.

Additionally, water-based inks are becoming increasingly popular due to their environmentally friendly nature, as they contain fewer harmful solvents and produce lower levels of air pollution. Major companies such as Siegwerk and Sun Chemical have embraced these safer alternatives to align with consumer preferences and comply with stricter food safety regulations. As consumer demand for safer, healthier, and more sustainable packaging grows, the market for these innovative inks continues to expand.

Trends

Emphasis on Reduction of Volatile Organic Compounds and NC-Free Inks.

The shift toward nitrocellulose-free (NC-free) inks and the reduction of volatile organic compounds (VOCs) is a key trend in the water-based and low-migration inks used in food packaging. Nitrocellulose, a commonly used resin in traditional printing inks, can pose safety risks due to its flammability and potential for migration into food. As regulatory bodies and consumers increasingly demand safer and more environmentally friendly packaging, food packaging manufacturers are moving away from NC-based inks. These formulations are being replaced by water-based alternatives that avoid the use of harmful chemicals, thereby reducing the risk of contamination and improving overall food safety.

For instance, in February 2025, Siegwerk introduced the nitrocellulose-free ink series specifically designed for surface printing on polyethylene (PE) and polypropylene (PP) packaging solutions. Additionally, the reduction of VOCs, which are volatile substances that contribute to air pollution and health problems, is further encouraged by regulatory frameworks to lessen the pollution and consumer demand for healthier solutions. Water-based inks, by nature, have lower VOC content, making them a preferred choice for food packaging. Leading ink manufacturers such as Kao Collins and Huber Group have been adapting their formulations to meet these growing demands, offering more sustainable solutions that comply with both food safety regulations and environmental standards.

Geopolitical Impact Analysis

Geopolitical Tensions Are Impacting the Water-Based and Low-Migration Inks for Food Packaging market by disrupting the Essential Supply Chains in the Market.

The current geopolitical tensions have had a noticeable impact on the water-based and low-migration inks for food packaging market, influencing supply chains, raw material availability, and manufacturing costs. Trade disruptions, particularly in regions such as Europe, Asia, and North America, have affected the availability of key raw materials used in ink formulations, such as pigments and resins.

For instance, sanctions on Russian exports and strained EU-China trade relations have affected the availability of certain chemical intermediates, forcing manufacturers to seek alternative, and often more expensive, sources. Additionally, the rising cost of energy, particularly in Europe, has placed upward pressure on manufacturing costs for ink producers, potentially increasing the price of water-based and low-migration inks.

Furthermore, the companies are facing delays in cross-border shipments and increased regulatory scrutiny, especially when sourcing from unstable regions, such as China and Southeast Asia, pushing manufacturers to either seek alternative sources or face delays in production. Some manufacturers are investing in local production and more diversified supply chains to mitigate the risks associated with geopolitical uncertainties.

Moreover, export-oriented countries such as Germany and Japan, which are significant players in the global printing and packaging industries, are experiencing slower growth due to reduced international demand and logistical bottlenecks.

Regional Analysis

Europe Held the Largest Share of the Global Water-Based and Low-Migration Inks for Food Packaging Market.

In 2024, Europe dominated the global water-based and low-migration inks for food packaging market, holding about 43.9% of the market share. According to the EuPIA (European Printing Ink Association), there are more than 1 million individual ink formulations in use across Europe, and approximately 700,000 tons of inks and coatings are used by printers of all kinds of products every year in the region. It holds the largest share of the global water-based and low-migration inks for food packaging market, driven by strict regulations, consumer demand for safer packaging, and a strong push for sustainability.

The European Union has the world’s most rigorous food safety and environmental standards, including regulations that limit the use of harmful chemicals in food packaging materials. These laws have accelerated the adoption of safer, low-migration inks that prevent the transfer of toxic substances to food. Additionally, there is a high awareness of environmental concerns among consumers in the region, and the demand for eco-friendly packaging is growing rapidly. Countries such as Germany, France, and the UK are at the forefront, with major packaging companies investing in water-based ink technologies to meet both regulatory and consumer expectations.

Key Regions and Countries

- North America

- The US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia & CIS

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- ASEAN

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

Companies in the water-based and low-migration ink market employ several strategies to gain a competitive edge. The major focus is on product innovation, where companies invest in research and development to create inks with superior performance, such as faster drying times, enhanced adhesion, and lower migration rates. The product development helps companies to meet stringent food safety regulations and consumer demands for eco-friendly solutions. Additionally, various companies emphasize offering customized solutions tailored to specific substrates and packaging formats, ensuring compatibility with a variety of materials used in food packaging.

Furthermore, major players focus on building strong partnerships with packaging manufacturers to secure long-term collaboration and ensure a steady supply of inks. Moreover, by adopting sustainable production processes and reducing carbon footprints, companies align themselves with environmentally-conscious brands and consumers. Similarly, expanding production capabilities and increasing local manufacturing have been a major focus of the companies in recent years.

The Major Players in The Industry

- Sun Chemical (DIC Corporation)

- Sakata INX Corporation

- Huber Group

- INX International Ink Co.

- Zeller + Gmelin GmbH & Co. KG

- T&K Toka Co., Ltd.

- ACTEGA (ALTANA AG)

- Wikoff Color Corporation

- Epple Druckfarben AG

- Fujifilm Ink Solutions Group

- Marabu GmbH & Co. KG

- Kao Collins Inc.

- Other Key Players

Key Development

- In July 2025, Huber Group launched water-based inks, such as Hydro-X Contact, and varnishes for direct food contact packaging. Water-based printing inks and varnishes, such as Hydro-X, can reduce VOC emissions and promote recyclability.

- In October 2025, the Flint Group launched the AQUACode range of solutions, including OctaCode, which is a water-based ink designed to protect and perform in paper and board printing.

Report Scope

Report Features Description Market Value (2024) US$445.8 Mn Forecast Revenue (2034) US$944.8 Mn CAGR (2025-2034) 7.8% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Ink Type (Acrylic Water-based, Maleic Resin Water-based, Bio-based Polyurethane Water-based, Shellac / Natural-based, Latex Dispersion Water-based, and Others), By Printing Process (Flexographic printing, Gravure printing, Digital inkjet printing, Offset printing, and Screen printing), By Packaging Substrate (Flexible packaging films, Paper & paperboard cartons, Rigid packaging, Labels & wraps, and Others), By End-use (Bakery and Confectionery, Dairy Products, Ready-to-eat Meals and Meal Kits, Meat, Poultry and Seafood, Fruits and Vegetables, and Others) Regional Analysis North America – The US & Canada; Europe – Germany, France, The UK, Spain, Italy, Russia & CIS, Rest of Europe; APAC– China, Japan, South Korea, India, ASEAN & Rest of APAC; Latin America– Brazil, Mexico & Rest of Latin America; Middle East & Africa– GCC, South Africa, & Rest of MEA Competitive Landscape Sun Chemical (DIC Corporation), Flint Group, Siegwerk Druckfarben AG & Co. KGaA, Sakata INX Corporation, Huber Group, INX International Ink Co., Zeller + Gmelin GmbH & Co. KG, T&K Toka Co., Ltd., ACTEGA (ALTANA AG), Wikoff Color Corporation, Epple Druckfarben AG, Fujifilm Ink Solutions Group, Marabu GmbH & Co. KG, Kao Collins Inc., and Other Players. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited Users and Printable PDF)  Water-Based and Low-Migration Inks for Food Packaging MarketPublished date: Nov 2025add_shopping_cartBuy Now get_appDownload Sample

Water-Based and Low-Migration Inks for Food Packaging MarketPublished date: Nov 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Sun Chemical (DIC Corporation)

- Sakata INX Corporation

- Huber Group

- INX International Ink Co.

- Zeller + Gmelin GmbH & Co. KG

- T&K Toka Co., Ltd.

- ACTEGA (ALTANA AG)

- Wikoff Color Corporation

- Epple Druckfarben AG

- Fujifilm Ink Solutions Group

- Marabu GmbH & Co. KG

- Kao Collins Inc.

- Other Key Players