Global Universal Milling Machine Market Size, Share, Growth Analysis By Product (Adjustable Cutter Head, Automated Adjustable), By Application (Plastic Industry, Wood Industry, Metal Industry), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Statistics, Trends and Forecast 2025-2034

- Published date: Dec 2025

- Report ID: 170475

- Number of Pages: 379

- Format:

-

keyboard_arrow_up

Quick Navigation

Report Overview

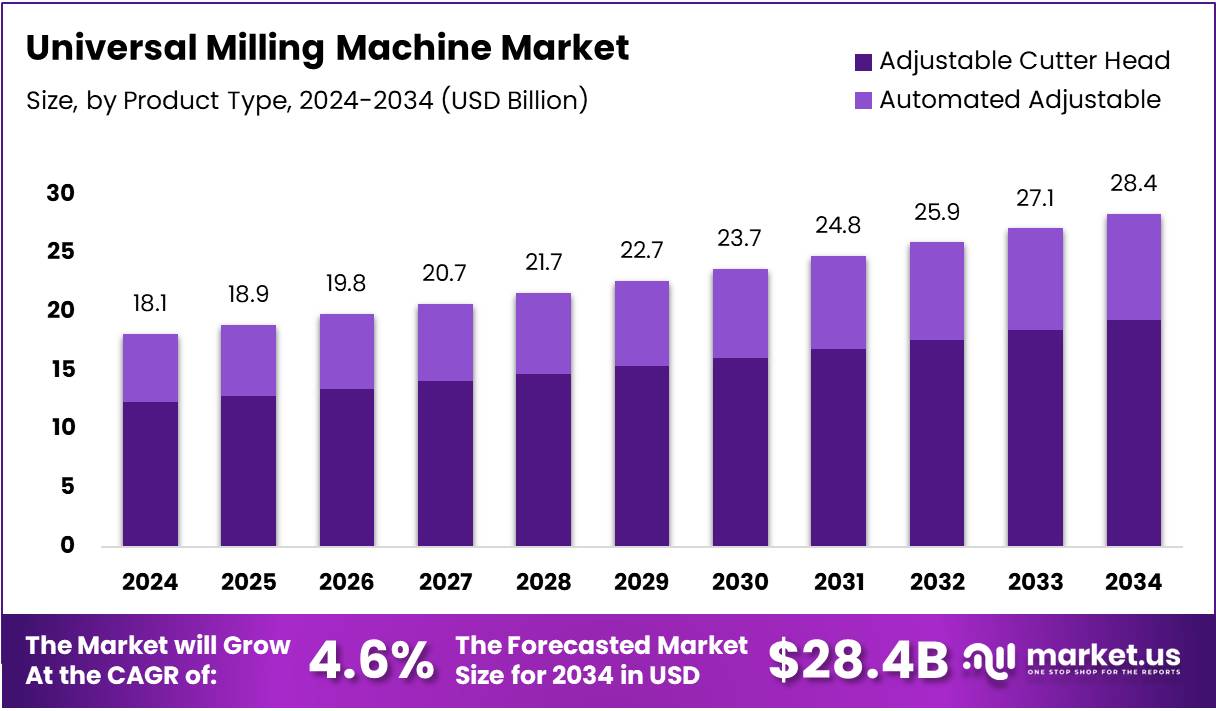

The Global Universal Milling Machine Market size is expected to be worth around USD 28.4 Billion by 2034, from USD 18.1 Billion in 2024, growing at a CAGR of 4.6% during the forecast period from 2025 to 2034.

The Universal Milling Machine Market represents a critical segment within precision manufacturing equipment. These versatile machines enable multi-directional cutting operations, accommodating various workpiece configurations. Consequently, industries demand enhanced machining capabilities for complex component production. The market demonstrates steady expansion driven by automation trends and manufacturing modernization initiatives globally.

Manufacturing sectors increasingly prioritize operational efficiency and cost-effectiveness. Universal milling machines deliver superior flexibility compared to conventional equipment. Therefore, automotive, aerospace, and metalworking industries actively invest in advanced machining solutions. This technological shift creates substantial growth opportunities for equipment manufacturers and service providers.

Government initiatives significantly influence market dynamics and investment patterns. Various nations implement industrial development programs supporting manufacturing infrastructure upgrades. Additionally, regulatory frameworks emphasize workplace safety and environmental compliance. These policies consequently drive demand for modern, efficient milling equipment across developed and emerging economies.

Emerging markets present considerable expansion potential for industry stakeholders. Developing regions experience rapid industrialization and infrastructure development activities. Furthermore, small and medium enterprises gradually adopt automated machining technologies. This democratization of advanced equipment broadens the customer base substantially.

Technical advancements enhance machine performance and operational economics considerably. Modern universal milling machines feature improved dimensional capabilities and processing efficiency. Specifically, contemporary models travel longitudinally up to 700/680mm and cross-directionally up to 255/244mm. Moreover, plunge milling cycle time achieves approximately 20% reduction compared to conventional milling procedures. These improvements favor economic sustainability while reducing tool wear significantly, thereby lowering operational costs and extending equipment lifespan for manufacturers.

Key Takeaways

- The global Universal Milling Machine Market is projected to grow from USD 18.1 Billion in 2024 to USD 28.4 Billion by 2034, registering a 4.6% CAGR.

- Adjustable Cutter Head machines dominate the product segment with a market share of 68.9% in 2024.

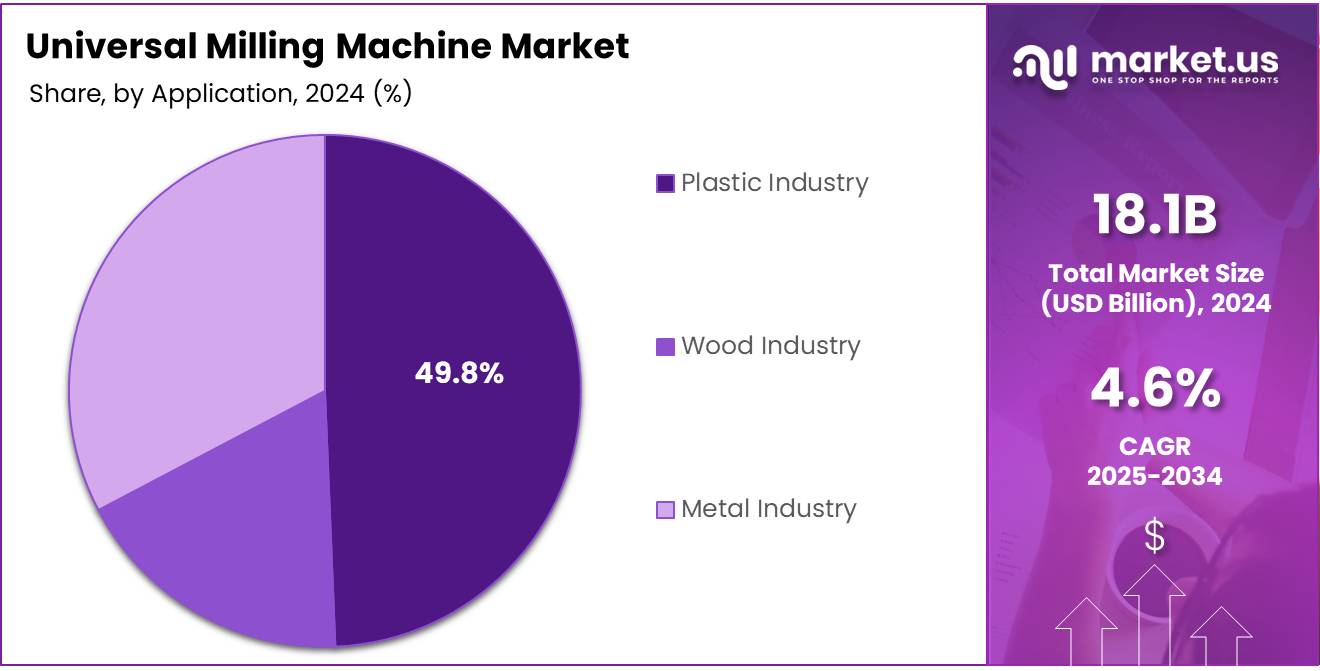

- The Plastic Industry leads application demand, accounting for 49.8% of the market share in 2024.

- Asia Pacific is the leading regional market with a 45.9% share, valued at USD 8.3 Billion.

Product Type Analysis

Adjustable Cutter Head held a dominant market position in the By Product Type Analysis segment of Universal Milling Machine Market, with a 68.9% share.

In 2024,Adjustable Cutter Head universal milling machines dominate with 68.9% share, driven by their exceptional versatility and precision. These machines enable operators to modify cutting angles seamlessly, accommodating diverse machining requirements. The adjustable mechanism facilitates complex geometries, making them essential for manufacturers seeking flexibility. Their widespread adoption stems from enhanced efficiency and reduced setup times, optimizing productivity while maintaining quality standards.

Automated Adjustable universal milling machines represent the evolving segment, integrating advanced automation with traditional features. These systems incorporate computer numerical control and sensors, delivering unprecedented accuracy. The automated functionality minimizes human intervention, reducing errors while maximizing throughput. Industries embracing digital transformation favor these machines for executing complex sequences. The integration of Industry 4.0 capabilities positions them as future-ready manufacturing solutions.

Application Analysis

Plastic Industry held a dominant market position in the By Application Analysis segment of Universal Milling Machine Market, with a 49.8% share.

In 2024, Plastic Industry dominates with 49.8% share, reflecting substantial demand for precision machining in plastic component manufacturing. Universal milling machines facilitate accurate shaping and finishing of materials used across automotive, packaging, and medical sectors. Growing emphasis on lightweight components drives investment in advanced milling technologies. These machines effectively handle diverse plastic grades, ensuring dimensional accuracy and quality throughout production.

Wood Industry represents a significant segment, utilizing universal milling machines for furniture manufacturing and decorative woodworking. These machines enable precise cutting and pattern creation on various wood types, supporting craftsmanship and production. Rising demand for customized wooden products sustains steady growth. Universal milling machines offer flexibility to execute intricate designs while maintaining structural integrity across product categories.

Metal Industry constitutes a crucial application where universal milling machines perform essential metalworking operations including cutting and finishing. These machines process metals for aerospace, automotive, and construction equipment manufacturing. The sector’s requirement for high-precision components drives adoption of advanced solutions. The ability to handle various alloys and perform multiple operations enhances manufacturing efficiency in fabrication processes.

Key Market Segments

By Product

- Adjustable Cutter Head

- Automated Adjustable

By Application

- Plastic Industry

- Wood Industry

- Metal Industry

Drivers

Rising Industrial Automation and Smart Factory Implementations Drive Market Growth

The universal milling machine market is experiencing strong growth due to increasing industrial automation across manufacturing sectors. Factories worldwide are adopting smart manufacturing practices to improve production efficiency and reduce operational costs. This shift is creating consistent demand for advanced milling equipment that can integrate with automated systems.

Precision engineering has become essential in modern manufacturing. Industries need components with exact specifications and tight tolerances for products ranging from medical devices to consumer electronics. Universal milling machines deliver the accuracy required for these complex parts, making them indispensable in precision manufacturing environments.

Technological improvements continue to enhance milling machine performance. Manufacturers are developing machines with better cutting accuracy, faster operation speeds, and improved reliability. These advancements help factories produce higher quality products while reducing waste and production time. The combination of better technology and growing precision requirements is pushing more companies to invest in modern universal milling machines for their production facilities.

Restraints

Limited Availability of Skilled Operators for Advanced Universal Milling Machines Restrains Market Expansion

The universal milling machine market faces challenges due to the shortage of trained operators. Modern milling machines require specialized knowledge and technical skills to operate effectively. Many manufacturers struggle to find workers who understand complex milling operations, programming requirements, and quality control procedures. This skills gap slows down market adoption as companies hesitate to invest in equipment they cannot operate properly.

Training programs take considerable time and resources, making it difficult for businesses to quickly build capable workforce teams. The learning curve for advanced milling machines is steep, requiring operators to understand mechanical principles, computer programming, and material properties. This extended training period creates operational delays and increases labor costs.

Maintenance complexity adds another layer of difficulty for market growth. Multi-axis milling machines contain sophisticated components that need regular servicing and calibration. Maintenance requires specialized knowledge and expensive diagnostic tools. When machines break down, companies face extended downtime waiting for qualified technicians. These maintenance challenges increase total ownership costs and make some businesses reluctant to adopt advanced milling technology.

Growth Factors

Expansion in Aerospace and Automotive Precision Component Manufacturing Creates Growth Opportunities

The aerospace industry presents significant opportunities for universal milling machine manufacturers. Aircraft components demand extremely tight tolerances and complex geometries that universal milling machines can deliver. As global air travel grows and airlines modernize their fleets, demand for precision-machined aerospace parts continues rising, creating sustained demand for advanced milling equipment.

Automotive manufacturers are increasingly adopting CNC-integrated universal milling machines to improve production flexibility. These computerized systems allow faster changeovers between different parts and better quality control. The automotive sector’s shift toward electric vehicles requires new components with different specifications, making versatile CNC milling machines valuable for adapting to changing production needs.

Small and medium enterprises represent an emerging growth segment. These businesses need customized milling solutions that fit their specific production requirements and budget constraints. Equipment manufacturers are responding by offering modular machines and flexible financing options. This approach makes advanced milling technology accessible to smaller manufacturers, expanding the total market size beyond large industrial corporations.

Emerging Trends

Integration of AI and IoT for Real-Time Milling Process Monitoring Shapes Market Trends

Artificial intelligence and Internet of Things technologies are transforming how universal milling machines operate. Modern machines feature sensors that continuously monitor cutting conditions, tool wear, and product quality. This real-time data helps operators identify problems immediately and adjust settings before defects occur. AI algorithms analyze performance patterns to predict maintenance needs and optimize cutting parameters automatically.

Environmental concerns are driving demand for energy-efficient milling equipment. Manufacturers are designing machines that consume less electricity and generate less waste during operation. Eco-friendly features include improved cooling systems, energy recovery mechanisms, and biodegradable cutting fluids. Companies prefer these sustainable options to reduce operating costs and meet environmental regulations.

Compact and modular milling systems are gaining popularity among manufacturers with limited floor space. These machines offer full functionality in smaller footprints, making them ideal for workshops and facilities with space constraints. Modular designs allow businesses to add capabilities as needs grow, providing flexibility without requiring complete equipment replacement.

Regional Analysis

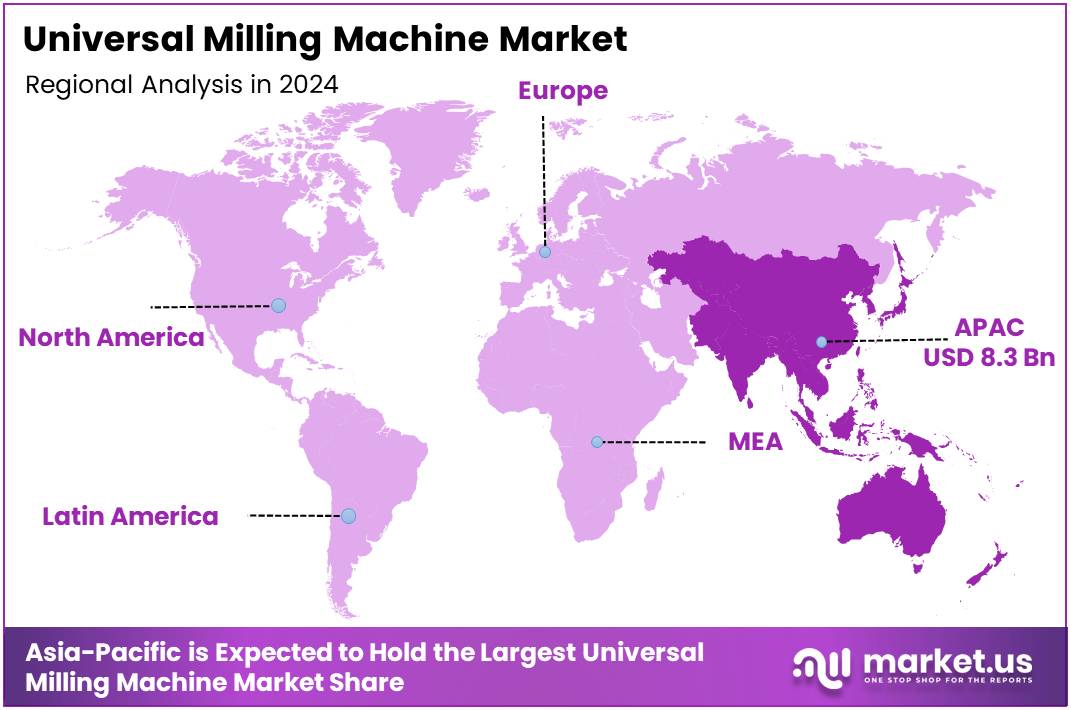

Asia Pacific Dominates the Universal Milling Machine Market with a Market Share of 45.9%, Valued at USD 8.3 Billion

Asia Pacific commands the largest share of the universal milling machine market, accounting for 45.9% of the global market with a valuation of USD 8.3 billion. The region’s dominance is driven by rapid industrialization, robust manufacturing sectors in China, India, and Japan, and favorable government initiatives promoting domestic production. The growing adoption of advanced CNC milling machines and automation in manufacturing processes continue to propel market growth across the region.

North America Universal Milling Machine Market Trends

North America represents a significant market supported by advanced manufacturing capabilities and technological innovation. The United States leads regional growth with substantial demand from aerospace, defense, and automotive industries requiring high-precision machining solutions. The ongoing trend of reshoring manufacturing operations and investments in smart factory technologies sustain steady demand for universal milling machines.

Europe Universal Milling Machine Market Trends

Europe maintains a strong position characterized by its mature industrial base and emphasis on precision engineering. Germany, Italy, and France drive market growth with well-established machinery manufacturing sectors. The increasing adoption of Industry 4.0 technologies and integration of IoT-enabled milling machines enhance productivity and sustain demand across automotive, aerospace, and general manufacturing industries.

Middle East and Africa Universal Milling Machine Market Trends

The Middle East and Africa region exhibits moderate but growing demand driven by infrastructure development and economic diversification efforts. GCC countries are investing in manufacturing and industrial sectors, creating opportunities for machining equipment suppliers. However, market penetration remains limited compared to other regions due to economic volatility and nascent industrial development in several nations.

Latin America Universal Milling Machine Market Trends

Latin America presents emerging opportunities with Brazil and Mexico leading regional demand, primarily driven by the automotive manufacturing sector. The market growth is supported by ongoing industrialization efforts and investments in modernizing manufacturing facilities. Despite economic instability and infrastructure challenges, government initiatives to strengthen industrial capabilities are expected to gradually boost demand for universal milling machines.

Key Regions and Countries

North America

- US

- Canada

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Universal Milling Machine Company Insights

Centauro continues to strengthen its position by emphasizing mechanical robustness and consistent machining accuracy rather than rapid technological shifts. From an analyst viewpoint, this approach aligns well with traditional workshops and vocational manufacturing units that value long equipment life and operational stability. Centauro’s restrained innovation cycle helps control costs while sustaining dependable output.

Kaast Machine tools Inc. differentiates itself through flexible machine configurations and responsiveness to customer-specific production needs. The company benefits from serving buyers that require adaptable universal milling machines for short production runs or prototype development. Analysts view Kaast’s model as margin-supportive, though future growth will depend on scaling customization without increasing lead times.

Knuth Machine tools leverages its established global presence to maintain demand in replacement and upgrade cycles. Its machines are often selected for their straightforward operation and compatibility with existing shop-floor practices. This conservative positioning supports steady sales in regions where training costs and operator familiarity strongly influence purchasing decisions.

DMG Mori remains the most technology-driven among these players, integrating digital monitoring, automation interfaces, and precision-enhancing software into universal milling platforms. Analysts see DMG Mori benefiting from customers transitioning toward smart manufacturing environments. Its higher upfront pricing is frequently justified by productivity gains, process consistency, and long-term operational efficiency.

Top Key Players in the Market

- Centauro

- Kaast Machine tools Inc.

- Knuth Machine tools

- DMG Mori

- Haas Automation

- Mazak

- Okuma

- Hurco Companies

- Toshiba Machine

- Fadal Engineering

Recent Developments

- In August 2025, CNC milling systems with AI-enabled adaptive control and real-time monitoring were integrated into smart factories by Chinese aerospace firms.This development highlights a clear shift toward digitalized, high-efficiency manufacturing to improve precision, uptime, and production consistency.

- In April 2025, Nidec initiated a tender offer worth ¥257 billion ($1.6 billion) to acquire Makino Milling Machine.The move reflects rising industry consolidation and stronger capital investment in advanced milling and machining technologies.

- In February 2025, DMG MORI announced plans to launch five new production platform machines at its in-house exhibition in Pfronten, Germany.The launch, aligned with its Machining Transformation (MX) strategy, emphasizes enhanced multi-axis milling capability and productivity.

Report Scope

Report Features Description Market Value (2024) USD 18.1 Billion Forecast Revenue (2034) USD 28.4 Billion CAGR (2025-2034) 4.6% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product (Adjustable Cutter Head, Automated Adjustable), By Application (Plastic Industry, Wood Industry, Metal Industry) Regional Analysis North America (US and Canada), Europe (Germany, France, The UK, Spain, Italy, and Rest of Europe), Asia Pacific (China, Japan, South Korea, India, Australia, and Rest of APAC), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, South Africa, and Rest of MEA) Competitive Landscape Centauro, Kaast Machine tools Inc., Knuth Machine tools, DMG Mori, Haas Automation, Mazak, Okuma, Hurco Companies, Toshiba Machine, Fadal Engineering Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Universal Milling Machine MarketPublished date: Dec 2025add_shopping_cartBuy Now get_appDownload Sample

Universal Milling Machine MarketPublished date: Dec 2025add_shopping_cartBuy Now get_appDownload Sample -

-

- Centauro

- Kaast Machine tools Inc.

- Knuth Machine tools

- DMG Mori

- Haas Automation

- Mazak

- Okuma

- Hurco Companies

- Toshiba Machine

- Fadal Engineering