Global Screen Printing Mesh Market Size, Share, And Enhanced Productivity By Material (Polyarylate Screen Printing Mesh, Polyester Screen Printing Mesh, Nylon Screen Printing Mesh, Steel Screen Printing Mesh), By Filament (Monofilament, Multi-filament), By Mesh Count (Below 80 TPI, 81 to 110 ΤΡΙ, 111 to 220 ΤΡΙ, 221 to 305 ΤΡΙ, Above 305 ΤΡΙ), By Thread Diameter (Below 30 Micron, 31 To 60 Microns, 61 To 90 Microns, Above 90 Micron), By Substrate (Paper and Paperboard, Metal, Plastic, Fabric, Glass), By End-use (Textile, Packaging, Glass and Ceramics, Electronics and Electrical, Advertising and Marketing, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2025-2034

- Published date: February 2026

- Report ID: 176974

- Number of Pages: 303

- Format:

-

keyboard_arrow_up

Quick Navigation

- Report Overview

- Key Takeaways

- By Material Analysis

- By Filament Analysis

- By Mesh Count Analysis

- By Thread Diameter Analysis

- By Substrate Analysis

- By End-use Analysis

- Key Market Segments

- Driving Factors

- Restraining Factors

- Growth Opportunity

- Latest Trends

- Regional Analysis

- Key Players Analysis

- Recent Developments

- Report Scope

Report Overview

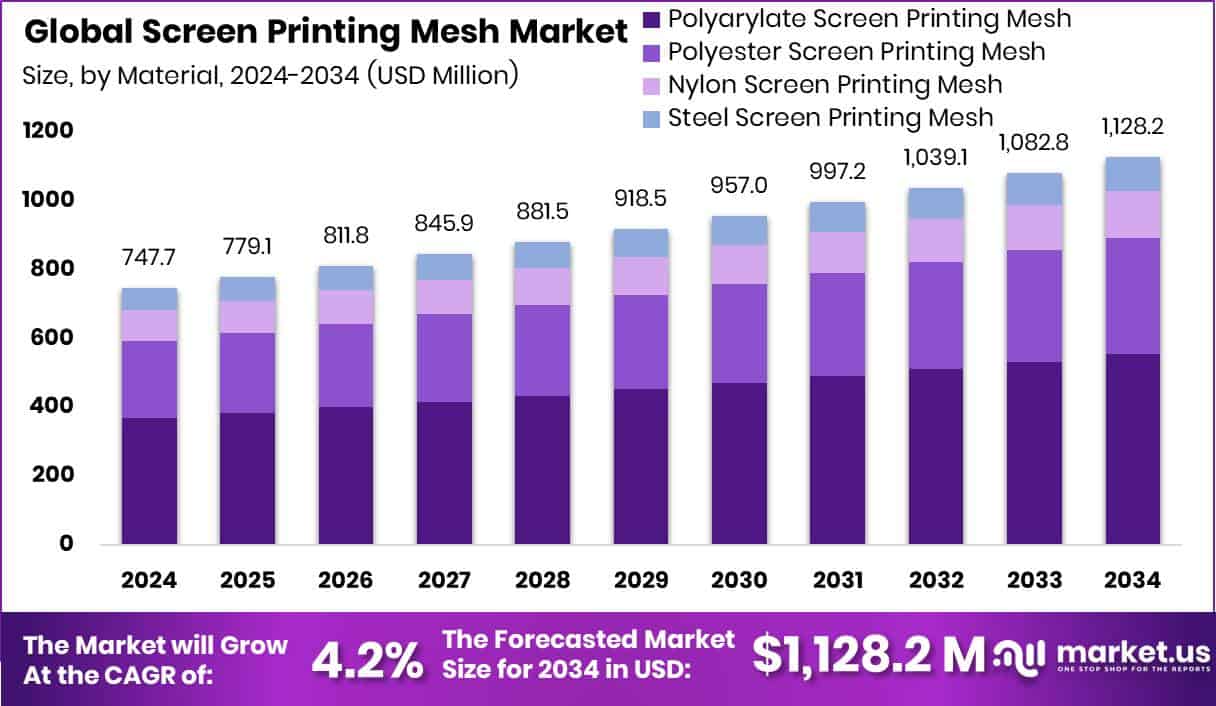

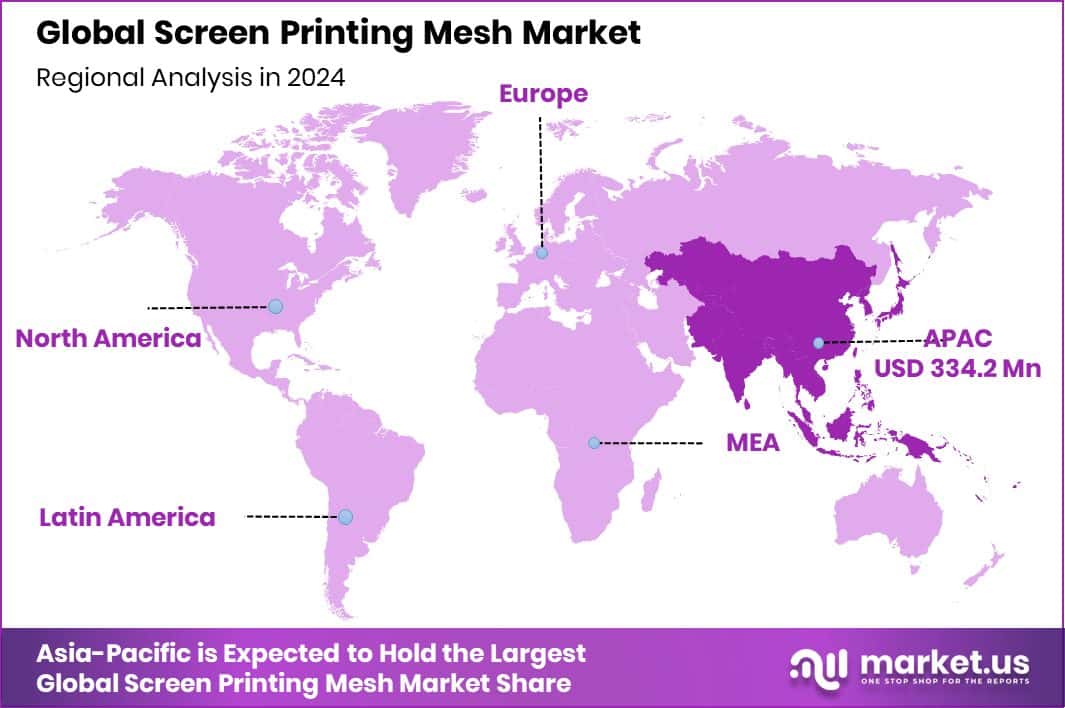

The Global Screen Printing Mesh Market is expected to be worth around USD 1,128.2 million by 2034, up from USD 747.7 million in 2024, and is projected to grow at a CAGR of 4.2% from 2025 to 2034. Asia Pacific maintained dominance, holding a 44.7% share valued at USD 334.2 Mn overall.

The global Screen Printing Mesh Market is structured across materials such as polyarylate, polyester, nylon, and steel meshes, alongside filament types, mesh counts, thread diameters, substrates, and diverse end-use industries. Screen printing mesh refers to the woven material stretched onto a frame that controls ink flow during printing, ensuring accuracy, sharpness, and consistency. The Screen Printing Mesh Market includes the production, distribution, and application of these meshes across textiles, packaging, electronics, ceramics, and advertising, supporting both mass-production and high-precision printing needs.

Growth in this market is supported by rising investments in digital display and printing-related infrastructure. For instance, BlackRock recently loosened weapons screens on $64bn worth of ESG funds, indirectly expanding institutional activity that can influence advanced printing technologies and materials. This shifting investment landscape encourages producers to innovate stronger and more efficient meshes.

Demand is also fueled by the evolution of visual communication. Croatia’s All Eyes On Screens securing €10M to transform advertising shows how the push for higher-quality visuals increases reliance on precision screen printing in promotional graphics, packaging, and industrial branding.

Significant opportunity arises from public infrastructure spending, such as Eden Park’s $1.4M ratepayer-funded big-screen upgrade in New Zealand’s largest stadium, Eden Park. Larger screens and display-driven environments indirectly boost demand for printed components, signage, decorative layers, and supporting mesh technologies.

Key Takeaways

- The Global Screen Printing Mesh Market is expected to be worth around USD 1,128.2 million by 2034, up from USD 747.7 million in 2024, and is projected to grow at a CAGR of 4.2% from 2025 to 2034.

- In the Screen Printing Mesh Market, Polyarylate material leads with 49.2%, driven by durability and precision.

- The Screen Printing Mesh Market sees Monofilament dominating with 69.4%, thanks to its uniform fiber structure.

- Within the Screen Printing Mesh Market, the 111–220 ΤΡΙ mesh count holds 38.5% due to balanced print quality.

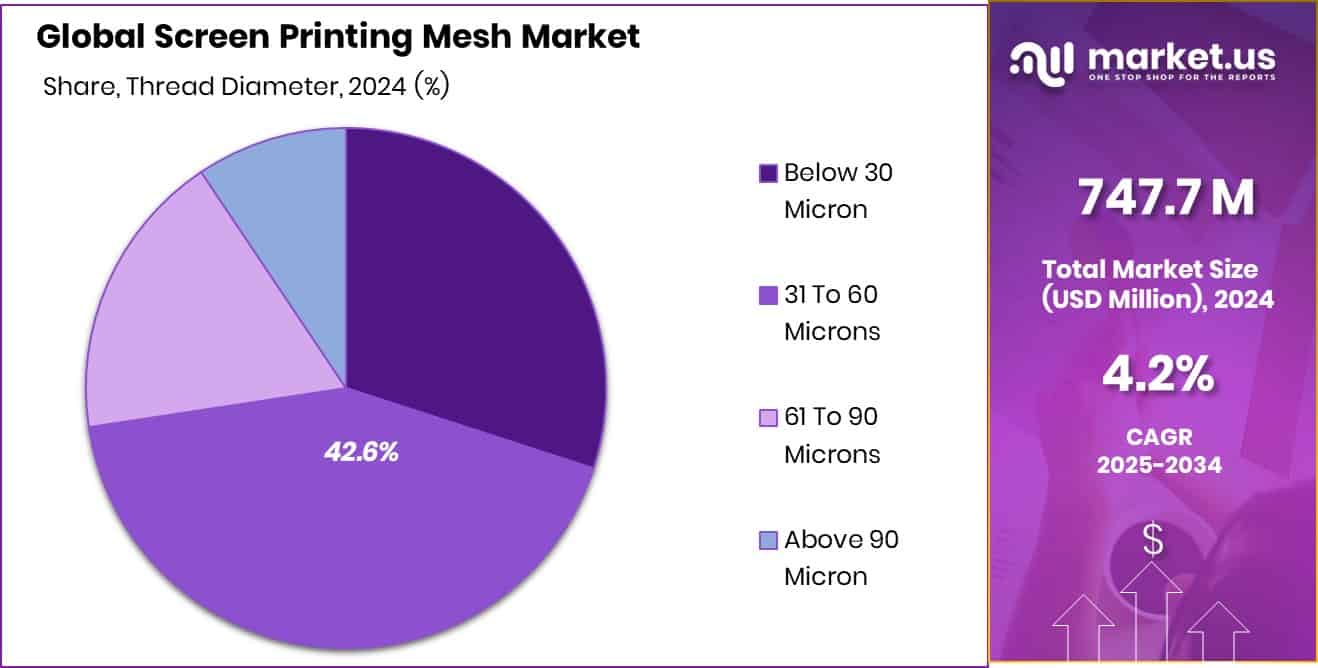

- The Screen Printing Mesh Market favors 31 to 60 microns thread diameter at 42.6% for fine detailing.

- Fabric substrate maintains 37.9% share in the Screen Printing Mesh Market owing to versatility and cost-efficiency.

- The textile end-use segment leads the Screen Printing Mesh Market with 38.1%, supported by rising apparel printing demand.

- Asia Pacific achieved strong market momentum overall, capturing 44.7% worth USD 334.2 Mn.

By Material Analysis

Polyarylate dominated the Screen Printing Mesh Markets with 49.2% material share globally.

In 2024, Polyarylate Screen Printing Mesh held a dominant position in the Screen Printing Mesh market with a 49.2% share. Its strong lead comes from its exceptional thermal resistance, high tensile strength, and superior print accuracy, making it highly preferred for advanced industrial and textile printing. Manufacturers increasingly rely on polyarylate materials to achieve consistent impressions, especially in high-speed production environments.

The segment benefits from rising demand for durable mesh solutions that maintain stability under continuous pressure. Additionally, its long service life reduces operational downtime, helping companies lower maintenance costs. As industries shift toward precision-driven printing applications, the polyarylate category continues to secure its dominant share, reinforcing its importance across global production facilities.

By Filament Analysis

Monofilament dominated Screen Printing Mesh Markets with 69.4% filament share in 2025.

In 2024, Monofilament dominated the Screen Printing Mesh Markets with a significant 69.4% share, emerging as the most widely adopted filament type. Its uniform thread structure provides excellent ink flow, reduced clogging, and consistent print quality, making it ideal for textile, electronics, and packaging applications. Industries prefer monofilament mesh due to its predictable performance, better tension retention, and superior durability during repeated printing cycles.

The segment’s dominance is also supported by its cost-efficiency and ease of cleaning, helping manufacturers maintain smooth production workflows. As demand rises for sharper, high-resolution prints, monofilament mesh continues to outperform multifilament options, maintaining its leading role in modern screen printing environments globally.

By Mesh Count Analysis

111 to 220 TPI dominated Screen Printing Mesh Markets with 38.5% share.

In 2024, the 111 to 220 ΤΡΙ mesh count category dominated the Screen Printing Mesh Markets with a 38.5% share. This range is preferred because it provides the ideal balance between ink deposit and print clarity, catering to diverse applications such as garment printing, industrial labels, and promotional graphics. The segment’s versatility allows printers to achieve fine-detail outputs without compromising ink coverage.

Its adoption continues to rise as brands demand high-definition prints for premium textile and packaging products. Additionally, this mesh count supports efficient ink usage and reduces printing errors, helping businesses improve overall productivity. As print quality becomes a top priority across industries, the 111 to 220 ΤΡΙ range maintains its strong leadership in the market.

By Thread Diameter Analysis

31 to 60 microns dominated the Screen Printing Mesh Markets with 42.6% share.

In 2024, the 31 to 60 microns thread diameter segment held a dominant 42.6% share in the Screen Printing Mesh Markets. This diameter range is highly preferred because it balances print precision with durability, enabling smooth ink passage while maintaining structural strength. It is widely used in textile printing, electronics, and industrial graphics, where detailed prints and long mesh life are essential.

The segment’s dominance also stems from its adaptability across multiple mesh counts, giving manufacturers flexibility in meeting varied printing specifications. With increasing demand for fine yet durable threading materials, this range supports consistent print results and reduced mesh breakage. As industries pursue high-efficiency solutions, the 31 to 60 microns segment remains the leading choice globally.

By Substrate Analysis

Fabric dominated the global Screen Printing Mesh Markets with 37.9% substrate share.

In 2024, the Fabric substrate segment dominated the Screen Printing Mesh Markets with a 37.9% share. Fabric substrates continue to lead because they are widely used in apparel printing, home textiles, banners, and industrial materials. Their excellent compatibility with various inks, along with their ability to deliver vivid and long-lasting prints, strengthens their demand.

The segment benefits from growing textile production across emerging markets and rising customization trends in fashion and décor. Fabric substrates also allow for efficient mass production while maintaining print quality, which is crucial for high-volume manufacturers. As global demand grows for detailed prints on soft surfaces, the fabric category retains its strong market position.

By End-use Analysis

Textile-dominated overall Screen Printing Mesh Markets with 38.1% end-use share globally.

In 2024, the Textile end-use segment dominated the Screen Printing Mesh Markets with a 38.1% share. The textile industry remains the largest consumer due to the extensive use of screen printing in apparel, sportswear, fashion accessories, and home furnishings. Screen printing continues to be preferred for its vibrant colors, durability, and cost-effectiveness in large production runs.

The segment’s dominance is further supported by the growing popularity of custom clothing, promotional wear, and branded merchandise. Additionally, advancements in mesh technology help textile manufacturers achieve higher precision and efficiency in printing intricate designs. As global textile production expands and consumer demand for high-quality printed fabrics increases, this segment continues to lead the market.

Key Market Segments

By Material

- Polyarylate Screen Printing Mesh

- Polyester Screen Printing Mesh

- Nylon Screen Printing Mesh

- Steel Screen Printing Mesh

By Filament

- Monofilament

- Multi-filament

By Mesh Count

- Below 80 TPI

- 81 to 110 ΤΡΙ

- 111 to 220 ΤΡΙ

- 221 to 305 ΤΡΙ

- Above 305 ΤΡΙ

By Thread Diameter

- Below 30 Micron

- 31 To 60 Microns

- 61 To 90 Microns

- Above 90 Micron

By Substrate

- Paper and Paperboard

- Metal

- Plastic

- Fabric

- Glass

By End-use

- Textile

- Packaging

- Glass and Ceramics

- Electronics and Electrical

- Advertising and Marketing

- Others

Driving Factors

Rising demand for high-precision printing

Rising demand for high-precision printing continues to strengthen the Screen Printing Mesh Market, especially as industries push for cleaner edges, consistent ink flow, and higher print accuracy. This demand aligns with broader global trade activity, including the €2.5bn worth of wood and paper product imports recorded in 2023, which reflects steady consumption of substrates used in printing processes.

As packaging, labeling, and industrial graphics expand, manufacturers rely on high-quality meshes to meet tighter tolerances and faster production speeds. The ongoing shift toward detail-oriented printing in textiles, electronics, and commercial graphics reinforces the need for robust monofilament and specialty mesh types. Collectively, these factors contribute to stable, long-term market growth across multiple industries.

Restraining Factors

Limited availability of premium materials

Limited availability of premium raw materials remains a major restraint for the Screen Printing Mesh Market, as high-grade polymers and metal alloys are crucial for achieving optimal mesh durability and precision. Supply constraints make it difficult for manufacturers to maintain consistent production quality, especially for fine-thread and high-tension mesh categories. This challenge is highlighted by redevelopment efforts such as the $1.5M grant awarded to the former Middletown Paperboard site, underscoring ongoing disruptions in legacy material and substrate production spaces.

Market participants must navigate fluctuating supply chains, tight global inventories, and higher procurement costs. These pressures collectively slow product innovation, increase lead times, and influence pricing trends.

Growth Opportunity

Expansion in electronics printing applications

Expansion in electronics printing applications offers strong opportunities for the Screen Printing Mesh Market, as components like circuit traces, conductive layers, and display elements increasingly rely on fine mesh precision. With industries adopting printed electronics for sensors, wearables, and compact devices, demand for ultra-fine meshes continues to rise. This momentum is supported by funding activity such as DetraPel’s $7.6M Series A, which signals growing interest in advanced coating, protection, and material technologies that integrate well with printed components.

As electronics manufacturing shifts toward lightweight, flexible, and miniaturized products, the need for high-performance mesh materials becomes even more critical. This creates space for product diversification, innovation, and higher-value mesh offerings.

Latest Trends

Shift toward sustainable mesh solutions

A major trend in the Screen Printing Mesh Market is the shift toward sustainable and recyclable mesh solutions as industries reduce waste and improve material efficiency. Companies are exploring mesh types designed for longer service life, lower ink consumption, and minimal environmental impact. This trend aligns with broader eco-focused investments, such as Celadon’s $267M commitment to a paperboard recycling facility in Virginia, highlighting global momentum toward circular manufacturing systems.

As sustainable substrates and packaging materials evolve, the printing processes supporting them must advance as well. This pushes mesh producers to invest in greener materials, improved production methods, and longer-lasting products, shaping the next generation of screen printing technology.

Regional Analysis

Asia Pacific leads the Printing Mesh Market with 44.7% and USD 334.2 Mn

North America emerged as the dominant region in the Screen Printing Mesh Market, securing a 41.2% share valued at USD 329.1 Mn, supported by strong demand from the textile, industrial graphics, and packaging sectors. North America benefits from mature printing technologies and consistent adoption of advanced mesh materials across manufacturing hubs.

In contrast, Europe shows steady growth driven by increasing preference for precision printing in automotive labels, fashion textiles, and high-quality promotional materials. Asia Pacific continues to expand rapidly as rising textile exports and mass-scale production strengthen mesh consumption across China, India, and Southeast Asia.

Meanwhile, the Middle East and Africa experience moderate growth, supported by developing apparel industries and the rising presence of local printing companies. Lastly, Latin America maintains a stable market outlook, with demand influenced by regional textile manufacturing and increasing interest in customized merchandise printing.

Together, these regions reflect diverse adoption patterns shaped by industrial capacity, printing technology penetration, and evolving end-use requirements within the global screen printing mesh landscape.

Key Regions and Countries

- North America

- US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of MEA

Key Players Analysis

Sefar AG remained an influential player, leveraging its long-standing expertise in high-performance mesh solutions. The company’s focus on consistent thread quality, improved tension stability, and advanced weaving techniques helped it support customers in textiles, electronics, and industrial printing. Its emphasis on durability and uniform ink deposition kept it well-positioned in demanding end-use sectors.

Meanwhile, NBC Meshtec Inc. continued to emphasize engineered mesh solutions designed for high-precision printing applications. Known for its technical innovation and strict quality control processes, the company strengthened its presence in segments such as food packaging, apparel printing, and specialty industrial components. Its ability to integrate material science with advanced production systems allowed clients to achieve sharper details and improved production efficiency.

Additionally, Nippon Tokushu Fabric Inc. played a strategic role by offering specialized technical fabrics tailored to modern screen-printing needs. The company’s focus on material purity, controlled mesh openings, and stable performance under continuous operations positioned it as a reliable supplier for high-volume manufacturing. Across these three companies, commitment to precision engineering, material innovation, and long-term reliability remained central to shaping the competitive landscape of the Screen Printing Mesh Market in 2024.

Top Key Players in the Market

- Sefar AG

- NBC Meshtec Inc.

- Nippon Tokushu Fabric Inc.

- Nakanuma Art Screen Co., Ltd.

- Weisse & Eschrich GmbH & Co. KG

- Asada Mesh Co., Ltd.

- Maishi Manufacture (Group) Limited

- Saati S.p.A.

- Extris Srl

- Haver & Boecker OHG

- Shanghai Shangshai Bolting Cloth Manufacturing Co., Ltd

Recent Developments

- In April 2025, Sefar actively showcased its SEFAR® PME mesh options along with the SEFAR® Tensocheck 200 at industry events, reinforcing its commitment to performance-oriented solutions for screen printing professionals.

- In October 2024, Weisse & Eschrich highlighted expanded offerings of custom mesh solutions using modern equipment for wire mesh suited for special industrial uses, which can include screen printing infrastructure applications.

Report Scope

Report Features Description Market Value (2024) USD 747.7 Million Forecast Revenue (2034) USD 1,128.2 Million CAGR (2025-2034) 4.2% Base Year for Estimation 2024 Historic Period 2020-2023 Forecast Period 2025-2034 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Material (Polyarylate Screen Printing Mesh, Polyester Screen Printing Mesh, Nylon Screen Printing Mesh, Steel Screen Printing Mesh), By Filament (Monofilament, Multi-filament), By Mesh Count (Below 80 TPI, 81 to 110 ΤΡΙ, 111 to 220 ΤΡΙ, 221 to 305 ΤΡΙ, Above 305 ΤΡΙ), By Thread Diameter (Below 30 Micron, 31 To 60 Microns, 61 To 90 Microns, Above 90 Micron), By Substrate (Paper and Paperboard, Metal, Plastic, Fabric, Glass), By End-use (Textile, Packaging, Glass and Ceramics, Electronics and Electrical, Advertising and Marketing, Others) Regional Analysis North America – US, Canada; Europe – Germany, France, The UK, Spain, Italy, Rest of Europe; Asia Pacific – China, Japan, South Korea, India, Australia, Singapore, Rest of APAC; Latin America – Brazil, Mexico, Rest of Latin America; Middle East & Africa – GCC, South Africa, Rest of MEA Competitive Landscape Sefar AG, NBC Meshtec Inc., Nippon Tokushu Fabric Inc., Nakanuma Art Screen Co., Ltd., Weisse & Eschrich GmbH & Co. KG, Asada Mesh Co., Ltd., Maishi Manufacture (Group) Limited, Saati S.p.A., Extris Srl, Haver & Boecker OHG, Shanghai Shangshai Bolting Cloth Manufacturing Co., Ltd Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF)  Screen Printing Mesh MarketPublished date: February 2026add_shopping_cartBuy Now get_appDownload Sample

Screen Printing Mesh MarketPublished date: February 2026add_shopping_cartBuy Now get_appDownload Sample -

-

- Sefar AG

- NBC Meshtec Inc.

- Nippon Tokushu Fabric Inc.

- Nakanuma Art Screen Co., Ltd.

- Weisse & Eschrich GmbH & Co. KG

- Asada Mesh Co., Ltd.

- Maishi Manufacture (Group) Limited

- Saati S.p.A.

- Extris Srl

- Haver & Boecker OHG

- Shanghai Shangshai Bolting Cloth Manufacturing Co., Ltd