Quick Navigation

Overview

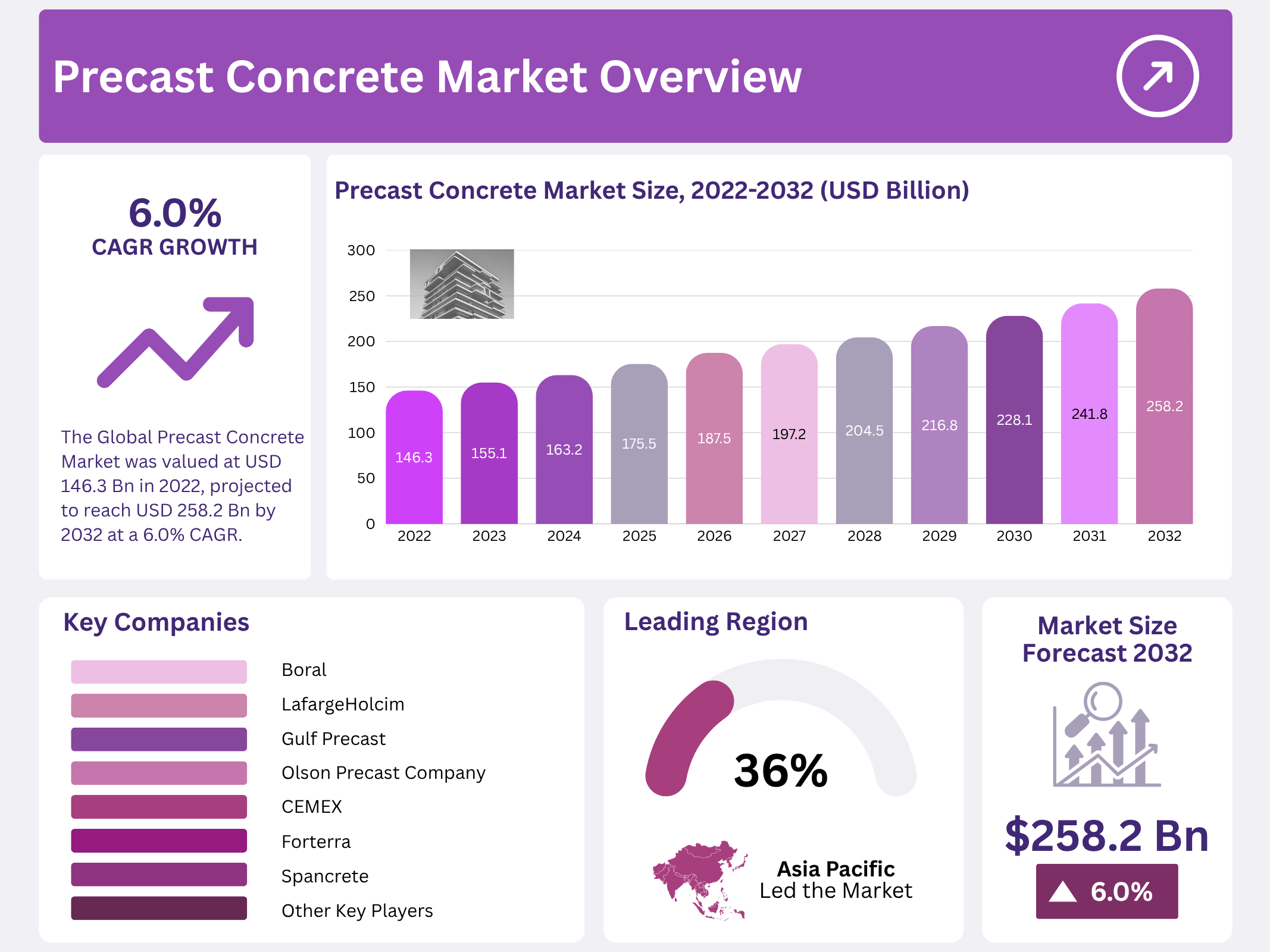

New York, NY – November 14, 2025 – The Global Precast Concrete Market, valued at USD 146.3 billion by 2022, is projected to reach USD 258.2 billion by 2032, registering a CAGR of 6.0% between 2023 and 2032. Precast concrete is produced by casting concrete in reusable molds, curing it in controlled environments, and then transporting it to the construction site. This process improves material consistency, reduces waste, and enhances construction speed compared to traditional onsite casting.

Producing concrete components at ground level provides significant benefits, including better oversight of material quality, improved worker safety, and more precise workmanship. As urbanization accelerates and construction demands rise, the use of precast concrete has gained strong traction across residential, commercial, and industrial developments. Its ability to support faster project delivery makes it increasingly appealing to contractors and developers.

Market growth is further supported by a larger shift toward sustainable, efficient, and cost-effective building methods. Developing nations, in particular, are adopting precast systems to modernize infrastructure and meet expanding urban needs. With increasing investments in infrastructure upgrades and smart city projects, precast concrete is expected to play a central role in shaping modern construction practices worldwide.

Key Takeaways

- The Global Precast Concrete Market was valued at USD 146.3 billion in 2022, projected to reach USD 258.2 billion by 2032 at a 6.0% CAGR.

- The structural beams segment leads in revenue due to extensive use in commercial and residential infrastructure amid rapid urbanization.

- The structural building components segment is set to dominate, driven by demand for precast slabs and façades in construction and affordable housing.

- Non-residential sector holds the largest share, fueled by investments in commercial spaces, infrastructure, and public facilities like hospitals and airports.

- Asia Pacific commands 36.4% market share, led by a strong industrial base and contributions from key regional companies.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2022) | USD 146.3 Billion |

| Forecast Revenue (2032) | USD 258.2 Billion |

| CAGR (2023-2032) | 6.0% |

| Segments Covered | By Product Type – Foundations, Structural Beams, Slabs, Walls, and Other Product Types; By Applications – Structural Building Components, Architectural Building Components, Transportation Products, Waste and Water Handling Products, and Other Applications; By End-User – Residential and Non-Residential. |

| Competitive Landscape | Boral, LafargeHolcim, Gulf Precast, Olson Precast Company, Larsen & Toubro Limited, CEMEX, Forterra, Tindall Corporation, Spancrete, Elementbau Osthessen GmbH & Co., ELO KG, Bouygues Construction, Balfour Beatty, Oldcastle Precast, and Other Key Players. |

Key Market Segments

Product Type Analysis

Precast Concrete Structural Beams Lead the Market

The structural beams segment commands the largest revenue share in the precast concrete market. These beams are widely utilized in commercial and residential infrastructure projects. Rapid global urbanization and surging residential and commercial developments are poised to fuel expansion in the columns and beams market.

Structural beams play a critical role in bearing building loads and ensuring safe load paths from slabs to foundations. Both residential and commercial sectors rely heavily on precast columns and beams. Precast columns reduce material costs and enable the use of higher-capacity cranes for lifting large modules.

The inherent advantages of precast concrete—coupled with rising public and private infrastructure investments in developing regions such as South America, Asia-Pacific, and the Middle East—are expected to propel demand for precast beams throughout the forecast period. Precast concrete walls offer enhanced design flexibility and improved profitability, driving overall adoption of precast building components in the coming years.

Applications Analysis

Structural Building Components Drive High Demand in the Precast Concrete Market

The structural building components segment is anticipated to dominate due to robust demand from the construction industry. This category encompasses a wide range of precast products essential for commercial and residential structures. Precast slabs, façades, and related items are increasingly adopted in industrial and manufacturing facilities.

Global industrialization, alongside the proliferation of malls, hotels, and hospitals, will accelerate segment growth over the forecast period. Precast structural components appeal to developers for their low or zero maintenance needs, further boosting demand. Precast concrete columns, beams, and other elements lower overall building material costs while enhancing durability and construction efficiency, generating strong interest in both residential and commercial applications.

Revenue from architectural buildings is expected to rise steadily. Precast concrete walls will particularly stimulate demand in this area due to their design versatility and profitability advantages. As cities expand, demand will grow for offices, hospitals, schools, shopping malls, apartments, and parking garages.

End-User Analysis

Non-Residential Segment Outpaces Residential in the Precast Concrete Market

The non-residential sector holds the dominant market share, driven by heightened investments in commercial spaces, flyovers, roads, educational institutions, and hospitals across various countries. Growth in non-residential applications is forecasted to accelerate, fueled by demand for stadiums, sports complexes, and airports. The residential segment will also see notable expansion during the forecast period, supported by global population growth and increased investments in infrastructure and real estate development.

Regional Analysis

The Asia Pacific region dominates the global precast concrete market, capturing 36.4% of the total share and emerging as the leading regional player. This leadership is fueled by the region’s robust industrial foundation and substantial contributions from prominent companies driving market expansion.

The Asia Pacific market holds immense growth potential, driven by a rising emphasis on modular and sustainable construction practices, alongside major investments in rehabilitation projects across countries such as India, China, Japan, and Indonesia. Additional growth catalysts include accelerating urbanization, booming residential, commercial, and infrastructure sectors, abundant access to raw materials, low labor costs, and cost-effective production.

Europe secures the second-largest revenue share, with Nordic countries pioneering the adoption of precast technology. Widespread integration of precast solutions in Europe’s construction sector is anticipated throughout the forecast period. The region’s GDP growth is bolstered by private investments in emerging economies, while a recovering construction industry and increasing product penetration are expected to drive significant expansion.

North America is projected to experience moderate growth over the forecast period, supported by technological advancements in the building and construction industry. High demand for single-family homes—particularly in states like Florida, Georgia, and North Carolina—combined with the U.S.’s strong manufacturing and industrial base, is fueling a rise in non-residential developments and sustaining precast concrete market momentum.

Top Use Cases

- Residential Housing: Precast concrete speeds up building homes by making walls, floors, and beams in a factory before delivery. This cuts down on-site work, saves money on labor, and ensures strong, weather-proof structures that last longer. Families get cozy, durable homes faster, perfect for growing cities needing quick, affordable options.

- Bridge Construction: Engineers use precast parts like girders and deck slabs to build sturdy bridges that handle heavy traffic safely. Made off-site, these pieces fit together easily, reducing road closures and costs. They blend with nature too, making travel smoother and greener for everyone.

- Parking Structures: Multi-level car parks rise quickly with precast columns, beams, and slabs that support tons of vehicles without cracking. Factory control means fewer defects, less upkeep, and open designs for easy parking. Urban spots stay clutter-free, boosting city life and business flow.

- Commercial Buildings: Offices and malls get sleek facades and frames from precast panels that look modern and resist fire or storms. Quick assembly means less disruption, while custom shapes add style without extra hassle. Businesses open sooner, drawing crowds to vibrant, safe spaces.

- Infrastructure Projects: Roads, culverts, and seawalls rely on precast pipes and barriers for tough drainage and protection against floods. Durable and easy to install, they cut repair needs and environmental harm. Communities stay connected and secure, supporting daily life without big delays.

Recent Developments

1. Boral

Boral is advancing its precast offerings through digital design integration and sustainable material use. A key development is the expansion of its high-performance architectural and structural precast solutions for commercial and infrastructure projects. The company is focusing on enhancing off-site manufacturing efficiency to improve project timelines and reduce on-site waste, aligning with broader industry trends towards construction digitalization and environmental responsibility.

2. LafargeHolcim

LafargeHolcim is aggressively expanding its ECOPact range of low-carbon concrete into precast applications. A major recent development is the integration of recycled aggregates and calcined clay technologies to reduce the embodied carbon of its precast products. They are also investing in automated precast plants to boost precision and output, supporting large-scale sustainable construction projects across their global network and driving the industry’s green transition.

3. Gulf Precast

Gulf Precast is focusing on complex, high-value projects in the Middle East, particularly in the UAE and Saudi Arabia. Recent developments include the production of large-scale, intricate façade elements for mega-profiles like NEOM and iconic cultural buildings. The company is leveraging advanced BIM (Building Information Modeling) for design and project management to ensure precision and handle the sophisticated architectural demands of these landmark developments.

4. Olson Precast Company

Olson Precast has recently invested in new production machinery and casting beds to increase its capacity for standard and custom precast concrete products. This expansion is aimed at meeting growing demand in the agricultural, utility, and residential markets in the Western U.S. Their focus remains on producing durable septic tanks, utility vaults, and agricultural components with improved manufacturing efficiency and shorter lead times for customers.

5. Larsen & Toubro Limited

L&T’s precast division is a leader in India, recently executing numerous large-scale residential, data center, and infrastructure projects using its L&T Precast solution. A key development is the increased use of hybrid construction methods, combining precast modules with in-situ concrete for speed and flexibility. They are also pioneering the use of digital twins and IoT sensors in their factories to monitor production quality and optimize the entire precast lifecycle.

Conclusion

Precast Concrete is a game-changer in today’s fast-paced building world. It’s off-site, making tackles labor shortages and weather woes, delivering tough, green structures that fit urban booms and smart city dreams. With pushes for quick, eco-friendly builds, this material will keep shining in homes, offices, and big projects, promising smarter growth ahead.