Market Overview

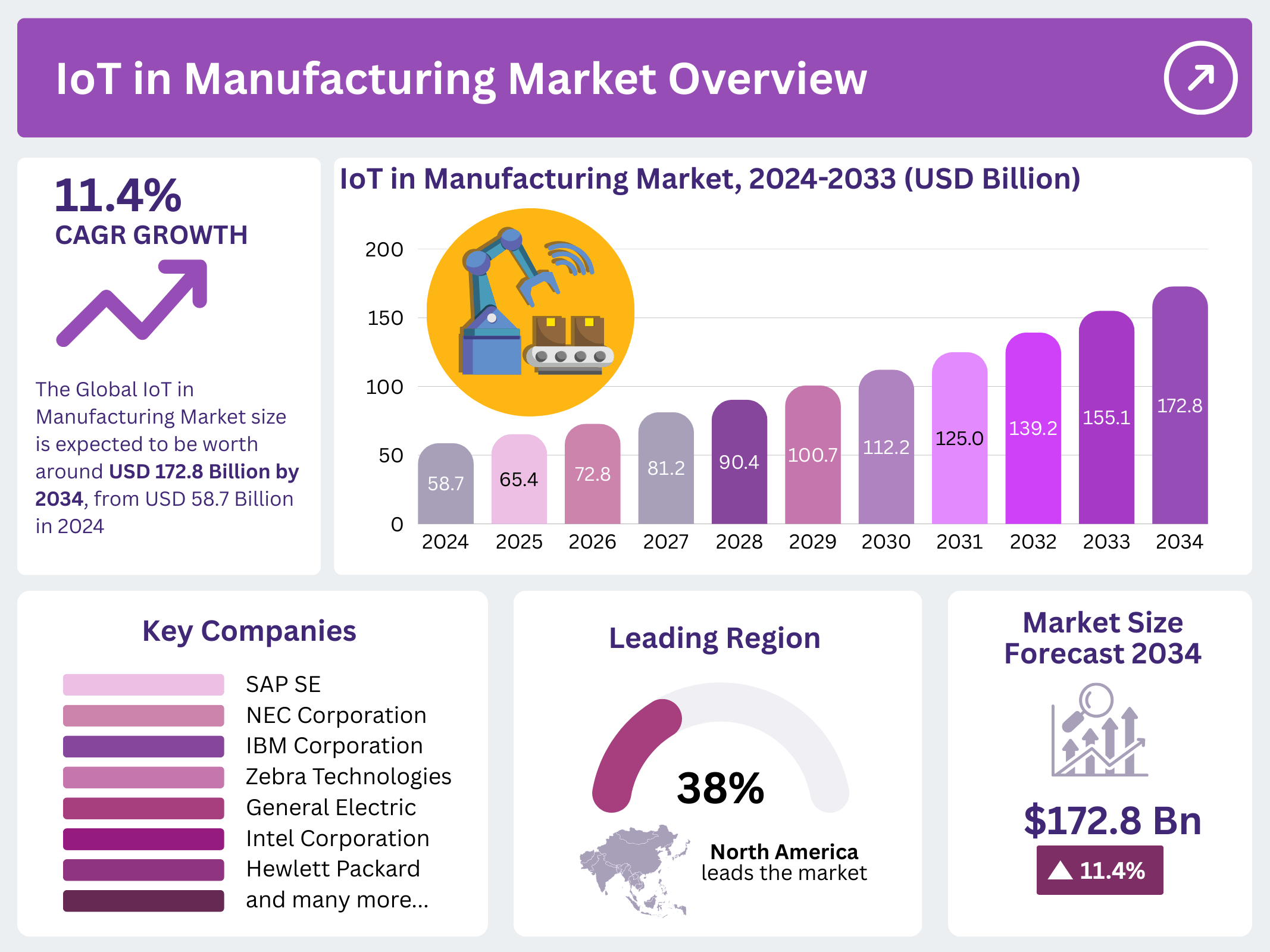

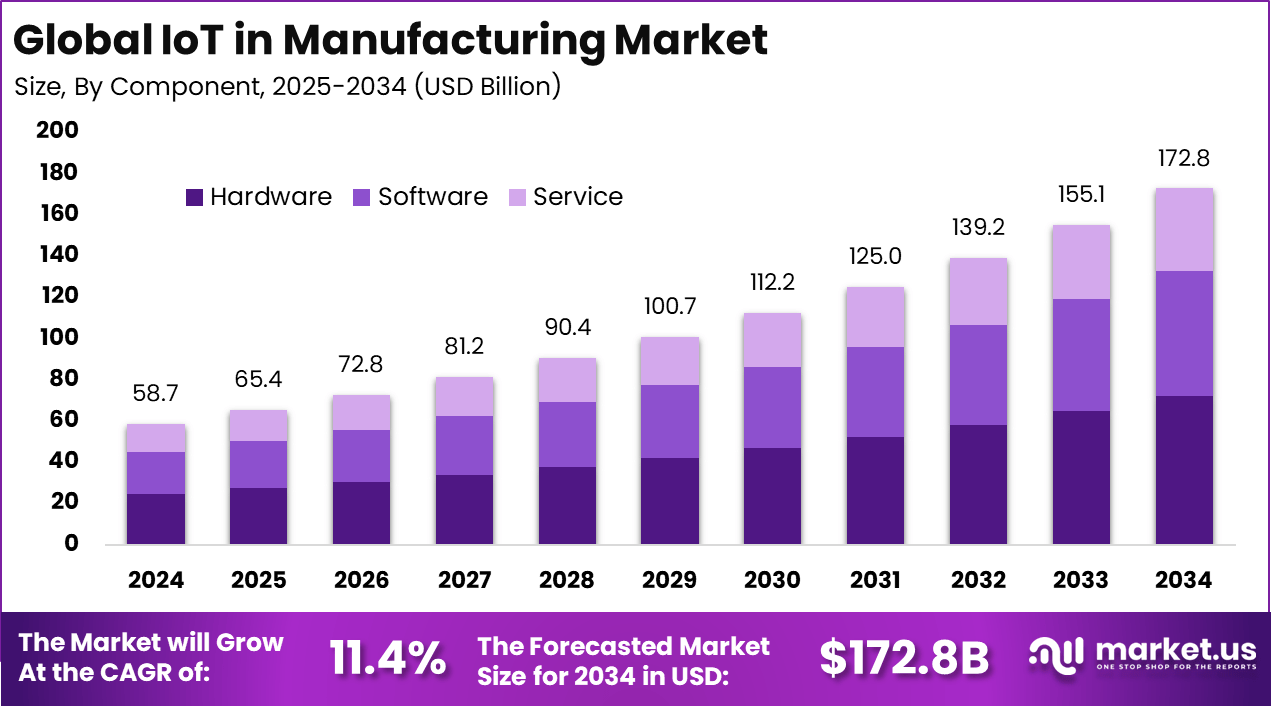

The global IoT in manufacturing market is poised for significant growth, reaching USD 172.8 billion by 2034, up from USD 58.7 billion in 2024, growing at a robust CAGR of 11.4%. The increasing adoption of IoT technologies in manufacturing processes for real-time monitoring, predictive maintenance, and improved operational efficiency is driving this growth. North America holds the largest market share of 32.7% in 2024, valued at USD 19.19 billion, as manufacturers in the region embrace IoT to enhance production efficiency and reduce downtime.

Key Takeaways

-

The market is projected to reach USD 172.8 billion by 2034.

-

North America leads with a 32.7% share, valued at USD 19.19 billion in 2024.

-

Growing demand for smart manufacturing solutions boosts IoT adoption.

-

The market is growing at a CAGR of 11.4%.

-

IoT-driven automation and real-time monitoring drive operational improvements.

Don’t guess! See the proof @ https://market.us/report/iot-in-manufacturing-market/free-sample/

Role of AI

AI is crucial in the IoT-driven manufacturing sector by enhancing data analysis and predictive capabilities. By integrating AI with IoT, manufacturers can use real-time data to optimize production, predict machine failures, and improve quality control. AI algorithms help identify patterns in large datasets, allowing for smarter decision-making and predictive maintenance, which reduces operational costs and increases efficiency. The synergy between AI and IoT enables the automation of critical processes, offering manufacturers the ability to respond quickly to changes in production needs and market demand.

Analyst’s Viewpoint

The IoT in manufacturing market is expected to grow significantly due to the increasing need for real-time data and automation to enhance productivity. The market’s growth will be driven by the need for improved efficiency, reduced downtime, and cost-effective operations. As more manufacturers adopt IoT solutions, they will gain a competitive edge through predictive analytics, automated processes, and better decision-making. Additionally, advancements in AI and machine learning are expected to further optimize the role of IoT in manufacturing, ensuring the continued expansion of this market.

Regional Highlights

North America holds the dominant market position, accounting for 32.7% of the global market share in 2024, valued at USD 19.19 billion. This dominance is driven by high technology adoption, robust industrial infrastructure, and significant investments in IoT technologies. Europe follows, with key growth in countries like Germany and the UK, where advanced manufacturing sectors are actively integrating IoT solutions. Asia Pacific is expected to experience rapid growth, fueled by emerging manufacturing hubs in China and India, where digital transformation is accelerating.

Key Market Segmentation

-

By Technology: Includes IoT sensors, RFID, and cloud computing platforms used to collect and analyze manufacturing data.

-

By Application: Applications include predictive maintenance, supply chain management, and inventory tracking in manufacturing settings.

-

By End-User: Segments include automotive, electronics, aerospace, and heavy industries, all leveraging IoT for increased operational efficiency.

-

By Region: North America, Europe, Asia Pacific, Latin America, and the Middle East, with North America leading the market.

Emerging Trends

-

Integration of IoT with AI and machine learning for predictive maintenance.

-

Increasing adoption of cloud-based IoT platforms for real-time data access.

-

Expansion of IoT-driven automation systems in factory settings.

-

Deployment of 5G networks to enhance IoT connectivity in manufacturing.

-

IoT solutions for improving energy management and sustainability in factories.

Top Use Cases

-

Predictive maintenance to reduce machine downtime.

-

Real-time inventory management and supply chain optimization.

-

Smart sensor systems for quality control in production.

-

Automated factory processes for improved production efficiency.

-

Energy usage monitoring and optimization in manufacturing plants.

Major Challenges

-

Security and privacy concerns regarding IoT data transmission.

-

High implementation and maintenance costs for IoT systems.

-

Lack of interoperability between IoT devices and legacy systems.

-

Data overload and the need for effective data management.

-

Skill shortages in the workforce to manage and analyze IoT data.

Attractive Opportunities

-

Development of IoT solutions for small and medium-sized manufacturers.

-

Expansion of IoT in sustainable manufacturing practices.

-

Integration of IoT with 3D printing and robotics for smart factories.

-

Growing demand for IoT-based asset management solutions.

-

Increasing interest in IoT-enabled smart logistics and supply chain systems.

Unlock growth secrets—buy the full report @ https://market.us/purchase-report/?report_id=154021

Business Benefits

IoT in manufacturing offers significant business benefits, including enhanced operational efficiency through real-time monitoring and automation, predictive maintenance that reduces downtime, and improved supply chain visibility. With IoT solutions, manufacturers can optimize resource allocation, streamline processes, and ensure product quality. The ability to make data-driven decisions in real time allows manufacturers to respond quickly to market demands, reduce operational costs, and stay competitive in a rapidly evolving industry.

Recent Developments

In 2024, several leading manufacturing companies implemented IoT-driven solutions, particularly in predictive maintenance and inventory management. These initiatives are expected to enhance productivity and reduce downtime, leading to significant cost savings for businesses.

Key Players Analysis

Leading players in the IoT in manufacturing market include General Electric, Siemens, Honeywell, and IBM. These companies are integrating IoT solutions into industrial automation, predictive maintenance, and energy management systems to drive operational efficiency and reduce costs across manufacturing processes.

- SAP SE Company Profile

- NEC Corporation

- IBM Corporation

- Zebra Technologies

- General Electric

- Intel Corporation

- Hewlett Packard Enterprise Development LP Company Profile

- Honeywell International Inc.

- Huawei Technologies Co. Ltd.

- Dell Inc.

- Hitachi Ltd. Company Profile

- Bosch Software Innovations GmbH

- ABB Ltd.

- Cisco Systems Inc.

- Other Major Players

Customer Insights

Manufacturers increasingly seek IoT solutions that provide real-time data for better decision-making and increased efficiency. Customers are looking for flexible, scalable solutions that integrate seamlessly with existing infrastructure. Predictive maintenance, supply chain optimization, and automation are among the top priorities. There is also growing demand for IoT-based solutions that offer sustainability benefits, such as energy monitoring and waste reduction, reflecting a broader industry trend towards eco-friendly practices.

Future Outlook

The IoT in manufacturing market is expected to continue growing as more companies embrace digital transformation. By 2034, IoT adoption will likely be an essential component of manufacturing strategies, helping businesses achieve greater productivity, cost savings, and sustainability. The ongoing advancements in connectivity, AI, and cloud platforms will play a crucial role in this expansion, enabling more manufacturers to benefit from IoT solutions.

Conclusion

The IoT in manufacturing market is undergoing rapid transformation, driven by the need for enhanced efficiency, reduced operational costs, and smarter decision-making. North America remains the dominant region, with global growth fueled by advancements in IoT technologies. The combination of IoT, AI, and automation will continue to shape the future of manufacturing, offering new opportunities for innovation, sustainability, and profitability. As the market grows, businesses that adopt IoT solutions will be better positioned to compete in an increasingly digital manufacturing landscape.

For additional insights, visit Market.us or follow us on LinkedIn and Facebook.

Contact Us:

Mr. Lawrence John

Global Business Development Manager

Address: Lexington Avenue, Suite 300 New York City, NY 10170, United States

Phone: +1 718 874 1545 (International), +91 78878 22626 (Asia)

Email: [email protected]